Introduction

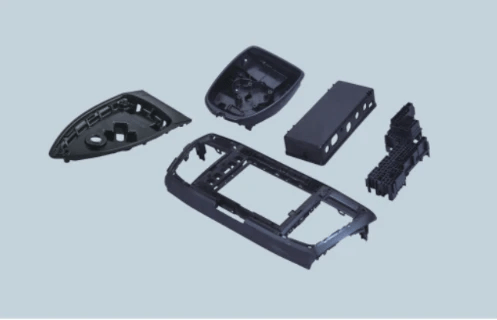

In plastic manufacturing, the choice of injection molding materials is crucial for efficiency and environmental impact. As companies seek to minimize their carbon footprint, the demand for sustainable injection moldable plastics has never increased. Baoyuan stands out as a leader in this field, with a proven track record of expertise in sustainable injection molding.

Exploring Sustainable Injection Molding Materials

Exploration of sustainable injection molding materials is essential for reducing the environmental impact of plastic manufacturing. As the industry evolves, there is a growing focus on finding innovative alternatives to traditional plastic injection molding. Baoyuan has been at the forefront of this exploration, continuously developing new and eco-friendly options for injection molding plastic.

Understanding the Importance of Eco-Friendly Choices

Plastic injection molding plays a crucial role in modern manufacturing, but its environmental impact has become a growing concern. By adopting eco-friendly practices, companies can contribute to a more sustainable future. Baoyuan's dedication to sustainability is evident in its commitment to the following:

- Utilizing recycled materials: Incorporating recycled plastics into production processes reduces the demand for virgin materials and minimizes waste.

- Implementing energy-efficient technologies: Baoyuan invests in advanced machinery and equipment that optimize energy consumption, lowering its carbon footprint.

- Promoting sustainable packaging: The company encourages using recyclable and biodegradable packaging solutions to minimize environmental impact throughout the product lifecycle.

- Adhering to strict quality control: Baoyuan's commitment to quality ensures that products meet high standards while minimizing defects and reducing waste.

Through these initiatives, Baoyuan demonstrates its leadership in eco-friendly plastic injection molding. By prioritizing sustainability, the company is paving the way for a greener and more responsible future for the industry.

Baoyuan's Expertise in Sustainable Injection Molding

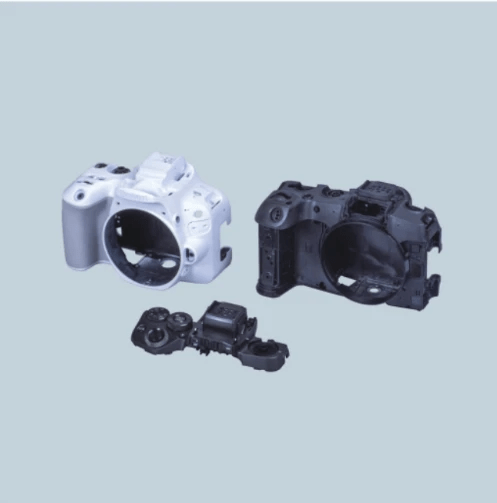

Baoyuan's expertise in sustainable injection molding is evident through its dedication to utilizing environmentally friendly materials and processes. Its investment in research and development has led to cutting-edge solutions that prioritize sustainability without compromising quality or performance. With Baoyuan's leadership, it's clear that sustainable injection molding is not just an option but a necessity for the future.

Bioplastics

Bioplastics are revolutionizing the world of plastic injection molding, offering a range of advantages that traditional plastics can't match. With biodegradable options, we can reduce the environmental impact of plastic manufacturing while still maintaining high-quality products. Baoyuan's innovative bioplastic solutions lead the way in sustainable injection molding materials, providing eco-friendly alternatives without sacrificing performance or durability.

Advantages of Biodegradable Options

Biodegradable bioplastics present a promising solution to the global plastic pollution crisis.

Key Benefits of Biodegradable Bioplastics:

- Environmental Sustainability: Biodegradable bioplastics decompose naturally, minimizing their impact on landfills and oceans.

- Renewable Resource Utilization: These materials are derived from sustainable sources like corn starch or sugarcane, reducing dependence on fossil fuels.

- Reduced Plastic Waste: Manufacturers can contribute to a cleaner and healthier planet by opting for biodegradable alternatives.

Adopting biodegradable bioplastics is a crucial step towards a more sustainable future. By incorporating these materials into their production processes, manufacturers can significantly mitigate the environmental consequences of traditional plastic use.

Baoyuan's Innovative Bioplastic Solutions

At Baoyuan, we understand the importance of eco-friendly choices in plastic manufacturing, which is why we have developed cutting-edge bioplastic solutions that meet the highest standards for quality and performance. Our expertise in mold plastic injection allows us to create innovative materials that benefit the environment and provide exceptional results for our clients. With our commitment to sustainability, we are proud to offer a wide range of bioplastic options for various applications.

Impact of Bioplastics on Environmental Sustainability

Bioplastics are emerging as a sustainable alternative to traditional plastics, offering a promising solution to the environmental challenges posed by plastic waste.

Benefits of Using Bioplastics in Plastic Injection Molding:

- Reduced Carbon Footprint: Bioplastics are often derived from renewable resources, such as plant-based materials, which can significantly lower greenhouse gas emissions than traditional petroleum-based plastics.

- Minimized Reliance on Non-Renewable Resources: Manufacturers can reduce their dependence on fossil fuels by utilizing bioplastics, contributing to a more sustainable and resilient supply chain.

- Combatting Plastic Pollution: Biodegradable bioplastics have the potential to decompose naturally in specific environments, reducing the accumulation of plastic waste in landfills and oceans.

- Enhanced Environmental Sustainability: Adopting bioplastics in plastic injection molding aligns with the growing emphasis on circular economy principles and sustainable practices, promoting a healthier planet for future generations.

The transition to bioplastics in plastic injection molding represents a crucial step towards a more sustainable and environmentally responsible manufacturing landscape. By embracing this innovative material, manufacturers can play a vital role in mitigating the environmental impact of plastic waste and contributing to a cleaner and healthier planet.

Recycled Polypropylene

Recycled polypropylene offers many benefits for injection molding materials. Reusing plastic reduces the need for virgin plastic production, conserving resources and energy. Baoyuan is fully committed to utilizing recycled polypropylene in its injection-moldable plastics, demonstrating its dedication to sustainable practices in plastic manufacturing. The environmental impact of using recycled injection molding materials is significant, as it helps decrease the amount of plastic waste in landfills and minimizes carbon emissions associated with traditional plastic production.

Benefits of Reusing Plastic Materials

Reusing plastic materials through recycled polypropylene reduces the environmental footprint and contributes to cost savings in the production process. By incorporating recycled materials into injection-mold plastic injection, manufacturers can lower their raw material expenses while promoting a circular economy. This approach aligns with Baoyuan's sustainability goals and commitment to responsible plastic molding practices.

Baoyuan's Commitment to Recycled Polypropylene

Baoyuan's dedication to sustainable practices is evident in its strong commitment to using recycled polypropylene in its plastic manufacturing processes. It actively seeks out opportunities to incorporate recycled materials into its injection molding operations, showcasing a proactive approach to environmental stewardship within the industry.

Environmental Impact of Recycled Injection Molding Materials

Using recycled polypropylene for injection molding has a positive environmental impact by reducing the demand for new plastic production and diverting waste from landfills. This approach significantly decreases the carbon footprint associated with traditional plastic manufacturing processes, making it an essential step toward achieving greater sustainability in the industry.

Polylactic Acid (PLA)

Properties and Applications of PLA

Polylactic Acid (PLA) is a biodegradable and bioactive thermoplastic derived from renewable resources like corn starch or sugarcane. Due to its versatility, high strength, and heat resistance, PLA is widely used in injection molding materials. It is also commonly found in packaging, disposable tableware, medical implants, and 3D printing applications.

Baoyuan's Expertise in PLA Injection Molding

Baoyuan has established itself as a leader in plastic injection molding by harnessing PLA's potential as an eco-friendly alternative to traditional plastics. With state-of-the-art equipment and a team of skilled professionals, Baoyuan offers precision molding solutions for various industries using PLA materials. Their expertise ensures high-quality products while reducing environmental impact.

Advancing Sustainability Through PLA Use in Manufacturing

By utilizing PLA injection-moldable plastics, manufacturers can significantly reduce their carbon footprint and contribute to environmental sustainability. Using PLA in plastic manufacturing not only decreases reliance on non-renewable resources but also promotes the adoption of eco-friendly alternatives across various industries. Embracing the potential of PLA is a step towards building a greener future for injection molding.

Hemp Plastics

Hemp plastics are revolutionizing the world of injection molding materials. With their lightweight and durable properties, hemp-based materials are gaining traction in plastic manufacturing. Baoyuan has been at the forefront of pioneering work with hemp plastic, leveraging its eco-friendly and renewable nature to create innovative injection-moldable plastics that are both sustainable and high-performing.

Harnessing the Potential of Hemp-Based Materials

Hemp plastics offer a promising alternative to traditional injection molding materials, providing a renewable and biodegradable option for plastic manufacturing. Baoyuan recognizes the potential of hemp-based materials in creating moldable plastics that meet industry standards while reducing environmental impact. By harnessing the versatile properties of hemp, Baoyuan is leading the way in utilizing this eco-friendly material for injection molding.

Baoyuan's Pioneering Work with Hemp Plastic

Baoyuan's commitment to sustainability extends to its pioneering work with hemp plastic, which is pushing the boundaries of what is possible in injection-moldable plastics. Through extensive research and development, Baoyuan has successfully incorporated hemp-based materials into its injection molding processes, demonstrating its dedication to innovation and environmental responsibility.

Environmental and Economic Benefits of Hemp-Based Injection Molding

Hemp-based injection molding materials offer several benefits for both the environment and manufacturers. Here are just a few:

- Reduced carbon footprint: Hemp plastics have a lower carbon footprint than traditional petroleum-based plastics, making them an attractive choice for companies looking to reduce their environmental impact.

- Enhanced brand image: As consumer demand for sustainable products grows, hemp-based materials can help companies improve their brand image and appeal to eco-conscious consumers.

- Economic advantages: Hemp-based injection molding can offer manufacturers economic advantages, such as reduced material costs and increased efficiency.

Hemp-based injection molding materials are a sustainable and economical solution that can benefit both the environment and manufacturers. If you are looking for ways to reduce your company's environmental impact and improve your brand image, hemp-based materials may be a good option.

Polyhydroxyalkanoates (PHA)

Polyhydroxyalkanoates (PHA) are a group of biodegradable polymers derived from renewable resources such as plant oils and sugars. These materials offer a sustainable alternative to traditional plastics, as they can be easily broken down by microorganisms in the environment, reducing the impact of plastic waste. Baoyuan has been at the forefront of PHA material development, leveraging its expertise in injection moldable plastics to create eco-friendly solutions for various industries.

Exploring the Biodegradable Properties of PHA

The biodegradable properties of PHA make it an attractive option for injection molding materials, as it helps address the growing concern over plastic pollution. Unlike conventional plastics, microorganisms can break PHA into natural components, reducing its environmental impact. This makes it an ideal choice for companies looking to minimize their carbon footprint and contribute to a cleaner, greener future.

Baoyuan's Role in PHA Material Development

Baoyuan has been actively involved in developing and refining PHA materials for injection molding applications. Their commitment to sustainable manufacturing has led them to explore innovative ways to harness the potential of PHA, creating high-quality mold plastic injection solutions that meet industry standards while prioritizing environmental responsibility.

Sustainable Manufacturing with PHA Injection Molding

By utilizing PHA injection molding materials, manufacturers can significantly reduce their reliance on non-renewable resources and minimize their contribution to plastic waste accumulation. Baoyuan's expertise in this area enables them to offer sustainable solutions that meet their client's needs and promote a more environmentally conscious approach to plastic manufacturing.

Eco-Friendly Polyethylene

Innovations in environmentally friendly polyethylene have revolutionized the world of plastic injection molding. With a focus on sustainable practices, companies like Baoyuan are leading the way in utilizing eco-friendly polyethylene for injection-moldable plastics. By incorporating recycled and bio-based polyethylene into its plastic manufacturing processes, Baoyuan is reducing its carbon footprint and promoting environmental sustainability.

Innovations in Environmentally-Friendly Polyethylene

The development of environmentally friendly polyethylene has brought about a significant shift in the plastic injection molding industry. Companies are now able to create high-quality injection-moldable plastics using sustainable polyethylene materials that offer the same level of performance as traditional options. These innovations have opened up new possibilities for eco-conscious manufacturers looking to reduce their environmental impact without compromising quality.

Baoyuan's Utilization of Sustainable Polyethylene

Baoyuan has been at the forefront of utilizing sustainable polyethylene in its plastic manufacturing processes. By incorporating recycled and bio-based polyethylene into its injection molding materials, it offers eco-friendly solutions without sacrificing performance or durability. This commitment to sustainability sets Baoyuan apart as a leader in the industry, demonstrating that it is possible to achieve both environmental responsibility and exceptional product quality.

Reducing Carbon Footprint through Eco-Friendly Injection Molding Materials

Through its use of eco-friendly polyethylene, Baoyuan is actively reducing its carbon footprint and contributing to a greener future for plastic injection molding. By choosing sustainable materials for mold plastic injection, companies can significantly impact environmental sustainability while still meeting their production needs. The shift towards eco-friendly injection molding materials represents a positive step forward for the industry, promoting responsible manufacturing practices and paving the way for a more sustainable future.

Bamboo Composites

Bamboo composites offer sustainable advantages in injection molding materials, providing a renewable and biodegradable alternative to traditional plastics. Baoyuan's expertise in bamboo composite injection molding showcases its commitment to eco-friendly solutions, promoting sustainable manufacturing with these innovative materials.

Baoyuan has harnessed the sustainable advantages of bamboo-based composites, utilizing their strength and durability to create environmentally friendly injection-moldable plastics. These materials offer a renewable solution for plastic manufacturing, reducing the reliance on non-renewable resources and minimizing environmental impact.

With its expertise in bamboo composite injection molding, Baoyuan is at the forefront of promoting sustainability in manufacturing. By embracing these innovative materials, companies can reduce their carbon footprint and contribute to a greener future for injection molding processes.

Baoyuan's Leadership in Eco-Friendly Materials

In conclusion, sustainable injection molding materials are crucial for the future of plastic manufacturing. By making informed choices and embracing eco-friendly options, companies can reduce their carbon footprint and contribute to a greener future. Baoyuan's leadership in developing innovative and environmentally friendly injection moldable plastics sets the standard for the industry, paving the way for a more sustainable approach to plastic injection molding.

Making Informed Choices for Sustainable Injection Molding

Companies must prioritize sustainable injection molding materials in their manufacturing processes. By choosing biodegradable and recycled options, they can minimize their environmental impact and contribute to a healthier planet. Baoyuan's expertise in this area provides valuable guidance for making informed decisions that benefit businesses and the environment.

Baoyuan's commitment to developing eco-friendly injection-moldable plastics showcases its dedication to sustainability. Its innovative solutions, such as bioplastics, recycled polypropylene, and bamboo composites, demonstrate its leadership in creating environmentally responsible materials for plastic manufacturing. With Baoyuan at the forefront of this movement, the industry is poised to make significant strides towards a greener future.

Embracing a Greener Future in Injection Molding

As companies increasingly embrace eco-friendly alternatives in plastic molding, they contribute to a more sustainable future for injection molding materials. Manufacturers can actively reduce their environmental impact by adopting Baoyuan's pioneering work with hemp plastics, PHA materials, and sustainable polyethylene while still meeting production demands. Embracing these advancements will lead to a brighter and more environmentally-conscious era of plastic manufacturing.