Introduction

Polycarbonate plastic is a versatile and durable material widely used in various industries. Known for its exceptional strength and clarity, it is a popular alternative to traditional materials like glass and acrylic. With its impact resistance and flexibility, polycarbonate sheets have become a go-to choice for many applications, from construction to automotive manufacturing.

What is Polycarbonate Plastic?

Polycarbonate plastic is also known for its lightweight nature, making it easy to transport and install. This makes it an ideal choice for applications such as skylights, greenhouse panels, and safety shields. In addition, polycarbonate plastic offers UV resistance, making it suitable for outdoor use without the risk of yellowing or degradation over time. Its ability to be easily shaped and molded into various forms also adds to its appeal in multiple industries.

Benefits of Polycarbonate Plastic

Polycarbonate plastic offers many advantages, making it a popular choice across various industries. Here's a breakdown of its key benefits:

- Lightweight and Easy to Handle: Polycarbonate's low weight simplifies transportation and installation, reducing project complexity.

- High Impact Resistance: Polycarbonate is incredibly strong and can withstand significant force, making it ideal for safety applications like bulletproof glass and riot shields.

- UV Protection and Insulation: Polycarbonate sheets shield against harmful ultraviolet rays and offer excellent thermal insulation, perfect for indoor and outdoor use.

- Excellent Flexibility: Polycarbonate can be easily shaped and molded into various forms, making it versatile for diverse applications. This flexibility allows customization to fit specific construction, automotive, and medical device design needs.

Polycarbonate plastic's strength, weight, UV protection, and adaptability make it a valuable material for various applications.

Applications of Polycarbonate Plastic

Polycarbonate plastic's applications are wide-ranging. From clear plastic sheets used in skylights and greenhouse panels to durable polycarbonate panels employed in construction projects, this material has repeatedly proven its versatility. Its use in the automotive industry for vehicle windows demonstrates its reliability in demanding environments.

Polycarbonate plastic's versatility extends beyond construction and automotive applications. Due to its impact resistance and durability, it is also widely used in the manufacturing of safety glasses and protective gear. Additionally, polycarbonate plastic is utilized to produce compact discs, DVDs, and Blu-ray discs, showcasing its optical clarity and ability to transmit light effectively. Its lightweight nature makes it an ideal material for consumer electronics such as smartphones and tablets, where it protects without adding unnecessary bulk.

The Versatility of Polycarbonate Plastic

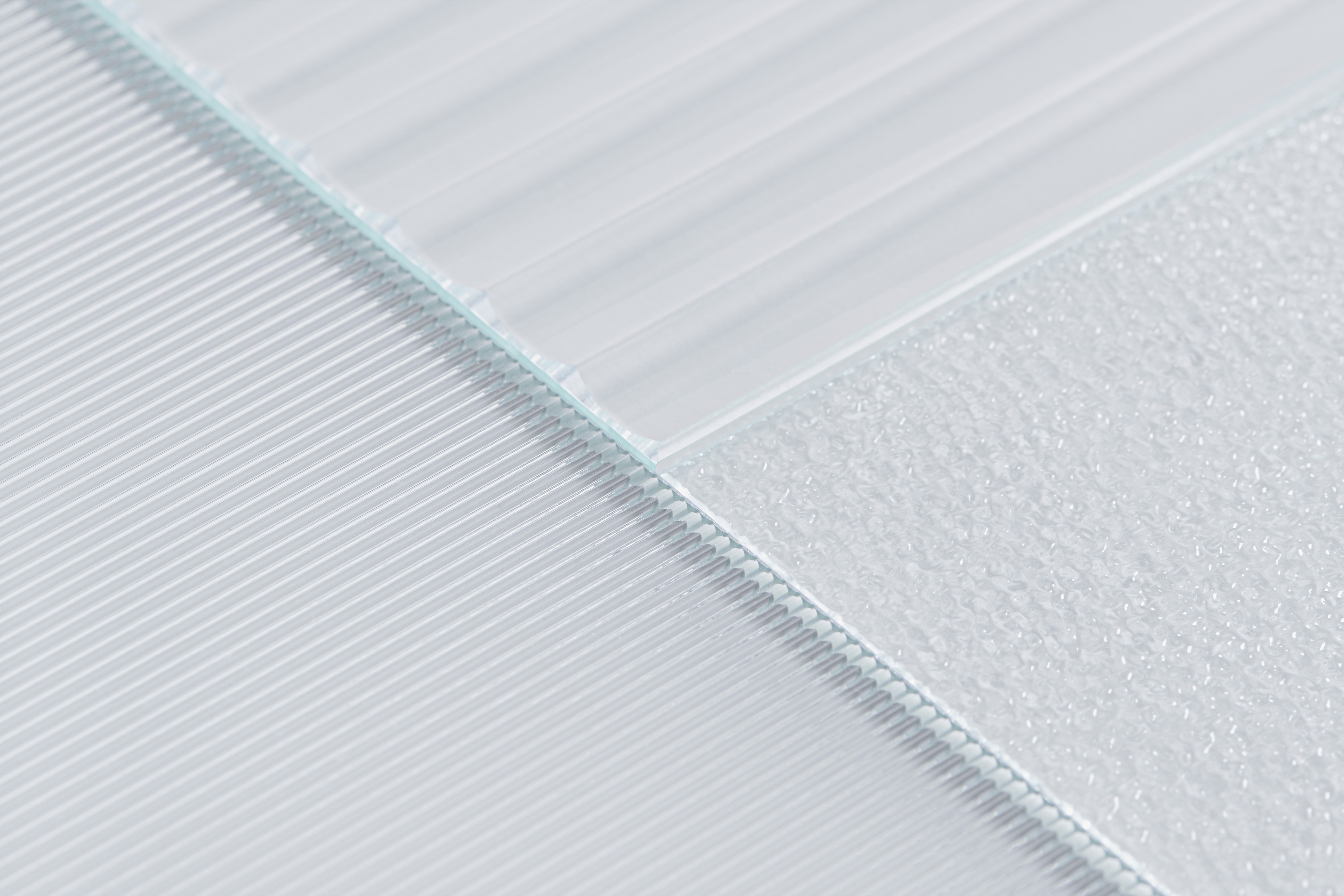

When it comes to versatility, polycarbonate plastic takes the cake. Whether you need transparent or opaque polycarbonate sheets, every application has a solution. Transparent polycarbonate panels are perfect for skylights and windows, while opaque ones provide privacy and shade for outdoor spaces. With its flexibility and durability, polycarbonate is a top choice for many projects.

Transparent vs

. Opaque Polycarbonate Sheets

Transparent polycarbonate sheets, also known as lexan sheets, offer the strength of plastic with the clarity of glass. They are lightweight and impact-resistant, ideal for architectural glazing and automotive windows. On the other hand, opaque polycarbonate sheets provide privacy and UV protection, making them great for outdoor structures like pergolas and patio covers.

Transparent polycarbonate sheets are also highly resistant to yellowing and fading, making them a long-lasting and durable option for windows and other transparent structures. Additionally, their lightweight nature makes them easy to install and work with, reducing construction projects' overall labor and cost. This combination of strength, clarity, and ease of use makes transparent polycarbonate sheets popular for various applications.

Polycarbonate Panels for Greenhouses

Polycarbonate panels offer a range of benefits for greenhouse construction, making them a superior choice for today's growers.

Here's why:

- Lightweight and Easy to Install: Polycarbonate panels are significantly lighter than traditional glass, making them easier to handle and maneuver during installation.

- High-Light Transmission: These panels allow for excellent light transmission, promoting healthy plant growth by providing sunlight for photosynthesis.

- Durable and Weather-Resistant: Polycarbonate is incredibly strong and can withstand harsh weather conditions, including hail, rain, and snow, without yellowing or deteriorating over time.

- Excellent Insulation: Polycarbonate panels provide superior insulation, helping to maintain a consistent temperature within the greenhouse, which is crucial for optimal plant growth.

- UV Protection: These panels have built-in UV protection, shielding plants from harmful rays and ensuring their health and vitality.

With their numerous advantages, polycarbonate panels are a perfect solution for creating a reliable and efficient greenhouse environment for all your plant cultivation needs.

Baoyuan's Expertise in Polycarbonate Molding

Baoyuan has mastered the art of polycarbonate molding, offering custom solutions for various industries. Their expertise in shaping and forming polycarbonate plastic, from automotive components to architectural features, sets them apart. With Baoyuan's innovative techniques, the possibilities for using polycarbonate in new ways are endless.

Baoyuan's expertise in polycarbonate molding extends beyond traditional applications, with their innovative techniques opening up new possibilities in the construction industry. Their ability to shape and form polycarbonate plastic creates durable, lightweight building materials that offer strength and flexibility. Whether using polycarbonate for roofing, cladding, or even structural elements, Baoyuan's custom solutions are revolutionizing how construction projects are approached.

Now that we've explored the versatility of polycarbonate plastic in various forms, such as transparent vs. opaque polycarbonate sheets and panels for greenhouses, and Baoyuan's expertise in polycarbonate molding, let's dive into its applications in construction!

Polycarbonate in Construction

Polycarbonate is a versatile material that offers numerous advantages in architecture. Its durability and impact resistance make it an ideal choice for building materials, providing long-lasting protection against harsh weather conditions and potential damage. Polycarbonate panels are lightweight, making them easy to transport and install, reducing construction time and costs.

Baoyuan has established itself as a leader in producing high-quality polycarbonate building materials. With a focus on innovation and sustainability, Baoyuan offers a wide range of polycarbonate sheets that meet the diverse needs of the construction industry. From transparent to opaque options, Baoyuan's products enhance architectural designs while providing superior performance.

Polycarbonate sheets for skylights are popular among architects and builders due to their exceptional light transmission properties. These clear plastic sheets allow natural light to illuminate interior spaces, creating a bright and inviting atmosphere while reducing the need for artificial lighting. Polycarbonate's versatility makes it an excellent alternative to traditional materials like acrylic glass sheets or Lexan sheets for skylight applications.

Polycarbonate Plastic in the Automotive Industry

Impact resistance is crucial in the automotive industry, and polycarbonate plastic excels in this area. Because it can withstand high impacts without shattering, polycarbonate sheets are a popular choice for automotive components.

Impact Resistance of Polycarbonate

The impact resistance of polycarbonate makes it an ideal material for automotive applications. Whether it's for headlight lenses, interior trim, or exterior body panels, polycarbonate offers superior protection against impacts and collisions on the road.

Polycarbonate's exceptional impact resistance also contributes to improved fuel efficiency in vehicles. By using polycarbonate for automotive components, manufacturers can reduce the weight of the vehicle, leading to better fuel economy. This lightweight yet durable material allows for the design of sleek and aerodynamic car parts, further enhancing the vehicle's overall performance on the road.

Baoyuan's Contributions to Automotive Polycarbonate Components

Baoyuan has been at the forefront of developing innovative polycarbonate components for the automotive industry. Their expertise in molding and shaping polycarbonate sheets has led to vehicle safety and design advancements.

Baoyuan's commitment to innovation has resulted in the development of clear plastic sheets for vehicle windows that provide unparalleled durability and impact resistance. These advanced polycarbonate sheets offer superior visibility and clarity, enhancing the overall driving experience while ensuring the safety of passengers. By revolutionizing the materials used in automotive windows, Baoyuan has set a new standard for quality and performance in the industry.

Clear Plastic Sheets for Vehicle Windows

In addition to impact resistance, clear plastic sheets made from polycarbonate are commonly used for vehicle windows. These durable and lightweight sheets provide excellent visibility while protecting against breakage and UV radiation.

Additionally, clear plastic sheets made from polycarbonate are highly resistant to scratches and abrasions, ensuring long-lasting clarity for vehicle windows. This means that drivers can enjoy unobstructed views of the road ahead without worrying about the appearance of unsightly marks on their windows. With polycarbonate sheets, drivers can confidently navigate various weather conditions without compromising visibility or safety.

Environmental Benefits of Polycarbonate

Recyclability of Polycarbonate

One of the key environmental benefits of polycarbonate is its recyclability. Polycarbonate plastic sheets can be recycled and repurposed into new products, reducing waste and promoting a circular economy. Baoyuan is committed to sustainable practices, offering recycling programs for used polycarbonate panels and clear plastic sheets to minimize environmental impact.

In addition to offering recycling programs for used polycarbonate panels and clear plastic sheets, Baoyuan also implements sustainable production practices to minimize environmental impact further. Our manufacturing processes are designed to reduce energy consumption and waste generation, ensuring that our polycarbonate products are produced with the utmost care for the environment. By prioritizing sustainability throughout our operations, we aim to set an example for the industry and inspire others to adopt similar eco-friendly practices.

Baoyuan's Sustainable Production Practices

Baoyuan takes pride in its sustainable production practices, ensuring minimal environmental impact throughout the manufacturing process of polycarbonate sheets and panels. From energy-efficient facilities to responsible waste management, Baoyuan prioritizes eco-friendly initiatives in producing polycarbonate materials.

In addition to its sustainable production practices, Baoyuan also strongly emphasizes the safety and well-being of its employees. By implementing strict safety protocols and providing ongoing training, the company ensures that its workforce is protected from potential hazards in the manufacturing process. This commitment to employee welfare further reinforces Baoyuan's dedication to responsible and ethical business practices.

Polycarbonate as an Alternative to Glass and Acrylic

Polycarbonate offers a more environmentally friendly alternative to traditional glass and acrylic glass sheets due to its durability and longevity. By choosing Lexan sheet over other materials, businesses and consumers can:

- Reduce their carbon footprint: Lexan sheets are built to last, requiring less frequent replacement than other options.

- Enjoy high-quality, long-lasting products: Polycarbonate offers superior durability and weather resistance.

- Unlock creative freedom: Its ability to be molded into various shapes and sizes allows for innovative architectural and application designs.

Lexan polycarbonate sheets are sustainable and versatile for those seeking quality and design flexibility.

Advancements in Polycarbonate Technology

When it comes to the future of polycarbonate plastic, the possibilities are endless. With ongoing advancements in polycarbonate technology, we expect even more innovative applications and products to emerge. From clear plastic sheets to polycarbonate panels, this material's versatility will continue to shape various industries for years to come.

The Future of Polycarbonate Plastic

As the demand for sustainable and durable materials grows, polycarbonate is poised to play a significant role in shaping the future of plastics. Its unique properties make it ideal for various applications, from automotive components to architectural elements.

Polycarbonate's strength, transparency, and heat resistance make it ideal for a wide range of applications. From safety goggles to bulletproof windows, its durability and impact resistance make it a popular choice for industries where safety is paramount. Its ability to be molded into complex shapes also makes it a versatile option for designers and engineers looking to push the boundaries of what is possible with plastic materials.

With continuous research and development, the potential for further enhancements in polycarbonate technology is vast. From improved impact resistance to enhanced optical clarity, manufacturers like Baoyuan are at the forefront of pushing the boundaries of what polycarbonate can achieve. As new applications for polycarbonate continue to emerge across industries such as automotive, aerospace, and electronics, Baoyuan's commitment to innovation ensures that its products remain versatile and adaptable to meet evolving demands.

Baoyuan: Leading the Way in Polycarbonate Innovation

As a leading polycarbonate molding and production manufacturer, Baoyuan's commitment to innovation has positioned them as pioneers in the industry. Their expertise in creating high-quality polycarbonate panels and clear plastic sheets has set a new standard for excellence.

Baoyuan's dedication to innovation extends beyond just the quality of its products. They are also committed to sustainability, ensuring their manufacturing processes are environmentally friendly. By investing in cutting-edge technology, Baoyuan is meeting current demands and shaping the future landscape of polycarbonate innovation. Their forward-thinking approach positions them as leaders in the industry, setting a benchmark for others to follow.

By embracing sustainable practices and investing in cutting-edge technology, Baoyuan is meeting current demands and shaping the future landscape of polycarbonate innovation. As we look ahead, it's clear that this remarkable material will continue to revolutionize various industries worldwide.