Introduction

When it comes to understanding automotive plastics components, the importance of these materials in the car manufacturing industry cannot be overstated. From the dashboard to the bumpers, automotive plastics play a crucial role in shaping the modern vehicle. Exploring the use of plastics in cars reveals their versatility and durability, making them indispensable in creating high-quality automobiles that meet safety and performance standards.

Understanding Automotive Plastics Components

Automotive plastics components encompass a wide range of parts that are essential for the functionality and aesthetics of a vehicle. These include interior and exterior components such as door panels, instrument panels, bumpers, and even engine components. The use of plastics in cars has revolutionized automotive design and manufacturing, allowing for greater flexibility in creating innovative and efficient vehicles.

Importance of Automotive Plastics

The importance of automotive plastics lies in their lightweight nature, which contributes to fuel efficiency and overall performance. Additionally, these materials offer durability and impact resistance, ensuring the safety of drivers and passengers on the road. With advancements in technology, automotive plastics have become integral to achieving sustainable and eco-friendly initiatives within the industry.

Exploring the Use of Plastics in Cars

The use of plastics in cars extends beyond mere aesthetics; it is an essential component in creating vehicles that are both functional and visually appealing. From reducing vehicle weight to enabling complex designs, automotive plastics have become a driving force behind innovation in car manufacturing.

What are Automotive Plastics Components?

Key plastic parts in modern cars

When it comes to automotive plastics components, modern cars are made up of numerous plastic parts that play crucial roles in the vehicle's functionality and design. From the dashboard and door panels to bumpers and engine components, plastics are used extensively throughout the entire vehicle.

Types of plastics used in automotive industry

The automotive industry utilizes a wide range of plastics, including polypropylene, polyurethane, PVC, ABS, and many more. Each type of plastic offers unique properties such as strength, flexibility, and heat resistance, making them suitable for specific car components.

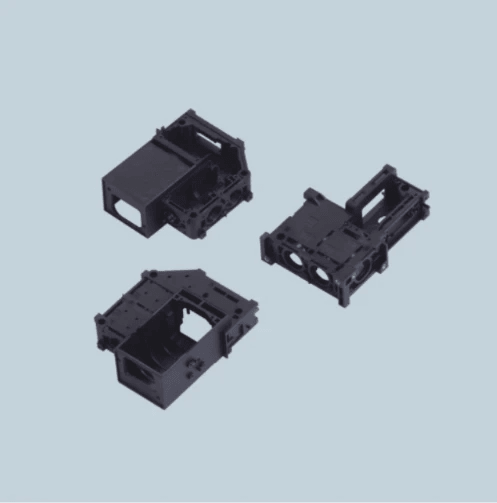

Baoyuan team expertise in designing molds and injection molding

At Baoyuan, our team excels in designing molds and performing injection molding for a variety of automotive plastic components. With our expertise in precision engineering and advanced technology, we ensure that the plastic parts meet the highest standards of quality and performance.

The Advantages of Automotive Plastics Components

When it comes to automotive plastics components, the advantages are numerous and significant. First and foremost, these components are lightweight, contributing to fuel efficiency and overall vehicle performance. This means that cars can achieve better mileage and reduce their environmental impact. Additionally, automotive plastics components offer exceptional durability and impact resistance, ensuring the safety of both the vehicle and its occupants. This is crucial in today's fast-paced world where safety is a top priority for car manufacturers. Furthermore, the flexibility in design and innovation that automotive plastics components provide allows for creative and unique car designs that stand out in the market.

Lightweight and fuel efficient

The use of automotive plastics components significantly reduces the overall weight of a vehicle, leading to improved fuel efficiency. By incorporating lightweight plastic parts in cars, manufacturers are able to enhance their vehicles' performance while also reducing their carbon footprint. This not only benefits the environment but also translates to cost savings for consumers at the pump.

Durability and impact resistance

Incorporating durable plastic parts into cars ensures that they can withstand various impacts on the road, providing an added layer of safety for drivers and passengers alike. Whether it's fender benders or more serious collisions, automotive plastics components play a crucial role in protecting individuals inside vehicles from harm.

Flexibility in design and innovation

One of the most exciting advantages of automotive plastics components is their flexibility in design and innovation. With advanced manufacturing techniques, car designers have endless possibilities when it comes to creating unique shapes and forms for plastic parts used in vehicles. This allows for greater creativity in car design while also meeting functional requirements.

The Most Important Plastics in Automotive Industry

When it comes to automotive plastics components, the Baoyuan team is proficient in producing single-color and double-color plastic products that are essential for modern cars. With our expertise in designing molds and injection molding, we ensure the highest quality and precision in every plastic part we produce.

Baoyuan team's proficiency in producing single-color and double-color plastic products

From interior trims to exterior body panels, specific plastics are used for different car components. For example, polypropylene is commonly used for bumpers and interior parts due to its impact resistance, while polycarbonate is used for headlights and taillights because of its transparency and durability.

Specific plastics used for different car components

Plastics play a crucial role in sustainability and eco-friendly initiatives within the automotive industry. By using lightweight plastics, cars can achieve better fuel efficiency, leading to reduced emissions and a smaller environmental footprint.

The role of plastics in sustainability and eco-friendly initiatives

With our proficiency in producing high-quality automotive plastics components, Baoyuan team is at the forefront of shaping the future of sustainable transportation. Our commitment to excellence ensures that every plastic part we produce contributes to a more environmentally friendly automotive industry.

What are Automotive Plastics Made of?

Understanding the composition of automotive plastics is crucial in comprehending the materials used in creating various car components. These plastics are typically made from a combination of polymers, additives, and reinforcements to enhance their strength and durability. Baoyuan team's technical expertise in plastic composition ensures that the right materials are used to meet the specific requirements for each automotive part.

Baoyuan team's technical expertise in plastic composition allows them to carefully select the appropriate materials for automotive plastics components. By understanding the unique properties of different polymers and additives, they can create custom formulations that provide optimal performance for specific applications in cars. This level of precision ensures that every plastic part meets industry standards for safety, reliability, and longevity.

Baoyuan team's technical expertise in plastic composition

Baoyuan team's proficiency in understanding the composition of automotive plastics enables them to develop tailored solutions for different car components. Whether it's interior trims, exterior panels, or under-the-hood parts, their knowledge allows them to optimize material selection based on factors such as temperature resistance, impact strength, and chemical compatibility. This attention to detail ensures that each plastic part performs optimally within its intended environment.

The technical expertise of Baoyuan team extends beyond just selecting materials; they also excel in optimizing manufacturing processes to achieve consistent quality and efficiency. Their deep understanding of plastic composition enables them to fine-tune injection molding parameters and tooling designs to produce precise and reliable automotive plastics components. This level of mastery ultimately results in high-performance parts that contribute to the overall functionality and safety of modern vehicles.

The Future of Automotive Plastics Components

As the automotive industry continues to evolve, so does the use of automotive plastics components. Innovations and advancements in automotive plastics are driving the development of more durable, lightweight, and eco-friendly materials for car manufacturing. With the demand for electric vehicles rising, there is a growing need for innovative plastic components that can contribute to improved energy efficiency and sustainability in the automotive sector.

Innovations and advancements in automotive plastics

Innovations in automotive plastics include the development of new composite materials that offer enhanced strength and heat resistance, making them ideal for high-performance car parts. Advancements in 3D printing technology also allow for more intricate and customized plastic components to be produced with greater precision and efficiency.

In addition to the development of new composite materials and advancements in 3D printing, Baoyuan team is at the forefront of exploring sustainable options for automotive plastics. This includes research into bio-based plastics derived from renewable sources such as plant-based materials, which not only reduce the environmental impact but also offer comparable performance to traditional plastics. By pioneering these eco-friendly alternatives, Baoyuan team is shaping the future of automotive plastics towards a more sustainable and responsible industry.

Baoyuan team's role in shaping the future of automotive plastics

Baoyuan's expertise in designing molds and injection molding positions them at the forefront of shaping the future of automotive plastics. Their commitment to using cutting-edge technologies and sustainable practices ensures that they play a pivotal role in driving innovation within the industry. As consumer demand for eco-friendly vehicles continues to grow, Baoyuan's focus on sustainability aligns perfectly with this trend. By prioritizing the use of recyclable materials and reducing waste in their manufacturing processes, Baoyuan is not only shaping the future of automotive plastics but also contributing to a greener, more sustainable automotive industry.

Environmental impact and sustainability efforts in the automotive industry

With a growing emphasis on sustainability, there is an increasing focus on developing eco-friendly alternatives to traditional plastic materials used in cars. The integration of biodegradable plastics, recycled materials, and bio-based polymers into automotive components is becoming more prevalent as manufacturers strive to reduce their environmental footprint.

As manufacturers continue to prioritize sustainability, they are also exploring innovative technologies such as 3D printing to create automotive components. This not only reduces material waste but also allows for the production of complex, lightweight designs that contribute to improved fuel efficiency. Additionally, the implementation of advanced manufacturing processes can streamline production and reduce energy consumption, further contributing to the industry's environmental efforts.

Conclusion

In conclusion, Baoyuan team is dedicated to ensuring quality assurance and production excellence in the automotive plastics components industry. With our expertise in designing molds and injection molding, we are committed to delivering top-notch plastic parts for modern cars. Our proficiency in producing single-color and double-color plastic products sets us apart in the automotive industry.

Baoyuan team's commitment to quality assurance and production excellence

Our team at Baoyuan takes pride in our commitment to maintaining high standards of quality assurance and production excellence. We understand the importance of precision and attention to detail when it comes to creating automotive plastics components, and we strive for perfection in every step of the process.

Our team at Baoyuan understands that the automotive industry demands durability, reliability, and innovation when it comes to plastics components. That's why we are constantly researching and testing new types of plastics to ensure that our products meet and exceed industry standards. From impact-resistant materials for bumpers to lightweight, high-performance polymers for interior components, we are dedicated to staying at the forefront of material advancements in the automotive sector.

Types of plastics used in the automotive industry

The types of plastics used in the automotive industry are diverse, ranging from polypropylene to polyurethane, each with its unique properties and applications. At Baoyuan, we have a deep understanding of these materials and their specific uses, allowing us to produce high-quality plastic components for various car models.

The use of plastics in the automotive industry has revolutionized car design and manufacturing, allowing for lighter and more fuel-efficient vehicles. Polypropylene, for example, is commonly used in interior components such as door panels and instrument panels due to its durability and moldability. On the other hand, polyurethane is preferred for exterior parts like bumpers and fenders because of its impact resistance and ability to withstand harsh weather conditions. Understanding the specific properties of each type of plastic is crucial in ensuring that the right material is used for each automotive component.

The significance of automotive plastics components

Automotive plastics components play a crucial role in modern cars, contributing to their lightweight, fuel efficiency, durability, impact resistance, flexibility in design, and innovation. As environmental concerns continue to grow, the use of sustainable materials like automotive plastics becomes increasingly important for the future of the automotive industry.

Automotive plastics components also offer a cost-effective solution for manufacturers, as they are generally cheaper to produce and easier to mold into complex shapes compared to traditional metal components. This cost savings can ultimately be passed on to consumers, making cars more affordable and accessible to a wider range of people. Additionally, the use of automotive plastics allows for greater design freedom, enabling car makers to create sleek, aerodynamic shapes that enhance both the visual appeal and performance of vehicles.