Introduction

Understanding Injection Molding Costs

Injection molding cost estimates are not just about the price of materials; they encompass a range of factors that contribute to the final figure. From the complexity of designs to the type of materials used, each element plays a crucial role in determining overall expenses. By understanding these components, businesses can better forecast their budgets and avoid unexpected financial pitfalls.

Key Factors Influencing Molding Estimates

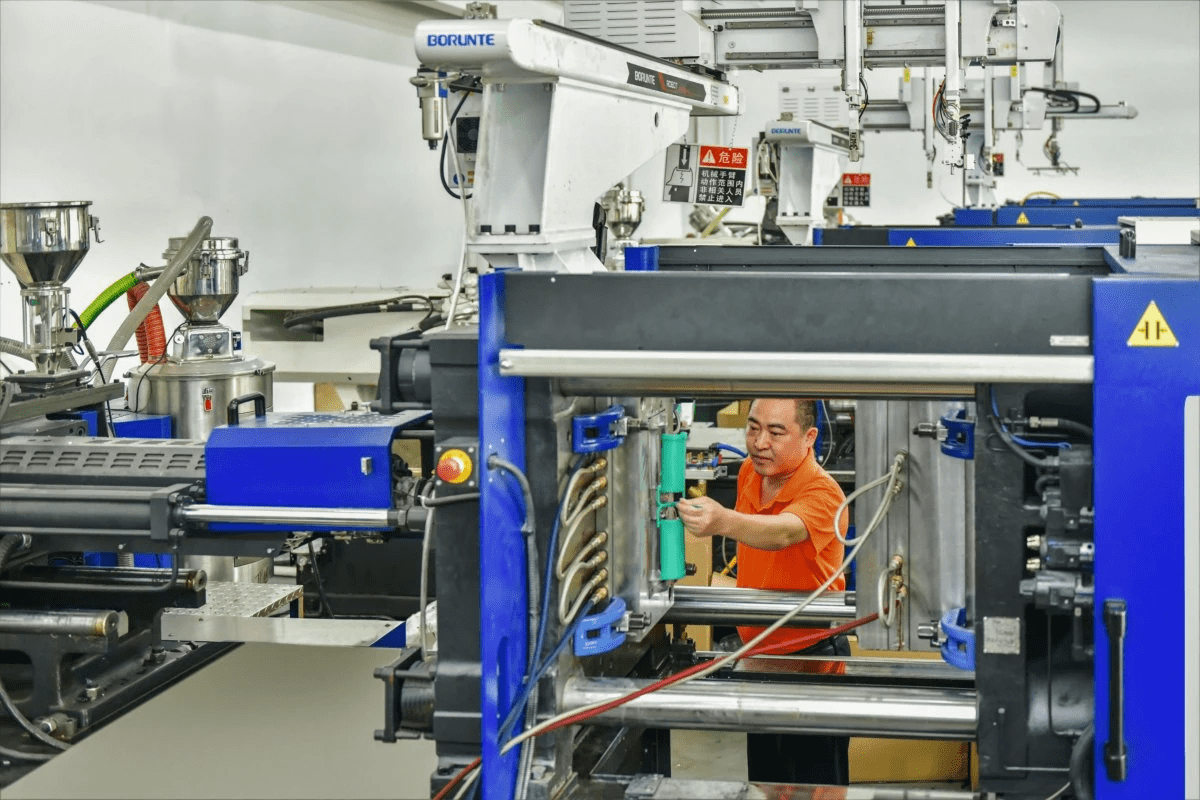

Several key factors influence molding estimates that every business should consider. Material selection stands out as one of the most significant elements—different plastics come with varying costs and properties that affect pricing. Additionally, labor and overhead expenses must be factored in; these can vary widely depending on location and workforce dynamics, particularly when comparing how much does injection molding cost in China versus other regions.

Importance of Accurate Cost Calculations

Accurate cost calculations are vital for successful project management in injection molding. Misestimating costs can lead to budget overruns and project delays, which no one wants to experience! Utilizing tools like an injection moulding part cost calculator Excel can streamline this process by providing precise figures based on your specific requirements, ensuring you stay on track financially while maximizing efficiency.

Defining Injection Molding Cost Estimate

What Influences Cost Estimates

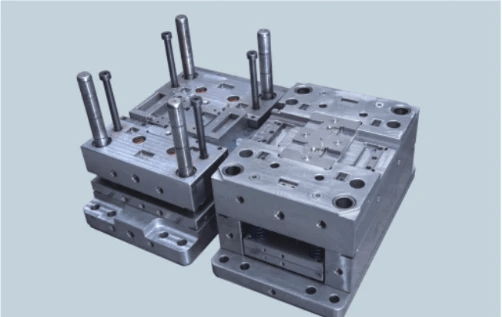

The intricacies of an injection molding cost estimate can be influenced by a variety of factors, including design complexity, production volume, and tooling requirements. For instance, a more intricate design may necessitate advanced molds that are pricier to produce. Additionally, larger production runs often reduce the per-unit cost but require a significant upfront investment in mold creation.

Moreover, geographical location plays a crucial role in determining costs; for example, how much does injection molding cost in China? While labor might be cheaper there, shipping and quality control must also be considered in your overall estimate. Ultimately, understanding what influences these estimates empowers you to make informed decisions when budgeting for your project.

Understanding Material Costs

Material costs are another critical component of any injection molding cost estimate. Different types of plastics and resins carry varying price tags; thus, selecting the right material can have substantial implications on your budget. For instance, specialty materials may offer enhanced properties but can also drive up costs significantly.

To put it into perspective: how much does injection molding cost per kg? This metric helps gauge the affordability of materials used in production and allows for better financial planning. It's essential to balance material choice with performance needs while keeping an eye on overall expenses.

Labor and Overhead Considerations

Labor and overhead are often overlooked yet vital aspects when calculating an injection mold cost. Labor costs can vary based on location and skill level required for both machine operation and quality assurance processes involved in manufacturing parts. The more specialized the workforce needed for your project, the higher these costs will likely climb.

Overhead includes all other indirect expenses associated with production—think utilities, equipment maintenance, and facility rental fees—all contributing to your bottom line without directly appearing as part of the mold's price tag. Therefore, having a comprehensive understanding of both labor rates and overhead is essential when using tools like an injection moulding part cost calculator Excel or any mold cost calculator available online.

How to Calculate Injection Mold Cost?

Calculating the cost of injection molding can feel like trying to solve a Rubik's Cube blindfolded, but it doesn't have to be that complicated. Understanding how to calculate injection mold cost involves breaking down various components, utilizing effective tools like calculators, and factoring in the role of prototypes. By the end of this section, you’ll be well-equipped to tackle your injection molding cost estimate with confidence.

Breaking Down the Cost Components

When considering an injection molding cost estimate, it's crucial to dissect the various elements that contribute to the final price tag. Key components include material costs, labor expenses, overheads, and tooling costs associated with creating molds. For example, if you're asking yourself what is the average cost of an injection mold? Keep in mind that factors such as complexity and size can significantly influence these costs.

Material selection plays a pivotal role in determining how much does injection molding cost per kg as different materials come with varying price points. Additionally, labor costs can fluctuate based on regional wage standards and expertise required for production. Lastly, don’t forget about overhead costs which encompass everything from facility maintenance to utility bills that keep your operation running smoothly.

Using Cost Calculators Effectively

In today’s digital age, using a mold cost calculator can streamline your calculations significantly—think of it as your trusty sidekick in navigating complex pricing landscapes! An injection moulding part cost calculator Excel file allows you to input specific parameters such as material type, part dimensions, and production volume for tailored estimates. This not only saves time but also minimizes errors that could arise from manual calculations.

When leveraging these calculators effectively, ensure you understand what inputs are necessary for accurate results; otherwise, you might end up with a figure that's more fiction than fact! Many calculators also provide insights into how different variables affect overall costs—this knowledge is invaluable when refining your designs or choosing materials based on budget constraints.

The Role of Prototypes in Costing

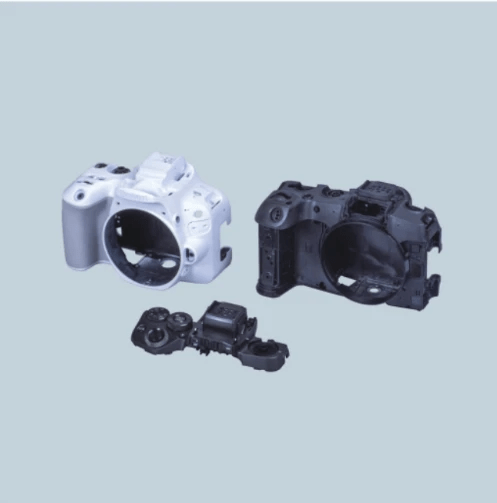

Prototypes play an essential role when estimating injection molding costs because they allow for testing designs before committing fully to production runs. By creating a prototype first, you can identify any design flaws or areas where material usage might be optimized—potentially saving you money down the line when calculating how much does injection molding cost per kg during mass production phases.

Moreover, developing prototypes gives manufacturers a better understanding of tooling requirements which directly impacts what is the average cost of an injection mold? This upfront investment may seem daunting but can lead to significant savings by preventing costly mistakes later on in production cycles. Ultimately, investing time and resources into prototyping not only refines your product but also contributes positively towards achieving accurate estimates for your project.

Average Costs of Injection Molding

When it comes to injection molding, understanding the average costs can help businesses make informed decisions. The injection molding cost estimate varies significantly based on several factors, including design complexity, material selection, and production volume. Hence, getting a clear picture of what to expect in terms of costs is essential for budgeting and planning.

What is the Average Cost of an Injection Mold?

The average cost of an injection mold can range widely depending on various elements involved in the process. Typically, you might find that basic molds start from a few thousand dollars and can escalate into tens or even hundreds of thousands for more intricate designs. To accurately determine what is the average cost of an injection mold for your specific project, consider using a mold cost calculator that factors in all necessary components.

Comparing Costs Across Different Regions

Geographical location plays a pivotal role in determining how much does injection molding cost in different regions around the world. For instance, while North American costs may be higher due to labor rates and overheads, countries like China often provide lower prices due to cheaper labor and materials. However, it's crucial to balance these savings with quality considerations; sometimes opting for lower-cost options can lead to increased expenses down the line if quality issues arise.

The Impact of Scale on Pricing

One key aspect that affects how much does injection molding cost per kg is production scale; larger volumes typically lead to reduced per-unit costs due to economies of scale. When you produce more parts at once, fixed costs such as tooling become diluted across a larger number of units, resulting in significant savings overall. Thus, when calculating your injection molding cost estimate, always consider how scaling up production can optimize your budget while ensuring product quality.

The Cost of Injection Molding Per KG

How Much Does Injection Molding Cost Per KG?

The average cost of injection molding can fluctuate widely, but on a general scale, prices typically range from $1 to $5 per kilogram for common thermoplastics. However, this estimate can rise depending on the specific materials used and any additional processing requirements. To accurately determine your injection molding cost estimate, you should factor in all relevant elements such as labor costs and overheads associated with production.

Understanding how to calculate injection mold cost is essential when assessing costs per kilogram. This involves breaking down the total expenses into manageable components—like raw materials and machine time—to arrive at a precise figure that reflects your product's needs. Ultimately, knowing how much does injection molding cost per kg empowers businesses to optimize their production strategies effectively.

Material Selection and Its Cost Implications

Material selection plays a pivotal role in shaping your overall injection molding costs. Different plastics have varying price points; for example, high-performance materials like polycarbonate or nylon often come with a heftier price tag compared to standard options like polypropylene or polyethylene. Thus, when considering an injection molding cost estimate, it's vital to weigh the benefits of using premium materials against their impact on your budget.

Moreover, remember that material properties can also influence not just the initial purchase price but also long-term performance and durability of the final product. Choosing cheaper materials might save money upfront but could lead to higher costs later due to increased failure rates or replacements needed over time. Therefore, understanding how much does injection molding cost in China or other regions where these materials are sourced can give you insights into optimizing your supply chain.

Optimizing Designs for Cost Efficiency

Optimizing designs for manufacturing is another key strategy for reducing overall costs in an injection molding project. By simplifying complex geometries or minimizing wall thicknesses where appropriate, manufacturers can save on both material usage and production time—ultimately lowering the average cost of an injection mold itself. Employing design principles such as draft angles and uniform wall thicknesses not only enhances manufacturability but also contributes positively to your bottom line.

Additionally, using tools like an Injection moulding part cost calculator Excel helps streamline this process by providing instant feedback on design choices before committing resources to production runs. These calculators allow designers to play with various parameters and instantly see how changes affect overall costs—making it easier than ever to achieve that sweet spot between quality and affordability in your products.

In summary, understanding how much does injection molding cost per kg is integral for businesses looking to enhance their profitability while maintaining quality standards through effective material selection and optimized designs.

Global Cost Comparisons

How Much Does Injection Molding Cost in China?

China has become a hotspot for manufacturing, particularly for injection molding services. The average cost of an injection mold in China can range from $1,000 to $10,000 depending on complexity and size, which is often much lower than costs in Western countries. However, when calculating the total investment—including shipping and potential tariffs—it's essential to consider how these factors influence your overall injection molding cost estimate.

Additionally, while initial costs may be lower, one must ask: how much does injection molding cost per kg? This metric helps provide a clearer picture of ongoing expenses related to production runs. By utilizing tools like an injection moulding part cost calculator Excel sheet, you can better compare these figures against local options.

Assessing Quality vs. Price in Global Markets

While it's tempting to chase the lowest price for your molds and parts abroad, assessing quality is equally crucial when evaluating your injection molding cost estimate. Often times, cheaper molds may lead to higher defect rates or lower durability—ultimately costing more over time due to rework or replacements. Therefore, understanding what is the average cost of an injection mold should also include considerations around material quality and craftsmanship.

In many cases, manufacturers may offer competitive pricing but cut corners on quality control processes or materials used. This could result in unexpectedly high costs down the line when you have to address production issues or product failures that stem from inferior materials or workmanship. Using a reliable mold cost calculator can help you weigh these factors effectively.

Navigating the Challenges of Offshore Manufacturing

Offshore manufacturing presents its own set of challenges that go beyond just price comparisons; navigating cultural differences and communication barriers can complicate project management significantly. When considering how much does injection molding cost in China versus other regions, it’s important not only to factor in labor costs but also time zone differences that might affect project timelines and responsiveness.

Moreover, shipping logistics play a vital role in determining whether offshore manufacturing is truly beneficial for your business model or if it leads to hidden costs that negate initial savings found through low pricing strategies. Understanding how to calculate injection mold cost accurately requires a comprehensive view of all associated expenses—material sourcing delays included!

In conclusion, while offshore manufacturing might seem like a golden opportunity for reduced costs at first glance; thorough research and careful planning are necessary steps before making any commitments based solely on price tags.

Using Cost Calculators

Injection Moulding Part Cost Calculator Excel

One of the most popular tools for calculating injection molding costs is the Injection Moulding Part Cost Calculator Excel template. This handy spreadsheet allows users to input various parameters such as material type, mold complexity, and production volume to generate a detailed cost estimate. By utilizing this calculator, manufacturers can effectively determine how much does injection molding cost per kg and make informed decisions on whether a project is feasible.

The beauty of using an Excel-based calculator lies in its flexibility; users can easily modify inputs and see real-time changes in their estimates. This adaptability is crucial when evaluating different materials or adjusting designs to optimize costs. Ultimately, it serves as an invaluable resource for anyone looking to streamline their injection molding cost estimate process.

Features of a Good Mold Cost Calculator

When searching for a mold cost calculator that meets your needs, there are several key features to consider that will enhance your experience. A good mold cost calculator should offer intuitive user interfaces that allow you to input data effortlessly while also providing clear outputs that are easy to interpret. Additionally, effective calculators will include built-in formulas for calculating labor and overhead costs alongside material expenses.

Another important feature is the ability to compare different scenarios side by side; this helps you answer questions like What is the average cost of an injection mold? without having to do tedious manual calculations each time. Furthermore, calculators with historical data can give insights into how much does injection molding cost in China versus other regions—an essential consideration if you're thinking about offshore manufacturing options.

Real-World Applications and Case Studies

Real-world applications of these calculators showcase their effectiveness in making precise injection molding cost estimates across various industries. For example, a company producing consumer electronics used an Injection Moulding Part Cost Calculator Excel template to refine their design before committing significant resources—resulting in substantial savings on both material and labor costs during production runs.

In another case study, a manufacturer exploring international options discovered through their mold cost calculator that shifting production overseas could drastically alter how much does injection molding cost per kg. By comparing local vs offshore pricing structures within the tool’s framework, they made informed choices about where best to allocate resources while maintaining quality standards.

Ultimately, leveraging these tools not only minimizes financial risk but also empowers businesses with knowledge—ensuring they remain competitive in today's fast-paced market landscape where understanding your injection molding costs has never been more critical.

Conclusion

In the world of injection molding, understanding and managing costs is crucial for success. A well-structured injection molding cost estimate can save you time and money, ensuring that your project stays on track without unexpected financial surprises. By streamlining your cost estimate process, you can focus on innovation and quality while keeping a close eye on the bottom line.

Streamlining Your Cost Estimate Process

To effectively streamline your cost estimate process, it's important to break down each component of how to calculate injection mold cost accurately. Utilizing tools like an injection moulding part cost calculator Excel can significantly enhance your efficiency by automating calculations and providing instant feedback on various scenarios. This allows you to quickly compare different materials, designs, and production scales without getting lost in the numbers.

Making Informed Decisions in Molding

Making informed decisions in molding requires a thorough understanding of what is the average cost of an injection mold in relation to your specific needs. By considering factors such as material selection and production volume, you can tailor your approach to achieve optimal results while minimizing expenses. Additionally, knowing how much does injection molding cost per kg will help you evaluate whether you're getting the best value for your investment.

The Benefits of Partnering with Experts like Baoyuan

When navigating the complexities of injection molding costs, partnering with experts like Baoyuan offers invaluable advantages. They not only provide insights into how much does injection molding cost in China but also guide you through global market dynamics that affect pricing and quality considerations. With their expertise and advanced mold cost calculator tools at hand, you'll be equipped to make smarter decisions that lead to successful project outcomes.