Introduction

In the world of manufacturing, injection molds play a pivotal role in transforming raw materials into finished products. Understanding injection molds cost is essential for businesses looking to optimize their production processes and budget effectively. This introduction sets the stage for a deeper dive into the intricacies of injection molds, their significance in various projects, and the factors that influence their costs.

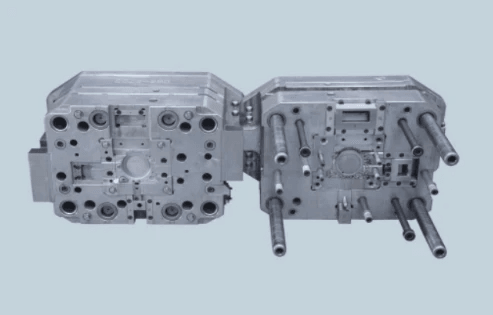

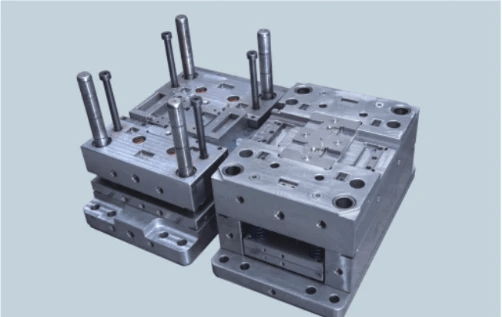

What Are Injection Molds?

Injection molds are specialized tools used to shape molten materials, typically plastics, into specific forms by injecting them into a mold cavity. This process allows for high-volume production of complex shapes with precision and consistency. Knowing what injection molds are is crucial for anyone involved in manufacturing or product design, as they form the backbone of many industrial applications.

Why Injection Molds Matter for Projects

Injection molds matter significantly for projects because they directly impact both production efficiency and product quality. A well-designed mold can streamline manufacturing processes while ensuring that the final products meet stringent specifications and standards. Additionally, understanding how much does injection molding cost can help project managers allocate resources wisely and avoid unexpected expenses.

Key Factors Influencing Injection Molds Cost

Several key factors influence injection molds cost, including material selection, mold complexity, and production volume requirements. The choice of materials not only affects durability but also has implications on pricing; different plastics come with varying costs that can add up quickly. Moreover, understanding how to calculate injection mold cost involves considering all these elements to arrive at an accurate estimate that reflects true project needs.

Understanding Injection Molds Cost

When embarking on a project that involves injection molding, understanding the associated costs is crucial. Injection molds cost can vary significantly based on numerous factors, making it essential to grasp the components that contribute to these expenses. This section will delve into an overview of injection molds costs, the determining factors, and how material choices impact pricing.

An Overview of Injection Molds Costs

The cost of injection molds can range widely depending on several elements, from design complexity to production volume. On average, what is the average cost of an injection mold? A simple mold might start at a few thousand dollars, while more intricate designs can soar into the tens or even hundreds of thousands. Thus, having a clear understanding of your project's requirements is vital to estimating your budget accurately.

In addition to initial costs for mold creation, ongoing expenses such as maintenance and repairs should also be factored in when considering overall injection molds cost. These additional expenses can accumulate over time and affect your project's financial viability if not accounted for early on. Therefore, it's wise to approach this topic with thorough research and careful planning.

Factors That Determine Injection Molds Cost

Several key factors influence injection molds cost and should be considered during project planning. First and foremost is the complexity of the mold design; more complex shapes require advanced engineering and increased manufacturing time, which drives up costs. Additionally, production volume plays a crucial role; higher volumes typically reduce per-unit costs due to economies of scale.

Another significant factor is labor costs associated with manufacturing the mold itself; skilled technicians are often required for intricate designs or high-quality finishes. Geographic location also impacts pricing—how much does injection molding cost in China compared to domestic options? Understanding these elements will help you navigate through potential price variations effectively.

The Role of Material Choices in Cost

Material selection plays a pivotal role in determining overall injection molds cost as different materials come with varying price tags and properties. For instance, using high-performance plastics may enhance product durability but could significantly increase material expenses compared to standard options. Therefore, balancing performance needs with budget considerations becomes essential when selecting materials for your project.

Moreover, specific materials may require specialized processing techniques or equipment that further add to production costs; this consideration cannot be overlooked when calculating how much does plastic injection molding cost overall. By understanding these nuances related to material choices, you can make informed decisions that align with both quality standards and budget constraints.

What is the Average Cost of an Injection Mold?

When diving into the world of injection molds, one burning question often arises: What is the average cost of an injection mold? The answer isn’t straightforward, as it varies greatly depending on several factors, including complexity, size, and material. However, understanding industry benchmarks can provide a clearer picture and help businesses navigate the intricate landscape of injection molds cost.

Industry Benchmarks for Injection Molds

Industry benchmarks reveal that the average cost of an injection mold can range from $5,000 to over $100,000. This wide range reflects not only the diversity in mold design but also the varying levels of precision required for different applications. For instance, simple molds for basic components may be on the lower end of this spectrum, while intricate molds designed for high-performance parts can push costs significantly higher.

Moreover, it's crucial to consider that these costs are just starting points; additional expenses may accrue based on modifications or specific requirements from clients. As companies seek to understand how much does injection molding cost in China versus domestic options, they must keep these benchmarks in mind to make informed decisions about their projects. Ultimately, knowing where your project falls within these industry standards can help you budget more effectively.

Comparing Costs Across Different Markets

When comparing costs across different markets—whether domestic or international—the disparities can be striking. For example, while North America might see higher labor and overhead costs contributing to overall injection molds cost, countries like China often offer more competitive pricing due to lower labor expenses and established manufacturing infrastructures. This has led many businesses to ask how much does injection molding cost in China compared to local options.

However, it’s essential not just to chase lower prices; quality should never be sacrificed at the altar of savings. Understanding regional market dynamics allows companies to weigh factors like shipping costs and lead times against potential savings when sourcing their molds globally. Therefore, conducting thorough research into market comparisons is vital for anyone looking at what is the average cost of an injection mold in various regions.

Factors Affecting Average Costs

Material choice plays a significant role; high-quality steel or aluminum will naturally drive up production expenses compared to less durable alternatives. Additionally, complexity in design—such as multi-cavity setups or intricate geometries—can significantly impact how much does plastic injection molding cost overall.

Another factor worth considering is production volume: larger runs typically reduce per-unit costs due to economies of scale but require a higher initial investment in mold creation itself. Finally, hidden costs such as maintenance fees or unexpected modifications can inflate your budget if not accounted for upfront; this leads many professionals wondering why do injection molds cost so much after all is said and done! Understanding these aspects will empower businesses with better tools for estimating their projects accurately.

How Much Does Injection Molding Cost in China?

Cost Comparison: Domestic vs. China

The first aspect to consider in understanding how much does injection molding cost in China is the stark difference in pricing compared to domestic options. On average, injection molds cost significantly less when produced in China due to lower labor costs and economies of scale achieved by larger factories. However, while upfront costs may be lower, it's essential to factor in shipping fees and potential tariffs when calculating total expenses.

In contrast, domestic manufacturers might charge higher prices for injection molds but often provide faster turnaround times and easier communication. This can be crucial for projects with tight deadlines or specific quality requirements. Ultimately, businesses must weigh these factors carefully to determine which option aligns best with their budget and project goals.

Advantages of Sourcing Injection Molds from China

One of the primary reasons companies are drawn to sourcing injection molds from China is the significant reduction in overall costs associated with manufacturing. Not only do lower labor rates contribute to a decrease in injection molds cost, but Chinese manufacturers also have access to advanced machinery that can produce high-quality molds at a fraction of the price found domestically. This combination makes it easier for businesses to keep their production budgets intact while still meeting quality standards.

Additionally, many Chinese companies offer a wide range of services beyond just mold creation—like design assistance and prototyping—that can streamline the entire manufacturing process. These value-added services mean that businesses can save both time and money by working with one supplier rather than coordinating between multiple vendors for different aspects of production.

Furthermore, China's vast network of suppliers means that finding specialized materials or unique mold designs often comes at a lower price compared to local markets—an essential consideration when thinking about how much does plastic injection molding cost overall.

Key Players in the Chinese Injection Molding Market

The landscape of China's injection molding market is populated by numerous key players who have established themselves as leaders through competitive pricing and innovation. Companies like HCDM (Huangshan Chuangda Mold) and JMT (Jiangmen Mingtao) are well-known for providing high-quality injection molds at attractive rates while maintaining robust customer service standards—vital when considering how to calculate injection mold cost accurately.

These firms not only cater primarily to local clients but also export their products worldwide, demonstrating their capability and reliability on an international scale. By engaging with these major players, businesses can benefit from their extensive experience and expertise within the industry—a factor that contributes significantly towards understanding why do injection molds cost so much if sourced incorrectly.

In conclusion, while exploring how much does injection molding cost in China offers enticing possibilities for savings, it's crucial for companies to conduct thorough research on potential suppliers before making any commitments.

How to Calculate Injection Mold Cost?

Calculating injection mold cost is crucial for anyone looking to embark on a manufacturing project. Understanding how to calculate injection mold cost can save you from unpleasant surprises down the road. By breaking down the various components involved, you can gain clarity on what contributes to the overall price and make informed decisions.

Breakdown of Cost Components

When evaluating injection molds cost, it's essential to consider several key components that contribute to the final price. First, there’s the design and engineering phase, which includes creating detailed blueprints and prototypes tailored for your specific needs. Next comes the actual manufacturing of the mold itself, which involves costs related to machinery, labor, and materials—each of these factors can significantly influence what is the average cost of an injection mold?

Additionally, don’t overlook post-production expenses such as testing and quality assurance, which ensure that your molds meet industry standards before they’re put into use. Other hidden costs might include maintenance fees or modifications needed later in production runs—these can add up quickly! Ultimately, understanding this breakdown will empower you in negotiations and budgeting.

Understanding Pricing Models

Pricing models for injection molds can vary widely depending on several factors including complexity and volume requirements. Many manufacturers offer tiered pricing based on order quantities; higher volumes often lead to reduced per-unit costs due to economies of scale. However, when asking yourself how much does injection molding cost in China compared to domestic options, remember that labor costs play a significant role in shaping these pricing models.

Another aspect worth noting is whether you're opting for standard molds or custom designs; custom molds typically incur higher upfront costs but may be necessary for specialized projects. In any case, it pays off to understand these models thoroughly so you can strategize according to your project’s needs while keeping an eye on why do injection molds cost so much?

Tips for Accurate Cost Estimation

Accurate cost estimation is paramount when planning your budget for plastic injection molding projects. Start by gathering multiple quotes from different manufacturers—this will give you a clearer picture of market rates and help identify any outliers in pricing strategies related to injection molds cost. Additionally, ensure that each quote breaks down all individual components so you can compare apples-to-apples across different suppliers.

Moreover, consider using software tools designed specifically for estimating mold costs; these tools often incorporate various factors like material choice and production volume into their algorithms for more precise calculations. Finally, always include a buffer in your budget for unforeseen expenses—this way you'll be prepared if something unexpected arises during production!

Why Do Injection Molds Cost So Much?

When it comes to injection molds cost, many factors contribute to the final price tag that can leave project managers scratching their heads. Understanding the economics behind injection molds is crucial for anyone looking to dive into this manufacturing method. With various elements at play, from materials to labor and technology, it's no wonder that many ask, What is the average cost of an injection mold?

The Economics Behind Injection Molds

The economics of injection molds revolve around several core principles that drive costs upward. First, consider the initial investment; creating a high-quality mold requires significant upfront capital for design and production. Additionally, as production volumes increase, the per-unit cost decreases, but this only happens after a substantial initial investment in tooling and setup.

Moreover, market demand plays a critical role in shaping injection molds cost; when demand spikes for certain products or materials, prices can soar due to scarcity and competition among manufacturers. This fluctuation often leads businesses to question how much does plastic injection molding cost across various industries? Ultimately, understanding these economic factors is essential for accurately predicting costs.

Investment in Technology and Expertise

Another reason why do injection molds cost so much is the need for advanced technology and skilled labor in their creation. High-precision machinery and software are required to ensure that molds are produced with exact specifications—this doesn’t come cheap! Investing in state-of-the-art equipment can significantly impact initial costs but often results in better quality products and reduced waste over time.

Skilled professionals are also necessary for designing these intricate tools; hiring experienced engineers and technicians ensures that your mold meets industry standards while minimizing errors during production. As companies weigh how to calculate injection mold cost effectively, they must factor in these investments as part of their overall budget strategy.

Hidden Costs in Molding Projects

Hidden costs can sneak up on even the most diligent project managers when dealing with injection molds cost. These expenses may include maintenance fees for machinery or unexpected repairs due to wear-and-tear over time—no one plans on those! Additionally, changes in design or material specifications during production can lead to costly revisions that weren’t accounted for initially.

Moreover, logistics plays a significant role; shipping costs for both raw materials and finished products must be considered when evaluating overall expenses related to how much does injection molding cost? Being aware of these hidden pitfalls allows businesses to create more accurate budgets while navigating the complexities of molding projects.

How Much Does Plastic Injection Molding Cost?

When exploring how much plastic injection molding costs, it’s essential to recognize the myriad of factors that influence the final price tag. The costs can vary widely based on the complexity of the design, volume of production, and materials used. Understanding these components can help businesses make informed decisions about their projects.

Various Cost Factors to Consider

Several cost factors come into play when determining injection molds cost. First, the complexity and size of the mold significantly impact expenses; intricate designs require more sophisticated molds and longer production times. Additionally, material choices—ranging from standard plastics to specialized compounds—can drive costs up or down depending on availability and processing requirements.

Labor costs are another critical element; skilled technicians are necessary for both mold creation and maintenance. Furthermore, production volume plays a role: higher quantities typically reduce per-unit costs due to economies of scale. Lastly, geographical location can affect pricing; for instance, How much does injection molding cost in China? often reveals lower rates compared to domestic markets due to lower labor expenses.

Case Studies of Cost Variations

To illustrate how injection molds cost can vary dramatically, consider two case studies in different industries. In the automotive sector, a company may invest upwards of $100,000 for a complex multi-cavity mold designed for high-volume production runs—this reflects both advanced technology and precision engineering requirements. Conversely, a small startup producing consumer goods might only need a simpler mold costing around $10,000.

Another notable example is a tech company sourcing its molds from China versus domestically; while they might pay $50,000 locally for an advanced mold with quick turnaround times, they could find similar quality in China for as little as $20,000 with longer lead times but significant savings overall. These case studies underscore why understanding what is the average cost of an injection mold is crucial before committing resources.

Cost-Saving Tips for Injection Molding

Navigating the world of injection molding doesn’t have to break the bank if you know where to look for savings! One effective strategy is optimizing your design before production; simpler shapes often yield lower tooling costs while maintaining functionality. Additionally, collaborating closely with suppliers during the design phase can lead to innovative solutions that cut down on material waste and manufacturing time.

Sourcing materials wisely also presents opportunities for savings—consider alternative resins or composite materials that might offer similar performance at reduced prices without sacrificing quality. Moreover, if you're wondering how to calculate injection mold cost accurately: obtaining multiple quotes from different manufacturers will provide leverage in negotiations while ensuring you get competitive pricing.

Lastly, don’t underestimate bulk ordering; larger volumes not only reduce per-unit costs but may also qualify you for discounts on future orders or services—after all, every penny saved contributes toward answering why do injection molds cost so much initially!

Conclusion

In wrapping up our exploration of injection molds cost, it's clear that understanding the intricacies of this essential manufacturing process is vital for any project manager or entrepreneur. From determining what is the average cost of an injection mold to analyzing how much does injection molding cost in China, every detail plays a crucial role in budgeting and project planning. With a comprehensive grasp of these factors, stakeholders can make informed decisions that align with their financial goals.

Key Takeaways on Injection Molds Cost

First and foremost, the injection molds cost can vary significantly based on multiple factors including design complexity, material choice, and production volume. It's essential to recognize that what is the average cost of an injection mold may not reflect your specific needs; customization often leads to variations in pricing. Additionally, understanding why do injection molds cost so much can help demystify the perceived high expenses associated with this manufacturing method.

Best Practices for Managing Costs

To effectively manage costs associated with injection molding, it’s crucial to start by accurately calculating your injection mold cost from the outset. This involves breaking down all components such as design fees, material costs, and manufacturing overheads—ensuring you don’t miss hidden expenses along the way. Moreover, exploring options like bulk ordering or sourcing from regions where how much does plastic injection molding cost is lower can yield significant savings without compromising quality.

The Future of Injection Molding and Costs

Looking ahead, the future of injection molding appears promising as advancements in technology continue to drive efficiency and reduce costs across the board. Innovations such as 3D printing integration and smart manufacturing practices are poised to transform how we calculate injection mold costs while enhancing production capabilities. As global markets evolve—especially regarding how much does injection molding cost in China—companies must remain adaptable to leverage these changes for competitive advantage.