Introduction

When it comes to the automotive industry, quality and innovation are paramount, and that's where top automotive injection molding companies come into play. These companies specialize in producing high-quality injection molded car components that are essential for the functionality and aesthetics of modern vehicles. As key players in the auto parts manufacturer industry, they have revolutionized foam injection molding and plastic injection mold technologies to meet the demands of the ever-evolving automotive sector.

Introduction to Top Automotive Injection Molding Companies

The world of automotive injection molding is dominated by a select group of companies known for their expertise in producing top-notch car components. These companies have mastered the art of foam injection molding and plastic injection mold, setting new standards for quality and durability in the industry. They play a crucial role in shaping the future of automotive design and engineering.

The Importance of Injection Molded Car Components

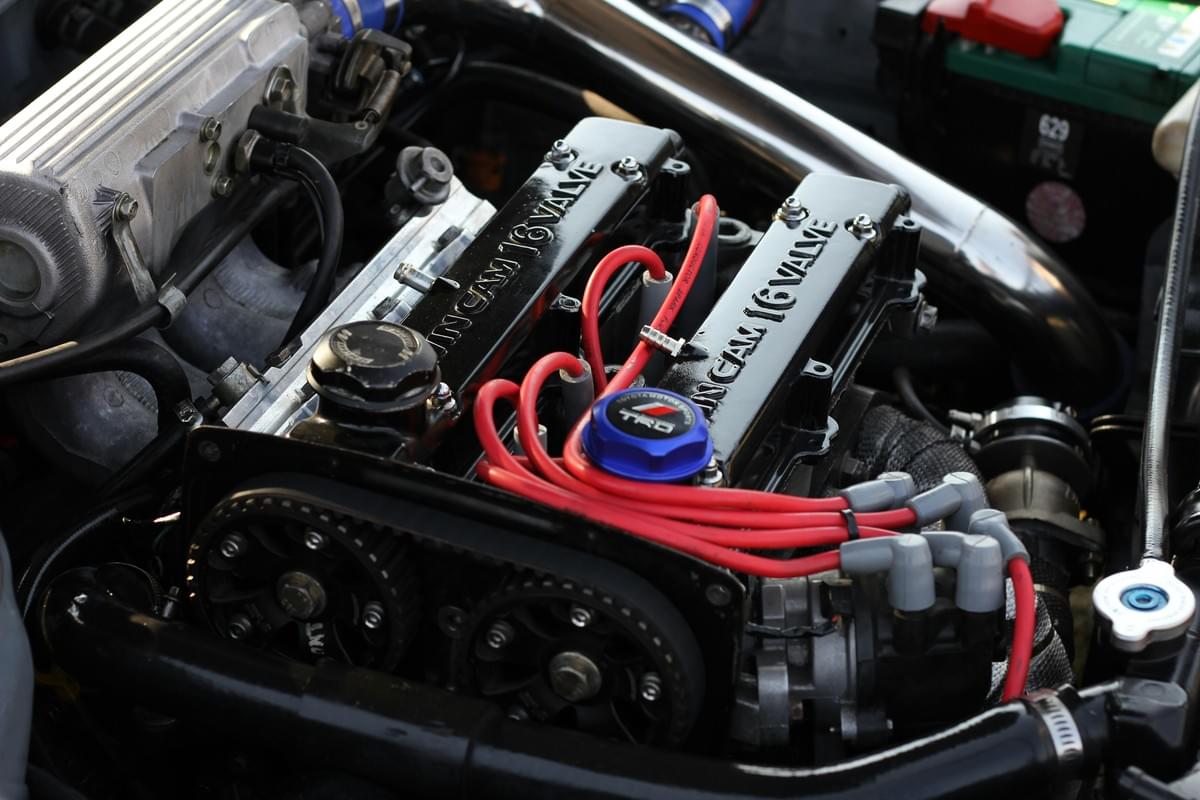

Injection molded car components are integral to the structural integrity, safety, and performance of modern vehicles. From interior trims to under-the-hood parts, these components produced by automotive plastic injection molding companies contribute significantly to the overall functionality and aesthetics of automobiles.

Overview of Auto Parts Manufacturers

Auto parts manufacturers are at the forefront of developing innovative solutions for automotive injection mold and plastic parts molding. Their commitment to excellence has led to groundbreaking advancements in foam injection molding technology, paving the way for more efficient and sustainable manufacturing processes.

Baoyuan

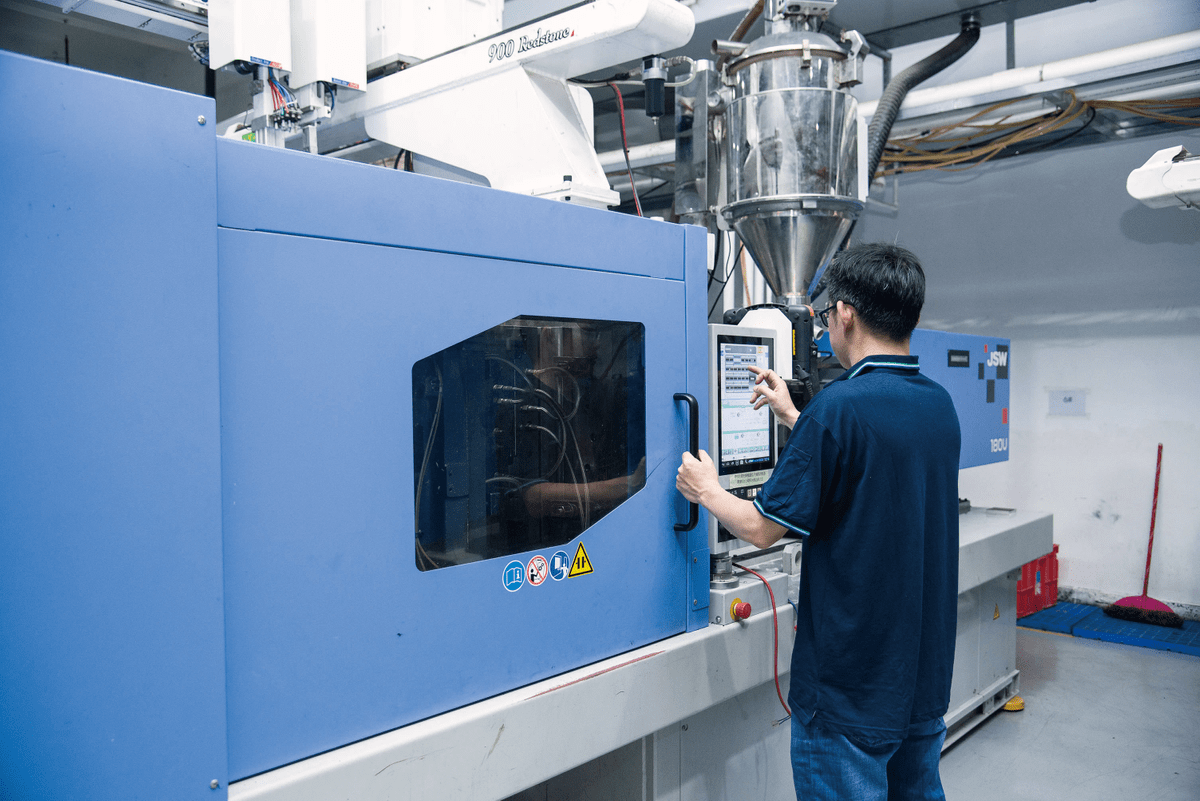

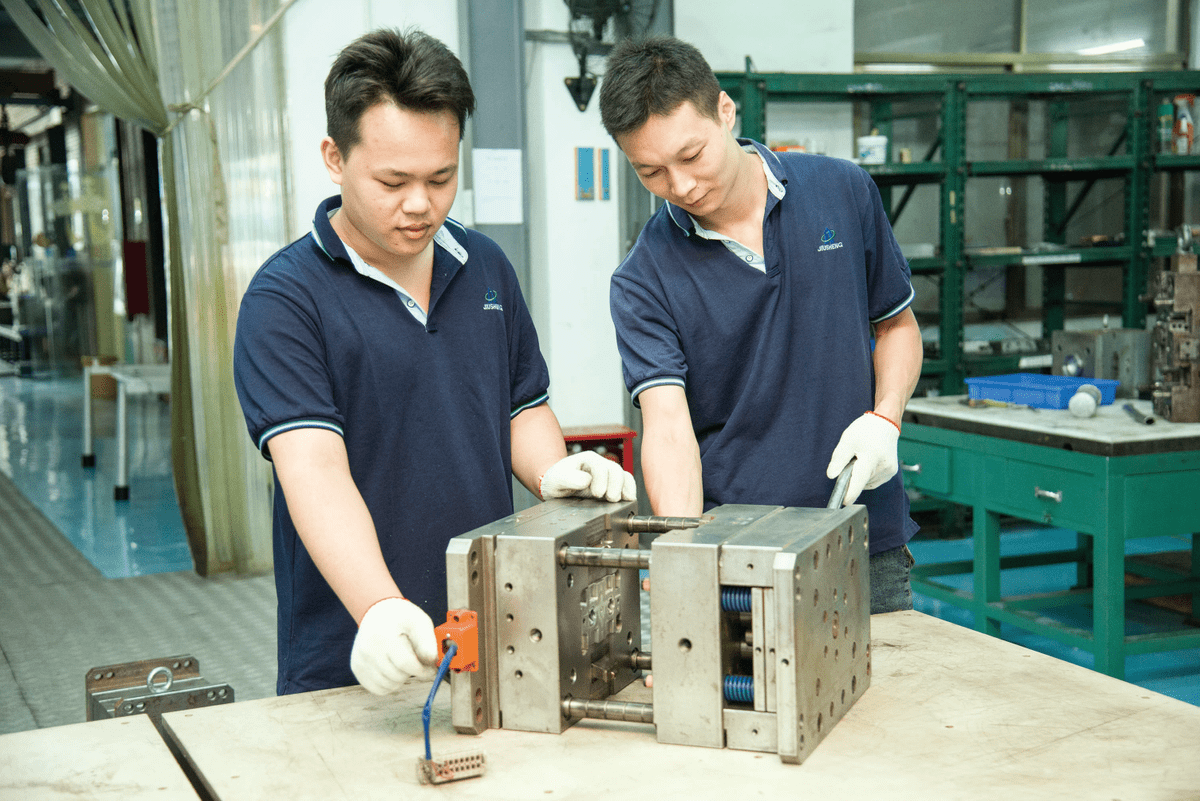

Baoyuan is a leading player among automotive injection molding companies, specializing in the production of high-quality injection molded car components. With a team of seasoned experts, Baoyuan's senior management and technical personnel bring a wealth of knowledge and experience to the table, ensuring top-notch results in automotive plastic injection molding. Moreover, Baoyuan boasts proficiency in foam injection molding, delivering innovative solutions for auto parts manufacturers.

Baoyuan's Expertise in Automotive Injection Molding

Baoyuan's expertise in automotive injection molding is unmatched, as they consistently produce precision-engineered plastic components that meet the highest industry standards. Their commitment to excellence has cemented their reputation as one of the foremost automotive plastic injection molding companies, trusted by leading auto manufacturers for top-tier products.

Baoyuan's Senior Management and Technical Personnel

The backbone of Baoyuan's success lies in its senior management and technical personnel who bring years of expertise to the table. Their collective knowledge and innovative approach drive the company's continuous advancements in automotive injection mold and plastic parts molding, ensuring that they remain at the forefront of industry developments.

Baoyuan's Proficiency in Foam Injection Molding

In addition to their prowess in traditional plastic injection mold techniques, Baoyuan has also excelled in foam injection molding. This specialized capability allows them to create lightweight yet durable components that contribute to enhanced vehicle performance and efficiency.

Magna International

Magna International is a powerhouse in the automotive injection molding industry, known for its innovative plastic injection molding techniques. The company has revolutionized the production of injection molded car components by implementing cutting-edge technology and processes that ensure high-quality and durable parts for vehicles. Magna's expertise in foam injection molding has also set a new standard for comfort and aesthetics in automotive interiors.

Magna's Innovation in Plastic Injection Molding

Magna International stands out among automotive plastic injection molding companies due to its relentless pursuit of innovation. The company consistently invests in research and development to improve plastic injection mold techniques, resulting in more efficient and cost-effective manufacturing processes for automotive parts.

Magna's Contribution to Automotive Plastic Injection Molding

As one of the leading auto parts manufacturers, Magna International has made significant contributions to the advancement of automotive plastic injection molding. Its commitment to producing high-quality and precision-engineered components has reshaped the industry, setting new benchmarks for performance, durability, and design flexibility.

Magna's Quality Assurance for Injection Molded Car Components

Magna International places a strong emphasis on quality assurance for its injection molded car components. The company implements rigorous testing protocols and quality control measures to ensure that every product meets or exceeds industry standards, providing customers with peace of mind regarding the reliability and safety of their vehicle components.

Denso Corporation

Denso's Role in Automotive Injection Mold and Plastic Parts Molding

Denso Corporation plays a pivotal role in the automotive industry as one of the leading companies specializing in automotive injection molding. Their expertise lies in producing high-quality plastic parts for vehicles, ensuring durability and precision in every component they manufacture. With a strong focus on innovation and cutting-edge technology, Denso continues to be a key player in shaping the future of automotive injection molded car components.

Denso's Expertise in Single-color and Double-color Plastic Products

One of Denso's notable strengths is their proficiency in producing single-color and double-color plastic products for automotive applications. This expertise allows them to cater to a wide range of design requirements, providing flexibility and customization options for their clients. By offering innovative solutions in color variations, Denso sets itself apart as a leader among automotive plastic injection molding companies.

Denso's Focus on Sustainable Plastic Injection Mold Solutions

Denso Corporation places a strong emphasis on sustainable practices within their plastic injection mold solutions. They are committed to minimizing environmental impact through responsible manufacturing processes and materials usage. By prioritizing sustainability, Denso aligns with the growing demand for eco-friendly initiatives within the auto parts manufacturer industry.

Bosch GmbH

Bosch GmbH is at the forefront of automotive injection molding technology, utilizing state-of-the-art machinery and processes to produce high-quality injection molded car components. Their cutting-edge technology allows for precision and efficiency in manufacturing plastic parts for the automotive industry, setting them apart from other auto parts manufacturers.

Bosch's Cutting-edge Technology for Automotive Injection Molding

Bosch's cutting-edge technology for automotive injection molding encompasses advanced machinery and innovative processes that ensure the production of top-quality plastic parts for vehicles. Their expertise in precision engineering and mold design allows them to create complex components with unparalleled accuracy, meeting the stringent requirements of modern automobiles.

Bosch's Commitment to Environmental Sustainability in Injection Molded Car Components

Bosch is committed to environmental sustainability in their production of injection molded car components, employing eco-friendly materials and energy-efficient manufacturing practices. By prioritizing sustainability, they reduce their carbon footprint while delivering durable and reliable plastic parts that meet the highest industry standards.

Bosch's Global Impact as an Auto Parts Manufacturer

As one of the leading automotive plastic injection molding companies, Bosch has a significant global impact as an auto parts manufacturer. Their products are renowned for their quality and reliability, making them a trusted supplier to major automobile manufacturers worldwide. With a strong presence in the global market, Bosch continues to shape the future of automotive injection mold and plastic parts molding.

Continental AG

Continental AG has made significant advancements in plastic injection mold for automotive applications, setting them apart from other automotive injection molding companies. Their cutting-edge technology and expertise in foam injection molding have allowed them to produce high-quality and durable injection molded car components that meet the rigorous standards of the auto parts manufacturer industry.

Continental's Advancements in Plastic Injection Mold for Automotive Applications

Continental AG has continuously pushed the boundaries of plastic injection mold for automotive applications, utilizing state-of-the-art technology to create innovative solutions for the industry. Their commitment to research and development has enabled them to stay ahead of the curve and deliver top-notch products that cater to the evolving needs of auto parts manufacturers.

Continental's Role in Pioneering Automotive Plastic Injection Molding Companies

As one of the pioneering automotive plastic injection molding companies, Continental AG has played a pivotal role in shaping the landscape of the industry. Their dedication to excellence and unwavering focus on quality have set a benchmark for others to follow, solidifying their position as a leader in automotive injection mold and plastic parts molding.

Continental's Contribution to High-Quality Injection Molded Car Components

Continental AG's contribution to high-quality injection molded car components cannot be overstated. Their relentless pursuit of perfection and commitment to precision have resulted in products that not only meet but exceed industry standards, making them a trusted partner for auto parts manufacturers worldwide.

Lear Corporation

Lear Corporation has carved a niche for itself in the realm of custom plastic injection molding within the automotive industry. Their specialization lies in creating tailor-made solutions for injection molded car components, catering to the specific needs of different auto parts manufacturers. With a keen eye for precision and durability, Lear's innovations in automotive injection mold and plastic parts molding have set them apart as a leader in the field.

Lear's Specialization in Custom Plastic Injection Molding

Lear Corporation prides itself on its expertise in custom plastic injection molding, offering unique solutions tailored to the individual requirements of auto parts manufacturers. Their ability to create specialized components for various automotive applications sets them apart as an industry leader in providing top-quality injection molded car components.

Lear's Innovations in Automotive Injection Mold and Plastic Parts Molding

Through continuous innovation, Lear has made significant strides in automotive injection mold and plastic parts molding, constantly pushing the boundaries of what is possible within the industry. Their commitment to staying ahead of the curve has enabled them to develop cutting-edge solutions that meet and exceed the demands of modern auto parts manufacturers.

Lear's Focus on Precision and Durability for Auto Parts Manufacturer

Lear Corporation places a strong emphasis on precision and durability when it comes to producing injection molded car components for auto parts manufacturers. By prioritizing these factors, they ensure that their products not only meet but exceed industry standards, setting a new benchmark for quality within automotive plastic injection molding companies.

Adient

Adient is a leader in automotive foam injection molding, providing innovative solutions for lightweight and durable car components. With a focus on comfort and aesthetics, Adient's expertise in foam injection molding ensures that their products meet the highest standards of quality and performance. Their collaborations with top automotive plastic injection molding companies have solidified their position as a trusted partner in the industry.

Adient's Leadership in Automotive Foam Injection Molding

Adient's leadership in automotive foam injection molding is evident in their ability to produce high-quality, lightweight components that enhance vehicle comfort and aesthetics. Their expertise in this specialized form of injection molding allows them to create products that meet the rigorous demands of the automotive industry, setting them apart as a leader in this field. By utilizing advanced materials and innovative design techniques, Adient is able to offer customizable solutions that cater to the unique needs of different vehicle models and manufacturers. This flexibility and attention to detail further solidify their position as a go-to provider for cutting-edge foam injection molded car components.

Adient's Contribution to Comfort and Aesthetics in Injection Molded Car Components

Adient's contribution to comfort and aesthetics in injection molded car components is unparalleled, thanks to their advanced foam injection molding techniques. By prioritizing both functionality and design, Adient ensures that their products not only meet performance standards but also enhance the overall driving experience for consumers.

Adient's Collaborations with Top Automotive Plastic Injection Molding Companies

Adient's collaborations with top automotive plastic injection molding companies have strengthened their position as an industry leader. By partnering with these key players, Adient gains access to the latest technological advancements and innovative manufacturing processes, allowing them to stay ahead of the competition. This strategic alliance also enables Adient to offer a wider range of high-quality products and services to their clients, further solidifying their reputation as a go-to supplier in the automotive industry.

Conclusion

The future of automotive injection molding looks promising as technology continues to advance, allowing for more efficient and sustainable production processes. With the increasing demand for high-quality, durable, and aesthetically pleasing injection molded car components, it's crucial for auto parts manufacturers to choose the right partner that can deliver innovative solutions.

The Future of Automotive Injection Molding

As automotive technology evolves, the demand for complex and lightweight injection molded car components will continue to grow. This creates opportunities for automotive injection molding companies to further develop their expertise in foam injection molding and plastic injection mold technologies to meet the industry's evolving needs.

Choosing the Right Partner for Injection Molded Car Components

Selecting a reliable partner in automotive plastic injection molding companies is critical in ensuring the production of top-quality car components. It's essential to consider a manufacturer's proficiency in foam injection molding, plastic parts molding, and their commitment to sustainability when making this decision.

Innovations Driving the Auto Parts Manufacturer Industry

Innovations such as single-color and double-color plastic products, cutting-edge technology, and a focus on precision and durability are driving advancements in the auto parts manufacturer industry. As consumer expectations continue to rise, it's imperative for companies to stay ahead of the curve by embracing these innovations.

Remember that choosing the right partner among automotive plastic injection molding companies is crucial in meeting the growing demands of the industry while staying ahead of technological advancements. As consumer preferences shift towards eco-friendly solutions and advanced designs, it's important for auto parts manufacturers to collaborate with leading experts in automotive injection mold and plastic parts molding.