Introduction

Polypropylene (PP) injection molding is a widely used method in plastic manufacturing, offering numerous advantages for various applications. Understanding the key benefits of polypropylene in injection molding is crucial for leveraging its superiority in the industry. With its versatility, sustainability factor, and economic benefits, polypropylene stands out as a top choice for thermoplastic injection moulding.

The Advantages of Using Polypropylene for Injection Molding

One of the most significant advantages of using polypropylene for injection molding is its ability to create lightweight and durable products suitable for a wide range of applications. Its resistance to chemicals and moisture makes it ideal for use in harsh environments, while its customizability and ease of molding allow it to meet unique design needs effectively.

Understanding the Key Benefits of Polypropylene in Plastic Manufacturing

Polypropylene's versatility in injection molding makes it a sought-after material due to its ability to produce products that are both lightweight and durable. Its resistance to chemicals and moisture further enhances its appeal, making it an ideal choice for various industries seeking reliable plastic solutions.

Exploring the Superiority of Polypropylene in Injection Molding

The superiority of polypropylene in injection molding lies in its ability to offer sustainable solutions that contribute to environmental responsibility. With recyclability, energy efficiency, and reduced waste, polypropylene plays a crucial role in enhancing cost-effectiveness and eco-friendliness within the plastic manufacturing industry.

Furthermore, polypropylene's versatility and durability make it an ideal choice for a wide range of applications, from automotive components to household products. Its ability to withstand high temperatures and resist chemicals and moisture makes it a reliable option for manufacturing parts that require long-term performance. This durability also contributes to reducing the need for frequent replacements, further minimizing waste and environmental impact.

The Versatility of Polypropylene in Injection Molding

Polypropylene (PP) injection molding is highly versatile, making it perfect for a wide range of applications. Its lightweight nature and durability make it an ideal choice for products that require strength without added weight. Whether it's automotive components, consumer goods, or medical devices, polypropylene can meet the demands of various industries.

Lightweight and Durable: Perfect for a Range of Applications

The use of polypropylene in injection molding offers the advantage of being lightweight yet incredibly durable. This makes it an excellent choice for products that require high strength-to-weight ratio, such as automotive parts, packaging materials, and household items. The versatility of polypropylene allows manufacturers to create products that are not only strong but also easy to handle and transport.

Polypropylene's resistance to chemicals and moisture makes it an ideal choice for products that will be used in harsh environments. Whether it's automotive parts that need to withstand exposure to various fluids, or packaging materials that must remain intact in damp conditions, polypropylene is up to the task. Its ability to maintain its integrity in challenging settings ensures that products made from this material will last longer and perform better.

Resistant to Chemicals and Moisture: Ideal for Harsh Environments

One key benefit of polypropylene in injection molding is its resistance to chemicals and moisture. This makes it an ideal material for products that need to withstand harsh environments or exposure to various substances. From industrial equipment to outdoor furniture, polypropylene can maintain its integrity even in challenging conditions, ensuring longevity and reliability.

Additionally, polypropylene is highly customizable and easy to mold, allowing for the creation of unique designs that meet specific product requirements. This flexibility makes it an attractive option for manufacturers looking to differentiate their products in the market. Whether it's intricate shapes or complex geometries, polypropylene can be molded with precision, providing endless possibilities for design innovation.

Customizable and Easy to Mold: Meeting Unique Design Needs

Polypropylene's moldability allows for intricate designs and customized shapes, making it a top choice for products with unique design requirements. Whether it's intricate patterns or specific dimensions, polypropylene can be easily molded into the desired form with precision and accuracy. This flexibility makes it a go-to material for manufacturers looking to bring their innovative designs to life through injection molding.

Polypropylene's versatility extends beyond just its moldability, as it also offers a wide range of color options for manufacturers to choose from. This allows for even more customization and personalization, making it an ideal choice for products that require specific branding or aesthetic requirements. Whether it's vibrant and bold colors or subtle and understated tones, polypropylene can be easily dyed to match any design vision, adding an extra layer of flexibility for manufacturers.

The Sustainability Factor of Polypropylene in Injection Molding

Recyclability: Contributing to Environmental Responsibility

Polypropylene (PP) injection molding is a sustainable choice for plastic manufacturing due to its recyclability, which allows for the reuse of materials and reduces environmental impact. By using PP injection molding materials, manufacturers can contribute to environmental responsibility by minimizing waste and promoting a circular economy.

Additionally, PP injection molding offers energy efficiency benefits. Lower processing temperatures are required for PP compared to other plastics, reducing the overall energy consumption during manufacturing. Quick cycle times also contribute to energy efficiency, as the materials can be processed and molded at a faster rate, further reducing energy usage. This makes PP injection molding a sustainable choice not only in terms of recyclability but also in its overall energy efficiency.

Energy Efficiency: Lower Processing Temperatures and Quick Cycle Times

One of the key benefits of polypropylene injection molding is its energy efficiency, as it requires lower processing temperatures and offers quick cycle times. This not only reduces energy consumption during production but also contributes to cost savings for manufacturers, making it an environmentally friendly and economical choice for plastic mold manufacturing.

Furthermore, the reduced processing temperatures and quick cycle times of polypropylene injection molding also lead to reduced waste during production. This enhancement in efficiency not only contributes to cost-effectiveness for manufacturers but also aligns with eco-friendly practices by minimizing material wastage. With less material being discarded, this process helps to conserve resources and reduce the environmental impact of plastic mold manufacturing.

Reduced Waste: Enhancing Cost-Effectiveness and Eco-Friendliness

Polypropylene injection molding resins are known for their ability to minimize waste during the manufacturing process, enhancing cost-effectiveness and eco-friendliness. With reduced scrap material and efficient production cycles, PP injection molding offers a sustainable solution that aligns with both economic and environmental goals.

The Baoyuan team has senior management and technical personnel with extensive experience in polypropylene injection molding. They are proficient in using software to design molds, mold opening, and injection molding processes, ensuring high-quality single-color and double-color plastic products that meet industry standards.

The Economic Benefits of Polypropylene in Injection Molding

Cost-Effective Material: Saving on Production Expenses

Polypropylene (PP) is a cost-effective material for injection molding, as it allows for efficient production processes and reduced material waste. With its low melting point, PP injection molding requires less energy, contributing to significant cost savings in production expenses. This makes it an ideal choice for businesses looking to maximize their budget without compromising on quality.

Moreover, the versatility of PP allows for the production of a wide range of products, from packaging to automotive components. This means businesses can streamline their production processes by using PP for multiple applications, further maximizing cost-effectiveness. Additionally, the durability and resistance to fatigue of PP make it a long-lasting material, reducing the need for frequent replacements and repairs, ultimately saving on maintenance expenses.

Fast Production Cycles: Meeting Market Demand Efficiently

The versatility of polypropylene in injection molding allows for fast production cycles, enabling businesses to meet market demand efficiently and effectively. Its quick cooling and setting times make it a preferred choice for manufacturers looking to streamline their production processes and deliver products to customers in a timely manner. This ensures that businesses can stay competitive in the market without sacrificing quality.

In addition to its fast production cycles, polypropylene also offers long-term durability, minimizing maintenance and replacement costs for businesses. This means that manufacturers can rely on polypropylene to create products that are built to last, reducing the need for frequent repairs or replacements. By choosing a material that is known for its durability, businesses can save time and money in the long run, ultimately contributing to their bottom line.

Long-Term Durability: Minimizing Maintenance and Replacement Costs

Polypropylene resins used in injection molding offer long-term durability, minimizing maintenance and replacement costs for businesses. The high resistance of PP plastic products to wear and tear ensures that they can withstand harsh environmental conditions, reducing the need for frequent repairs or replacements. This durability translates to cost savings over time, making polypropylene an economically advantageous choice for plastic manufacturing.

The Baoyuan team has extensive experience and technical proficiency in thermoplastic injection moulding using polypropylene resins. Their senior management and technical personnel are skilled in designing molds, mold opening, and injection molding processes with a focus on delivering high-quality single-color and double-color plastic products.

By leveraging the economic benefits of polypropylene in injection molding, businesses can save on production expenses while meeting market demand efficiently with long-term durable products. Baoyuan's expertise in PP injection molding ensures that businesses can make informed decisions for their plastic manufacturing needs while partnering with a reliable plastic mold manufacturer like Baoyuan.

Baoyuan's Expertise in Polypropylene Injection Molding

Extensive Industry Experience and Technical Proficiency

At Baoyuan, our team boasts extensive industry experience and technical proficiency in the field of polypropylene injection molding. Our senior management and technical personnel have been engaged in the industry for many years, allowing us to skillfully use software to design molds, mold opening, and injection molding processes with precision and expertise.

In addition to our expertise in software design for molds and injection molding processes, our team at Baoyuan also specializes in optimizing mold opening techniques to ensure efficient and precise production. With a keen understanding of the mechanical aspects of mold opening, we are able to minimize downtime and maximize productivity, ultimately saving time and costs for our clients. Our technical proficiency extends to troubleshooting and resolving any issues that may arise during the mold opening process, further demonstrating our commitment to delivering high-quality results.

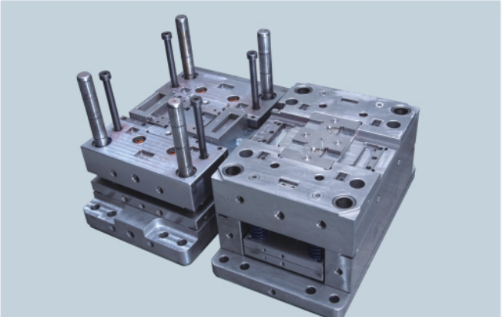

Specialization in Mold Design, Mold Opening, and Injection Molding

We specialize in every aspect of the injection molding process, from mold design to mold opening and injection molding itself. Our team is well-versed in working with polypropylene resins, ensuring that each step of the process is executed with accuracy and attention to detail.

Our expertise in mold design, mold opening, and injection molding allows us to deliver high-quality single-color and double-color plastic products with precision and efficiency. We understand the importance of using polypropylene resins in the injection molding process, and our team is dedicated to ensuring that each product meets the highest standards of quality. With our attention to detail and commitment to excellence, we can guarantee that our clients will receive durable and flawless plastic products that meet their specific needs.

Commitment to Delivering High-Quality Single-Color and Double-Color Plastic Products

At Baoyuan, we are committed to delivering high-quality single-color and double-color plastic products through our expertise in polypropylene injection molding. We prioritize precision and quality assurance throughout the production process to ensure that our clients receive durable and reliable plastic products for their specific needs.

We understand the importance of meeting our clients' specific requirements, which is why we offer customization options for single-color and double-color plastic products. Our team works closely with clients to ensure that their unique specifications are met, resulting in personalized and tailored plastic products that exceed expectations. By offering customization, we aim to provide solutions that perfectly fit our clients' needs and add value to their businesses.

Conclusion

Leveraging the Superiority of Polypropylene for Injection Molding

Polypropylene (PP) injection molding is a game-changer in plastic manufacturing, offering unmatched versatility and sustainability. With its lightweight, durable, and customizable nature, PP is the go-to material for a wide range of applications. Its recyclability and energy efficiency make it an environmentally responsible choice, while its cost-effectiveness and fast production cycles bring economic benefits.

Making Informed Decisions for Plastic Manufacturing with Polypropylene

When it comes to injection molding materials, polypropylene resins stand out for their exceptional properties. PP injection molding offers endless possibilities for creating high-quality single-color and double-color plastic products with long-term durability. Choosing polypropylene means making an informed decision that aligns with both environmental responsibility and cost-effectiveness.

Polypropylene resins are known for their versatility, making them ideal for a wide range of applications. From automotive parts to household items, PP injection molding can meet the demands of various industries with ease. This flexibility allows for the creation of intricate designs and complex shapes, giving manufacturers the freedom to innovate and differentiate their products in the market. With polypropylene, businesses can stay ahead of the competition by delivering unique and functional plastic solutions.

Partnering with Baoyuan for Exceptional Polypropylene Injection Molding Services

Baoyuan is a leading plastic mold manufacturer specializing in thermoplastic injection moulding, including polypropylene injection molding. With a team of senior management and technical personnel boasting years of industry experience, Baoyuan delivers expertise in mold design, mold opening, and injection molding to ensure top-notch quality assurance for all your plastic product needs.

Baoyuan's commitment to excellence extends beyond just the manufacturing process. The company also places a strong emphasis on sustainable and eco-friendly practices, ensuring that their production processes have minimal impact on the environment. By choosing Baoyuan as your plastic mold manufacturer, you can be confident that you are not only receiving high-quality products, but also supporting a company that prioritizes sustainability. This dedication to environmental responsibility sets Baoyuan apart from other manufacturers in the industry.