Introduction

In the ever-evolving world of plastic products manufacturing, staying ahead is crucial. With new techniques constantly being developed, it's essential to keep up with the latest advancements to maintain a competitive edge. As we explore the future of plastic products manufacturing, it's clear that innovation and quality will continue to drive the industry forward.

The Latest Plastic Products Manufacturing Techniques

From injection molding to additive manufacturing, the landscape of manufacturing plastic products is constantly changing. Cutting-edge technologies and processes are revolutionizing the way plastic products are made, leading to higher efficiency and superior quality.

Stay Ahead in Plastic Products Manufacturing

To excel in the field of contract manufacturing plastic products, it's vital to embrace innovation and adapt to new methodologies. By staying ahead of the curve and integrating state-of-the-art techniques, companies can ensure their position as leaders in the industry.

Explore the Future of Plastic Products Manufacturing

As we look towards the future, it's evident that sustainability and technological advancements will play a pivotal role in shaping the landscape of manufacturing of plastic products. Embracing these changes will not only drive progress but also contribute to a more environmentally conscious approach.

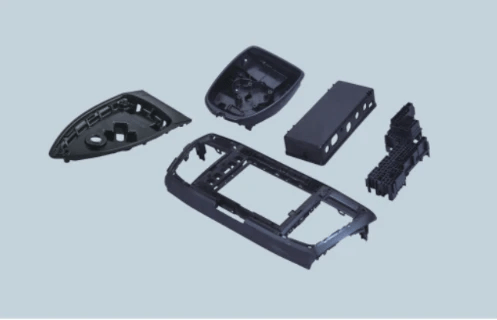

Injection Molding

When it comes to plastic products manufacturing, Baoyuan's expertise in injection molding is second to none. Our state-of-the-art facilities and skilled technicians ensure that we deliver top-quality plastic products every time. With our commitment to precision and efficiency in injection molding, we guarantee that your products will meet the highest standards in the industry.

Baoyuan's Expertise in Injection Molding

At Baoyuan, we take pride in our expertise in injection molding for plastic products manufacturing. Our team of professionals has years of experience and a deep understanding of the intricacies involved in this process. From small-scale components to large, complex parts, we have the knowledge and resources to handle any project with finesse.

Precision and Efficiency in Injection Molding

Our dedication to precision and efficiency sets us apart in the manufacturing of plastic products. We utilize advanced technologies and cutting-edge equipment to ensure that every product meets the strictest quality standards. By focusing on precision, we minimize waste and maximize productivity, providing cost-effective solutions for our clients without compromising on quality.

Innovations in Injection Molding Technology

As a quality plastic products manufacturing factory, we are constantly pushing the boundaries of innovation in injection molding technology. Our investment in research and development allows us to stay ahead of the curve, integrating new materials and techniques into our processes for superior results. With Baoyuan, you can be confident that your plastic products are manufactured using the latest advancements in injection molding technology.

Blow Molding

When it comes to plastic products manufacturing, Baoyuan is at the forefront of cutting-edge blow molding techniques. Our state-of-the-art facilities and expert team ensure that we can produce a wide range of high-quality plastic products using advanced blow molding methods that guarantee precision and efficiency.

Baoyuan's Cutting-Edge Blow Molding Techniques

Our quality plastic products manufacturing factory prides itself on utilizing cutting-edge blow molding techniques that allow for the production of complex, durable, and cost-effective plastic products. With our expertise in blow molding, we can cater to various industries and deliver customized solutions that meet our clients' specific needs and requirements.

Advancements in Blow Molding for Plastic Products

At Baoyuan, we are constantly exploring advancements in blow molding for plastic products to stay ahead in the industry. By investing in innovative technology and refining our processes, we can offer our clients the latest solutions for their manufacturing needs, ensuring that their products are of the highest quality and meet industry standards.

Quality Assurance in Blow Molding Processes

Quality assurance is paramount in our blow molding processes at Baoyuan. We implement stringent quality control measures to guarantee that every product meets our high standards before it reaches our clients. Our commitment to excellence ensures that we deliver reliable and durable plastic products manufactured through top-notch blow molding techniques.

Extrusion Molding

Extrusion molding is a key process in the manufacturing of plastic products, and Baoyuan excels in this area. With state-of-the-art equipment and a team of skilled technicians, Baoyuan ensures the highest quality standards in extrusion molding. Their proficiency in this technique allows for the production of a wide range of plastic products, from pipes to sheets and films.

Baoyuan's Proficiency in Extrusion Molding

Baoyuan's expertise in extrusion molding is unmatched, making them a top choice for contract manufacturing plastic products. Their advanced machinery and extensive knowledge enable them to handle complex projects with precision and efficiency. Whether it's custom profiles or standard components, Baoyuan's proficiency ensures superior results for all plastic manufacturing products.

Enhancing Productivity with Extrusion Molding

In today's fast-paced market, enhancing productivity is crucial for manufacturers of plastic products. Baoyuan understands this need and continuously invests in technology to improve their extrusion molding processes. By streamlining operations and optimizing workflows, they are able to meet high-volume demands while maintaining exceptional quality standards.

Sustainable Practices in Extrusion Molding

As sustainability becomes increasingly important in the manufacturing industry, Baoyuan is committed to implementing sustainable practices in their extrusion molding processes. From using recycled materials to minimizing waste and energy consumption, their dedication to sustainability sets them apart as a quality plastic products manufacturing factory that prioritizes environmental responsibility.

Compression Molding

When it comes to plastic products manufacturing, Baoyuan's mastery of compression molding sets them apart from the competition. With years of experience and a commitment to excellence, Baoyuan has perfected the art of compression molding, delivering top-quality products to their clients.

Baoyuan's Mastery of Compression Molding

Baoyuan's state-of-the-art facilities and skilled technicians make them a leader in the field of compression molding for plastic products manufacturing. Their expertise allows them to produce high-quality, durable products that meet the strictest industry standards, ensuring customer satisfaction with every order.

Customization and Precision in Compression Molding

One of the key advantages of working with Baoyuan is their ability to customize and precision in compression molding. They work closely with their clients to understand their unique requirements and then utilize advanced techniques to deliver tailor-made solutions that exceed expectations.

Advantages of Compression Molding for Diverse Products

Compression molding offers a range of advantages for manufacturing plastic products, including the ability to produce complex shapes and intricate designs with ease. This method also allows for cost-effective production without sacrificing quality, making it an ideal choice for diverse product lines.

Thermoforming

Thermoforming is a crucial aspect of plastic products manufacturing, and at Baoyuan, we have revolutionized this process with our innovative techniques. Our state-of-the-art thermoforming methods ensure that we can create a wide range of plastic products with precision and efficiency. By incorporating cutting-edge technology, we have elevated the standards of manufacturing plastic products to meet the evolving needs of various industries.

Baoyuan's Innovation in Thermoforming

Our innovation in thermoforming sets us apart as a quality plastic products manufacturing factory. We have perfected the art of creating intricate designs and shapes through thermoforming, allowing us to cater to diverse client requirements. With our expertise in this area, we can produce high-quality components for various applications, ensuring that our clients receive top-notch products that meet their specifications.

Streamlining Production with Thermoforming

Thermoforming enables us to streamline the production process for manufacturing plastic products, resulting in cost-effective solutions without compromising on quality. By utilizing advanced machinery and techniques, we can efficiently produce large quantities of plastic components within shorter timeframes while maintaining exceptional precision and consistency.

Quality Control in Thermoformed Plastic Products

At Baoyuan, quality control is paramount in every stage of manufacturing plastic products through thermoforming. We implement rigorous quality assurance measures to ensure that each thermoformed product meets the highest standards of durability, functionality, and aesthetic appeal. Our commitment to delivering superior quality thermoformed plastic products has earned us a reputation as a reliable partner for contract manufacturing plastic products.

Rotational Molding

Rotational molding is a crucial aspect of plastic products manufacturing, and at Baoyuan, we have honed our expertise in this technique. Our skilled technicians utilize advanced rotational molding equipment to create high-quality and durable plastic products for various industries.

Baoyuan's Expertise in Rotational Molding Techniques

Our team at Baoyuan has mastered the art of rotational molding, ensuring that each product is manufactured with precision and attention to detail. With years of experience in this field, we have perfected our techniques to deliver top-notch plastic products that meet the highest industry standards.

Advancements in Rotational Molding Technology

We stay at the forefront of technological advancements in rotational molding to enhance our manufacturing processes. By incorporating state-of-the-art machinery and innovative methods, we are able to produce plastic products with improved strength, consistency, and performance.

Sustainable Solutions with Rotational Molding

Baoyuan is committed to sustainable practices in plastic products manufacturing. Through rotational molding, we minimize material wastage and energy consumption, contributing to a more eco-friendly production process. Our dedication to sustainability ensures that our clients receive quality plastic products manufactured in a responsible manner.

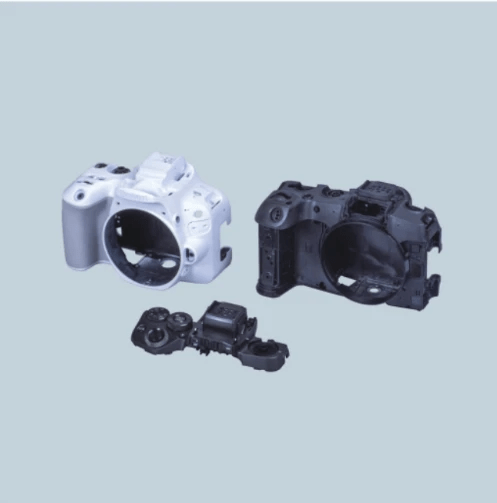

Fabrication

At Baoyuan, we have honed our specialization in plastic fabrication to deliver top-notch products that meet the highest industry standards. Our state-of-the-art facilities and expert team ensure that every product is meticulously crafted with precision and care, making us a quality plastic products manufacturing factory you can trust.

Baoyuan's Specialization in Plastic Fabrication

Our expertise in plastic fabrication sets us apart as a leader in the manufacturing of plastic products. With years of experience and a deep understanding of materials and techniques, we excel in producing a wide range of customized plastic products that cater to diverse industry needs.

Customized Solutions through Fabrication Techniques

We take pride in offering tailored solutions through advanced fabrication techniques, allowing us to create unique and innovative products for our clients. Whether it's custom shapes, sizes, or finishes, our team is dedicated to bringing your vision to life with precision and attention to detail.

Versatility and Durability in Fabricated Plastic Products

The versatility and durability of our fabricated plastic products make them suitable for various applications across different industries. From robust industrial components to intricate consumer goods, our fabricated products are designed to withstand rigorous use while maintaining their quality and aesthetic appeal.

Design for Manufacturability (DFM)

Design for Manufacturability (DFM) is a critical aspect of plastic products manufacturing, and at Baoyuan, we prioritize it to ensure efficient and cost-effective production processes. Our team of experts emphasizes DFM principles in every stage of product development, from concept to final design, to optimize manufacturability and minimize production costs.

Baoyuan's Emphasis on DFM for Plastic Products

Baoyuan's commitment to DFM for plastic products manufacturing is evident in our collaborative approach with clients. We work closely with our partners to integrate manufacturability into the product design phase, ensuring that the final product can be efficiently manufactured without compromising quality or performance. By prioritizing DFM, we enable our clients to bring their innovative ideas to life while maintaining cost-effectiveness.

Enhancing Efficiency through DFM Principles

By incorporating DFM principles into the design process, Baoyuan enhances efficiency in plastic products manufacturing. Our focus on manufacturability allows us to streamline production processes, reduce lead times, and minimize material waste. This not only benefits our clients by accelerating time-to-market but also contributes to sustainable practices within the industry.

Collaborative Approach to DFM for Innovative Products

At Baoyuan, we take a collaborative approach to DFM for innovative products, working hand-in-hand with our clients' design teams to optimize manufacturability without compromising creativity or functionality. By fostering open communication and sharing expertise, we ensure that the final product meets both design aspirations and manufacturing requirements. This collaborative effort results in high-quality plastic products manufactured with precision and efficiency.

Additive Manufacturing

In the realm of plastic products manufacturing, additive manufacturing has revolutionized the industry. Baoyuan has seamlessly integrated additive manufacturing into its processes, allowing for unparalleled flexibility and customization in product design and production. By leveraging cutting-edge 3D printing technology, we are able to push the boundaries of what is possible in manufacturing plastic products, delivering exceptional results that exceed expectations.

Baoyuan's Integration of Additive Manufacturing

Baoyuan's commitment to innovation is evident in our seamless integration of additive manufacturing into our production processes. By harnessing the power of 3D printing, we are able to create intricate and complex plastic products with unmatched precision and efficiency. Our expertise in additive manufacturing allows us to bring your unique designs to life, offering endless possibilities for customization and creativity.

Advancements in 3D Printing for Plastic Products

The advancements in 3D printing technology have opened up a world of possibilities for manufacturing plastic products. Baoyuan stays at the forefront of these developments, constantly exploring new techniques and materials to enhance our 3D printing capabilities. From rapid prototyping to on-demand production, our state-of-the-art 3D printers enable us to deliver high-quality plastic products with unprecedented speed and accuracy.

Benefits of Additive Manufacturing in Rapid Prototyping

Additive manufacturing offers numerous benefits when it comes to rapid prototyping for plastic products. With the ability to swiftly create prototypes directly from digital designs, we can significantly reduce lead times and costs associated with traditional prototyping methods. This allows for quick iterations and adjustments, ensuring that the final product meets your exact specifications without compromising on quality or durability.

Quality Assurance and Control

At Baoyuan, we prioritize quality assurance in every step of the plastic products manufacturing process. Our state-of-the-art factory is equipped with cutting-edge technology and staffed by skilled professionals who are dedicated to upholding the highest standards of quality.

Baoyuan's Commitment to Quality Assurance

Our commitment to quality assurance is unwavering, as we understand the importance of delivering top-notch plastic products to our clients. We adhere to strict quality control protocols, ensuring that each product meets our rigorous specifications before leaving our facility.

Implementing Stringent Quality Control Measures

We implement stringent quality control measures at every stage of manufacturing, from material selection to final inspection. Our team meticulously monitors and evaluates each product to guarantee that it meets our exacting standards for durability, functionality, and aesthetic appeal.

Sustainability and Compliance in Plastic Products Manufacturing

Baoyuan is dedicated to sustainability and compliance in plastic products manufacturing. We actively seek eco-friendly materials and processes while adhering to all industry regulations and standards. Our commitment to sustainability ensures that our clients receive high-quality, environmentally responsible plastic products.

Conclusion

Elevate Your Plastic Products Manufacturing Standards

When it comes to manufacturing plastic products, quality is paramount. Baoyuan's state-of-the-art facilities and commitment to excellence ensure that your products meet the highest industry standards. Trust in our expertise to elevate your plastic products manufacturing standards and exceed customer expectations.

Embrace Innovation with Baoyuan

As a leading contract manufacturing plastic products company, Baoyuan is at the forefront of innovation. Our advanced techniques and cutting-edge technologies enable us to offer customized solutions that cater to diverse needs. Embrace innovation with Baoyuan and stay ahead in the competitive market of plastic manufacturing products.

The Future of Plastic Products Manufacturing

The future of manufacturing of plastic products lies in sustainability, efficiency, and adaptability. Baoyuan is dedicated to implementing sustainable practices while maintaining top-notch quality in our processes. By partnering with us, you are not just investing in a quality plastic products manufacturing factory; you are investing in the future of plastic products manufacturing.