Introduction

When it comes to manufacturing automotive parts, the process of injection molding plays a crucial role in creating high-quality plastic components. Automotive injection molding is essential for producing durable, lightweight, and cost-effective parts that meet the industry's stringent requirements. Working with top automotive plastic injection molding companies ensures access to cutting-edge technology and expertise, leading to superior products and streamlined production processes.

The Importance of Automotive Injection Molding

Automotive injection molding is vital for producing a wide range of components, including interior and exterior trim, engine components, and electronic housings. The ability to create complex shapes and intricate designs with precision makes it indispensable in the automotive industry. This process allows for mass production of parts with consistent quality, contributing to the overall efficiency and performance of vehicles on the road.

Automotive injection molding is also advantageous for its cost-effectiveness and speed. By using molds to produce identical parts, manufacturers can save on production costs and reduce waste. Additionally, the high-speed production capabilities of injection molding allow for quick turnaround times, meeting the demands of the automotive industry for efficient manufacturing processes. This makes it a preferred method for producing large quantities of components in a timely manner.

Advantages of Working with Top Injection Molding Companies

Collaborating with top automotive plastic injection molding companies offers numerous advantages, such as access to advanced machinery and materials, expertise in design optimization for manufacturability, and stringent quality control measures. These companies are well-equipped to handle large-scale production while maintaining exceptional product quality and meeting tight deadlines.

In addition, top injection molding companies often have extensive experience in working with a wide range of industries, including automotive, medical, and consumer goods. This diverse expertise allows them to offer valuable insights and recommendations for improving product design and functionality. By leveraging their knowledge across various sectors, these companies can provide innovative solutions that enhance the performance and durability of plastic components.

Understanding the Process of Plastic Injection Molding

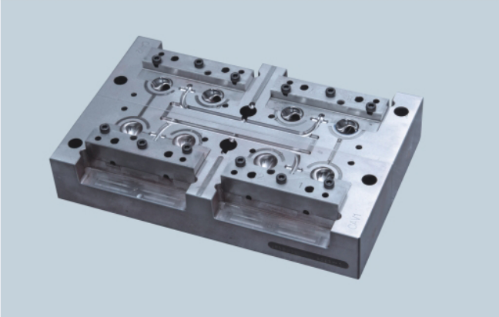

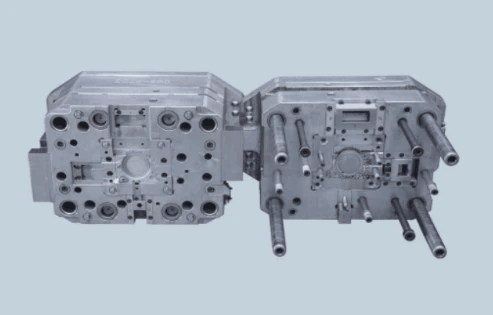

The process of plastic injection molding involves melting plastic resin pellets and injecting them into a mold cavity under high pressure. Once the material cools and solidifies, the mold opens to reveal the finished part. This versatile process allows for the production of a wide variety of automotive components with different shapes, sizes, and material properties.

Plastic injection molding is a cost-effective and efficient method for producing automotive components. The ability to create complex shapes and intricate designs makes it an ideal process for manufacturing parts such as bumpers, dashboards, and interior trim. Additionally, the high-pressure injection ensures that the finished products have consistent dimensions and properties, meeting the strict quality standards of the automotive industry.

Baoyuan: A Leader in Automotive Plastic Injection Molding

Baoyuan has established itself as a leader in automotive plastic injection molding, with a proven track record of delivering high-quality products to meet the industry's demands. Their expertise in automotive injection molding is unmatched, making them a top choice for companies seeking reliable and innovative solutions for their plastic products.

Baoyuan's Expertise in Automotive Injection Molding

Baoyuan's expertise in automotive injection molding is evident through their extensive experience and knowledge of the industry. They understand the unique requirements of automotive plastic products and are able to tailor their injection molding processes to meet specific needs, ensuring precision and efficiency in every project they undertake. With a focus on innovation, Baoyuan consistently develops new solutions for automotive plastic products, staying ahead of industry trends and technological advancements. Their commitment to staying at the forefront of automotive injection molding technology sets them apart as a leader in the field, providing their clients with cutting-edge solutions for their plastic product needs.

Innovative Solutions for Automotive Plastic Products

Baoyuan is at the forefront of providing innovative solutions for automotive plastic products, constantly pushing the boundaries of what is possible with injection molding technology. Their team of experts works tirelessly to develop new techniques and processes that result in superior quality and performance, setting them apart from other automotive plastic injection molding companies.

The Baoyuan Advantage in Injection Molding Technology

The Baoyuan advantage lies in their cutting-edge injection molding technology, which allows them to deliver exceptional results with every project. Their state-of-the-art machinery and advanced processes ensure that they can meet the most demanding requirements of automotive plastic products, making them a trusted partner for companies looking for excellence in injection molding.

Top Automotive Injection Molding Companies Worldwide

When it comes to the largest injection molding company in the world, there's no denying that Husky Injection Molding Systems Ltd. takes the top spot. With their cutting-edge technology and global presence, Husky has solidified its position as a leader in automotive plastic injection molding companies.

As for who makes injection molding molds in China, it's hard to overlook the impact of Foshan Mogel Hardware & Plastic Co., Ltd. Their expertise in mold manufacturing has made them a go-to choice for automotive injection molding molds, earning them a reputation for quality and reliability.

Exploring the global leaders in automotive injection molding reveals a diverse landscape of companies such as Arburg GmbH + Co KG, Sumitomo (SHI) Demag Plastics Machinery GmbH, and Engel Austria GmbH. Each of these companies brings its own unique strengths and innovations to the table, contributing to the advancement of automotive plastic injection molding worldwide.

The Best Choice for Injection Molding Machinery

When it comes to choosing the best company for an injection molding machine, it's important to consider factors such as reliability, performance, and customer support. Companies like Arburg, Engel, and Haitian are renowned for their high-quality injection molding machines that cater to the automotive industry's specific needs.

Which company is best for an injection molding machine?

Arburg is widely recognized as one of the best companies for injection molding machines in the automotive industry. With a strong focus on innovation and technology, Arburg offers a wide range of machinery options tailored to meet the unique requirements of automotive plastic injection molding companies.

Arburg's commitment to innovation and technology makes them a top choice for automotive plastic injection molding companies. Their wide range of machinery options allows for customization to meet the unique requirements of each client, ensuring that the final product meets the highest standards of quality and efficiency. Additionally, Arburg's reputation for reliability and customer service further solidifies their position as a leading supplier in the industry.

Key Considerations When Choosing an Injection Molding Machinery Supplier

When selecting a supplier for injection molding machinery, it's crucial to consider factors such as the supplier's reputation, experience in the automotive industry, after-sales support, and their ability to provide customized solutions. Working with a trusted supplier ensures that you have access to reliable equipment that meets your specific production needs.

In addition to reputation and experience, it's important to assess the supplier's track record in delivering on-time and within budget. A supplier that consistently meets deadlines and stays within budget can help you avoid costly production delays and financial setbacks. Furthermore, their ability to provide ongoing technical support and maintenance services is crucial for ensuring the long-term reliability of your injection molding equipment. By choosing a supplier with a proven track record of on-time delivery, cost-effectiveness, and reliable after-sales support, you can minimize the risks associated with equipment downtime and production disruptions.

Ensuring Quality and Reliability in Injection Molding Equipment

To ensure quality and reliability in injection molding equipment, it's essential to partner with suppliers who offer advanced technology and robust machinery. By investing in high-quality equipment from reputable suppliers, automotive plastic injection molding companies can achieve greater efficiency, precision, and consistency in their manufacturing processes.

By partnering with suppliers who offer advanced technology and robust machinery, automotive plastic injection molding companies can also benefit from improved durability and longevity in their equipment. This means less downtime for maintenance and repairs, ultimately leading to increased productivity and profitability. Additionally, high-quality equipment can provide a greater level of safety and reliability in the manufacturing process, giving companies peace of mind and reducing the risk of costly errors or accidents.

Cost Considerations for Automotive Injection Molding

When it comes to automotive plastic injection molding companies, cost is a significant factor to consider. Many companies turn to China for cost-effective injection molding solutions. The cost of injection molding in China can vary depending on factors such as the complexity of the mold design, material selection, and production volume. It's important to work with reputable manufacturers who can provide transparent pricing and ensure quality results.

How much does injection molding cost in China?

The cost of injection molding in China can range from as low as $1,000 to upwards of $80,000, depending on the size and complexity of the mold, as well as the quantity of parts needed. It's essential to partner with experienced automotive plastic injection molding companies that can offer competitive pricing without compromising on quality.

Factors Affecting the Cost of Automotive Injection Molding

Several factors can impact the overall cost of automotive injection molding. These include tooling costs, material selection, part complexity, and production volume. Working with a knowledgeable manufacturer can help navigate these factors and find cost-effective solutions without sacrificing quality or performance.

Maximizing Efficiency and Cost Savings in Injection Molding Processes

To maximize efficiency and cost savings in automotive injection molding processes, it's crucial to optimize tooling designs, streamline production processes, and leverage advanced technologies such as automation and robotics. Choosing the right materials and production methods can also contribute to reducing costs while maintaining high-quality standards.

Quality Assurance in Automotive Plastic Injection Molding

Automotive plastic injection molding companies understand the critical importance of quality assurance in their processes. Baoyuan, a leader in automotive injection molding, prioritizes quality at every step of production. Their state-of-the-art facilities and stringent quality control measures ensure that each automotive plastic product meets the highest standards.

Baoyuan's Commitment to Quality Assurance in Injection Molding

Baoyuan's commitment to quality assurance sets them apart from other automotive plastic injection molding companies. They invest in cutting-edge technology and employ skilled professionals to maintain the highest level of precision and consistency in their products. This unwavering dedication to quality has earned them a stellar reputation among their clients and peers.

Ensuring Precision and Consistency in Automotive Plastic Products

Precision and consistency are non-negotiable when it comes to automotive plastic products. Baoyuan utilizes advanced techniques and rigorous testing protocols to guarantee that each component meets exact specifications. Their attention to detail ensures that every part functions seamlessly within the larger automotive system.

Industry Standards and Best Practices for Automotive Injection Molding

Adhering to industry standards and best practices is paramount for automotive injection molding companies. Baoyuan is at the forefront of implementing these standards, staying ahead of regulatory requirements and technological advancements. By aligning with global best practices, they consistently deliver top-tier automotive plastic products that exceed expectations.

Now let's dive into some of the top automotive injection molding companies worldwide and explore who makes injection molding molds in China.

Conclusion

Choosing the Right Partner for Automotive Injection Molding

When it comes to automotive plastic injection molding companies, it's crucial to partner with a reliable and experienced manufacturer like Baoyuan. Their expertise in automotive injection molding ensures high-quality products and innovative solutions for your specific needs.

The Future of Automotive Injection Molding

As technology continues to advance, the future of automotive injection molding looks promising. With top companies leading the way in innovation and efficiency, we can expect to see even more groundbreaking developments in automotive plastic products.

Elevating Automotive Products with Top Injection Molding Companies

By collaborating with the largest injection molding company in the world and leveraging their expertise, automotive manufacturers can elevate their products to new heights. With cost-effective solutions and cutting-edge technology, these top companies are driving the industry forward.