Introduction

When it comes to manufacturing plastic products, PVC injection molding is a popular and efficient process. This method involves injecting molten PVC into a mold to create a wide range of products. With its versatility and cost-effectiveness, PVC injection molding has become a preferred choice for many industries.

Understanding PVC Injection Molding

PVC injection molding is a specialized form of plastic injection molding that focuses on the use of polyvinyl chloride (PVC) material. This process allows for the creation of durable and high-quality products that meet various industry standards and requirements. One of the key benefits of PVC injection molding is its versatility, as it can be used to produce a wide range of products, from pipes and fittings to medical devices and automotive components. Additionally, PVC injection molding offers cost-effective production solutions, making it an attractive option for businesses looking to optimize their manufacturing processes while maintaining product quality.

Benefits of PVC Injection Molding

The benefits of PVC injection molding are numerous, including its ability to produce complex shapes, its resistance to chemicals and weathering, as well as its cost-effectiveness in large-scale production. Additionally, PVC injection molding offers flexibility in product design and customization.

Furthermore, PVC injection molding is an environmentally friendly option, as it can be recycled and reused multiple times without losing its properties. This makes it a sustainable choice for companies looking to reduce their carbon footprint and minimize waste. In addition, PVC injection molding allows for precise and consistent production, ensuring high-quality products that meet strict industry standards. This level of reliability is crucial for businesses looking to maintain a strong reputation and customer satisfaction.

The Baoyuan Advantage in PVC Injection Molding

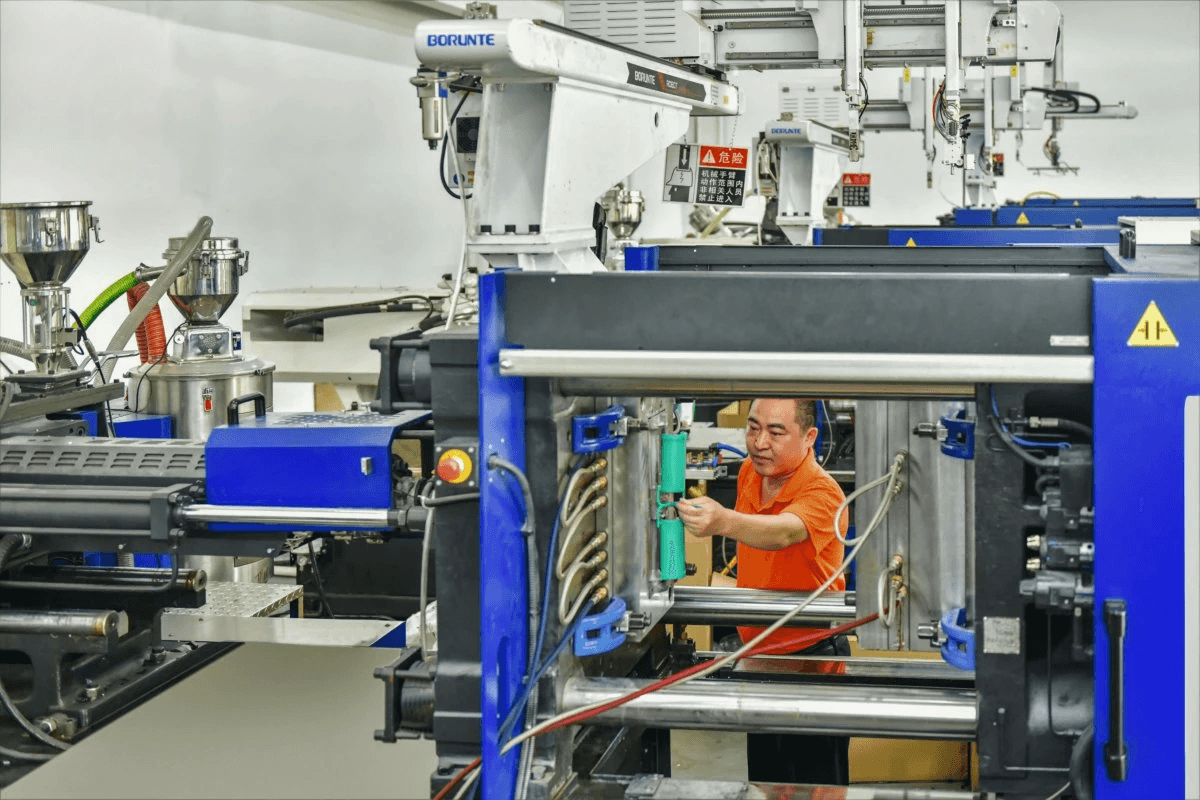

Baoyuan's expertise in plastic injection molding polyvinyl chloride (PVC) sets them apart in the industry. With their state-of-the-art facilities and commitment to quality assurance, Baoyuan ensures that their clients receive top-notch products that meet their specifications and exceed expectations. Moreover, Baoyuan's team of experienced engineers and technicians are constantly innovating and refining their PVC injection molding processes to stay ahead of the curve. This dedication to continuous improvement allows Baoyuan to offer cutting-edge solutions and stay at the forefront of PVC injection molding technology.

The Process of PVC Injection Molding

PVC Injection Molding is a precise and efficient process that begins with mold design and production. The mold is carefully crafted to ensure the final product meets exact specifications, taking into account factors such as cooling time and material flow. Baoyuan's expertise in this stage ensures high-quality molds for superior PVC products.

Mold Design and Production

The first step in PVC Injection Molding is the design and production of the mold. This involves creating a detailed blueprint of the product, which is then used to manufacture the mold using precision machinery. Baoyuan's attention to detail in this stage guarantees that every aspect of the mold meets the highest standards, resulting in flawless PVC products.

After the mold is produced, it is carefully inspected to ensure that it meets all specifications and requirements. Any imperfections or flaws are addressed and corrected before moving on to the next stage of the PVC Injection Molding process. This meticulous attention to detail at every step of the mold design and production phase is what sets Baoyuan apart from other manufacturers, guaranteeing top-quality results for every client.

Injection Molding Process

Once the mold is ready, the injection molding process begins by heating PVC resin pellets until they reach a molten state. The molten PVC is then injected into the mold cavity at high pressure, where it cools and solidifies into the desired shape. Baoyuan's state-of-the-art equipment and skilled technicians ensure that this process is executed with utmost precision for consistent, high-quality results.

After the PVC has solidified, the mold opens, and the newly formed part is ejected. Baoyuan's quality assurance team then thoroughly inspects each part to ensure it meets the specified requirements and standards. Any imperfections or defects are carefully addressed to maintain the high-quality standards that Baoyuan is known for in the industry.

Quality Assurance in PVC Injection Molding

Quality assurance is paramount in PVC Injection Molding to guarantee that each product meets strict standards for durability, flexibility, and chemical resistance. Baoyuan employs rigorous testing procedures throughout every stage of production to ensure that only top-notch PVC products are delivered to customers, providing peace of mind and satisfaction.

Baoyuan's commitment to quality assurance extends beyond just meeting industry standards. The company continuously invests in research and development to innovate new PVC formulations that offer enhanced performance and longevity. By staying at the forefront of material science, Baoyuan ensures that its PVC products are not only reliable but also cutting-edge, giving customers a competitive edge in their respective markets.

Remembering that quality matters most when it comes to plastic injection molding processes like those involving polyvinyl chloride (PVC), it's crucial to trust experts like Baoyuan for reliable results every time!

Characteristics of PVC Injection Molding

Flexibility and Durability

PVC injection molding offers exceptional flexibility, allowing for the production of a wide range of products with varying shapes and sizes. This material also boasts impressive durability, making it ideal for long-lasting applications in industries such as construction, automotive, and healthcare.

In addition to its flexibility and durability, PVC injection molding also offers resistance to chemicals and weathering. This means that products made from PVC can withstand exposure to harsh chemicals and extreme weather conditions without deteriorating or losing their structural integrity. This makes PVC an excellent choice for outdoor applications, as well as for products that come into contact with corrosive substances in industrial settings.

Resistance to Chemicals and Weathering

One of the key characteristics of PVC injection molding is its resistance to chemicals and weathering. This makes it an excellent choice for products that are exposed to harsh environments or corrosive substances, ensuring longevity and reliability in use.

In addition to its resistance to chemicals and weathering, PVC injection molding offers versatility in product design. This means that manufacturers can create a wide range of shapes, sizes, and textures, allowing for customized solutions to meet specific application requirements. Whether it's intricate detailing or complex geometries, PVC injection molding can accommodate various design needs, making it a highly adaptable choice for product development.

Versatility in Product Design

With PVC injection molding, the versatility in product design is unparalleled. Whether it's intricate details, unique textures, or vibrant colors, PVC allows for endless possibilities in creating visually appealing and functional products across various industries. The ability to achieve complex shapes and structures with precision makes PVC injection molding a top choice for manufacturers looking to push the boundaries of design and innovation. Additionally, the durability and resistance to corrosion and chemicals make PVC an ideal material for products that require longevity and reliability in harsh environments.

Now that we've explored the characteristics of PVC injection molding, let's delve into the role of Baoyuan in PVC processing to understand how their expertise sets them apart in this field.

The Role of Baoyuan in PVC Processing

Baoyuan has established itself as a leader in PVC injection molding, offering expertise in single-color and proficiency in double-color products. With a keen focus on quality assurance and customer satisfaction, Baoyuan ensures that every PVC product meets the highest standards.

Expertise in Single-Color Products

Baoyuan's expertise in single-color PVC injection molding allows for the production of high-quality, uniform products that meet the specific needs of our clients. Our team's attention to detail and precision in mold design and production ensures that each single-color product is flawless and durable.

Furthermore, our extensive experience in single-color PVC injection molding allows us to offer a wide range of customization options for our clients. Whether it's adjusting the size, shape, or texture of the product, we have the expertise to meet any specific requirements. This flexibility ensures that our clients receive products that not only meet their needs but also exceed their expectations.

Proficiency in Double-Color Products

In addition to single-color products, Baoyuan excels in the production of double-color PVC injection molded items. Our advanced injection molding process enables us to seamlessly integrate two colors, resulting in visually striking and versatile products that stand out from the competition.

Furthermore, our team of experienced designers and engineers are adept at creating innovative and eye-catching designs that make the most of the double-color injection molding process. This allows us to offer a wide range of unique and customizable products to meet the diverse needs of our clients. Whether it's adding a pop of color to a traditional item or creating intricate patterns, Baoyuan has the expertise to deliver exceptional double-color products.

Quality Assurance and Customer Satisfaction

At Baoyuan, quality assurance is at the heart of our PVC processing. We are committed to delivering products that not only meet but exceed our customers' expectations. Our dedication to customer satisfaction ensures that every step of the PVC injection molding process is executed with precision and care.

Our team of highly skilled technicians and engineers work tirelessly to ensure that our PVC products are of the highest quality. From the initial design phase to the final inspection, we implement rigorous quality control measures to guarantee that every product meets our strict standards. By prioritizing quality assurance, we can confidently say that our customers receive nothing but the best from Baoyuan.

Conclusion

PVC Injection Molding is a game-changer in the manufacturing industry, offering unparalleled flexibility, durability, and resistance to chemicals and weathering. With Baoyuan's expertise in PVC Processing in Plastic Injection Molding, the future of PVC Processing looks bright. Choosing Baoyuan for PVC Injection Molding ensures top-notch quality and customer satisfaction.

Achieving Success with PVC Injection Molding

With its exceptional characteristics and Baoyuan's proficiency, achieving success with PVC Injection Molding is within reach for businesses of all sizes. The process offers endless possibilities for product design and functionality, making it a highly sought-after solution in various industries. Furthermore, PVC injection molding allows for the production of complex shapes and intricate details, giving businesses the flexibility to create innovative and eye-catching products that stand out in the market. Additionally, PVC is a cost-effective material, making it an economical choice for companies looking to optimize their production processes without sacrificing quality.

The Future of PVC Processing

The future of PVC Processing in Plastic Injection Molding is promising, with continuous advancements in technology and manufacturing processes. As demand grows for high-quality, durable products, the role of PVC Injection Molding will only become more significant in shaping the future of manufacturing.

The continuous advancements in technology and manufacturing processes for PVC processing have opened up new possibilities for creating innovative and sustainable products. With the ability to produce high-quality, durable items, PVC injection molding is poised to play a crucial role in meeting the evolving demands of various industries. As manufacturers seek solutions that offer both performance and environmental benefits, PVC processing stands out as a versatile and reliable option for shaping the future of manufacturing.

Choosing Baoyuan for PVC Injection Molding

When it comes to choosing a reliable partner for PVC Injection Molding, Baoyuan stands out as an industry leader known for its expertise and commitment to delivering exceptional results. With a focus on quality assurance and customer satisfaction, Baoyuan is the go-to choice for businesses seeking top-tier PVC processing solutions.

In addition to its proven track record of excellence, Baoyuan also offers a wide range of customization options to meet the unique needs of each client. Whether it's color matching, material selection, or specific product requirements, Baoyuan has the expertise and flexibility to deliver tailored solutions that exceed expectations. This level of personalized service sets Baoyuan apart as a trusted partner in the PVC injection molding industry.