Introduction

Navigating the world of injection moulding costs can feel like trying to solve a Rubik's Cube blindfolded. With numerous factors at play, from material choices to design complexity, it’s crucial to grasp how these elements intertwine to affect your budget. Whether you're pondering How much does injection molding cost? or seeking insight into How to calculate injection mold cost?, understanding the basics is your first step toward making informed decisions.

Understanding the Basics of Injection Moulding Costs

At its core, injection moulding is a manufacturing process that can yield high-quality plastic parts efficiently—but it doesn’t come without its expenses. Injection moulding costs encompass everything from raw materials to labor and machine operation, making it essential for businesses to grasp this financial landscape. When asking How much does injection molding cost per hour?, remember that various components contribute significantly to the overall price tag.

Key Factors Influencing Moulding Expenses

Several key factors influence moulding expenses that every manufacturer should consider. Material selection and quality play a significant role; higher-grade plastics often lead to increased costs but may offer better performance and durability in the long run. Additionally, the complexity of your design and mold manufacturing intricacies can dramatically shift your budget—so it's wise to evaluate all angles before diving in.

Why Investment in Quality Matters

When contemplating Why is injection moulding expensive?, one must acknowledge that investing in quality today can save you money tomorrow. High-quality molds and materials not only enhance product reliability but also reduce defect rates, ultimately minimizing waste and rework costs over time. In a market where low-cost plastic molding options might seem tempting, prioritizing quality ensures your products stand out while maintaining cost-effectiveness.

What Drives Injection Moulding Costs?

When diving into the world of injection moulding costs, several factors come into play that can significantly impact the overall expense. Understanding these elements is crucial for anyone looking to produce plastic components efficiently and cost-effectively. Let’s break down the primary drivers of injection moulding costs to give you a clearer picture.

Material Selection and Quality

The choice of materials is one of the most significant factors influencing injection moulding costs. High-quality materials often come with a higher price tag, but they can lead to better durability and performance in the final product, ultimately saving money in the long run. Conversely, opting for lower-cost materials may seem appealing initially but could result in increased defects or failures, raising your overall expenses over time.

Additionally, different types of plastics have varying characteristics that affect both processing and cost. For example, engineering plastics like polycarbonate or nylon offer superior strength but will drive up your How much does injection molding cost? question significantly compared to standard options like polypropylene or polyethylene. Thus, while selecting materials for your project, consider both upfront costs and long-term value—after all, quality matters!

Complexity of the Design

The complexity of your design plays a pivotal role in determining how much does injection molding cost? Intricate designs require more sophisticated molds and longer production times which can inflate costs significantly. Features such as undercuts, thin walls, or intricate geometries demand advanced tooling techniques that add layers to your budget.

Moreover, complex designs often necessitate additional prototyping and testing phases to ensure functionality before mass production begins. This means that understanding how to calculate injection mold cost accurately is essential; it’s not just about material but also about time and expertise involved in crafting those designs correctly. Simplifying your design where possible can help mitigate some expenses without sacrificing quality.

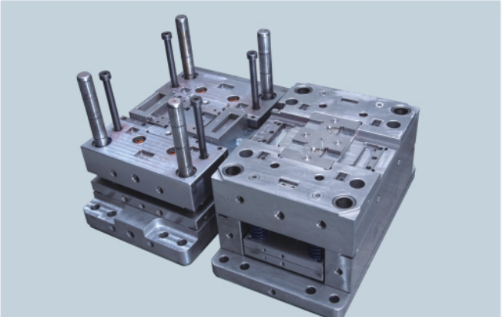

Mold Design and Manufacturing

Mold design is arguably one of the most critical aspects influencing injection moulding costs—it's where precision meets investment! A well-designed mold ensures efficient production runs while minimizing waste; however, achieving this requires skilled craftsmanship and sometimes expensive machinery. Therefore, when pondering Why is injection moulding expensive?, remember that high-quality mold manufacturing demands both time and resources.

Furthermore, molds need regular maintenance to remain effective over their lifespan; neglecting this aspect can lead to increased downtime during production—another factor in how much does injection molding cost per hour? Investing upfront in quality mold design pays dividends through reduced cycle times and fewer defects down the line—so don’t skimp on this critical phase!

In conclusion, understanding these drivers behind injection moulding costs will empower you as you navigate through budgeting for projects effectively while maintaining high standards for quality.

How to Calculate Injection Mold Cost

Calculating injection mold costs can feel like navigating a maze filled with unexpected turns, but fear not! By breaking down the components and utilizing effective methods and tools, you can arrive at a clearer picture of how much injection molding costs. Understanding how to calculate injection mold cost is essential for budgeting your project effectively and avoiding those pesky surprises later on.

Break Down of Cost Components

First, consider the material selection; high-quality materials may come with a higher price tag but often yield better results in durability and aesthetics. Next, factor in labor costs associated with skilled technicians who operate machinery and manage production processes—these are crucial for maintaining efficiency and quality control.

Mold design and manufacturing also play significant roles in determining how much does injection molding cost? The complexity of the mold itself can affect both initial setup expenses and ongoing production rates. Finally, don’t forget about overhead costs such as facility maintenance, utilities, and administrative expenses that contribute indirectly to your total investment.

Methods for Estimating Costs

Estimating injection moulding costs can be approached through various methods tailored to your project's specifics. One common method is using historical data from previous projects; this allows you to draw parallels based on similar designs or materials used. Additionally, consulting industry benchmarks can provide valuable insights into average pricing structures in the market.

Another effective approach involves creating detailed prototypes or 3D models using computer-aided design (CAD) software; this not only helps visualize the final product but also assists in identifying potential issues early on—thus saving time and money later in production. Ultimately, knowing how to estimate injection molding cost accurately empowers you to make informed decisions that align with your budgetary constraints.

Tools for Accurate Cost Analysis

To ensure you're making well-informed choices regarding injection moulding costs, leveraging specialized tools for accurate cost analysis is vital. Software programs tailored for manufacturing cost estimation can streamline calculations by incorporating factors like material prices, labor rates, machine hours needed per cycle time, and more—all while providing real-time updates as variables change.

Additionally, collaborating with suppliers who offer transparent pricing models will help clarify what each component of your project entails financially—after all, transparency breeds trust! Lastly, don't underestimate the value of expert consultation; engaging professionals with experience in low-cost plastic molding options can yield insights that might save you both time and money during production.

How Much Does Injection Molding Cost per Hour?

When diving into the world of injection moulding costs, one of the most pressing questions is: how much does injection molding cost per hour? The answer isn’t as straightforward as one might hope, as it involves a myriad of factors that can fluctuate based on specific project requirements. Understanding these elements is crucial for businesses looking to budget effectively and maximize their investment in quality.

Labor Costs vs. Machine Costs

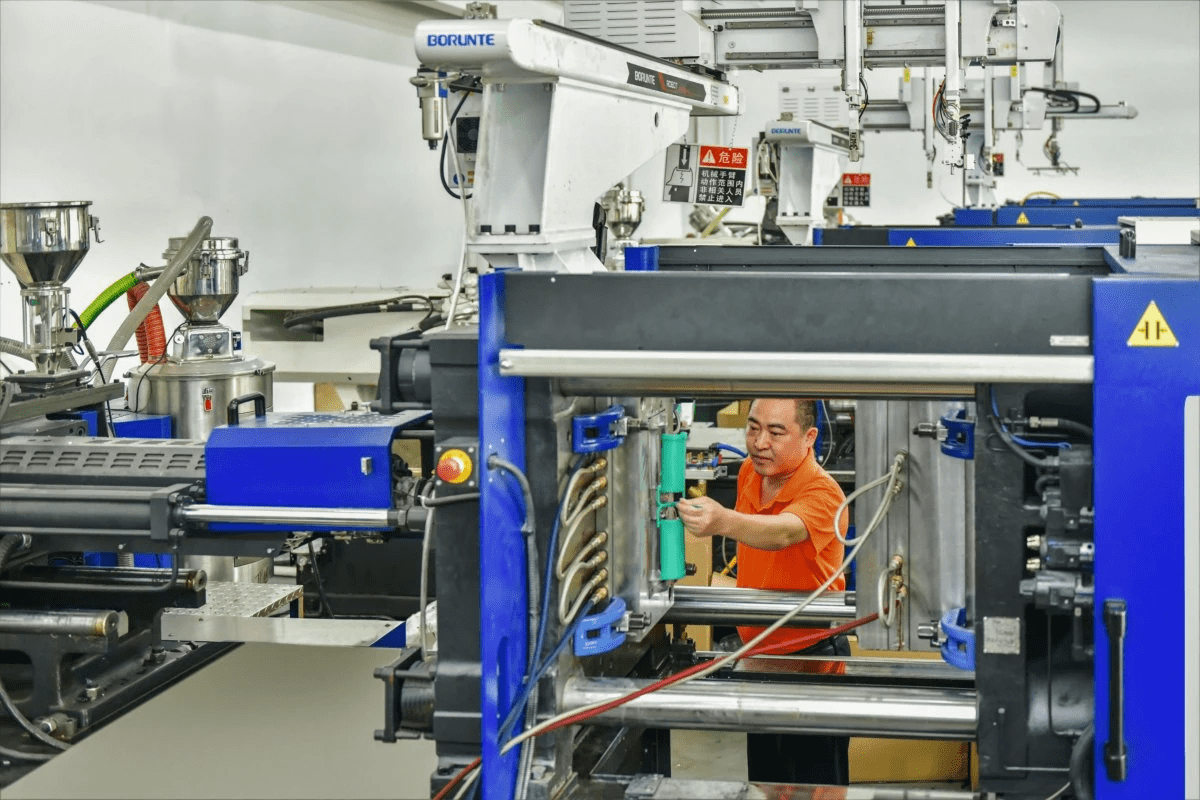

In the realm of injection moulding, labor costs and machine costs play pivotal roles in determining overall expenses. Labor costs encompass not just the wages of operators but also any additional personnel needed for quality assurance or maintenance tasks during production runs. On the flip side, machine costs include depreciation, energy consumption, and operational efficiency—each contributing significantly to how much does injection molding cost per hour.

Balancing labor and machine expenditures can be tricky; while investing in advanced machinery may reduce operational time and enhance precision, it often comes with a hefty price tag upfront. However, if you’re wondering how to calculate injection mold cost accurately, consider both labor rates and machine efficiency together for a clearer picture of your hourly expenses. Ultimately, finding this equilibrium will help you make informed decisions about your manufacturing processes.

Production Speed and Efficiency

Another crucial factor influencing injection moulding costs is production speed and efficiency. Faster production cycles typically mean lower costs over time; however, achieving high-speed output often requires more sophisticated machinery or optimized processes that could initially raise capital investment. Businesses must weigh these factors when asking themselves: why is injection moulding expensive?

To truly understand how to estimate injection molding cost effectively, consider not only the speed at which parts are produced but also the quality of those parts over time—after all, rework due to defects can quickly inflate overall expenses. Efficient production methods can lead to significant savings on a per-hour basis; thus investing in training staff or upgrading equipment may yield long-term returns that justify initial expenditures.

Maintenance and Downtime Considerations

Maintenance and downtime are often overlooked aspects when discussing how much does injection molding cost per hour but can have substantial implications on overall expenses. Regular maintenance ensures machines operate at peak performance; neglecting this can lead to unexpected breakdowns that halt production entirely—resulting in costly delays and lost revenue opportunities. Therefore, understanding maintenance schedules should be part of your strategy when assessing total injection moulding costs.

Moreover, unplanned downtime not only affects productivity but also impacts labor allocation since skilled workers might be left idle while waiting for repairs or adjustments to be made on machines. To mitigate these risks while exploring low-cost plastic molding options or alternatives for budget-conscious projects, having contingency plans in place becomes essential for maintaining efficiency without compromising quality standards.

In conclusion, comprehending how much does injection molding cost per hour involves analyzing various components such as labor versus machine expenses alongside production speed efficiencies—all while keeping maintenance considerations top-of-mind! By doing so diligently—and perhaps consulting with industry experts—you’ll find yourself better equipped to navigate this complex landscape without breaking the bank.

Why Is Injection Moulding Expensive?

When diving into the world of injection moulding, one question often arises: why is injection moulding expensive? The answer lies in several interconnected factors, starting with the initial capital investment required to get operations up and running. From high-quality machinery to specialized molds, understanding these costs can help businesses navigate their budget effectively.

Initial Capital Investment Explained

In order to grasp injection moulding costs, it's essential to consider the initial capital investment involved. Setting up an injection moulding operation requires significant expenditure on machinery and equipment, which can run into hundreds of thousands of dollars. This hefty price tag is a major contributor to the question How much does injection molding cost? as it encompasses not just the machines but also the facilities needed for production.

Moreover, custom molds can add a substantial amount to this initial investment, especially if they require intricate designs or high-quality materials. These molds are typically designed for longevity and precision, which means that cutting corners could lead to poor quality products down the line—something no business wants. Thus, when calculating how much does injection molding cost overall, it’s vital to factor in these upfront expenses as they set the stage for future operations.

The Role of Expertise in Quality

Another reason why injection moulding is often viewed as expensive is due to the expertise required in both design and manufacturing processes. Skilled professionals are necessary not only for operating complex machinery but also for ensuring that each mold meets stringent quality standards. This expertise comes at a price; however, it’s an investment that pays off by reducing defects and enhancing product reliability.

Quality assurance processes are integral parts of any successful project involving injection molding costs—after all, who wants to deal with product recalls or customer dissatisfaction? Understanding how to calculate injection mold cost accurately involves considering these labor costs associated with skilled workers who bring invaluable experience to your project. Ultimately, investing in expertise can lead you toward more efficient production cycles and better end products.

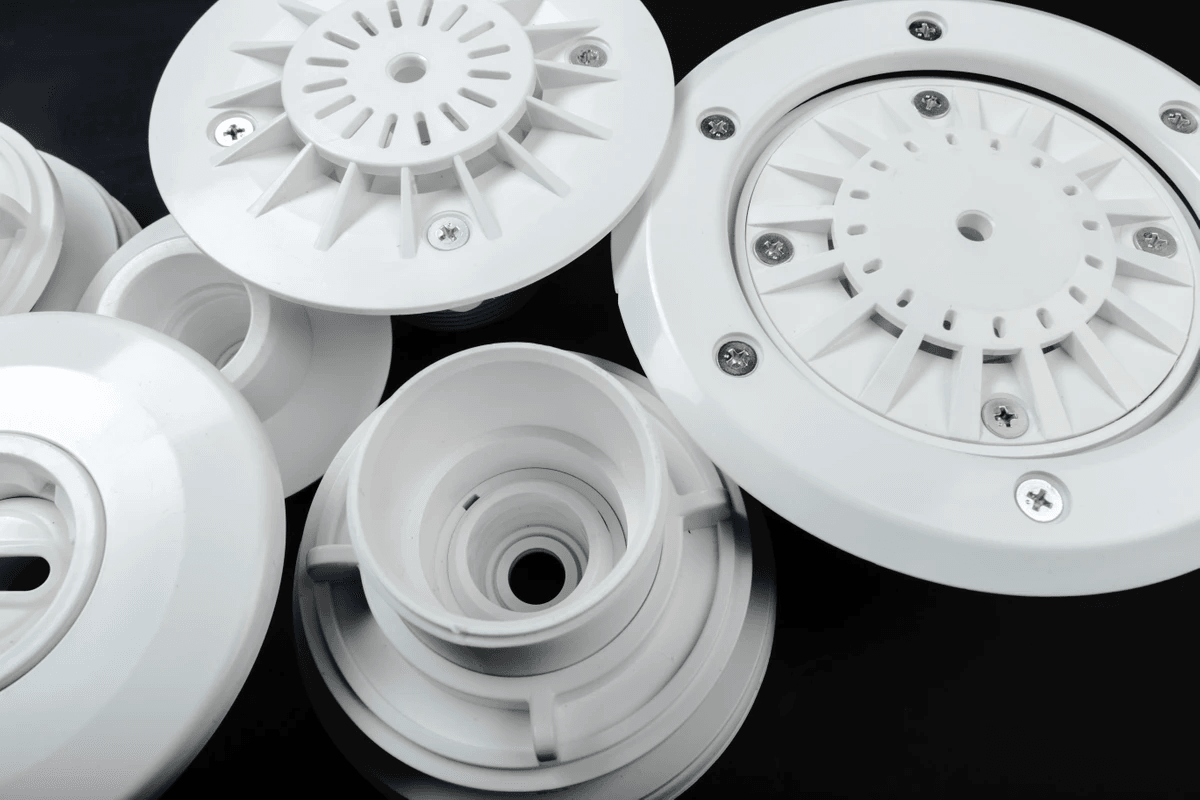

Industry-Specific Customizations

Finally, industry-specific customizations play a pivotal role in determining why is injection moulding expensive? Different industries have unique requirements that necessitate tailored solutions—from automotive components needing durability under stress conditions to medical devices requiring stringent hygiene standards. These specific needs often translate into additional design complexities that further drive up costs.

When exploring low-cost plastic molding options, it’s crucial not just to look at base prices but also at how well those solutions meet your particular industry demands without compromising quality or safety standards. As you ponder how much does injection molding cost per hour or how to estimate injection molding cost accurately for your specific application, remember that customization can significantly influence overall expenses while delivering value through superior performance.

Exploring Low-Cost Plastic Molding Options

When it comes to injection moulding costs, the pursuit of budget-friendly solutions can feel like navigating a maze. Fortunately, there are several alternatives available for those looking to keep expenses in check without sacrificing too much quality. Understanding these options can help you answer the perennial question: How much does injection molding cost?

Alternatives for Budget-Conscious Projects

For budget-conscious projects, one viable option is to consider using lower-cost materials that still meet basic functional requirements. Materials like recycled plastics or less expensive thermoplastics can significantly reduce overall injection moulding costs while still allowing for decent product performance. Another alternative is to utilize simpler designs that require less intricate molding processes, thus lowering manufacturing expenses.

Additionally, exploring regional manufacturers may yield lower production costs due to reduced shipping and labor expenses. This approach allows you to find local partners who specialize in low-cost plastic molding while maintaining acceptable quality standards. By comparing quotes and capabilities from various suppliers, you can effectively determine how to estimate injection molding cost without breaking the bank.

Pros and Cons of Lower-Cost Solutions

While the allure of lower-cost solutions is undeniable, it's essential to weigh their pros and cons carefully before diving in headfirst. On the plus side, these options often lead to substantial savings on initial investments—an attractive proposition for startups or small businesses facing tight budgets. However, one must also consider potential trade-offs in terms of material durability and overall product quality; after all, why is injection moulding expensive if not for the premium materials and expertise involved?

Moreover, opting for cheaper alternatives might result in longer lead times or increased maintenance needs down the line due to inferior materials or design choices that compromise structural integrity. These factors could ultimately impact your bottom line more than anticipated when calculating how much does injection molding cost over time. Balancing cost with quality becomes a crucial consideration in ensuring project success.

Finding the Right Balance in Quality

The key takeaway when exploring low-cost plastic molding options is finding that sweet spot where quality meets affordability—a delicate dance indeed! To achieve this balance, it's vital first to identify your project's specific requirements: Is durability non-negotiable? Will aesthetics play a significant role? Answering these questions will guide your material selection and design choices while keeping an eye on how much does injection molding cost overall.

Investing time upfront into research will pay dividends later as you navigate through various manufacturers' offerings and their associated pricing structures. Don't forget about testing prototypes; this step can reveal insights into whether your chosen low-cost solution meets expectations without compromising essential qualities—after all, no one wants their product falling apart right after launch!

In conclusion, understanding low-cost plastic molding options requires diligence but offers opportunities for significant savings when done correctly—not just a way to cut corners but rather an intelligent approach toward managing injection moulding costs effectively.

Conclusion

Navigating the world of injection moulding costs can feel like a maze, but understanding the key factors involved can illuminate your path. From material selection to mold design and manufacturing, each element plays a crucial role in determining overall expenses. By grasping these components, you can better manage your budget and expectations when embarking on your next project.

Recap of Key Cost Factors

When pondering how much does injection molding cost?, consider several pivotal factors: material quality, design complexity, and mold manufacturing intricacies. Each of these elements contributes significantly to the final price tag attached to your product. Additionally, while exploring low-cost plastic molding options may seem tempting, it's essential to weigh the potential trade-offs in quality and durability against initial savings.

Importance of Accurate Cost Estimation

Understanding how to calculate injection mold cost? is vital for any project manager or business owner looking to budget effectively. Accurate cost estimation not only helps avoid unpleasant surprises down the line but also allows for more strategic decision-making regarding materials and production methods. Remember that knowing how much does injection molding cost per hour? can further refine your financial planning by providing insights into labor and machine expenses.

Insights from Baoyuan Team Experts

The Baoyuan team emphasizes that one of the primary reasons why is injection moulding expensive? stems from the initial capital investment required for high-quality molds and machinery. However, their extensive experience has shown that investing in quality pays off in terms of reduced defects and enhanced production efficiency over time. They also recommend being mindful when considering low-cost plastic molding solutions; while they may fit a tighter budget initially, long-term costs could outweigh these savings if quality suffers.