Introduction

Injection molding is a cornerstone of modern manufacturing, but navigating the landscape of injection mold costs can feel like deciphering a complex puzzle. From initial design to final production, understanding what drives these costs is crucial for businesses looking to optimize their budget and enhance efficiency. In this guide, we’ll explore the ins and outs of injection mold expenses, helping you answer questions like What is the average cost of an injection mold? and How much does injection molding cost in China?

The Basics of Injection Mold Costs

At its core, injection mold costs encompass everything from design and engineering to raw materials and labor. These expenses can vary widely based on factors such as complexity, material choice, and production volume. By grasping these basics, manufacturers can better prepare for the financial implications associated with producing high-quality molded parts.

Factors Influencing Injection Mold Expenses

Several key elements influence the overall expenses tied to injection molds. For instance, the intricacy of a part's design can significantly impact both initial tooling costs and production efficiency. Additionally, geographical location plays a role; many wonder how much does injection molding cost in China compared to domestic options? Understanding these factors allows businesses to make informed decisions about their manufacturing processes.

Understanding Different Pricing Models

When it comes to pricing models for injection molding services, there's no one-size-fits-all approach; different manufacturers may offer varying structures based on their capabilities and market strategies. Some firms might charge per unit produced while others may provide flat-rate pricing that covers all aspects from design through delivery. Familiarizing oneself with these models not only clarifies how to calculate injection mold cost but also empowers companies to negotiate better deals tailored to their specific needs.

What is an Injection Mold?

Injection molding is a manufacturing process that involves creating parts by injecting molten material into a mold. This method allows for the production of complex shapes and high volumes of parts, making it popular across various industries. Understanding injection mold costs is essential for businesses looking to optimize their production processes and budgets.

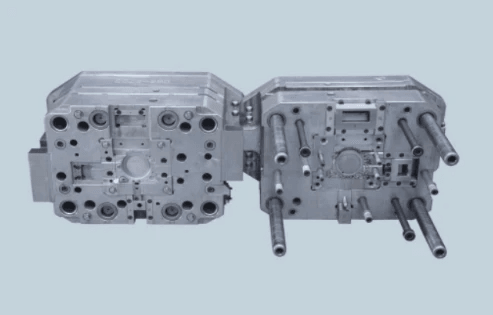

Definition and Key Components

An injection mold consists of two main halves: the cavity, which shapes the part, and the core, which forms the interior features. These components are precision-engineered to ensure that they fit together perfectly, allowing for consistent production quality. The complexity of an injection mold can significantly influence its cost; intricate designs may require advanced materials and machining techniques.

When considering What is the average cost of an injection mold?, it's crucial to factor in these key components since they directly affect both initial investment and long-term operational expenses. Additionally, features such as cooling channels, ejection systems, and surface finishes can add to overall costs. Thus, understanding these elements helps businesses make informed decisions when calculating injection mold costs.

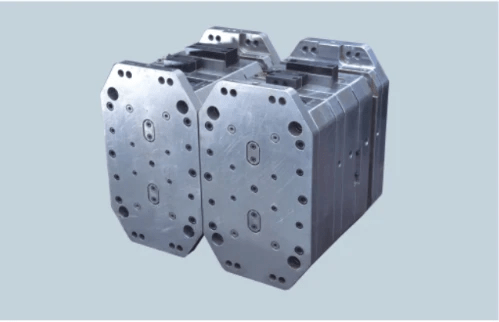

Types of Injection Molds

There are several types of injection molds tailored for different applications and materials. The most common types include single cavity molds for simple designs, multi-cavity molds that produce multiple parts per cycle, and family molds that create different parts simultaneously from one setup. Each type comes with its own set of advantages and associated costs.

For example, while single cavity molds may be less expensive initially, multi-cavity options can reduce How much does plastic injection molding cost? by increasing production efficiency over time. Additionally, specialized molds like hot runner systems or stack molds allow for more complex geometries but come with higher upfront costs due to their advanced design requirements. Therefore, understanding these types can help businesses choose wisely based on their specific needs while keeping an eye on overall injection mold costs.

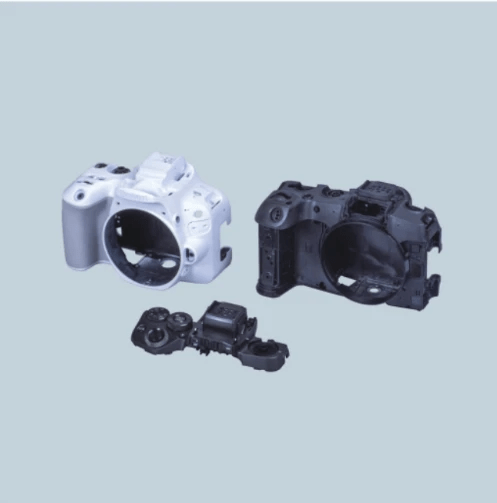

Applications in Various Industries

Injection molding finds applications in a plethora of industries including automotive, consumer goods, medical devices, electronics, and packaging. Each sector leverages this technology's ability to produce high-quality components quickly and efficiently at scale—think car dashboards or intricate medical device housings that demand precision engineering at competitive prices.

In regions like China where manufacturing costs are often lower—How much does injection molding cost in China?—businesses can benefit from reduced expenses while maintaining quality standards in their products. Furthermore, knowing How much does injection molding cost per kg? becomes vital when evaluating material choices against production volume targets across diverse applications; this knowledge empowers companies to make strategic financial decisions regarding their manufacturing processes.

Breaking Down Injection Mold Costs

Understanding injection mold costs requires a deep dive into various components that contribute to the overall expense. Each element plays a significant role in determining how much you’ll ultimately pay for your molds and the injection molding process. Let’s break it down into manageable sections, so you can get a clearer picture of what to expect.

Initial Design and Engineering Expenses

The initial design and engineering expenses are often where the journey of injection mold costs begins. This phase involves creating detailed blueprints, prototypes, and simulations to ensure that the mold will produce parts accurately and efficiently. Depending on complexity, these design services can range from a few hundred to several thousand dollars; thus, understanding how to calculate injection mold cost at this stage is crucial for budgeting purposes.

Moreover, if you're wondering what is the average cost of an injection mold? Keep in mind that these initial expenses can significantly influence that average. A well-thought-out design not only minimizes future complications but also optimizes production efficiency—saving you money in the long run.

Raw Material Costs for Injection Molding

Next up are raw material costs for injection molding, which can vary widely depending on the type of plastic used. Common materials like polypropylene or ABS might be more economical than specialty plastics such as PEEK or polycarbonate, which could drive up your overall costs significantly. If you’re curious about how much does injection molding cost per kg? The answer lies largely in your choice of material; prices fluctuate based on market demand and availability.

In addition to material selection, it's essential to account for waste during production—inevitably some material will be lost during the process. Therefore, keeping an eye on raw material prices is vital when estimating total injection mold costs; even small changes can have big impacts on your bottom line.

Labor and Overhead Factors

Labor and overhead factors are another critical piece of the puzzle when discussing injection mold costs. Skilled labor is required not just for operating machinery but also for quality control throughout production runs; this adds another layer of expense that shouldn't be overlooked. In many cases, labor rates vary by region or country—this could explain why many companies ask how much does injection molding cost in China?

Furthermore, overhead expenses include everything from facility rent to utilities and equipment maintenance—these should all be factored into your overall calculations as they contribute significantly to operational costs over time. Understanding these elements will help you create a comprehensive budget when considering both initial investments like the cost of an injection molding machine and ongoing operational expenses.

Average Cost of Injection Molds

When diving into the world of injection molding, understanding average costs is crucial for budgeting and planning. Injection mold costs can vary widely based on design complexity, materials used, and the manufacturer’s location. Therefore, knowing what to expect in terms of pricing can help businesses make informed decisions.

What is the Average Cost of an Injection Mold?

The average cost of an injection mold typically ranges from $1,000 to $100,000 or even more for complex designs. Factors such as mold size, material type, and production volume heavily influence these costs. So when asking What is the average cost of an injection mold? it’s essential to consider these variables that can significantly sway the final price.

In general, simpler molds for small parts may hover around the lower end of this spectrum while intricate molds designed for high-volume production could skyrocket costs. Additionally, one must account for ongoing expenses related to maintenance and repairs that are part and parcel of managing injection mold costs over time. Ultimately, understanding these aspects helps businesses better navigate their budgets.

How Much Does Injection Molding Cost in China?

When looking at global manufacturing options, many wonder: How much does injection molding cost in China? Generally speaking, China offers competitive pricing due to lower labor costs and material availability. Prices can start as low as $500 for basic molds but can escalate depending on complexity and quality requirements.

However, while initial costs might be attractive in China, it’s vital to factor in shipping fees and potential tariffs when calculating total expenses. Additionally, communication barriers or quality control issues may arise with overseas manufacturers that could affect overall satisfaction with your investment. In essence, while Chinese manufacturers provide appealing rates for injection molding services, thorough research remains essential.

Comparisons Across Different Manufacturers

Comparing different manufacturers reveals a broad spectrum of prices associated with injection mold costs—no two companies are alike! Some manufacturers may charge premium prices based on their reputation or advanced technology capabilities while others might offer budget-friendly options without compromising quality too much. When assessing how much does plastic injection molding cost across various suppliers it’s wise to request detailed quotes that outline all potential expenses.

Moreover, examining customer reviews and case studies can provide insights into each manufacturer’s reliability and service levels which directly impact overall satisfaction with your investment in molds. Understanding how different manufacturers structure their pricing helps you not only gauge value but also identify which partners align best with your project needs and budget constraints. The right choice will ultimately lead to better management of your injection mold costs over time.

How to Calculate Injection Mold Cost

Calculating injection mold costs can feel like navigating a labyrinth, but with the right approach, it becomes a manageable task. The process involves several steps that encompass design, materials, labor, and overheads. Understanding how to calculate injection mold cost accurately is essential for anyone looking to venture into plastic manufacturing.

Step-by-Step Cost Calculation Process

To begin with, the first step in calculating injection mold costs is determining the initial design and engineering expenses. This includes fees for CAD designs and prototyping, which can vary significantly based on complexity. Next, consider raw material costs; this requires knowing how much does injection molding cost per kg of the chosen resin or plastic.

Once you have these foundational elements figured out, you'll need to factor in labor and overhead expenses associated with the production process. These can include machine operation costs and utilities—essentially everything that keeps your molding machine humming along smoothly. Finally, tally up all these components to arrive at a comprehensive figure that reflects your total injection mold costs.

Tools and Software for Cost Estimation

In today’s digital age, various tools and software are available to simplify the cost estimation process for injection molds. Programs like SolidWorks or Moldflow can help visualize designs while providing real-time cost analysis based on materials used and production volume. By leveraging these advanced tools, you can get a more accurate understanding of what is the average cost of an injection mold before committing fully.

Additionally, there are specialized calculators designed specifically for estimating injection molding costs that take multiple variables into account—like machine time and material waste—allowing for precise budgeting ahead of production runs. Using such software not only speeds up calculations but also enhances decision-making by presenting clear data on potential expenses involved in your project.

Working with Experts like Baoyuan for Accurate Pricing

While DIY methods are helpful, collaborating with experts like Baoyuan can elevate your understanding of how much does injection molding cost in China or any other market you're considering. Their industry knowledge means they can provide insights into hidden costs that might not be apparent at first glance—like tariffs or shipping fees—that significantly impact overall pricing structures.

Furthermore, experienced professionals can guide you through complex calculations related to the cost of an injection molding machine versus other options available in the market today—whether rental or purchase makes more financial sense based on your needs. Ultimately, working alongside seasoned experts ensures you receive accurate pricing tailored specifically to your project's requirements while keeping those pesky unexpected expenses at bay.

Cost of Injection Molding Machine

When it comes to injection mold costs, the machinery involved plays a crucial role in determining the overall expense. The cost of injection molding machines can vary significantly based on several factors, including size, technology, and capabilities. Understanding these factors will help you make informed decisions whether you're looking to rent or purchase equipment for your production needs.

Factors Affecting Machine Costs

Several factors influence the cost of an injection molding machine. First and foremost is the machine's size; larger machines capable of producing bigger parts typically come with a heftier price tag. Additionally, technological advancements such as energy efficiency features and automation capabilities can drive up costs but may offer long-term savings on operational expenses.

Another critical factor is the brand reputation and quality; well-known manufacturers often charge more due to their reliability and service support. Moreover, specialized machines designed for specific materials or applications will also impact how much does injection molding cost overall—especially if you require unique functionalities that standard machines do not provide. Lastly, market conditions can affect pricing; fluctuations in demand or supply chain issues may lead to unexpected changes in machine costs.

Rental vs. Purchase Options

Deciding between renting or purchasing an injection molding machine is a significant choice that impacts your budget directly when considering injection mold costs. Renting may be appealing for businesses just starting out or those with fluctuating production needs since it requires less upfront capital and provides flexibility without long-term commitments. However, keep in mind that rental fees can accumulate over time, potentially leading to higher overall expenditures compared to outright purchasing.

On the flip side, buying equipment allows for full control over maintenance schedules and modifications tailored to your specific production processes—this could be advantageous if you're committed to long-term manufacturing goals. Plus, owning your machinery means you won't have to worry about rental agreements or availability issues during peak production times. Ultimately, weighing these options against how much does plastic injection molding cost per kg will help determine which route aligns best with your financial strategy.

Maintenance and Operational Expenses

Maintenance and operational expenses are often overlooked when calculating how to calculate injection mold cost accurately but are essential for understanding total expenditures related to the cost of an injection molding machine. Regular maintenance ensures optimal performance while minimizing downtime; this could mean scheduling routine check-ups or investing in spare parts as needed—both of which add up over time but are necessary for longevity.

Moreover, consider energy consumption as part of operational costs since modern machines vary widely in efficiency levels; investing in energy-efficient models might raise initial costs but pay off through reduced utility bills down the line. Finally, labor associated with operating the machinery must also be factored into your budget; skilled operators command higher wages but are crucial for maintaining product quality during production runs.

In summary, understanding all aspects surrounding the cost of an injection molding machine—from initial purchase decisions through ongoing maintenance—is vital for managing overall expenses effectively while keeping an eye on evolving trends within this dynamic industry.

Conclusion

In the intricate world of manufacturing, understanding injection mold costs is paramount for businesses aiming to optimize their production processes. From the initial design phase to raw material expenses, every factor plays a crucial role in determining overall costs. By grasping these elements, companies can make informed decisions that impact their bottom line.

Key Takeaways on Injection Mold Costs

When considering injection mold costs, it’s essential to recognize that various factors contribute to the final price tag. For instance, many ask, What is the average cost of an injection mold? while also wondering about specific regional pricing variations like How much does injection molding cost in China? Additionally, understanding how much does injection molding cost per kg can provide valuable insights into overall project budgeting. Ultimately, comprehending these aspects enables businesses to strategize effectively and manage expenses.

The Role of Expertise in Cost Management

Navigating the complexities of how to calculate injection mold cost requires a blend of technical knowledge and industry experience. Collaborating with experts can significantly streamline this process and lead to more accurate estimates for projects like plastic injection molding. Having professionals on your side not only helps in managing current costs but also prepares businesses for future challenges in operational efficiency and budgeting.

Future Trends in Injection Molding Pricing

As technology evolves, so do the dynamics surrounding the cost of injection molding machines and processes involved in production. Innovations such as automation and advanced materials are set to reshape pricing structures significantly over time. Businesses will need to stay ahead by continually assessing how these trends influence their own operational expenditures related to injection mold costs.