Introduction

Two-shot injection molding is the way to go when creating complex and aesthetically pleasing plastic products. This innovative process creates double-color or double-material components in a single operation, resulting in seamless and durable finished products. At Baoyuan, we have honed our expertise in two-shot injection molding to deliver top-notch solutions to our clients.

Understanding Two-Shot Injection Molding

Two-shot injection molding involves using two different materials or colors in a single mold to produce a single part. This process eliminates additional assembly steps, reducing production time and costs while ensuring precise component alignment and consistency.

Furthermore, two-shot injection molding allows for creating complex and intricate designs that would be difficult or impossible to achieve with traditional molding processes. This opens up new possibilities for product innovation and differentiation in the market, giving companies a competitive edge. Additionally, by combining different materials in a single part, manufacturers can create products with enhanced functionality, durability, and aesthetic appeal, meeting consumers' diverse needs and preferences.

Advantages of Two-Shot Molding

Two-shot molding offers a compelling set of advantages for manufacturers, making it a versatile and efficient production technique. Here's how it benefits you:

- Improved Part Quality: The single-tool process ensures strong bonds and tight tolerances, leading to more reliable and functional parts.

- Reduced Production Time: Two-shot molding significantly speeds up production cycles by eliminating secondary assembly steps.

- Enhanced Design Flexibility: Complex geometries and multi-material combinations become achievable, opening doors for innovative product design.

- Increased Efficiency: Streamlined production with fewer operators and a single machine cycle translates to cost savings and higher output.

- Boosted Aesthetics: Two-shot molding allows for incorporating different colors and textures, creating visually appealing and distinctive products.

Two-shot molding empowers manufacturers to create high-quality, functional, visually striking products with optimal production efficiency.

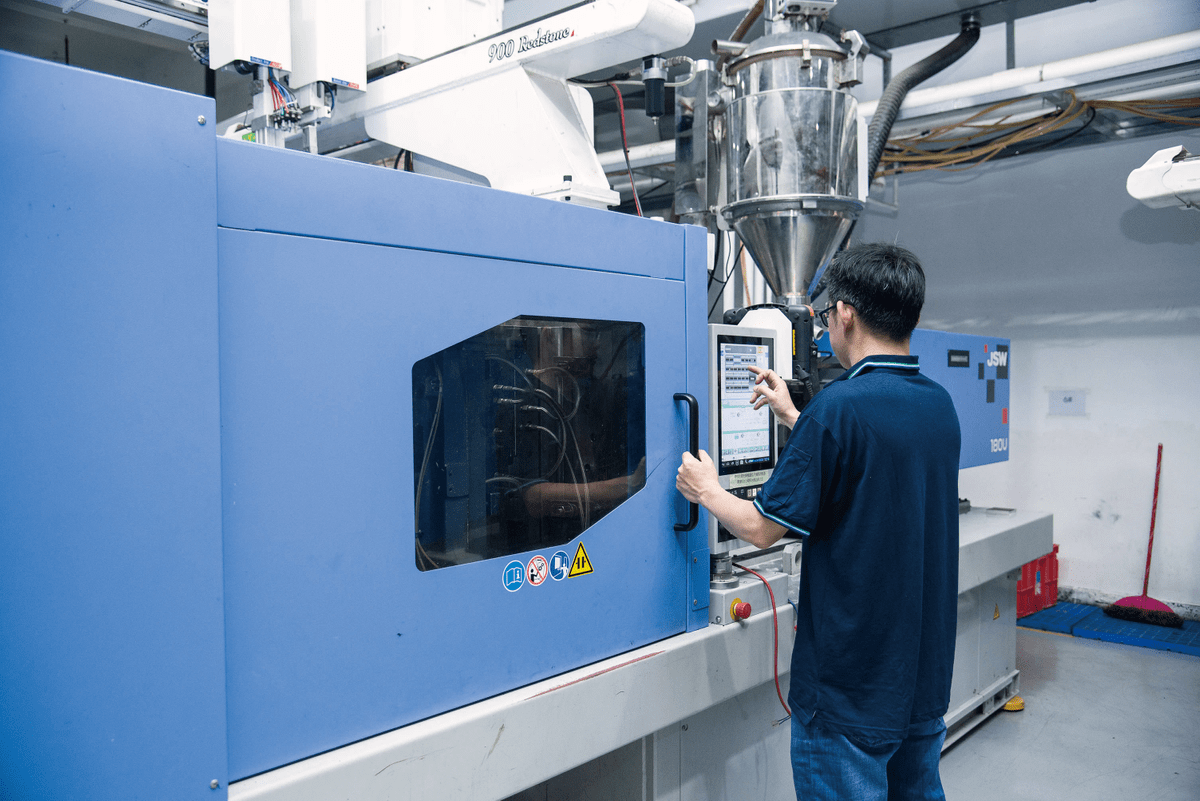

Baoyuan's Expertise in Two-Shot Injection Molding

At Baoyuan, we pride ourselves on our extensive experience and two-shot injection molding technology proficiency. Our team of experts is dedicated to delivering high-quality double-color plastic products that meet our client's unique specifications and requirements. With our advanced machinery and cutting-edge techniques, we can produce intricate designs and complex geometries with precision and accuracy. This allows us to offer our clients a wide range of creative options for their double-color plastic products, giving them a competitive edge in the market.

What is Two-Shot Injection Molding?

Process Overview

Two-shot injection, or double-shot molding, is a versatile manufacturing process that produces complex plastic parts with two different materials or colors in a single operation. This innovative process involves injecting one material into a mold to form the initial part and then injecting another to create the final product. The result is a seamless, high-quality component with enhanced functionality and aesthetic appeal.

Two-shot injection molding offers a cost-effective solution for producing complex parts with multiple materials or colors. Eliminating the need for secondary operations reduces production time and labor costs while ensuring consistent quality. Additionally, combining different materials in a single part allows for creating products with unique properties, such as soft-touch grips or over-molded seals, enhancing their functionality and performance.

Materials Used

Two-shot injection molding utilizes a wide range of materials, including thermoplastic elastomers (TPE), thermoplastic polyurethanes (TPU), and engineering-grade resins such as polycarbonate (PC) and acrylonitrile butadiene styrene (ABS). These materials offer varying degrees of hardness, flexibility, and durability, allowing for the creation of diverse products with unique performance characteristics. Manufacturers can achieve superior functionality and design versatility by combining different materials in a single mold.

In addition to the diverse materials mentioned, two-shot injection molding allows for specialized additives and colorants, further expanding the range of possible product characteristics. This capability is precious in industries such as automotive, where manufacturers can create multi-colored components with integrated seals and gaskets in a single production step. By leveraging the versatility of two-shot molding, companies can streamline manufacturing processes and reduce assembly costs while delivering high-quality, visually appealing products to consumers.

Applications in Various Industries

The applications of two-shot injection molding are vast and diverse, spanning industries such as automotive, electronics, medical devices, consumer goods, and more. From soft-touch grips for handheld devices to automotive interior components with integrated buttons and displays, two-shot molding enables the production of complex parts that would be difficult or impossible to achieve using traditional manufacturing methods. This advanced technology opens up new possibilities for product design and innovation across multiple sectors.

In the electronics industry, two-shot injection molding creates products with integrated buttons, displays, and other intricate features. This technology allows for the production of complex electronic components with seamless integration, enhancing the functionality and aesthetics of devices such as smartphones, remote controls, and wearable gadgets. By utilizing two-shot molding, electronics manufacturers can achieve high precision and design flexibility that traditional manufacturing methods cannot match.

When is Two-Shot Injection Molding Used?

Two-shot injection molding is used when manufacturers want to achieve complex designs and color combinations in a single process, leading to significant benefits and cost savings. Two-shot molding allows for more efficient production and lower overall manufacturing costs by eliminating the need for secondary operations and reducing material waste.

Benefits and Cost Savings

The benefits of two-shot injection molding are numerous, including reduced labor costs, faster production times, and improved product quality. By combining different materials or colors in a single mold, manufacturers can create more visually appealing and functional products while minimizing waste. This innovative process also reduces the need for assembly or finishing operations, resulting in additional time and cost savings.

Additionally, two-shot injection molding allows for greater design flexibility, enabling manufacturers to create more complex and intricate products easily. This process opens up new possibilities for product designs that were previously difficult or impossible to achieve with traditional manufacturing methods. By seamlessly integrating multiple materials or colors into a single part, manufacturers can enhance their products' functionality and aesthetic appeal, giving them a competitive edge in the market.

Design Flexibility

Two-shot molding offers unparalleled design flexibility, allowing for the creation of intricate shapes and multi-material components that would be impossible to achieve with traditional injection molding methods. This versatility opens up new possibilities for product designers and engineers, enabling them to push the boundaries of what is possible in terms of aesthetics, functionality, and performance.

Furthermore, two-shot molding allows for integrating different materials and colors within a single component, reducing the need for secondary assembly processes and minimizing production costs. This streamlined approach saves time and resources and results in a more durable and reliable end product. By leveraging the capabilities of two-shot molding, designers can create seamless transitions between materials, enhancing their designs' visual appeal and functionality.

Examples of Two-Shot Molding in Action

Two-shot injection molding has become a game-changer in manufacturing, creating complex and functional parts with unique features. Here's how it benefits various industries:

- Enhanced Functionality and Aesthetics: Two-shot molding allows the combining of different materials within a single part. This creates exciting possibilities, like soft-touch grips on power tools or integrated buttons with clear labels on electronics.

- Streamlined Production: By combining features into one molding step, two-shot molding eliminates the need for separate assembly processes, saving time and resources.

- Improved Product Performance: Integrating seals and gaskets directly into parts during molding reduces the risk of leaks and malfunctions, leading to more reliable products.

In the medical field, two-shot molding allows for the creation of complex devices with built-in seals, improving hygiene and functionality.

Two-shot injection molding is a powerful tool for manufacturers seeking to create innovative, high-performance products.

Baoyuan's Expertise in Two-Shot Injection Molding

Senior Management and Technical Personnel

At Baoyuan, our team of senior management and technical personnel is highly experienced in two-shot injection molding. With years of expertise and a deep understanding of the intricacies involved in this process, they ensure that every project is executed with precision and excellence.

Advanced Software for Mold Design

Our advanced software takes two-shot mold design to the next level. By utilizing cutting-edge technology, we achieve:

- Unmatched Accuracy: We create intricate and complex two-shot molds with exceptional precision, allowing you to bring your innovative designs to life.

- Optimized Manufacturing: Our software helps identify potential design flaws early on, streamlining the process, reducing lead times, and increasing efficiency.

- Cost-Effectiveness: By proactively addressing issues, we minimize errors and ensure a smooth production run, saving you time and money.

This commitment to precision and efficiency sets us apart, giving you peace of mind and molds built to the highest standards.

Proficiency in Production and Quality Assurance

Our proficiency in production and quality assurance sets us apart as industry leaders. We adhere to strict quality control measures throughout the manufacturing process, ensuring that every two-shot product meets the highest durability, functionality, and aesthetics standards.

Our commitment to excellence extends beyond the manufacturing process to include ongoing research and development efforts to improve our products continuously. By staying ahead of industry trends and technological advancements, we can offer innovative two-shot products that meet current standards and anticipate future needs. This forward-thinking approach allows us to maintain our position as leaders in the industry and ensures that our customers receive the most advanced and reliable products available.

Explore the Versatility of Two-Shot Molding

Two-shot molding is a game-changer in plastic manufacturing, offering endless possibilities for innovative designs and products. Baoyuan's expertise in double-color plastic products showcases the potential of two-shot injection molding to create eye-catching and functional items that stand out in the market. By embracing the future of injection molding with two-shot technology, companies can stay ahead of the competition and meet the evolving demands of consumers.

The versatility of two-shot molding allows for intricate designs, vibrant color combinations, and seamless integration of multiple materials in a single product. This opens up new creative opportunities for designers and engineers to push boundaries and create unique solutions that capture attention and drive sales.

The ability to combine different materials in a single product through two-shot molding enhances the aesthetic appeal of the final product and improves its functionality. This allows for creating products with unique textures, finishes, and performance characteristics that stand out in the market. By leveraging this capability, designers and engineers can develop innovative solutions that cater to specific customer needs and preferences, setting their products apart from the competition.

Leveraging Baoyuan's Experience in Double-Color Plastic Products

Baoyuan's extensive experience in producing high-quality double-color plastic products demonstrates their mastery of two-shot molding techniques. Their expertise enables them to bring complex designs to life with precision and efficiency, providing customers with exceptional results that exceed expectations. With an unwavering commitment to innovation, Baoyuan stays ahead of the curve in the injection molding industry. Their dedication to embracing new technologies, such as two-shot technology, ensures that they can offer cutting-edge solutions to meet the evolving needs of their clients.

Embracing the Future of Injection Molding with Two-Shot Technology

As technology advances, two-shot injection molding is poised to become even more integral in manufacturing processes across industries. Embracing this cutting-edge technology allows businesses to stay at the forefront of innovation, delivering products that are not only visually striking but also durable and functional.