Introduction

Are you curious about two-shot injection molding and how it can benefit your manufacturing process? In this comprehensive guide, we'll delve into the world of two-shot and multi-shot molding, uncovering the advantages of each technique and introducing you to Baoyuan, an industry leader in two-shot molding.

Understanding

Two-Shot Injection Molding

Two-shot injection molding, also known as two-shot or 2K molding, is a versatile manufacturing process that involves injecting two different materials into a single mold to produce a multi-material part. This innovative technique allows for enhanced design flexibility and improved product functionality, making it a popular choice in various industries.

Exploring the Benefits of

Multi-Shot Injection Molding

Multi-shot injection molding takes the concept of two-shot molding to the next level, providing greater design flexibility and production efficiency. This advanced method allows manufacturers to create complex components with:

- Multiple Materials: Incorporate unique properties from different plastics, metals, or silicones into a single part.

- Enhanced Functionality: Combine rigid structures with soft-touch grips, create living hinges, or integrate colored accents, all within one mold.

- Streamlined Production: Eliminate secondary assembly steps like welding or bonding, saving time and labor costs.

By combining these advantages, multi-shot injection molding revolutionizes how complex parts are manufactured.

Meet Baoyuan: Experts in

Two-Shot Molding

Baoyuan is at the forefront of two-shot injection molding, providing unparalleled expertise and cutting-edge solutions to meet your unique manufacturing needs. With a proven track record of delivering high-quality multi-material parts, Baoyuan is your trusted partner for all things related to two-shot and multi-shot molding.

What is Two Shot Injection Molding

Process Overview of

Two-Shot Molding

Two-shot injection molding, or two-shot molding, is a manufacturing process that allows the production of complex molded parts with two different materials or colors in a single operation. The process involves injecting one material into a mold to form the initial part and then injecting another to create the second shot or component. This innovative technique eliminates additional assembly processes, resulting in more efficient production and cost savings.

Two-shot molding offers the advantage of improved part quality and consistency. Allowing different materials or colors in a single operation ensures the two components are seamlessly integrated, resulting in a more uniform and aesthetically pleasing final product. This can be particularly beneficial for applications with critical appearance and finish, such as consumer electronics or automotive interiors. Additionally, eliminating assembly processes reduces the risk of errors or defects during manual handling, contributing to overall part quality.

Advantages of

Two-Shot Molding

Two-shot molding offers a range of benefits for manufacturers, making it a valuable technique for creating complex and functional parts. Here are some key advantages:

- Design Flexibility: Two-shot molding allows for creating intricate designs and patterns that would be difficult or impossible with traditional methods.

- Improved Efficiency: It reduces production time and labor costs by eliminating the need for secondary operations like assembly and bonding.

- Enhanced Functionality: This process combines different materials with varying properties in a single component, improving part performance.

- Increased Durability: By combining materials, manufacturers can create parts that are stronger, better resist wear and tear, and withstand harsh environments. This translates to longer product lifespans and reduced maintenance costs.

Two-shot molding offers a compelling combination of design freedom, efficiency, functionality, and durability, making it a versatile technique for various applications.

Examples of Two Shot Injection Molding

One notable example of two-shot injection molding is the production of multi-colored buttons for electronic devices such as remote controls or keypads. This process allows for the creation of buttons with different colors for various functions without requiring additional assembly steps. Another example is the manufacturing of overmolded tools and handles, where a soft rubber grip is molded over a hard plastic core in one seamless operation.

Another application of two-shot injection molding is in the production of automotive interior components such as shift knobs and steering wheel controls. This process allows combining different materials, such as hard plastic and soft rubber, to create a more ergonomic and visually appealing design. Additionally, two-shot injection molding is used in the manufacturing of medical devices, where different materials with varying properties can be combined to create a single component that meets strict performance and safety requirements.

Multi-Shot Injection Molding Explained

Multi-shot injection molding differs from two-shot molding in that it involves the use of more than two materials or colors in a single mold. This allows for greater design flexibility and creating complex, multi-material products.

How

Multi-Shot Molding Differs from Two-Shot Molding

Unlike two-shot molding, which involves the use of two materials or colors in a single mold, multi-shot molding allows for the simultaneous use of more than two materials or colors in a single mold. This enables the production of intricate and multi-functional parts with varying material properties.

Applications of

Multi-Shot Injection Molding

Multi-shot injection molding is commonly used in the production of consumer goods, automotive components, medical devices, and electronic products. It is ideal for creating products with soft-touch grips, overmolded buttons, and multi-colored components.

Baoyuan's Expertise in

Multi-Shot Molding

Baoyuan has extensive experience and technical proficiency in multi-shot injection molding. Their team of experts is skilled at designing and manufacturing high-quality multi-material products with precision and efficiency.

The Benefits of Two-Shot Molding

Improved Product Quality with Two Shot Molding

Two-shot molding is a highly efficient process that allows for the creation of complex, multi-material parts in a single operation. Using two different materials or colors in one mold eliminates the need for additional assembly processes, resulting in improved product quality and durability. This innovative method gives designers more flexibility to create intricate designs and enhance the product's overall functionality.

Cost Savings and Efficiency Gains

One of the major advantages of two-shot molding is its ability to reduce production costs and increase efficiency. With fewer manufacturing steps required, labor costs and material waste are significantly reduced, leading to substantial savings for businesses. Additionally, the streamlined process results in faster production cycles, allowing companies to bring their products to market more quickly and stay ahead of their competition.

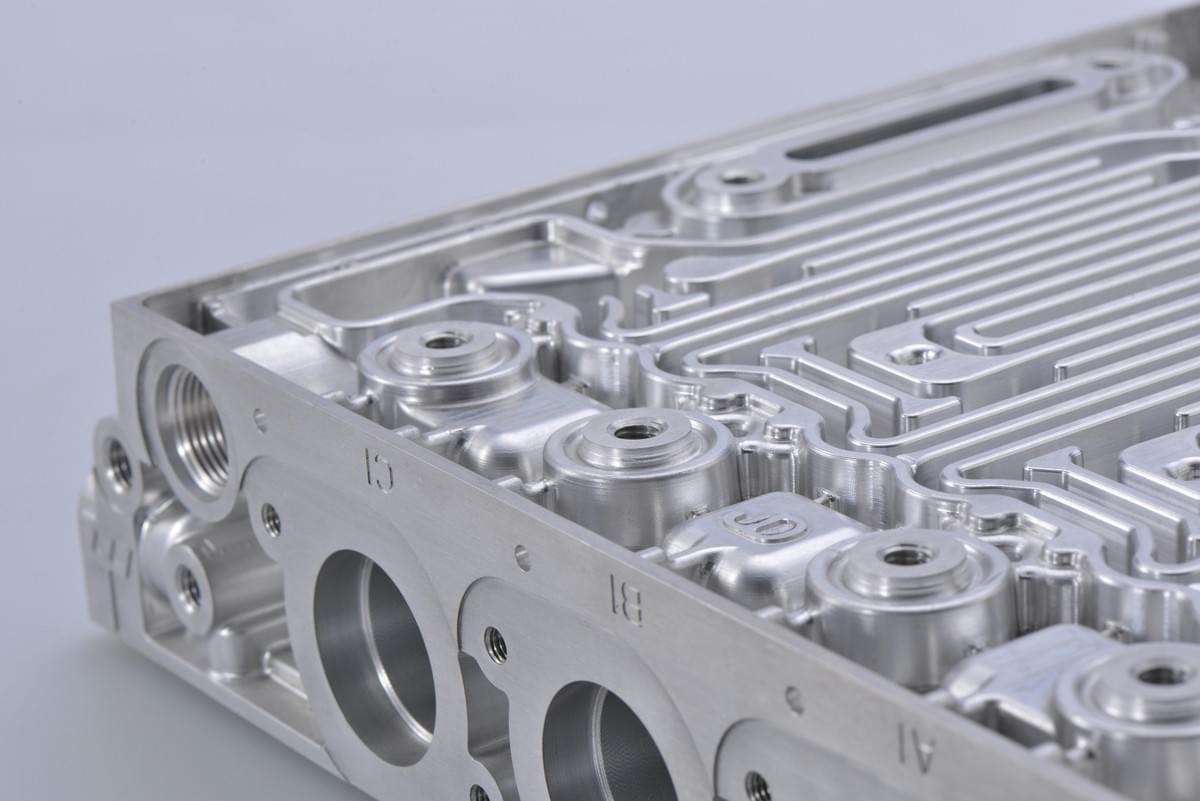

Baoyuan's Experience in

Two-Shot Mold Design

At Baoyuan, we have extensive experience designing and producing high-quality two-shot molds for various industries. Our team of experts understands the intricacies of this molding process and has the technical know-how to deliver exceptional results. With our state-of-the-art facilities and advanced technology, we are committed to providing our clients with top-notch two-shot molding solutions that meet their specific requirements.

Advantages of Multi-Shot Injection Molding

Enhanced Design Flexibility

Multi-shot injection molding offers enhanced design flexibility by allowing for the creation of complex, multi-material components in a single process. This innovative technique enables the production of intricate parts with varying colors, textures, and materials, giving designers unprecedented creative freedom to bring their visions to life.

Multi-shot injection molding also streamlines the production process by reducing the need for additional assembly and labor. This technique can create complex, multi-material components in a single process and eliminates the time and resources required for assembling individual parts. This saves on labor costs and reduces the potential for errors or defects that can arise during assembly, resulting in a more efficient and cost-effective manufacturing process.

Reduced Assembly and Labor Costs

With multi-shot injection molding, manufacturers can produce fully assembled components in a single operation, eliminating the need for additional assembly processes and reducing labor costs. By streamlining production and minimizing manual handling, multi-shot molding offers significant cost savings while enhancing overall efficiency.

Baoyuan's Technical Proficiency in

Multi-Shot Molding

Baoyuan is at the forefront of multi-shot injection molding technology, leveraging our advanced expertise to deliver high-quality, precision-engineered products that meet the most demanding specifications. Our skilled team of engineers and technicians is adept at maximizing the benefits of multi-shot molding to create innovative solutions for a wide range of industries.

Baoyuan: Leaders in Two-Shot and Multi-Shot Molding

Baoyuan's Extensive Industry Experience

With a focus on precision and innovation, Baoyuan has consistently delivered high-quality products to satisfied clients. Our commitment to staying ahead of industry trends and investing in state-of-the-art technology sets us apart. We pride ourselves on our ability to tackle even the most challenging projects with creativity and expertise, ensuring that our clients receive top-notch results every time.

Expertise in Mold Design and Injection Molding

Baoyuan's expertise in mold design and injection molding is unparalleled. We have a deep understanding of the intricacies of two-shot and multi-shot molding processes, allowing us to deliver precise, high-quality products to our clients. Our innovative approach to mold design sets us apart from the competition.

Our team at Baoyuan takes pride in our ability to consistently meet and exceed our client's expectations when it comes to two-shot and multi-shot molding processes. With a keen eye for detail and a commitment to precision, we produce high-quality products that are durable and reliable. Our innovative approach to mold design sets us apart from the competition and ensures that our clients receive the best possible solutions for their molding needs.

Quality Assurance in Two Shot and

Multi-Shot Products

At Baoyuan, quality assurance is at the core of everything we do. We take pride in delivering top-notch two-shot and multi-shot products that meet industry standards. Our commitment to quality ensures that our clients receive durable, reliable, and cost-effective solutions for their specific needs. Furthermore, our rigorous quality control processes guarantee that each product undergoes thorough testing to meet all performance and safety requirements. This attention to detail sets us apart in the industry and gives our clients peace of mind, knowing they receive high-quality products.

Now that you know why Baoyuan is a leader in two-shot and multi-shot molding, let's explore the benefits of each process in more detail.

Make Informed Decisions: Two Shot vs Multi-Shot Molding

When deciding between two-shot and multi-shot molding, it's essential to consider the complexity of your product and the desired outcome. Two-shot injection molding is ideal for creating intricate designs with multiple materials, while multi-shot molding offers enhanced design flexibility and reduced assembly costs. Additionally, two-shot molding can help streamline manufacturing by eliminating the need for secondary operations and saving time and resources. On the other hand, multi-shot molding allows for integrating different materials in a single mold, creating complex components with varying properties in a single operation. This can be particularly advantageous for products that require rigid and flexible materials.

Choosing the Right Molding Process for Your Project

Selecting the right molding process for your project can be a game-changer. Two-shot injection molding might be the best fit if you want to improve product quality and reduce assembly costs. On the other hand, if design flexibility and labor cost reduction are your priorities, multi-shot injection molding could be the way to go.

When considering the right molding process for your project, it's important to weigh the benefits of each option. Two-shot injection molding offers improved product quality and reduced assembly costs, making it an attractive choice for those looking to enhance the overall value of their products. On the other hand, multi-shot injection molding provides greater design flexibility. It can help reduce labor costs, offering different advantages that may better align with your project's specific needs.

Baoyuan: Your Trusted Partner in Two-Shot and

Multi-Shot Molding

With Baoyuan's expertise, you can achieve precision, efficiency, and cost-effectiveness for your next molding project. Here's what sets us apart:

- Two-Shot and Multi-Shot Molding Specialists: Our team offers innovative design solutions for complex projects.

- Advanced Technology and Equipment: We utilize state-of-the-art resources to deliver high-quality products efficiently.

- Cost-Effective Manufacturing: We streamline production processes to save you time and money.

Don't settle for less. Contact Baoyuan today and bring your ideas to life.