Introduction

Injection molding flash is a common issue that can affect the quality and functionality of molded parts. Baoyuan, with its extensive expertise in injection molding, has the knowledge and skills to address this issue effectively. Understanding the causes of flash in injection molding is crucial for troubleshooting and preventing this defect.

Understanding Injection Molding Flash

Flashing in injection molding refers to the excess material that escapes from the mold cavity during the molding process, leading to unwanted protrusions on the final product. This can result from various factors such as mold design issues, injection pressure, and speed.

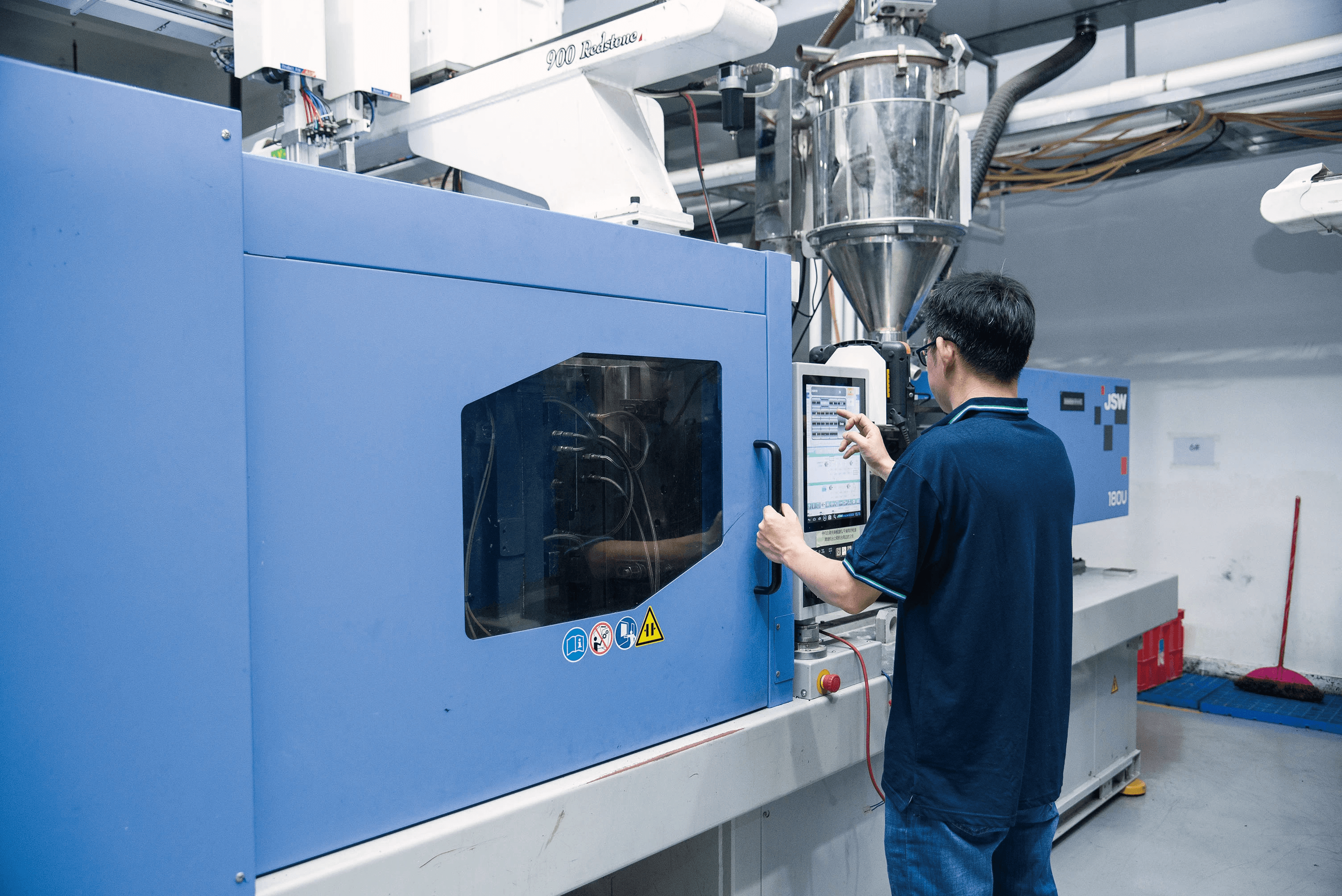

Baoyuan's Expertise in Injection Molding

The Baoyuan team comprises senior management and technical personnel with years of industry experience. They are proficient in using software for mold design, mold opening, and injection molding, ensuring precision and efficiency in their processes.

Common Causes of Flash in Injection Molding

Common causes of flash include inadequate venting and cooling, as well as quality control measures that may be overlooked during production. Identifying these causes is essential for implementing effective solutions to prevent or remove flash defects.

Identifying the Flash Issue

Visual Inspection of Molded Parts

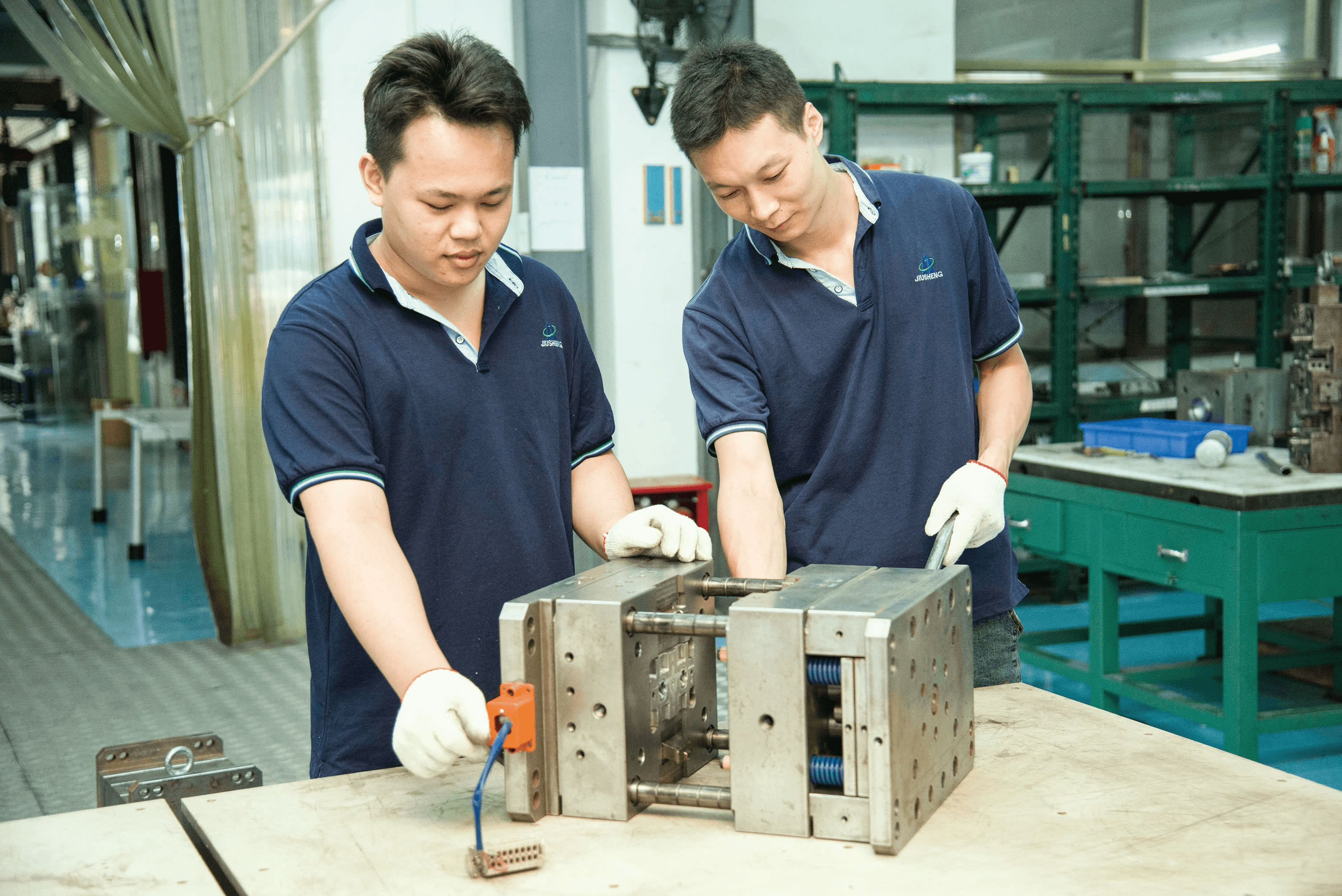

When identifying the flash issue in injection molding, visual inspection of molded parts is crucial. Baoyuan's team meticulously examines each part for any signs of excess material, ensuring that no flash defects are overlooked. This attention to detail is essential in delivering high-quality injection molded products.

In addition to visual inspection, Baoyuan's team also utilizes precise measuring tools to determine the thickness of any flash present on the molded parts. By accurately measuring the flash thickness, they can identify any areas where excess material may have accumulated and address these issues promptly. This proactive approach ensures that the final products meet the highest quality standards and are free from any imperfections that may result from flash defects.

Measuring Flash Thickness

Measuring flash thickness is another key step in identifying the flash issue in injection molding. Baoyuan's quality assurance techniques include precise measurements of flash thickness to determine if it falls within acceptable limits. This meticulous approach ensures that any excess material is promptly addressed, preventing potential quality issues.

After measuring flash thickness, Baoyuan's quality assurance team utilizes advanced technology to analyze the data and identify any patterns or trends that may indicate potential issues in the injection molding process. By closely monitoring the flash thickness over time, they can proactively address any deviations from the acceptable limits, ensuring consistent quality in the final product. This proactive approach not only prevents quality issues but also helps optimize the manufacturing process for greater efficiency and cost-effectiveness.

Baoyuan's Quality Assurance Techniques

Baoyuan's team employs advanced quality assurance techniques to identify and address the flash issue in injection molding. With a focus on precision and accuracy, they utilize cutting-edge tools and technologies to ensure that each molded part meets stringent quality standards, effectively minimizing the occurrence of flash defects.

Furthermore, Baoyuan's team continuously monitors and evaluates their quality assurance processes to ensure they are up-to-date with the latest industry standards and best practices. This proactive approach allows them to stay ahead of potential flash issues and make necessary adjustments before they become larger problems. By staying current with technological advancements and industry trends, Baoyuan's team remains at the forefront of quality assurance in injection molding.

By incorporating these strategies into their process, Baoyuan demonstrates their commitment to delivering flawless injection molded products while maintaining their reputation as industry leaders.

What Causes Flash in Injection Molding

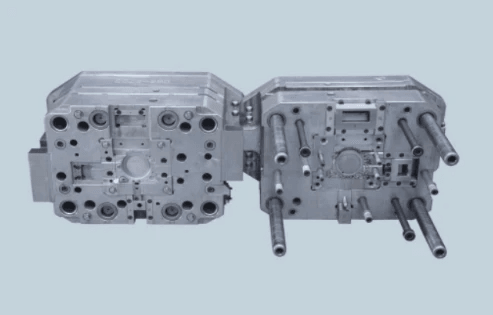

When it comes to what causes flash in injection molding, one of the main factors is mold design issues. Poorly designed molds can lead to excess material escaping during the injection process, resulting in flash defects. Baoyuan's team of experienced professionals understands the importance of meticulous mold design to prevent such issues and ensure high-quality production.

Mold Design Issues

Mold design issues such as inadequate venting or improper parting line alignment can contribute to flashing in injection molding. Baoyuan's senior technical personnel are adept at using software to meticulously design molds, ensuring proper venting and parting line alignment to minimize the risk of flash defects. Their expertise in this area plays a crucial role in preventing flash and maintaining product quality.

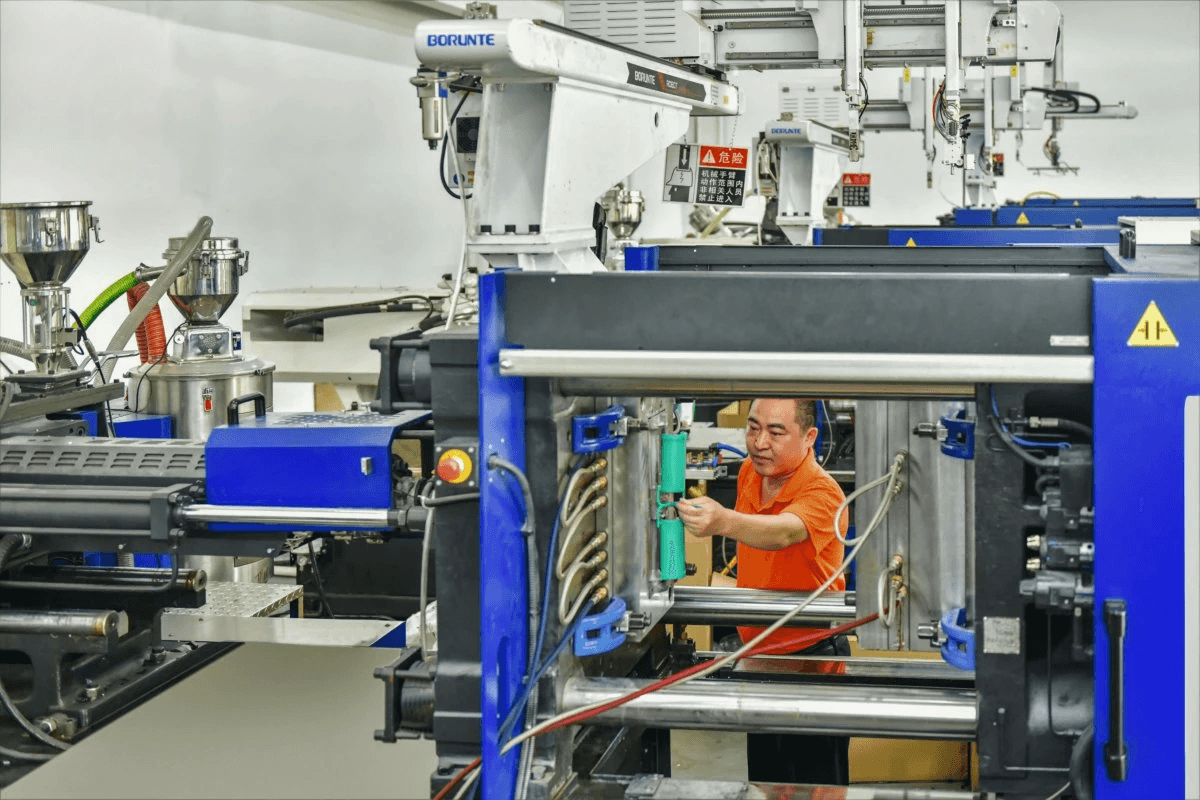

In addition to mold design issues, injection pressure and speed are also critical factors that can affect the occurrence of flashing in injection molding. Baoyuan's technical team carefully monitors and adjusts the injection pressure and speed during the molding process to ensure that they are optimized for each specific mold design. By controlling these variables, they can minimize the risk of flash defects and maintain consistent product quality.

Injection Pressure and Speed

Another factor that contributes to flashing is excessive injection pressure and speed. When these parameters are not carefully controlled, they can lead to material seepage and flash formation. Baoyuan's team understands the importance of optimizing injection pressure and speed for each specific molding project, ensuring precise control over these variables to prevent flash defects.

The proper adjustment of injection pressure and speed is crucial to achieving high-quality molded products. By carefully controlling these parameters, Baoyuan's team ensures that the material is injected into the mold at the optimal rate and pressure, minimizing the risk of seepage and flash formation. This meticulous approach to injection pressure and speed optimization sets Baoyuan apart in delivering flawless molding solutions.

Baoyuan's Mold Opening Solutions

Baoyuan's technical personnel are well-versed in effective mold opening solutions to address potential flashing issues. By implementing proper mold opening techniques, they can minimize the risk of excess material escaping during the molding process, ultimately reducing the occurrence of flash defects.

Furthermore, Baoyuan's technical personnel are constantly staying updated on the latest advancements in mold opening solutions to ensure that they are equipped with the most effective techniques. This dedication to ongoing education and skill development allows them to adapt to new challenges and provide innovative solutions for addressing flashing issues in injection molding processes. By staying ahead of the curve, Baoyuan's team can offer cutting-edge strategies for minimizing flash defects and maximizing production efficiency.

Troubleshooting Injection Molding Flash

Adjusting Injection Parameters

To address what causes flash in injection molding, adjusting injection parameters is crucial. Baoyuan's team of experts carefully analyze and tweak the injection pressure, speed, and temperature to minimize the occurrence of flash defects. By fine-tuning these parameters, they can ensure a smoother and more precise molding process.

Cleaning Mold Surfaces

One effective method to prevent flash in injection molding is by maintaining clean mold surfaces. Baoyuan's meticulous approach includes regular cleaning and inspection of mold surfaces to remove any debris or contaminants that could contribute to flashing issues. This attention to detail helps in achieving high-quality molded parts with minimal flash defects.

Baoyuan's Software for Mold Design

Baoyuan's proficiency in mold design is enhanced by their use of advanced software tools. These tools enable them to create precise and efficient mold designs that minimize the risk of flash defects during the injection molding process. By leveraging technology, Baoyuan ensures that their molds are optimized for superior performance and quality.

Remember that preventing flash in injection molding requires a combination of expertise, precision, and attention to detail throughout the entire process. With Baoyuan's commitment to excellence and their comprehensive approach to troubleshooting flash issues, you can trust in their ability to deliver exceptional results every time.

Preventing Flash in Injection Molding

Proper Venting and Cooling

To prevent flash in injection molding, proper venting and cooling are essential. Inadequate venting can lead to trapped air, causing flashing, while insufficient cooling can result in uneven cooling rates and increased risk of flash. Baoyuan's team ensures that molds are designed with proper venting channels and cooling systems to minimize the risk of flash.

In addition to proper venting and cooling, Baoyuan's team also pays close attention to the material being used for the molds. Using high-quality materials that are able to withstand the heat and pressure of injection molding is crucial in preventing flash. By carefully selecting the right materials, the risk of flashing can be significantly reduced, ensuring a smoother and more efficient manufacturing process.

Quality Control Measures

Quality control measures play a crucial role in preventing flash in injection molding. Baoyuan's team implements stringent quality checks at every stage of the molding process to identify any potential issues that could lead to flashing. This proactive approach helps to address any concerns before they escalate into significant problems, ensuring high-quality finished products without flash defects.

Baoyuan's Single-color and Double-color Products Expertise

Baoyuan's expertise in producing single-color and double-color plastic products not only prevents flash during injection molding but also ensures the highest quality and precision in their final products. The team's meticulous attention to detail in mold design and injection molding processes allows them to create molds that are perfectly suited to minimize the risk of flashing. This level of expertise and dedication to excellence sets Baoyuan apart in delivering flawless single-color and double-color products without any flash defects, meeting the highest standards of quality in the industry.

Removing Flash from Injection Molding

When it comes to removing flash from injection molding, trimming and finishing techniques are essential. Baoyuan's team utilizes precision trimming tools and methods to carefully remove excess material from molded parts, ensuring a smooth and flawless finish. By implementing corrective actions such as adjusting mold temperature and pressure, Baoyuan effectively eliminates flash defects in injection molding. Their proficiency in flash defect solutions is evident in the impeccable quality of their finished products.

Trimming and Finishing Techniques

Baoyuan's skilled technicians employ advanced trimming and finishing techniques to remove flash from injection molded parts. Using specialized tools and equipment, they meticulously trim excess material from the edges of the molded components, resulting in a clean and polished appearance. This attention to detail is crucial in achieving high-quality finished products that meet stringent industry standards.

Implementing Corrective Actions

To address the issue of flashing in injection molding, Baoyuan's team implements corrective actions based on thorough analysis and problem-solving expertise. By making adjustments to mold design, injection parameters, and production processes, they effectively eliminate flash defects and ensure optimal product quality. Their proactive approach to troubleshooting flash-related issues sets them apart as industry leaders in injection molding excellence.

Baoyuan's Proficiency in Flash Defect Solutions

Baoyuan's proficiency in flash defect solutions is demonstrated through their comprehensive understanding of what causes flash in injection molding. With a focus on mold design optimization, precise control of injection pressure and speed, as well as innovative software for mold design, they consistently deliver flawless results. Their commitment to excellence extends to the removal of flash from injection molding, ensuring that every product meets the highest standards of quality.

Furthermore, Baoyuan's expertise in flash defect solutions is evident in their proactive approach to problem-solving. By conducting thorough analyses of the injection molding process, they are able to identify potential areas of weakness and implement preventative measures to minimize the occurrence of flash. This proactive mindset not only saves time and resources but also ensures a smoother production process with minimal disruptions.

Conclusion

In conclusion, Baoyuan's expertise in injection molding flash troubleshooting is unmatched. With a team of experienced professionals and advanced software for mold design and quality assurance, Baoyuan is committed to delivering excellence in injection molding. By addressing what causes flash in injection molding and implementing effective strategies for prevention and removal, Baoyuan ensures top-notch quality in every product.

Effective Strategies for Flash Troubleshooting

Baoyuan's team excels at identifying the root causes of flash defects in injection molding and implementing targeted solutions. By adjusting injection parameters, cleaning mold surfaces, and utilizing advanced software for mold design, Baoyuan effectively troubleshoots flash issues to ensure impeccable quality in every product.

Baoyuan's Commitment to Quality Injection Molding

Baoyuan's commitment to quality injection molding is evident through their dedication to preventing flash defects. Through proper venting and cooling techniques, along with stringent quality control measures, Baoyuan ensures that their single-color and double-color products meet the highest standards of excellence.

Ensuring Molding Excellence with Baoyuan's Expertise

With a focus on removing flash from injection molding through precise trimming and finishing techniques, as well as implementing corrective actions when necessary, Baoyuan's proficiency in flash defect solutions sets them apart as industry leaders. Their commitment to excellence guarantees superior results for every client.