Introduction

When it comes to manufacturing automotive parts, injection molding has become a game-changer. This process involves injecting molten material into a mold to create various components used in vehicles. From exterior body panels to electrical and electronic parts, injection molded automotive parts are crucial for the functionality and aesthetics of automobiles. Baoyuan is a leading supplier in this field, offering expertise in the production of high-quality injection molded automotive parts.

Overview of Injection Molded Automotive Parts

Injection molded automotive parts are components manufactured through the process of injecting molten material into a mold. These parts play a vital role in the overall structure and function of vehicles, including exterior body panels, interior trim, and electrical components.

Injection molded automotive parts are not only crucial for the structural integrity of vehicles but also for their overall performance and safety. These parts are designed to withstand extreme temperatures, high impact, and constant wear and tear, making them essential for the longevity of automobiles. Additionally, injection molded parts contribute to the aesthetics of vehicles, providing sleek and seamless designs that enhance the overall appeal of cars.

Importance of Injection Molded Parts in Automobiles

The significance of injection molded parts in automobiles cannot be overstated. These components contribute to the durability, strength, and overall performance of vehicles. They also enhance the aesthetic appeal and functionality of different car models.

Injection molded parts are also crucial for reducing the overall weight of vehicles, which in turn improves fuel efficiency and reduces emissions. This is especially important as the automotive industry continues to prioritize sustainability and environmental impact. Additionally, these parts play a key role in ensuring the safety of passengers by providing structural integrity and impact resistance in the event of a collision. With advancements in materials and manufacturing processes, injection molded parts are becoming increasingly innovative and versatile, allowing for greater design freedom and customization in vehicle production.

Baoyuan: Expertise in Injection Molded Automotive Parts

Baoyuan is an expert supplier of injection molded automotive parts with a proven track record for delivering top-notch products to clients worldwide. With their advanced technology and skilled workforce, Baoyuan is dedicated to providing high-quality injection molded parts that meet industry standards.

Baoyuan's commitment to excellence extends beyond just the quality of their products. Their customer service team is dedicated to providing exceptional support and assistance to clients throughout the entire process, from initial design concepts to final production. This level of care and attention ensures that clients receive personalized solutions that meet their specific needs and requirements, setting Baoyuan apart as a trusted partner in the automotive industry.

Types of Injection Molded Parts in a Car

When it comes to injection molded automotive parts, there are several types that play a crucial role in the overall design and functionality of a car. Exterior body panels, such as bumpers, fenders, and hoods, are commonly manufactured using injection molding due to the process's ability to produce complex shapes with high precision.

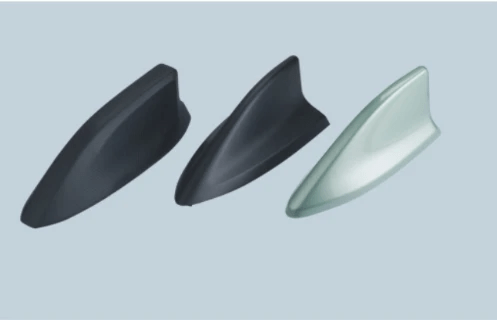

Exterior Body Panels

The exterior body panels of a car are often subjected to various environmental elements and impacts, making durability and strength crucial factors in their production. Injection molding allows for the creation of lightweight yet sturdy body panels that can withstand the rigors of everyday use on the road.

Furthermore, injection molding allows for the seamless integration of design elements and complex shapes into the body panels, providing a sleek and modern aesthetic for the vehicle. This process also enables manufacturers to produce body panels with consistent quality and precision, ensuring a uniform appearance across all parts of the car. As a result, car owners can enjoy a visually appealing exterior that is not only durable but also enhances the overall look of their vehicle.

Interior Trim and Components

Interior trim and components, including dashboard parts, door panels, and center consoles, also benefit from injection molding. This process enables manufacturers to produce intricate designs with smooth finishes that enhance both the aesthetics and functionality of the car's interior.

In addition to enhancing the aesthetics and functionality of the car's interior, injection molding also allows for the production of lightweight yet durable interior trim and components. This is particularly important in modern vehicles, where weight reduction is a key focus for improving fuel efficiency and overall performance. The ability to create intricate designs with smooth finishes also contributes to a more visually appealing and comfortable driving experience for consumers.

Electrical and Electronic Components

In addition to body panels and interior trim, many electrical and electronic components in modern cars are also made using injection molding. This includes items such as connectors, sensors, and housings for various electronic systems within the vehicle.

By incorporating injection molded parts into these key areas of car design, manufacturers can ensure that their vehicles not only meet performance standards but also provide a high level of durability and reliability for consumers.

Application of Injection Molding in Automotive Parts Production

Injection molded automotive parts are widely used in the automotive industry due to their numerous benefits. The application of injection molding in automotive parts production allows for the mass production of complex and intricate parts with high precision and consistency. This process is essential for creating a wide range of automotive components, including exterior body panels, interior trim, and electrical and electronic parts.

Benefits of Injection Molding in Automotive Industry

The benefits of injection molding in the automotive industry are manifold. It enables the production of lightweight yet durable parts, which is crucial for improving fuel efficiency and overall vehicle performance. Additionally, injection molding allows for the integration of multiple functionalities into a single component, reducing assembly time and costs.

Furthermore, injection molding in the automotive industry allows for the production of complex shapes and designs that would be difficult or impossible to achieve with other manufacturing processes. This flexibility opens up possibilities for innovative and visually appealing vehicle components, enhancing the overall aesthetic and marketability of the automobile. The ability to create intricate designs also contributes to improved aerodynamics, further boosting fuel efficiency and performance.

Efficiency and Cost-effectiveness of Injection Molding

Injection molding offers significant efficiency and cost advantages in automotive parts production. The high-speed production capabilities of injection molding result in shorter cycle times, leading to increased productivity and lower manufacturing costs. Furthermore, the ability to use recyclable materials in the injection molding process contributes to sustainability efforts within the automotive industry.

In addition to the efficiency and cost advantages, injection molding also offers design flexibility, allowing for complex and intricate automotive parts to be produced with precision. This means that manufacturers can create parts with intricate details and unique shapes that would be difficult or impossible to achieve with other production methods. The ability to produce such complex parts with injection molding not only enhances the aesthetic appeal of automotive components but also contributes to improved functionality and performance.

Baoyuan: Leading Supplier of Injection Molded Automotive Parts

As one of the leading injection molded automotive parts suppliers, Baoyuan is committed to providing top-quality components that meet the stringent requirements of automobile manufacturers. With extensive expertise in mold design and injection molding processes, Baoyuan delivers cost-effective solutions that enhance the performance and aesthetics of vehicles.

Furthermore, Baoyuan's dedication to quality extends beyond the manufacturing process. The company also places a strong emphasis on rigorous testing and inspection to ensure that each component meets the highest standards for durability and reliability. This commitment to excellence means that automakers can trust Baoyuan to deliver parts that not only look great but also perform flawlessly in demanding automotive applications.

The Process of Injection Molding in Automotive Industry

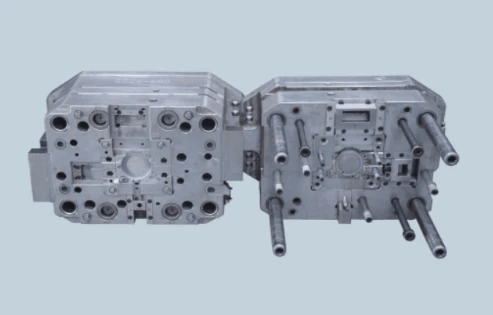

Mold Design and Manufacturing

The first step in the production of injection molded automotive parts is the design and manufacturing of molds. These molds are created with precision to ensure that the final parts meet the required specifications. Injection molded automotive parts suppliers, like Baoyuan, invest heavily in cutting-edge technology to create molds that guarantee high-quality products.

Injection Molding Process

Once the molds are ready, the injection molding process begins. This involves injecting molten material into the mold cavity at high pressure, allowing it to cool and solidify before being ejected as a finished part. This process is highly efficient and allows for mass production of automotive parts with minimal waste.

Quality Assurance in Injection Molded Automotive Parts

Quality assurance is crucial in ensuring that injection molded automotive parts meet industry standards. Suppliers like Baoyuan implement rigorous quality control measures throughout the production process to guarantee the durability, strength, and reliability of their products.

Advantages of Different Types of Injection Molded Parts

Durability and Strength of Exterior Body Panels

Injection molded automotive parts, such as exterior body panels, offer exceptional durability and strength, providing excellent protection against impact and harsh weather conditions. The high-quality materials used in injection molding ensure that these parts can withstand the rigors of daily use on the road. Additionally, the precise molding process allows for intricate designs and shapes to be created, enhancing the overall aesthetics of the vehicle while maintaining structural integrity. This means that not only are these parts durable and strong, but they also contribute to the overall visual appeal of the vehicle.

Aesthetics and Functionality of Interior Trim and Components

When it comes to interior trim and components, injection molding allows for intricate designs and precise detailing, enhancing the aesthetics and functionality of the car's interior. Whether it's a sleek dashboard or a comfortable armrest, injection molded parts elevate the overall look and feel of the vehicle.

Furthermore, injection molding allows for the production of durable and long-lasting interior trim and components. The high-quality materials used in the process ensure that these parts can withstand wear and tear, maintaining their aesthetic appeal for years to come. This reliability adds value to the overall driving experience, giving car owners peace of mind knowing that their vehicle's interior will continue to look and function at its best.

Reliability and Performance of Electrical and Electronic Components

In the realm of electrical and electronic components, injection molded parts play a crucial role in ensuring reliability and optimal performance. These parts are designed to meet strict industry standards for safety, efficiency, and longevity, making them essential for modern automotive technology.

In addition to their role in automotive technology, injection molded parts are also essential for the functionality of electronic devices such as smartphones, laptops, and home appliances. These parts are designed to withstand the demands of daily use and provide a high level of performance and durability. From circuit boards to connectors, injection molded components are integral to the reliability and longevity of electrical and electronic devices.

Baoyuan's Expertise in Injection Molded Automotive Parts

Baoyuan is a leading supplier of injection molded automotive parts, with a team of senior management and technical personnel who bring years of experience and expertise to the table. Their knowledge and skills ensure that they are at the forefront of innovation in the industry, providing top-notch solutions for their clients.

Baoyuan's Senior Management and Technical Personnel

Baoyuan's team consists of seasoned professionals who have a deep understanding of the intricacies of injection molding in the automotive industry. Their expertise allows them to provide valuable insights and guidance to clients, ensuring that every project is executed with precision and excellence.

Baoyuan's Proficiency in Mold Design and Injection Molding

With a focus on mold design and injection molding, Baoyuan has honed their skills to perfection, delivering high-quality automotive parts that meet the stringent standards of the industry. Their proficiency in these areas sets them apart as one of the most reliable suppliers in the market.

Baoyuan's Commitment to Quality Assurance

Baoyuan places great emphasis on quality assurance, implementing rigorous testing and inspection processes to guarantee that every injection molded part meets or exceeds industry standards. Their commitment to excellence ensures that clients receive products that are reliable, durable, and perform at optimal levels.

Conclusion

The Versatility of Injection Molded Automotive Parts

Injection molded automotive parts are incredibly versatile, being used for a wide range of applications from body panels to electronic components. Their ability to be customized and manufactured in large quantities makes them indispensable in the automotive industry.

Baoyuan: A Reliable Partner for Injection Molded Parts

When it comes to injection molded automotive parts suppliers, Baoyuan stands out as a reliable and experienced partner. With their expertise in mold design, injection molding, and commitment to quality assurance, they are the go-to choice for top-notch automotive parts.

The Future of Injection Molded Parts in Automobiles

As technology continues to advance, the future of injection molded parts in automobiles looks promising. With ongoing innovations in materials and manufacturing processes, we can expect even more durable, efficient, and high-performing injection molded automotive parts to drive the industry forward.