Introduction

Are you in need of high-quality injection plastic molding services for your next project? Look no further! Whether you're new to injection molding or a seasoned pro, it's crucial to understand the process and what factors to consider when choosing a service provider. At Baoyuan, we pride ourselves on delivering top-notch solutions that meet your specific needs and budget.

Understanding Injection Plastic Molding Services

Injection plastic molding is a manufacturing process used to produce a wide range of products by injecting molten material into a mold. This versatile technique is commonly used for creating everything from car parts to medical devices, making it an essential part of many industries.

Key Factors to Consider

Selecting the ideal injection molding service for your project requires careful evaluation of several key factors. Here's a breakdown of essential considerations to ensure you make an informed decision:

Understanding Your Needs

- Production Volume: Consider the quantity of parts you require. High-volume production might favor certain molding techniques, while low-volume projects might benefit from more flexible options.

- Material Selection: The type of plastic or material needed for your parts will influence the molding process. Different materials have varying properties and require specific molding techniques.

- Cost Efficiency: While cost is significant, prioritize quality and long-term value over the cheapest option. Factor in tooling costs, material pricing, and potential per-unit costs based on your production volume.

Assessing the Manufacturer's Capabilities

- Quality Control: Robust quality control procedures are paramount. Look for certifications demonstrating the manufacturer's commitment to quality standards and consistent production.

- Material Expertise: Choose a manufacturer with experience in handling your desired material. Their knowledge ensures proper processing and minimizes the risk of defects.

- Technological Advancements: Does the manufacturer utilize advanced injection molding techniques? This can translate to faster production cycles, better part complexity, and, potentially, reduced material waste.

Additional Considerations

- Communication and Customer Service: Clear and open communication throughout the project is essential. Choose a manufacturer who prioritizes keeping you informed and addresses your concerns promptly.

- Project Management: Evaluate the manufacturer's project management capabilities. Look for a proven track record of delivering projects on time and within budget.

- Sustainability: In today's world, consider the manufacturer's environmental practices. Do they prioritize eco-friendly materials and energy-efficient processes?

By carefully considering these factors and tailoring them to your specific project requirements, you can select an injection molding service that becomes a valuable partner in your success. They should possess the expertise, technology, and commitment to quality that aligns with your vision, ensuring a smooth and successful collaboration.

The Baoyuan Advantage

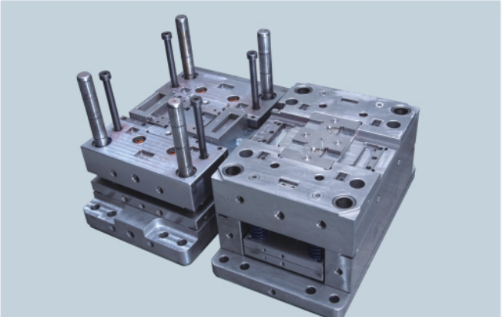

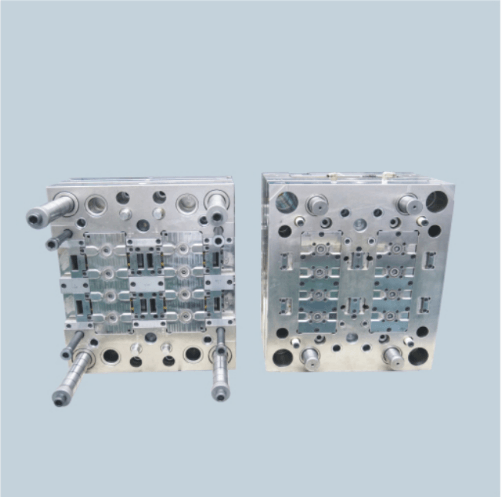

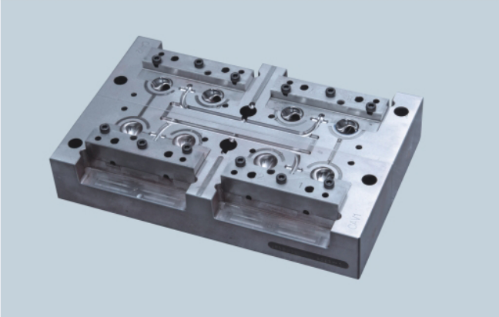

At Baoyuan, we stand out from the competition by offering expert consultation, advanced technology, and a commitment to quality at every process stage. Our team is dedicated to providing cost-effective solutions without compromising on excellence. Furthermore, our state-of-the-art facilities and cutting-edge equipment allow us to tackle even the most complex injection plastic molding projects with precision and efficiency. This means that our clients can trust us to deliver high-quality results within their budget and timeline.

Types of Injection Plastic Molding Services

When it comes to injection plastic molding, it's essential to understand the different processes available. From thermoplastic injection molding to liquid silicone rubber molding, there are various techniques to consider for your project. Each process has unique advantages and applications, so it's crucial to evaluate which aligns best with your needs.

Choosing the right service for your injection plastic molding project is critical. Factors such as material compatibility, production volume, and part complexity all play a role in determining the most suitable molding service for your specific requirements. It's essential to work with a provider offering a wide range of options to ensure you find the perfect fit for your project.

When exploring injection plastic molding services, Baoyuan stands out with its exceptional specializations. Whether you need precision moldable plastics or intricate tooling solutions, Baoyuan has the expertise and capabilities to deliver top-notch results. Their commitment to innovation and quality makes them a trusted partner for various injection molding needs.

Factors Affecting Affordability

Material Costs and Options

When it comes to injection plastic molding, material costs play a significant role in determining the overall affordability of the process. Different plastics come with varying price points, and selecting the right material for your project can make a substantial difference in cost. Baoyuan's extensive range of moldable plastics ensures that you have access to cost-effective options without compromising on quality.

Tooling and Production Volume

The tooling and production volume also heavily impact the affordability of injection plastic molding services. The initial investment in tooling can be significant, but it is essential to consider long-term production volume to maximize cost efficiency. Baoyuan's state-of-the-art injection molding machines are capable of handling high production volumes, allowing you to benefit from economies of scale and lower costs per unit.

Additionally, Baoyuan's experienced team of engineers and designers can work with you to optimize tooling designs for cost efficiency without compromising quality. Leveraging their expertise can minimize initial tooling investment while maximizing long-term production volume benefits. This collaborative approach ensures that your injection plastic molding project is affordable and tailored to your specific needs and goals.

Leveraging Baoyuan's Cost-Saving Solutions

Baoyuan understands the importance of providing cost-saving solutions for injection plastic molding projects. With their expertise in process optimization and efficient manufacturing techniques, they can help you minimize waste, reduce production time, and ultimately lower overall costs without sacrificing quality or precision.

Baoyuan's dedication to cost-saving solutions extends beyond just the manufacturing process. They also work closely with clients to identify areas for improvement and offer tailored recommendations to optimize production efficiency. By understanding the specific needs of each project, Baoyuan can provide customized solutions that result in significant cost reductions while maintaining the highest standards of quality and precision.

Finding Affordable Injection Plastic Molding Services

Researching Local and Global Options

When looking for injection plastic molding services, it's crucial to research both local and global options. Local companies may offer convenience and easier communication, while global providers could provide cost savings and specialized expertise in injection molding.

Local companies may offer convenience and easier communication, while global providers could offer cost savings and specialized expertise in injection molding. It's crucial to weigh the pros and cons of each option carefully. Local companies may have a better understanding of local regulations and standards, which could be beneficial for specific projects. On the other hand, global providers may have access to a broader range of materials and technology, allowing for more flexibility and innovation in the manufacturing process.

Evaluating Quality and Reputation

Don't compromise on quality in your search for affordable injection plastic molding services. Look for providers with a solid reputation for delivering high-quality products. Customer reviews, industry certifications, and case studies can help you evaluate the quality and reputation of potential partners.

When evaluating the quality and reputation of potential injection plastic molding service providers, it's essential to consider their track record of delivering on time and within budget. Look for companies with a history of meeting or exceeding customer expectations, which is a strong indicator of their commitment to quality. Additionally, seek testimonials from previous clients to get a sense of the provider's reputation in the industry.

Baoyuan's Commitment to Competitive Pricing

At Baoyuan, we understand the importance of competitive pricing in injection plastic molding services. Our commitment to offering cost-effective solutions doesn't mean sacrificing quality. We strive to provide affordable services without compromising on the precision and excellence that our clients expect.

We also understand that cost savings are important for our clients, which is why we continuously review our processes to identify areas where we can increase efficiency and reduce waste. By streamlining our operations and implementing lean manufacturing principles, we can pass on the cost savings to our customers without compromising on the quality of our injection plastic molding services.

Tips for Saving on Injection Plastic Molding

1. Design Optimization for Cost Efficiency

When it comes to injection plastic molding, design optimization is crucial for cost efficiency. By designing parts with uniform wall thickness and minimal use of undercuts, you can significantly reduce material and production costs. Baoyuan's expert engineers can provide valuable insights to help you achieve the most cost-effective design without compromising quality.

By working closely with Baoyuan's expert engineers, you can explore alternative materials and production methods that may further optimize cost efficiency. Their knowledge and experience in the industry can help you identify opportunities to streamline the manufacturing process and reduce lead times, ultimately saving both time and money. With their guidance, you can make informed decisions that align with your budget without sacrificing the quality of your plastic molded parts.

2. Utilizing Baoyuan's Expert Consultation

Partnering with Baoyuan for your injection plastic molding needs means gaining access to expert consultation. Their team of experienced professionals can offer valuable advice on material selection, tooling options, and production processes to help you save costs without sacrificing quality. By leveraging their expertise, you can make informed decisions that lead to cost-efficient solutions.

In addition to providing expert consultation, Baoyuan can also assist in streamlining your production processes. Their team can offer insights into optimizing workflow, reducing lead times, and improving overall efficiency in your injection plastic molding operations. By implementing their recommendations, you can enhance productivity and minimize downtime, ultimately leading to increased output and cost savings.

3. Streamlining Production Processes

Streamlining production processes is essential for saving on injection plastic molding. Baoyuan's state-of-the-art facilities and advanced injection molding machines ensure efficient and precise manufacturing processes, reducing cycle times and minimizing waste. By optimizing production workflows, they can help you achieve cost savings while delivering high-quality moldable plastics for your projects.

By optimizing design and production processes with Baoyuan's expertise, you can achieve significant cost savings in your injection plastic molding projects while maintaining top-notch quality.

Making the Best Decision for Your Project

When it comes to injection plastic molding, finding the perfect balance between cost and quality is crucial. You want to ensure that your project stays within budget without compromising on the excellence of the final product. Baoyuan understands this delicate balance and is committed to delivering high-quality results at competitive prices.

Balancing Cost and Quality

Balancing cost and quality in injection plastic molding involves careful consideration of materials, production processes, and design optimization. At Baoyuan, we work closely with our clients to understand their specific needs and provide cost-effective solutions without sacrificing the quality of the end product. Our state-of-the-art injection molding machines ensure precision and consistency in every project.

Our commitment to balancing cost and quality extends beyond the production process. We also prioritize sustainability and environmental responsibility in our manufacturing practices. By using recycled materials and optimizing our production processes to minimize waste, we can offer cost-effective solutions while reducing our environmental impact. This approach not only benefits our clients but also aligns with the growing demand for eco-friendly manufacturing.

Long-Term Partnerships with Baoyuan

Choosing a reliable partner for your injection plastic molding needs is essential for long-term success. Baoyuan values long-term partnerships with our clients, offering consistent quality, on-time delivery, and cost-effective solutions for all types of projects. Our expertise in moldable plastics allows us to cater to a wide range of industries, ensuring that your needs are always met with precision and efficiency.

In addition to our commitment to quality and efficiency, Baoyuan prioritizes open communication and collaboration with our clients. Understanding your unique needs and goals is crucial to delivering the best solutions for your injection plastic molding projects. By working closely with you every step of the way, we can ensure that the final product meets and exceeds your expectations.

Ensuring Satisfaction and Success

At Baoyuan, customer satisfaction is our top priority. We are dedicated to ensuring that every project we undertake meets or exceeds our clients' expectations regarding quality, affordability, and timely delivery. Our team of experts is committed to providing personalized support throughout the entire process, from initial design consultations to final production stages.

Our commitment to customer satisfaction extends beyond the completion of a project. We prioritize open communication and transparency, keeping our clients informed every step of the way. This ensures that any concerns or adjustments can be addressed promptly, resulting in a final product reflecting our clients' vision.

Choose a Trusted Partner like Baoyuan

When it comes to injection plastic molding, making informed decisions for your projects is crucial. With so many options available, choosing a trusted partner like Baoyuan can ensure you get the quality and affordability you need. You can take your projects to the next level by unlocking affordable and quality solutions.

Making Informed Decisions for Your Projects

It's important to weigh your options regarding injection plastic molding carefully. Consider factors such as material costs, production volume, and quality of service. By doing thorough research and understanding your needs, you can make the best decisions for your projects.

With Baoyuan's expertise in injection molding, you can have peace of mind knowing that your projects are in good hands. Their commitment to competitive pricing and quality solutions makes them a reliable partner for all your injection plastic molding needs.

Unlocking Affordable and Quality Solutions

By partnering with Baoyuan, you can unlock affordable and quality solutions that meet your specific requirements. Their specialization in various injection plastic molding services ensures you get the best value for your investment.