Introduction

In the world of healthcare, precision and reliability are paramount, and this is where medical injection molding comes into play. This specialized manufacturing process is crucial for producing high-quality components used in various medical devices. Understanding the intricacies of Medical Device Injection Molding can significantly impact the effectiveness and safety of healthcare products.

What is Medical Injection Molding?

Medical injection molding refers to a manufacturing technique specifically designed for creating parts from thermoplastic materials that meet stringent medical standards. This process allows for the efficient production of complex shapes and designs, making it ideal for medical-grade plastics injection molding applications. By utilizing advanced technology, medical injection molding companies can produce components that are not only precise but also consistent in quality.

Importance of Choosing the Right Company

Selecting the right medical injection molding company is critical to ensuring that your products meet regulatory requirements and perform as intended in real-world scenarios. The expertise and experience of a company can greatly influence the success of your project, from initial design to final production. A reputable partner will not only provide high-quality Medical Device Injection Molding solutions but also help navigate compliance with industry standards.

Overview of Top Players in the Industry

The market for medical-grade plastics injection molding is populated by several key players who have established themselves through innovation and quality assurance practices. Companies like Baoyuan, Medbio, and Accu-Mold stand out due to their commitment to excellence in manufacturing processes tailored specifically for healthcare applications. By examining these industry leaders, one can gain insight into what makes a successful medical injection molding company thrive.

Understanding Medical Device Injection Molding

In the world of healthcare, precision and reliability are paramount, and that's where Medical Device Injection Molding comes into play. This specialized manufacturing process allows for the creation of intricate parts used in various medical devices, ensuring that they meet stringent industry standards. By understanding the key processes and techniques involved, as well as their applications and benefits, companies can better appreciate the value of partnering with a reputable medical injection molding company.

Key Processes and Techniques

Medical-Grade Plastics Injection Molding involves several sophisticated techniques tailored to produce high-quality components. The primary method is injection molding itself, where heated plastic is injected into a mold cavity under high pressure to form specific shapes. Other techniques include blow molding for hollow products and thermoforming for creating thin-walled items—each method chosen based on the desired properties of the final product.

Moreover, advancements in technology have introduced innovative processes such as multi-shot molding, which allows for multiple materials to be combined in a single piece. This capability enhances functionality while reducing assembly time—a crucial factor in medical device manufacturing. As a result, partnering with a forward-thinking medical injection molding company can lead to cutting-edge solutions that elevate product performance.

Applications in the Medical Field

The applications of Medical Device Injection Molding are vast and varied, ranging from simple components like syringes to complex devices such as surgical instruments or diagnostic equipment. Each application demands precision engineering to ensure safety and efficacy since these devices often interact directly with patients or critical biological systems.

Furthermore, this process is essential for producing disposable items that require strict hygiene standards—think catheters or IV bags—where consistency and reliability are non-negotiable. The ability to rapidly produce large quantities without sacrificing quality makes Medical-Grade Plastics Injection Molding an invaluable asset in modern healthcare.

Benefits of Specialized Molding

Choosing specialized Medical Device Injection Molding provides numerous advantages beyond just production efficiency. First and foremost is compliance; working with a dedicated medical injection molding company ensures adherence to regulatory requirements such as ISO 13485 or FDA standards—critical factors when bringing any medical device to market.

Additionally, specialized molding offers enhanced material properties tailored specifically for medical applications; materials can be selected based on biocompatibility or resistance to sterilization methods like autoclaving or ethylene oxide treatment. Finally, collaboration with experienced manufacturers leads to innovation opportunities—new designs can be prototyped faster without compromising quality—all while keeping costs manageable.

Industry Leaders in Medical-Grade Plastics Injection Molding

In the competitive landscape of medical-grade plastics injection molding, several companies have emerged as leaders, each offering unique strengths and innovations. These industry players not only provide advanced manufacturing solutions but also contribute to the overall quality and reliability of medical devices. Understanding their expertise can help stakeholders make informed decisions when selecting a medical injection molding company.

Baoyuan's Expertise and Innovations

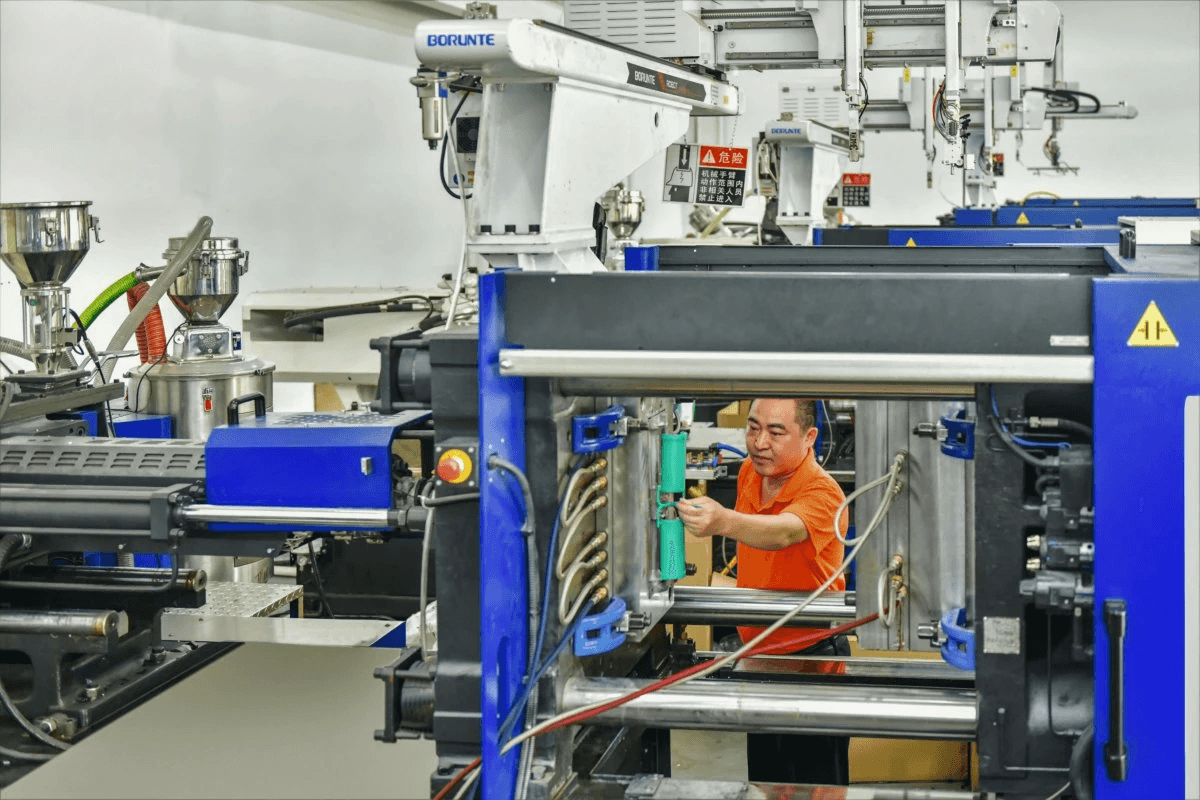

Baoyuan has positioned itself as a frontrunner in the field of Medical Device Injection Molding through its commitment to innovation and excellence. With state-of-the-art facilities and cutting-edge technology, Baoyuan specializes in producing high-precision components that meet stringent industry standards. Their expertise extends beyond mere production; they actively engage in research and development to create new materials that enhance the performance of medical devices.

The company is particularly noted for its ability to customize solutions tailored to specific client needs, ensuring that every product adheres to rigorous regulatory requirements. This adaptability makes Baoyuan a favored choice among businesses seeking a reliable medical injection molding company with extensive experience in various applications. Their innovative approach not only streamlines production but also significantly reduces time-to-market for new medical products.

Medbio’s Advanced Solutions

Medbio stands out for its advanced solutions in Medical-Grade Plastics Injection Molding, focusing on high-quality manufacturing processes that prioritize safety and efficacy. The company employs advanced techniques such as overmolding and insert molding, which allow for the creation of complex assemblies with minimal handling—crucial for maintaining sterility in medical environments. Medbio’s commitment to continuous improvement ensures they remain at the forefront of technology while meeting evolving market demands.

Moreover, Medbio emphasizes collaboration with clients throughout the product development cycle, from concept to final production. This partnership approach not only enhances design accuracy but also fosters innovation tailored specifically for each project’s requirements. By leveraging their extensive knowledge base and technological capabilities, Medbio has cemented its reputation as a leading medical injection molding company dedicated to delivering exceptional results.

Accu-Mold’s Quality Assurance Practices

Accu-Mold distinguishes itself through rigorous quality assurance practices that are pivotal in Medical Device Injection Molding operations. The company implements comprehensive testing protocols at every stage of production, ensuring that each component meets or exceeds industry standards before reaching clients’ hands. Their dedication to quality control is underscored by certifications from relevant regulatory bodies, reinforcing their status as a trusted partner in the healthcare sector.

Additionally, Accu-Mold invests heavily in employee training programs focused on best practices within the realm of Medical-Grade Plastics Injection Molding. This emphasis on skill development translates into improved efficiency and reduced error rates during manufacturing processes—a critical factor when dealing with life-saving devices where precision is paramount. As such, choosing Accu-Mold means aligning with a medical injection molding company committed not just to quality but also to fostering long-term partnerships based on trust and reliability.

Comparing Capabilities of Medical Injection Molding Companies

Technology and Equipment Used

The technology employed by a medical injection molding company significantly influences the quality and efficiency of production. Cutting-edge machinery, such as multi-cavity molds and precision CNC machines, enables companies to produce intricate designs while maintaining tight tolerances essential for medical devices. Additionally, advancements in automation and robotics are streamlining processes, reducing lead times while enhancing consistency in Medical Device Injection Molding.

Another critical aspect is the integration of advanced software solutions that facilitate real-time monitoring and data analysis during production runs. This tech-savvy approach not only boosts productivity but also ensures that any deviations from quality standards are immediately addressed. Ultimately, the right equipment can make all the difference in ensuring your products meet stringent regulatory requirements.

Customization and Flexibility in Production

Customization is a hallmark of successful medical injection molding companies, allowing clients to tailor products to their specific requirements. Whether it's adjusting dimensions or incorporating unique features into a design, flexibility can be a game-changer for manufacturers looking for specialized solutions in Medical-Grade Plastics Injection Molding. The ability to adapt quickly to changing demands without compromising quality makes a significant impact on project timelines and costs.

Moreover, many companies offer rapid prototyping services that allow clients to visualize their designs before full-scale production begins. This not only saves time but also minimizes costly mistakes down the line—an invaluable asset when working on intricate medical devices where precision is paramount. In this fast-paced industry, choosing a partner who values customization can lead to innovative breakthroughs.

Regulatory Compliance and Certifications

Navigating the labyrinth of regulatory compliance is an essential factor when evaluating any medical injection molding company. The medical device industry operates under strict guidelines set by organizations like the FDA (Food and Drug Administration) or ISO (International Organization for Standardization), making certifications a non-negotiable aspect of any manufacturing partnership. Companies with robust quality management systems ensure that every step—from design through production—adheres strictly to these regulations.

Certifications such as ISO 13485 indicate that a company has met international standards for quality management systems specifically tailored for medical devices. This level of compliance not only assures clients about product safety but also enhances marketability across various regions worldwide—essentially opening doors for global distribution opportunities in Medical Device Injection Molding markets. Therefore, when assessing potential partners, always scrutinize their certification status; it’s your first line of defense against potential pitfalls.

Factors to Consider When Choosing a Medical Injection Molding Company

When it comes to selecting a medical injection molding company, several factors should take center stage in your decision-making process. The right partner can significantly influence the quality and functionality of your medical devices, so it's crucial to weigh your options carefully. In this section, we'll explore key considerations that can guide you toward making an informed choice.

Experience and Industry Reputation

Experience is paramount when evaluating a medical injection molding company. A company with a solid track record in the Medical Device Injection Molding sector is likely to have honed its skills over time, ensuring they are well-versed in industry standards and best practices. Additionally, reputation matters; companies recognized for their reliability and innovation often stand out as leaders in Medical-Grade Plastics Injection Molding.

A seasoned provider not only brings technical expertise but also an understanding of regulatory requirements that can affect product development timelines. Their experience often translates into fewer production hiccups and better outcomes for your medical devices. Therefore, don’t hesitate to dig into their history—ask about previous projects or partnerships within the field.

Client Testimonials and Case Studies

Client testimonials are more than just fluff—they provide real insight into how a medical injection molding company operates on a day-to-day basis. Positive feedback from previous clients can indicate that the company delivers consistent results while maintaining strong communication throughout the project lifecycle. Additionally, case studies showcasing successful collaborations offer tangible proof of their capabilities in Medical Device Injection Molding.

Look for testimonials that highlight specific challenges faced during production and how the company overcame them; this will give you an idea of their problem-solving abilities under pressure. Moreover, consider reaching out directly to past clients for candid discussions about their experiences—this firsthand information can be invaluable when making your choice.

Cost vs. Quality Analysis

Navigating the landscape of cost versus quality is crucial when selecting a medical injection molding company. While it might be tempting to opt for the lowest bid, remember that compromising on quality could lead to larger expenses down the line due to recalls or product failures in critical applications like healthcare devices. Balancing cost with quality ensures you receive reliable products without breaking the bank.

A thorough analysis involves not just looking at upfront costs but also considering long-term value—think durability, compliance with regulations, and overall performance of your Medical-Grade Plastics Injection Molding solutions over time. Engaging multiple companies for quotes can help you gauge market rates while allowing you to assess which providers offer competitive pricing alongside high-quality service.

Future Trends in Medical Device Injection Molding

The landscape of Medical Device Injection Molding is evolving rapidly, driven by innovations in technology and changing market demands. As the healthcare industry continues to grow, so does the need for advanced solutions from a reliable medical injection molding company. Understanding these future trends will be crucial for stakeholders aiming to stay competitive and meet regulatory standards.

Advancements in Material Science

Material science is at the forefront of revolutionizing Medical-Grade Plastics Injection Molding processes. New polymers and composites are being developed that not only enhance the performance of medical devices but also improve patient safety and comfort. These advancements allow medical injection molding companies to create products that are lighter, stronger, and more resistant to sterilization processes.

Moreover, innovative materials can lead to cost savings and increased efficiency in production cycles, making it an attractive option for manufacturers. This push towards advanced materials not only enhances product functionality but also opens doors for more complex designs that were previously unattainable with traditional materials. As a result, companies specializing in Medical Device Injection Molding must continuously adapt their strategies to incorporate these cutting-edge materials into their offerings.

Increased Demand for Biocompatible Products

With rising awareness regarding patient safety and environmental health, there’s an increasing demand for biocompatible products within the realm of Medical Device Injection Molding. Manufacturers are now prioritizing materials that do not elicit adverse reactions when used within the human body, thereby expanding their product lines to include safer alternatives. The focus on biocompatibility is transforming how medical injection molding companies approach design and material selection.

This trend is particularly significant as regulatory bodies tighten guidelines around what constitutes acceptable materials for medical devices. Companies that can demonstrate expertise in biocompatible solutions will have a competitive edge over others who may lag behind in this critical area of compliance and innovation. Ultimately, this shift towards biocompatibility reflects a broader commitment within the industry to prioritize patient well-being while maintaining high-quality manufacturing standards.

Sustainability Initiatives in Manufacturing

Sustainability has become a buzzword across various industries, including Medical-Grade Plastics Injection Molding, where eco-friendly practices are increasingly prioritized by consumers and regulators alike. Many medical injection molding companies are now adopting sustainable manufacturing techniques such as recycling scrap material or utilizing energy-efficient machinery to reduce their carbon footprint. This not only helps protect the environment but also appeals to clients looking for responsible partners.

Furthermore, there is a growing trend toward using biodegradable or recyclable materials in medical device production—a move that aligns with global sustainability goals while still meeting stringent quality requirements essential for healthcare applications. As more organizations recognize the importance of sustainability initiatives, those involved in Medical Device Injection Molding will find themselves under pressure to innovate while keeping ecological considerations at the forefront of their operations.

In conclusion, staying ahead of these trends requires vigilance from both manufacturers and clients alike who rely on them for high-quality products tailored specifically for healthcare needs—after all, quality should never be compromised when it comes to patient care!

Conclusion

In summary, selecting the right medical injection molding company is crucial for the success of any medical device project. With a plethora of options available, understanding the nuances of Medical Device Injection Molding can significantly influence outcomes. By focusing on key factors such as expertise, technology, and regulatory compliance, stakeholders can make informed decisions that enhance product quality and reliability.

Key Takeaways on Company Selection

When choosing a medical injection molding company, prioritize their experience in Medical-Grade Plastics Injection Molding and their reputation within the industry. Look for proven track records through client testimonials and case studies that highlight successful projects and innovative solutions. Remember that while cost is an important factor, it should never overshadow the significance of quality—after all, lives depend on these devices!

The Impact of Quality on Medical Devices

Quality in Medical Device Injection Molding directly affects not only product performance but also patient safety. High-quality molds ensure precision manufacturing, which minimizes defects and enhances device functionality. In an industry where failure is not an option, partnering with a reliable manufacturer can mean the difference between success and catastrophic results.

Looking Ahead: The Future of Medical Injection Molding

The future of medical injection molding looks promising with advancements in material science paving the way for innovative solutions in healthcare technology. As demand for biocompatible products rises, companies will need to adapt their processes to meet these evolving standards while also embracing sustainability initiatives within manufacturing practices. By staying ahead of trends and investing in cutting-edge technologies, medical injection molding companies will continue to play a pivotal role in shaping the future landscape of healthcare.