Introduction

When choosing the right material for your project, understanding the differences between plexiglass and polycarbonate is crucial. Both materials have unique properties and applications, so weighing the pros and cons of each is important. Knowing which material best suits your needs, whether you're looking for durability, clarity, or impact resistance, is essential.

Understanding Plexiglass and Polycarbonate

Plexiglass, also known as acrylic glass, is a transparent thermoplastic often used as a lightweight alternative to glass. Polycarbonate is a durable, impact-resistant thermoplastic commonly used in applications where safety and strength are paramount. While both materials offer transparency and versatility, they differ in key characteristics, making them suitable for different applications.

Here's a quick comparison to help you choose the right material for your needs:

- Strength: Polycarbonate is significantly stronger and more impact-resistant than plexiglass.

- Weight: Plexiglass is lighter than polycarbonate.

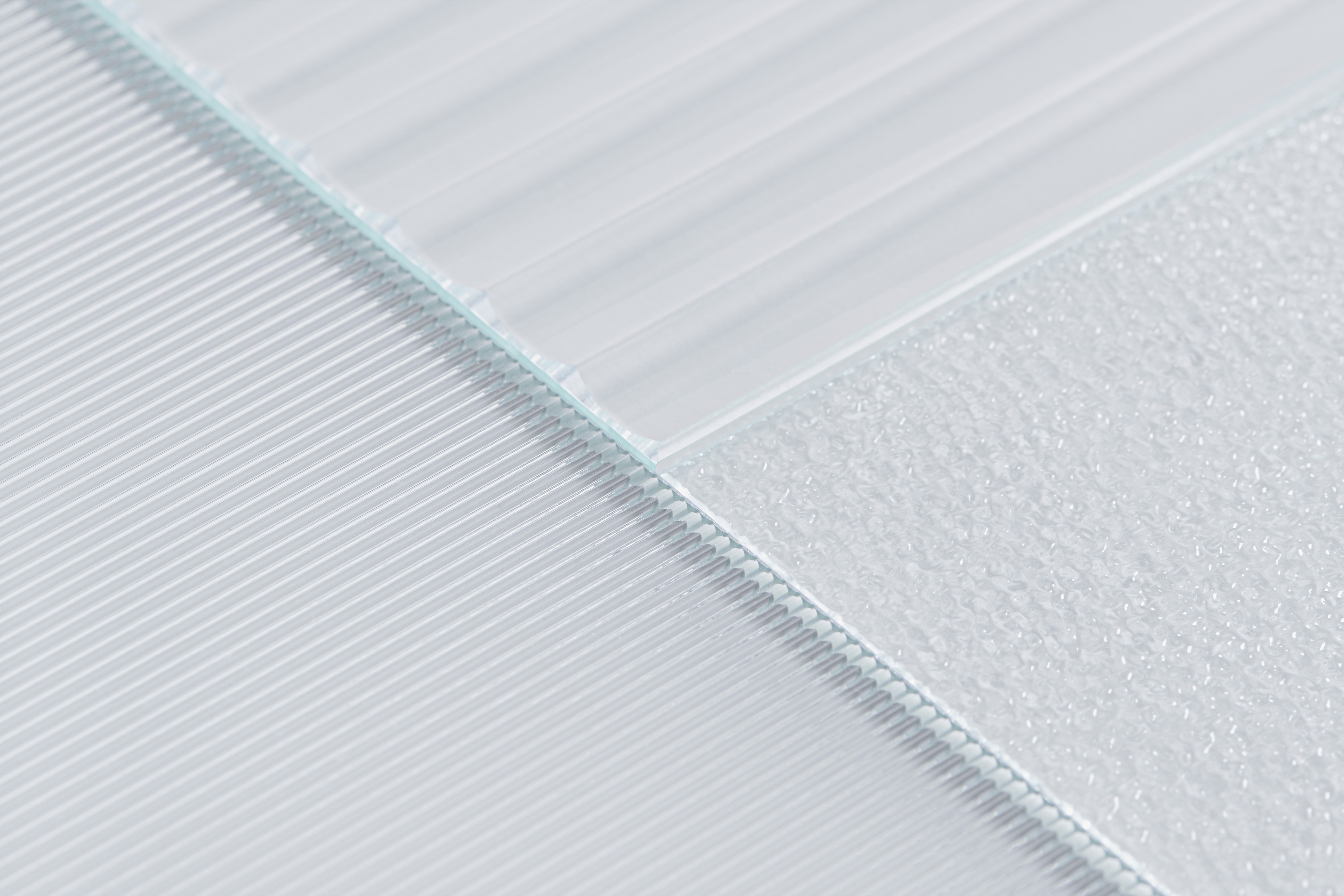

- Clarity: Both materials offer excellent clarity, but plexiglass may provide a slightly higher gloss finish.

- Scratch Resistance: Plexiglass is generally more scratch-resistant than polycarbonate.

- Weather Resistance: Both plexiglass and polycarbonate offer good weather resistance.

Both plexiglass and polycarbonate are valuable materials with unique properties. Considering the factors above, you can select the best material for your project.

Application of Plexiglass vs Polycarbonate

Plexiglass is commonly used in signage, display cases, aquariums, and protective shields due to its clarity and weatherability. Polycarbonate, on the other hand, is used in safety glasses, face shields, greenhouses, skylights, bulletproof glass, and automotive headlights due to its exceptional impact resistance and durability.

Plexiglass is also favored for its ease of fabrication and low cost, making it a popular choice for DIY projects and small-scale applications. Its lightweight nature and resistance to shattering also make it an ideal material for protective barriers and enclosures. Additionally, Plexiglass can be easily shaped and molded into various forms, allowing for creative design possibilities in architectural and artistic installations.

Key Differences between Plexiglass and Polycarbonate

The key differences between plexiglass and polycarbonate are their properties, such as transparency, impact resistance, heat resistance, chemical resistance, durability, and applications. Understanding these differences will help you decide when choosing the right material for your specific project needs.

In addition to their physical properties, plexiglass and polycarbonate differ in cost and availability. Plexiglass is generally more affordable and easier to find, making it a popular choice for budget-conscious projects or applications where large quantities are needed. On the other hand, polycarbonate tends to be more expensive and may require special ordering or sourcing from specific suppliers. This factor should be considered when deciding which material best fits your project.

Properties of Plexiglass

Plexiglass, also known as acrylic glass, offers exceptional transparency and clarity, making it a popular choice for applications where visibility is crucial. Its optical properties are comparable to those of glass but are much lighter and more impact-resistant. This makes plexiglass ideal for windows, skylights, and protective barriers.

Transparency and Clarity

Plexiglass boasts outstanding transparency and clarity, allowing maximum light transmission without compromising strength. Its high optical quality makes it an excellent alternative to traditional glass, especially in applications where weight is a concern.

Durability and Impact Resistance

One of the key advantages of plexiglass is its exceptional durability and impact resistance. It is significantly stronger than glass and less prone to shattering upon impact, making it a safer option for protective barriers and display cases.

Weatherability and UV Resistance

Plexiglass exhibits excellent weatherability and UV resistance, making it suitable for outdoor applications such as signage and architectural glazing. Its ability to withstand prolonged exposure to sunlight without yellowing or becoming brittle makes it a reliable choice for various outdoor projects.

Properties of Polycarbonate

Strength and Impact Resistance

Polycarbonate is known for its exceptional strength and impact resistance, making it a popular choice for applications that require durability and protection. It is much stronger than plexiglass, making it suitable for bulletproof glass, safety glasses, and face shields. Its ability to withstand high-impact forces without shattering or cracking makes it a reliable material for safety and security.

Heat Resistance and Flame Retardancy

Polycarbonate's key properties are its impressive heat resistance and flame retardancy. Unlike plexiglass, polycarbonate can withstand high temperatures without melting or deforming, making it ideal for use in applications where exposure to heat is a concern. Its flame-retardant properties also make it a safe choice for environments where fire safety is paramount.

In addition to its heat resistance and flame retardancy, polycarbonate also boasts impressive chemical resistance and durability. This means it can withstand exposure to a wide range of chemicals without deteriorating, making it suitable for use in industrial settings where contact with corrosive substances is common. Its durability ensures that it can withstand heavy impact without shattering or breaking, making it a reliable choice for applications where strength is essential.

Chemical Resistance and Durability

Polycarbonate exhibits excellent chemical resistance and durability, allowing it to withstand exposure to harsh chemicals without deteriorating or becoming damaged. This makes it suitable for use in industrial settings where contact with chemicals is common. Its durability ensures that it can maintain its integrity over time, making it a long-lasting material for various applications.

Polycarbonate's chemical resistance and durability make it a popular choice for outdoor applications, such as greenhouses, skylights, and signage. Its ability to withstand exposure to UV radiation without yellowing or becoming brittle ensures that it can maintain its clarity and strength even after prolonged exposure to the elements. This makes it a reliable option for structures and products that need to endure harsh weather conditions while retaining their visual appeal.

Stay tuned as we delve into the comparison of plexiglass vs polycarbonate in the next section!

Applications of Plexiglass

Plexiglass, or acrylic glass, is a versatile material with many applications. Signage and display cases often utilize plexiglass due to its transparency and durability. Its lightweight nature makes it ideal for aquariums and protective shields, providing a clear view while ensuring safety. Additionally, plexiglass is commonly used in lighting fixtures and picture frames, as it can be easily shaped and molded to fit various designs.

Signage and Display Cases

Plexiglass is a versatile material prized for its unique clarity, strength, and ease of use. Here's why it's a perfect choice for signage and displays:

- Crystal Clear Visibility: Plexiglass offers exceptional transparency, allowing customers to see products or information displayed flawlessly.

- Durable Protection: Unlike glass, plexiglass is highly impact-resistant, safeguarding displayed items from accidental bumps or scratches.

- Lightweight Champion: Plexiglass's lightweight nature makes it easy to transport, install, and maneuver, perfect for various display settings.

- Modern Aesthetic Appeal: Plexiglass boasts a sleek and modern look. Its smooth surface and crystal-clear appearance create a professional and polished presentation, enhancing any display.

- Customizable Canvas: Plexiglass can be easily customized with logos or designs, allowing creative branding opportunities that elevate your displays.

Plexiglass offers the perfect blend of functionality and style, making it a superior choice for creating eye-catching and impactful signage and displays.

Aquariums and Protective Shields

In aquariums and protective shields, plexiglass offers the benefit of being shatter-resistant while maintaining exceptional clarity. This makes it a safe option for containing aquatic life or providing protection in industrial settings without compromising visibility. Its versatility allows for customization in size and shape to fit specific requirements.

Lighting Fixtures and Picture Frames

Plexiglass is often used in lighting fixtures and picture frames because it can transmit light effectively while offering impact resistance. This makes it an ideal material for creating illuminated displays or protecting valuable artwork or photographs from damage. Its versatility also allows for creative design flexibility in these applications.

Applications of Polycarbonate

Safety Glasses and Face Shields

Polycarbonate offers several advantages that make it the go-to material for safety glasses and face shields:

- High Impact Resistance: Polycarbonate is significantly more resistant to impact than glass, making it ideal for protecting your eyes from flying debris or projectiles.

- Durability: Polycarbonate lenses are strong and scratch-resistant, ensuring they can withstand wear and tear in harsh environments.

- Lightweight Comfort: Polycarbonate is remarkably lightweight compared to glass. This translates to comfortable wear for extended periods, which is especially important for industrial workers and athletes.

Polycarbonate's superior strength, durability, and comfort make it the clear choice for superior eye protection.

Greenhouses and Skylights

Polycarbonate is a popular choice for greenhouses and skylights in the construction industry due to its exceptional light transmission properties. Its ability to diffuse light evenly helps promote plant growth in greenhouses, while its impact resistance makes it a reliable option for skylights in residential and commercial buildings. The durability of polycarbonate also ensures long-term performance in outdoor environments.

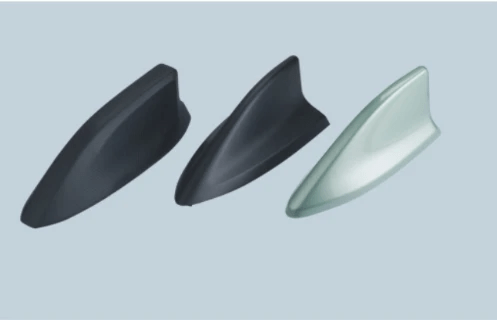

Bulletproof Glass and Automotive Headlights

One of the most impressive applications of polycarbonate is in producing bulletproof glass and automotive headlights. Its unmatched strength and impact resistance make it an essential material for security, protecting against ballistic threats. Additionally, the heat resistance of polycarbonate makes it suitable for use in automotive headlights, ensuring clear visibility and safety on the road.

Now that we've explored the diverse applications of plexiglass and polycarbonate materials across different industries...

Comparison of Plexiglass vs Polycarbonate

Regarding cost-effectiveness and maintenance, plexiglass and polycarbonate have their advantages. Plexiglass is generally more affordable than polycarbonate, making it a popular choice for budget-conscious projects. However, polycarbonate requires less maintenance due to its superior scratch resistance, which can save money in the long run.

Cost-effectiveness and Maintenance

Regarding cost-effectiveness, plexiglass is often the preferred choice for those working within a budget. Its lower price point makes it an attractive option for various applications such as signage and display cases. On the other hand, polycarbonate may have a higher upfront cost, but its exceptional durability and scratch resistance results in lower long-term maintenance expenses. Additionally, the impact resistance of polycarbonate makes it a more cost-effective choice in high-traffic areas or where vandalism is a concern. This can reduce replacement and repair costs, making it a smart investment for businesses looking to minimize long-term expenses.

Environmental Impact and Recyclability

Both plexiglass and polycarbonate have pros and cons when considering the environmental impact and recyclability. While plexiglass is recyclable, it is not biodegradable and may release harmful chemicals when incinerated. On the other hand, polycarbonate is not easily recyclable due to its complex chemical composition, but it can be repurposed into other plastic products with proper processing.

Regarding aesthetics and design flexibility, plexiglass offers a clear and transparent appearance, making it suitable for applications where visibility is essential. It can also be easily shaped and molded into various forms, allowing creative design possibilities. On the other hand, polycarbonate provides high impact resistance and can be formed into complex shapes without sacrificing strength. This makes it a preferred choice for applications requiring durability and structural integrity.

Aesthetics and Design Flexibility

Both plexiglass and polycarbonate offer unique advantages in terms of aesthetics and design flexibility. Plexiglass provides exceptional clarity and transparency, making it ideal for applications where visual appeal is important. On the other hand, polycarbonate offers greater impact resistance and can be molded into various shapes without sacrificing strength, providing designers with more creative freedom.

In addition to their aesthetic and design advantages, plexiglass and polycarbonate offer excellent weather resistance, making them suitable for outdoor applications. Plexiglass is known for its UV resistance, preventing yellowing or degradation from sun exposure, while polycarbonate is highly durable and can withstand extreme temperatures and harsh weather conditions. This makes both materials versatile for architectural and outdoor design projects, providing long-lasting performance and visual appeal.

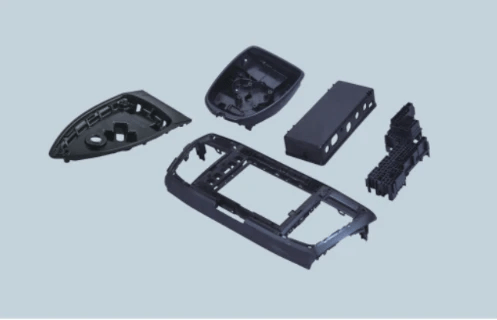

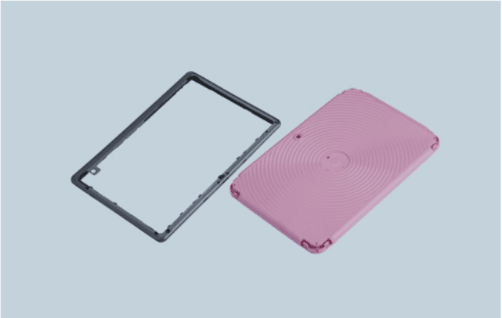

Baoyuan's Expertise in Plastic Product Manufacturing

When deciding between plexiglass and polycarbonate for your project, consider each material's specific properties and applications. Baoyuan's expertise in plastic product manufacturing can help you make an informed decision that meets your needs.

Choosing the Right Material for Your Project

Whether you're looking for durability or transparency, understanding the differences between plexiglass and polycarbonate is crucial. Polycarbonate lenses vs glass offer superior impact resistance, while plexiglass vs polycarbonate provides better weatherability. Make sure to choose the right material for your specific project requirements.

With Baoyuan's extensive experience in plastic product manufacturing, you can trust their knowledge and guidance when choosing between polycarbonate vs acrylic or acrylic vs polycarbonate. Their expertise ensures that you receive high-quality materials tailored to your unique needs. Additionally, Baoyuan's team stays up-to-date with the latest advancements in plastic technology, allowing them to offer innovative solutions that meet the demands of modern industries.

Making an Informed Decision for Your Needs

Understanding whether polycarbonate is plastic and what polycarbonate lenses are can help you make an informed decision when selecting materials for your project. With Baoyuan's support, you can confidently choose between plexiglass and polycarbonate based on cost-effectiveness, maintenance, and environmental impact.