Introduction

Plastic product manufacturing plays a crucial role in meeting consumer demands for everyday items. From household goods to industrial components, this industry covers a wide range of products that are essential to our daily lives. Understanding the intricacies of plastic product manufacturing is key to appreciating its impact on various sectors.

Understanding Plastic Product Manufacturing

Plastic product manufacturing involves creating a wide array of items through various processes, such as injection molding and extrusion. Plastics' versatility allows for the production of products with diverse shapes, sizes, and functionalities, making them a cornerstone of modern manufacturing.

Plastic product manufacturing has revolutionized our lives, providing essential items for everyday use, such as packaging, household goods, and medical equipment. The efficiency and cost-effectiveness of plastic production have made it an integral part of many industries, from automotive to electronics. Additionally, the durability and lightweight nature of plastics make them ideal for creating practical and sustainable products, contributing to a greener future.

Key Players in

the Plastic Product Manufacturing Industry

The plastic product manufacturing industry is a dynamic sector comprised of numerous companies, each specializing in creating a wide range of plastic products. From small-scale operations to multinational corporations, these companies contribute significantly to the industry's landscape.

Key characteristics of the plastic product manufacturing industry include:

- Diverse product range: Companies produce a vast array of plastic products, including packaging materials, consumer goods, industrial components, and more.

- Continuous innovation: The industry is driven by a constant pursuit of innovation, with companies investing in research and development to create new materials, processes, and products.

- Sustainability focus: Many companies increasingly prioritize sustainability, exploring ways to reduce their environmental impact and promote eco-friendly practices.

- Global market: The plastic product manufacturing industry operates globally, with companies involved in international trade and competition.

The plastic product manufacturing industry is a vibrant and ever-evolving sector crucial in various aspects of modern life. Through innovation, sustainability efforts, and global reach, companies in this industry continue to shape the future of plastic product production.

Trends and Innovations in Plastic Product Manufacturing

As technology advances, so does the innovation within plastic product manufacturing. From biodegradable materials to automation and sustainability practices, manufacturers constantly adapt to meet evolving consumer needs while minimizing environmental impact. One of the latest trends in plastic product manufacturing is recycled plastics, which reduce waste and conserve resources. Additionally, advancements in 3D printing technology have allowed for more intricate and customized plastic products to be created with greater efficiency and precision.

Plastic Product Manufacturing Process

Plastic product manufacturing involves a complex process that requires precision and expertise. One of the most common techniques is injection molding, where molten plastic is injected into a mold to create the desired shape. This method is favored for its efficiency and ability to produce large quantities of products in a short amount of time.

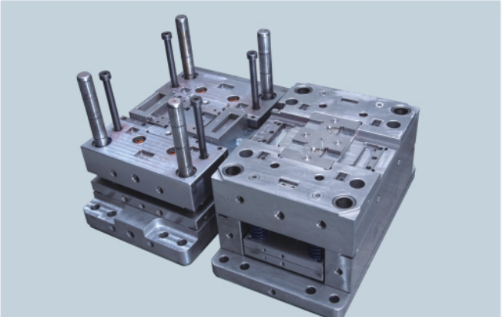

Injection Molding Techniques

Injection molding techniques involve several steps, including clamping, injection, cooling, and ejection. The process begins with clamping the mold, followed by injecting molten plastic into the mold cavity. The mold opens once the plastic has cooled and solidified, and the newly formed product is ejected. This method allows for intricate designs and precise detailing, making it ideal for manufacturing a wide range of plastic products.

Injection molding techniques involve several steps, including clamping, injection, cooling, and ejection. The process begins with clamping the mold, followed by injecting molten plastic into the mold cavity. The mold opens once the plastic has cooled and solidified, and the newly formed product is ejected. This method allows for intricate designs and precise detailing, making it ideal for manufacturing a wide range of plastic products.

Mold Design and Mold Opening

The design of the mold is crucial in ensuring that the final product meets quality standards. Mold design considerations include material selection, cooling system design, and part ejection mechanism. Additionally, precision in mold opening is essential to prevent damage to the product and ensure smooth production flow.

Quality Assurance in Plastic Product Manufacturing

Quality assurance plays a pivotal role in plastic product manufacturing, guaranteeing that each item meets industry standards and customer expectations. This involves rigorous testing procedures at various production stages to identify defects or imperfections early on. Implementing quality control measures ensures that only high-quality products reach consumers. In addition, quality assurance also involves monitoring the production process to ensure that all components and materials used meet the required specifications, leading to consistent product quality.

Understanding injection molding techniques, mold design considerations, and quality assurance practices in plastic product manufacturing processes is vital for producing top-notch products efficiently.

Choosing the Right Plastic Product Manufacturing Company

Factors to Consider When Selecting a Manufacturer

Several key factors should be carefully evaluated when selecting a plastic product manufacturing company to ensure a successful partnership.

- Experience and Reputation: Prioritize companies with a proven track record of consistently delivering high-quality plastic products. Research their experience in the industry and read customer reviews to assess their reputation for reliability and professionalism.

- Production Capabilities: Assess the manufacturer's production facilities and equipment to determine if they can meet your specific requirements. Consider factors such as production capacity, available technologies, and customization options.

- Quality Assurance: Inquire about the manufacturer's quality control measures and certifications. Look for companies that adhere to industry standards and have implemented robust quality assurance processes to minimize defects and ensure product consistency.

- Sustainability Practices: Evaluate the company's commitment to sustainability and environmental responsibility. Consider their use of recycled materials, energy efficiency initiatives, and waste management practices.

- Customer Support and Communication: Assess the manufacturer's responsiveness to customer inquiries and ability to provide timely support and communication throughout production.

By carefully considering these factors, you can select a plastic product manufacturing company that aligns with your business goals and delivers the quality, reliability, and sustainability you expect.

Baoyuan: A Leader in Plastic Product Manufacturing

Baoyuan is renowned for its excellence in plastic product manufacturing. It offers a wide range of services, including injection molding, mold design, and biodegradable product manufacturing. With state-of-the-art facilities and a team of skilled professionals, Baoyuan has established itself as a leader in the industry. Its dedication to innovation and sustainable practices sets it apart from other manufacturers.

Baoyuan's commitment to quality and customer satisfaction has led to successful collaborations with experienced manufacturing companies. By partnering with companies that share their values and dedication to excellence, Baoyuan can deliver top-notch products and services to their clients. This collaborative approach allows them to leverage the expertise of other industry leaders, ensuring that they stay at the forefront of plastic product manufacturing.

Collaborating with Experienced Manufacturing Companies

Collaborating with experienced manufacturing companies like Baoyuan can benefit businesses seeking plastic product production. Companies can leverage expertise, access cutting-edge technology, and ensure efficient production processes by partnering with an established manufacturer. Working with experienced manufacturers also opens opportunities for developing innovative products that align with market trends.

In addition to the technical expertise and access to advanced technology, collaborating with experienced manufacturing companies can provide businesses with valuable insights into market demand and consumer preferences. By tapping into the knowledge and experience of established manufacturers like Baoyuan, businesses can better understand industry trends and customer needs, allowing them to develop products that are more likely to succeed in the market.

Biodegradable Plastic Product Manufacturing

Sustainable Practices in Manufacturing

As the demand for eco-friendly products continues to rise, sustainable practices in plastic product manufacturing have become crucial. Companies now focus on reducing their carbon footprint by implementing energy-efficient production processes and using biodegradable materials. By adopting sustainable practices, manufacturers can minimize environmental impact and contribute to a greener future for the industry.

Baoyuan's Expertise in Biodegradable Products

Baoyuan has become a leader in biodegradable plastic product manufacturing, offering various environmentally friendly solutions. With a strong focus on research and development, Baoyuan has developed innovative bioplastics that are durable and biodegradable, meeting the growing demand for sustainable packaging and products. Their expertise in this area makes them a top choice for businesses looking to create eco-friendly alternatives.

Meeting the Demand for Eco-Friendly Products

The shift towards eco-friendly products has increased demand for biodegradable plastic products. Manufacturers like Baoyuan are at the forefront of meeting this demand, providing businesses with sustainable options that align with their environmental goals. By offering biodegradable alternatives, companies can appeal to environmentally conscious consumers while contributing to a more sustainable future for the plastic product manufacturing industry.

Advancements in the Plastic Product Manufacturing Industry

Automation and Technology Integration

The plastic product manufacturing industry is experiencing a significant shift towards automation and technology integration. This trend is driven by the need for increased efficiency, reduced production costs, and improved product quality. Automated systems are now being used to streamline processes such as injection molding, mold design, and quality control, leading to faster production times and higher precision in manufacturing plastic products.

In addition to improving efficiency and reducing costs, automation and technology integration in the plastic product manufacturing industry also contribute to a safer working environment. By automating repetitive and potentially hazardous tasks, such as handling heavy molds or working near machinery, the risk of workplace accidents is significantly reduced. This not only protects the well-being of employees but also minimizes downtime and associated costs due to injuries.

Baoyuan's Senior Management and Technical Personnel

Baoyuan, a leading plastic product manufacturing company, has demonstrated its commitment to staying ahead of industry advancements by investing in a team of senior management and technical personnel with expertise in automation and technology integration. With its innovative approach to production processes, Baoyuan has offered clients cutting-edge solutions while maintaining high-quality control standards.

Baoyuan's commitment to investing in senior management and technical personnel with expertise in automation and technology integration has positioned the company as a frontrunner in the plastic product manufacturing industry. By leveraging its innovative approach to production processes, Baoyuan has not only been able to offer cutting-edge solutions to clients but also maintain exceptionally high standards of quality control. As a result, the company has solidified its reputation as a reliable and forward-thinking partner for businesses seeking top-notch plastic products.

Future of Plastic Product Manufacturing

Baoyuan is a company at the forefront of the plastic product manufacturing industry, leveraging automation and technology to drive innovation and efficiency.

- Robotics: Implementing robotic systems can streamline production processes, reduce labor costs, and improve product quality and consistency.

- Artificial intelligence (AI): AI-powered algorithms can optimize manufacturing operations, predict equipment failures, and enable predictive maintenance.

- Data analytics: Analyzing vast amounts of data can provide valuable insights into production performance, identify areas for improvement, and inform strategic decision-making.

By embracing these technological advancements, Baoyuan is poised to survive and thrive in the evolving landscape of plastic product manufacturing. The company's commitment to innovation and sustainability will undoubtedly position it as a leader in the industry for years to come.

The Role of Innovation in the Industry

Embracing Sustainable Plastic Product Manufacturing

The plastic product manufacturing industry must embrace sustainable practices in today's environmentally conscious world. From using recycled materials to reducing waste and energy consumption, manufacturers must prioritize eco-friendly production methods to minimize their environmental impact. One way to achieve this is through innovation in materials and processes. The industry can significantly reduce its carbon footprint and contribute to a cleaner, healthier planet by developing new biodegradable plastics or finding ways to make existing plastics more easily recyclable.

Innovation is the driving force behind advancements in plastic product manufacturing. Companies that invest in research and development, explore new materials, and adopt cutting-edge technologies are paving the way for the industry's more efficient and sustainable future. Embracing innovation is key to staying competitive and meeting evolving consumer demands.

In addition to driving efficiency and sustainability, innovation in plastic product manufacturing also opens opportunities for new and improved product designs. By investing in R&D and exploring new materials, companies can create innovative solutions that meet consumers' evolving needs. This focus on innovation not only keeps companies competitive but also allows them to lead the way in shaping the industry's future.

Collaborating with Leading Manufacturing Companies, like Baoyuan

Choosing the right manufacturing partner is essential for businesses looking to bring high-quality plastic products to market. Collaborating with established companies like Baoyuan ensures access to expertise, state-of-the-art facilities, and a commitment to delivering top-notch products. It's important to align with manufacturers who share your values and prioritize sustainability.

By embracing sustainable practices, prioritizing innovation, and collaborating with leading manufacturers like Baoyuan, businesses can contribute to a more environmentally friendly future while delivering top-notch plastic products that meet consumer needs. The future of plastic product manufacturing lies in responsible production methods and forward-thinking partnerships.