Introduction

When it comes to manufacturing plastic products, HDPE injection molding has become the go-to choice for many industries. The benefits of using high-density polyethylene (HDPE) in injection molding processes are numerous, making it a popular material for a wide range of applications. As the demand for HDPE molding continues to grow, companies like Baoyuan have established themselves as experts in the field, providing top-notch solutions for clients seeking high-quality plastic products.

Benefits of HDPE Injection Molding

One of the key advantages of HDPE injection molding is its ability to produce durable and lightweight plastic products that offer excellent impact resistance and strength. This makes it an ideal choice for applications where durability is crucial, such as in automotive components, packaging materials, and consumer goods.

Growing Demand for HDPE Molding

With the increasing focus on sustainable and eco-friendly manufacturing practices, there has been a surge in demand for HDPE molding. Its recyclability and reduced carbon footprint make it an attractive option for businesses looking to minimize their environmental impact while still delivering high-quality products to their customers.

Baoyuan's Expertise in HDPE Injection Molding

As a leading manufacturer specializing in polyethylene injection molding, Baoyuan has honed its expertise in producing top-tier HDPE plastic products. With state-of-the-art facilities and a team of skilled professionals, Baoyuan is well-equipped to meet the growing demand for high-density polyethylene injection molding solutions.

Cost-Efficiency of HDPE Injection Molding

Reduced Production Costs

When it comes to HDPE injection molding, one of the key advantages is the reduced production costs. The high flow properties of HDPE allow for faster injection molding cycles, resulting in lower energy consumption and reduced material waste. This ultimately leads to significant cost savings for manufacturers.

In addition to the immediate cost savings, the reduced production costs associated with HDPE injection molding also lead to long-term benefits for manufacturers. By optimizing energy consumption and minimizing material waste, companies can enjoy sustainable cost savings over time. This not only contributes to a healthier bottom line but also aligns with environmentally friendly practices, enhancing the overall reputation of the business.

Long-Term Cost Savings

In addition to reduced production costs, HDPE injection molding offers long-term cost savings due to the durability and longevity of HDPE plastic products. With its exceptional resistance to chemicals, moisture, and impact, HDPE products require minimal maintenance and replacement, saving businesses money over time.

Furthermore, the strength and flexibility of HDPE plastic products make them ideal for a wide range of applications, reducing the need for multiple materials and components. This versatility not only streamlines production processes but also minimizes the risk of product failure or breakage, ultimately saving businesses from costly repairs or replacements. Additionally, the lightweight nature of HDPE products reduces shipping costs and fuel consumption, contributing to overall long-term cost savings for businesses.

Baoyuan's Competitive Pricing

At Baoyuan, we understand the importance of cost-efficiency for our clients. That's why we offer competitive pricing for our HDPE injection molding services without compromising on quality. Our streamlined manufacturing processes and expertise in working with HDPE ensure that our clients receive top-notch products at a competitive price point.

Additionally, we pride ourselves on the durability of our HDPE plastic products. Our materials are known for their resistance to chemicals, corrosion, and impact, making them ideal for a wide range of applications. Whether our clients need components for automotive, medical, or consumer goods industries, they can trust that our HDPE products will stand the test of time.

Durability of HDPE Plastic Products

Strength and Impact Resistance

When it comes to durability, HDPE plastic products are unmatched in their strength and impact resistance. The high density polyethylene used in injection molding results in products that can withstand heavy use and harsh environments without cracking or breaking. This makes them ideal for applications where durability is crucial, such as automotive components, industrial containers, and outdoor furniture.

In addition to their exceptional strength and impact resistance, HDPE plastic products also boast an extended product lifespan. This means that they can endure years of heavy use without showing signs of wear and tear, making them a cost-effective choice for businesses and consumers alike. Whether it's a durable automotive component or a long-lasting outdoor furniture piece, HDPE plastic products are designed to stand the test of time.

Extended Product Lifespan

The durability of HDPE plastic products also translates into an extended product lifespan. Unlike other materials that may degrade over time, HDPE molding ensures that the products retain their structural integrity and functionality for longer periods. This not only reduces the need for frequent replacements but also contributes to cost savings and resource conservation in the long run.

Furthermore, the extended product lifespan of HDPE plastic products means less waste and a reduced environmental impact. With fewer replacements needed, there is less disposal of old products, leading to a decrease in landfill usage and overall pollution. This aligns with Baoyuan's commitment to sustainability and eco-friendly practices, making HDPE products a responsible choice for businesses and consumers alike.

Baoyuan's Quality Assurance for HDPE Products

At Baoyuan, we understand the importance of consistency and reliability in our HDPE products. That's why we have implemented strict quality control measures to ensure that each and every item that leaves our facility is of the highest standard. From raw material inspection to final product testing, we leave no stone unturned in our pursuit of perfection. You can have peace of mind knowing that when you choose Baoyuan, you are choosing quality you can rely on.

Versatility of HDPE Molding

HDPE injection molding offers a wide range of product applications, from packaging and containers to automotive components and toys. Its versatility makes it an ideal choice for various industries, providing durable and cost-effective solutions for different needs.

Wide Range of Product Applications

With its excellent strength, chemical resistance, and durability, HDPE plastic injection molding is commonly used in the production of bottles, caps, and closures for the food and beverage industry. It is also utilized in the manufacturing of industrial drums, crates, and pallets due to its ability to withstand heavy loads and harsh environments.

In addition to these applications, HDPE plastic injection molding is also commonly used in the production of automotive components such as fuel tanks, bumpers, and fenders. Its ability to withstand impact and harsh weather conditions makes it an ideal material for these critical parts. Furthermore, HDPE is often chosen for the manufacturing of household products such as toys, hangers, and storage containers due to its lightweight nature and resistance to chemicals.

Customization Options

HDPE molding allows for customization options to meet specific design requirements. Whether it's color matching, surface textures, or intricate designs, HDPE injection molding can be tailored to create unique products that stand out in the market.

With Baoyuan's expertise in custom mold design, clients can expect innovative solutions that push the boundaries of what is possible with HDPE injection molding. Our team of experienced engineers and designers are well-versed in creating complex and intricate designs that add value to the final product. By leveraging advanced technology and techniques, we can bring unique concepts to life, helping our clients differentiate their products in a competitive market.

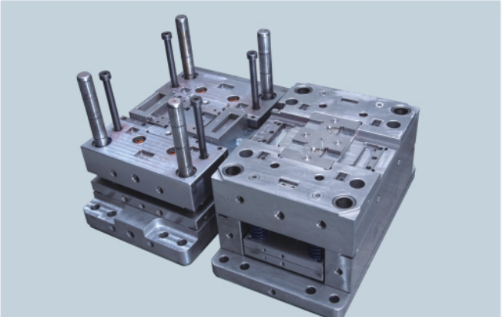

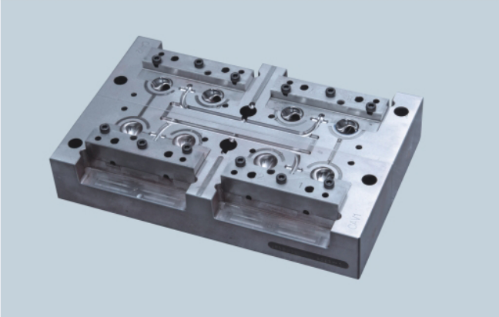

Baoyuan's Expertise in Custom Mold Design

Baoyuan has extensive experience in custom mold design for HDPE injection molding. Their team of skilled engineers can work closely with clients to develop molds that precisely fit their product specifications. This expertise ensures that each product is manufactured with precision and consistency.

Environmental Benefits of HDPE Injection Molding

Recyclability of HDPE

One of the key environmental benefits of HDPE injection molding is the material's high recyclability. HDPE plastic can be easily recycled and reused, reducing the amount of waste that ends up in landfills. This not only helps to conserve resources but also minimizes environmental impact, making it a sustainable choice for various industries.

In addition to its high recyclability, HDPE injection molding also offers the advantage of a reduced carbon footprint. By using recycled HDPE plastic in manufacturing processes, companies can significantly lower their greenhouse gas emissions and energy consumption. This not only helps to combat climate change but also contributes to a more sustainable and eco-friendly production model. As a result, HDPE injection molding stands out as an environmentally responsible choice for businesses looking to minimize their environmental impact.

Reduced Carbon Footprint

HDPE injection molding offers a significant advantage in terms of reducing carbon footprint compared to other materials. The production process for HDPE involves lower energy consumption and greenhouse gas emissions, contributing to a more eco-friendly manufacturing method. By choosing HDPE molding, companies can play their part in mitigating climate change and promoting environmental responsibility.

Baoyuan's Commitment to Sustainable Practices

At Baoyuan, we are dedicated to sustainable practices in our HDPE injection molding processes. We prioritize the use of recycled materials whenever possible and employ energy-efficient manufacturing techniques to minimize our environmental impact. Our commitment to sustainability extends beyond production, as we actively seek out opportunities to support eco-friendly initiatives within our industry.

In addition to our focus on using recycled materials and energy-efficient manufacturing techniques, we are also committed to reducing waste in our production processes. By implementing lean manufacturing principles, we strive to minimize material and resource waste while maintaining high-quality standards. This not only benefits the environment but also allows us to offer cost-effective solutions to our customers.

High-Quality Production with HDPE Molding

Consistency in Product Quality

At Baoyuan, we take pride in the consistent quality of our HDPE plastic products. Our state-of-the-art injection molding process ensures that each item meets the highest standards for strength, durability, and precision. Whether it's a small component or a large industrial part, you can rely on us for reliable and uniform quality every time.

Baoyuan's Skilled Technical Personnel

Our team of skilled technical personnel is dedicated to delivering excellence in HDPE injection molding. With years of experience and expertise in polyethylene injection molding, they are well-equipped to handle complex projects and ensure the highest level of craftsmanship. Their attention to detail and commitment to perfection set us apart from the competition.

Our team's expertise extends to superior mold design and injection techniques, ensuring that every project is executed with precision and efficiency. By staying abreast of the latest industry developments and innovations, our skilled technical personnel are able to implement cutting-edge methods that result in high-quality finished products. From initial design to final production, we prioritize excellence at every stage of the injection molding process.

Superior Mold Design and Injection Techniques

When it comes to mold design and injection techniques, Baoyuan leads the way with innovative solutions that maximize efficiency and precision. We utilize cutting-edge technology and advanced methods to create molds that deliver superior results for our clients' specific needs. From intricate designs to large-scale production runs, our capabilities are unmatched in the industry.

Our team of experienced engineers and designers are constantly pushing the boundaries of mold design and injection techniques, staying ahead of industry trends and technological advancements. By staying at the forefront of innovation, we are able to offer our clients the most cutting-edge solutions for their specific needs. This dedication to continuous improvement sets us apart from our competitors and ensures that our clients receive the highest quality molds available.

Conclusion

When considering your next project, choosing HDPE injection molding is a no-brainer. Its cost-efficiency, durability, versatility, environmental benefits, and high-quality production make it the ideal choice for a wide range of applications. Baoyuan's commitment to excellence in HDPE molding ensures that your project will be in good hands.

Choosing HDPE Injection Molding for Your Next Project

With its numerous advantages, including cost-efficiency and durability, HDPE injection molding is the perfect solution for your next project. Whether you need custom mold design or a wide range of product applications, HDPE molding can meet your needs effectively and efficiently.

Baoyuan's Commitment to Excellence in HDPE Molding

Baoyuan's expertise in polyethylene injection molding is unmatched. With skilled technical personnel and superior mold design and injection techniques, Baoyuan ensures high-quality production that meets the highest standards.

Benefits of Partnering with Baoyuan for HDPE Injection Molding

By partnering with Baoyuan for your HDPE injection molding needs, you can expect nothing less than excellence. From reduced production costs to environmental sustainability, Baoyuan's commitment to delivering top-notch results makes them the perfect partner for all your HDPE plastic injection molding projects.