Introduction

When it comes to automotive manufacturing, the role of injection molding companies cannot be overstated. These companies are responsible for producing a wide range of plastic components used in vehicles, from interior trim to exterior body panels. Choosing the right automotive injection molding company is crucial for ensuring the quality, precision, and reliability of these components in the final product. There are several key factors to consider when selecting an automotive injection molding company, and understanding these factors is essential for making an informed decision that will impact the overall performance and durability of vehicles.

Overview of Automotive Injection Molding Companies

The automotive industry relies heavily on injection moulding automotive companies to produce high-quality plastic components that meet stringent performance and safety standards. These companies specialize in using advanced injection molding techniques to manufacture a wide variety of parts and products used in vehicles, including interior and exterior trims, bumpers, dashboards, and more.

Importance of Choosing the Right Automotive Injection Molding Company

Selecting the right automotive plastic injection molding company is crucial for ensuring the overall quality, durability, and safety of vehicle components. The choice of an injection moulding company directly impacts the performance and reliability of automotive parts, which ultimately affects customer satisfaction and brand reputation.

Key Factors to Consider When Selecting an Automotive Injection Molding Company

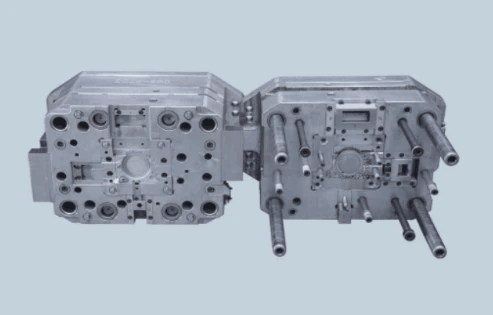

There are several key factors to consider when choosing an automotive injection molding company, including expertise in automotive manufacturing, innovative approach to injection moulding techniques, commitment to quality and precision, compliance with industry standards and regulations, as well as investment in advanced technology and equipment.

Baoyuan: A Leader in Automotive Injection Molding

Baoyuan has established itself as a top player among automotive injection molding companies, with a strong focus on delivering high-quality products. Their expertise in automotive injection molding is evident through their extensive experience and proven track record in the industry.

Baoyuan's Expertise in Automotive Injection Molding

Baoyuan's expertise in automotive injection molding companies is unmatched, as they have consistently delivered exceptional results for their clients. With a deep understanding of the unique requirements of the automotive industry, they have successfully produced complex and precision-engineered components for various vehicles.

Baoyuan's innovative approach to injection molding sets them apart from their competitors. By staying ahead of the curve in terms of technology and techniques, they are able to offer cutting-edge solutions to their automotive clients. Their commitment to research and development ensures that they are always at the forefront of industry advancements, allowing them to consistently deliver high-quality, cost-effective products.

Baoyuan's Innovative Approach to Injection Moulding

Baoyuan stands out among injection moulding automotive companies due to its innovative approach to manufacturing processes. They leverage cutting-edge technologies and advanced techniques to ensure efficiency and accuracy in their production methods, setting them apart from other automotive plastic injection molding companies.

Baoyuan's Commitment to Quality and Precision

The commitment of Baoyuan to quality and precision is unwavering, making them a trusted partner for automotive injection moldina companies globally. Their dedication to upholding the highest standards throughout the manufacturing process ensures that their clients receive products that meet or exceed industry requirements.

Baoyuan's dedication to quality and precision extends beyond just the manufacturing process. They are committed to continuous improvement and innovation, investing in the latest technology and machinery to ensure that they stay at the forefront of automotive injection molding. This proactive approach allows them to anticipate industry trends and meet the evolving needs of their clients, setting them apart as a reliable and forward-thinking partner in the market.

Top Automotive Injection Molding Companies in the Market

Comparing Automotive Plastic Injection Molding Companies

When comparing automotive plastic injection molding companies, it's essential to look at their track record, expertise, and client testimonials. You want to ensure that the company has a proven history of delivering high-quality automotive parts and components, as well as a strong understanding of industry standards and regulations.

In addition to a company's track record and expertise, it's important to consider their manufacturing capabilities and technological advancements. Look for a company that invests in state-of-the-art equipment and processes, as this can directly impact the quality and efficiency of the final automotive parts. By choosing a company with advanced manufacturing capabilities, you can ensure that your products are produced with precision and consistency, meeting the highest industry standards.

Advantages of Working with Established Automotive Injection Molding Companies

Working with established automotive injection molding companies provides numerous advantages, including access to advanced technology and equipment, extensive industry knowledge, and a commitment to quality and precision. These companies have the experience and resources to handle complex automotive projects efficiently and effectively.

In addition, established automotive injection molding companies often have strong relationships with suppliers and other industry partners, allowing them to source high-quality materials and components at competitive prices. This can result in cost savings for their clients without sacrificing the quality of the final product. Furthermore, these companies are often well-versed in industry regulations and standards, ensuring that all automotive components meet the necessary requirements for safety and performance. By working with an established injection molding company, automotive manufacturers can have peace of mind knowing that their products are compliant with all relevant guidelines.

Factors to Look for in Automotive Injection Molding Company

When selecting an automotive injection molding company, it's crucial to consider factors such as their production capabilities, quality control processes, material expertise, and adherence to industry standards. Additionally, assessing their ability to meet specific project requirements and deadlines is essential for a successful partnership.

In addition to the aforementioned factors, it's important to evaluate the company's track record and reputation within the automotive industry. A proven history of successful projects and positive client feedback can provide valuable insight into their capabilities and reliability. Furthermore, exploring their experience with different types of automotive components and technologies can help determine if they are well-equipped to handle the specific needs of your project. By thoroughly researching these aspects, you can ensure that you are partnering with a reputable and experienced automotive injection molding company.

Key Considerations for Selecting an Automotive Injection Molding Company

When selecting an automotive injection molding company, it's crucial to understand the specific needs of the automotive industry. From producing durable components to meeting strict safety standards, automotive injection molding companies must have a deep understanding of the unique requirements of this sector.

Understanding the Specific Needs for Automotive Injection Molding

Automotive injection molding companies need to have expertise in manufacturing components that can withstand high temperatures, pressure, and constant wear and tear. They must also be able to produce parts with precision and consistency to ensure optimal performance in vehicles. Furthermore, understanding the importance of lightweight materials and cost-efficiency is essential for meeting the demands of the automotive industry.

Automotive injection molding companies must also keep up with the latest advancements in technology and equipment to meet the evolving needs of the automotive industry. This includes investing in state-of-the-art machinery and tools that can handle complex designs, high-speed production, and advanced materials. By staying ahead of technological developments, these companies can ensure that they are able to deliver innovative solutions that meet the stringent requirements of modern vehicles.

Importance of Advanced Technology and Equipment in Automotive Injection Molding

Innovation is key when it comes to automotive injection molding, as advanced technology and equipment play a critical role in achieving high-quality results. Companies that invest in state-of-the-art machinery and cutting-edge techniques are better equipped to meet the complex requirements of automotive manufacturers. From 3D printing capabilities to advanced material testing, staying ahead of technological advancements is vital for success in this field.

Investing in advanced technology and equipment also allows automotive injection molding companies to improve efficiency and reduce production costs. By utilizing cutting-edge machinery, companies can streamline their processes and minimize waste, ultimately leading to cost savings that can be passed on to their clients. Additionally, advanced technology enables manufacturers to produce intricate and complex automotive parts with precision, meeting the high standards set by the industry.

Ensuring Compliance and Certification in Automotive Injection Molding

Compliance with industry regulations and certifications is non-negotiable for automotive injection molding companies. Adhering to standards such as ISO/TS 16949 ensures that products meet stringent quality requirements specific to the automotive sector. Additionally, certifications from regulatory bodies demonstrate a company's commitment to maintaining high standards in manufacturing processes.

In today's highly competitive automotive industry, ensuring compliance and certification in automotive injection molding is crucial for maintaining a strong reputation and winning new business. By adhering to industry regulations and obtaining certifications such as ISO/TS 16949, companies can demonstrate their commitment to producing high-quality products that meet the rigorous standards of the automotive sector. This not only gives them a competitive edge but also instills confidence in their customers, ultimately leading to long-term success in the market.

The Future of Automotive Injection Molding Companies

Trends and Innovations in Automotive Injection Molding

As the automotive industry continues to evolve, automotive injection molding companies are embracing new trends and innovations to stay ahead. One of the key trends in automotive injection molding is the increasing focus on sustainability and environmental responsibility. Companies are now exploring ways to reduce their carbon footprint and minimize waste in the manufacturing process. This includes using recyclable materials, optimizing energy usage, and implementing eco-friendly production practices.

Sustainability and Environmental Responsibility in Automotive Injection Molding

With a growing emphasis on sustainability, automotive injection molding companies are prioritizing environmentally responsible practices. This includes the development of eco-friendly materials, as well as the implementation of energy-efficient manufacturing processes to minimize their carbon footprint.

As automotive companies continue to prioritize sustainability, they are also focusing on reducing waste and improving recycling processes within their injection molding operations. This involves implementing closed-loop systems that allow for the recycling of materials and the reduction of overall waste generation. By creating a more circular approach to material usage, automotive injection molding companies can minimize their environmental impact while also reducing costs associated with raw material procurement.

Impact of Automotive Industry Growth on Injection Moulding Automotive Companies

The rapid growth of the automotive industry has a direct impact on injection moulding automotive companies. As demand for vehicles continues to rise, these companies are under pressure to increase production capacity while maintaining high quality standards. This requires a strategic approach to expansion and investment in state-of-the-art equipment.

The need for increased production capacity has led many injection moulding automotive companies to seek out partnerships with industry leaders. By collaborating with companies like Baoyuan, these manufacturers can benefit from the expertise and experience of a trusted partner. This strategic approach allows for the implementation of cutting-edge technologies and processes, ensuring that the quality standards are not only maintained but exceeded.

Conclusion

Making the Right Choice: Automotive Injection Molding Companies

When it comes to automotive injection molding companies, the right choice can make all the difference. By selecting a company with expertise, innovation, and a commitment to quality like Baoyuan, you can ensure superior results for your automotive projects.

Key Takeaways for Selecting the Best Automotive Injection Molding Company

In summary, when evaluating automotive injection molding companies, it's crucial to compare their expertise, advantages, and key considerations. Look for advanced technology, compliance, and certification to make an informed decision that aligns with your specific needs.

Partnering with Baoyuan for Automotive Injection Molding Excellence

For automotive injection molding excellence, consider partnering with Baoyuan. Their leadership in the industry, innovative approach, and dedication to precision make them a top choice for automotive plastic injection molding companies.

With Baoyuan's commitment to quality and precision in automotive injection molding processes, you can trust that your projects will be in good hands. Choose excellence with Baoyuan as your partner in automotive injection molding.