Introduction

When diving into the world of manufacturing, one question often looms large: how much does an injection mold cost? Understanding the various factors that influence injection mold pricing is crucial for businesses looking to optimize their production processes and budgets. As we explore this topic, we'll highlight why comprehending these costs is not just a matter of numbers but a strategic consideration for successful manufacturing.

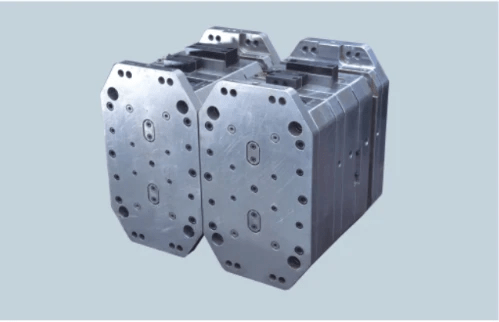

Understanding Injection Mold Cost Factors

The cost of an injection mold can vary significantly based on several key factors, including material selection, design complexity, and production volume. For instance, if you're wondering what is the average cost of an injection mold, you'll find that it fluctuates widely depending on these elements. By grasping these cost factors, manufacturers can make informed decisions that align with their project goals and budget constraints.

The Importance of Cost in Manufacturing

In the competitive landscape of manufacturing, understanding how much injection molding costs is essential for maintaining profitability. Costs not only impact the bottom line but also influence decisions regarding product pricing and market positioning. Therefore, manufacturers must carefully evaluate all aspects of injection mold expenses to ensure they remain competitive while delivering quality products.

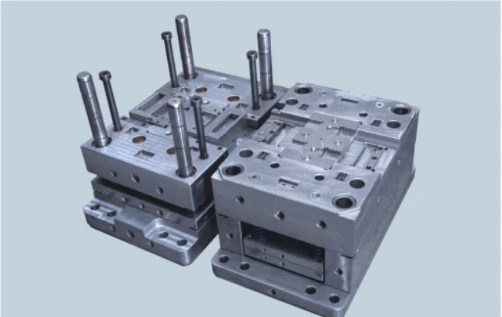

Overview of Injection Molding Process

The injection molding process involves melting plastic pellets and injecting them into a precisely designed mold to create parts or products. This method allows for high-volume production with consistent quality; however, it also raises questions about initial investments like how much does an injection molding machine cost? As we delve deeper into this subject, we will uncover insights on calculating injection mold costs effectively using tools like an injection mold cost calculator.

What Influences Injection Mold Pricing

Material Selection Impact

The choice of materials is one of the most significant factors affecting how much does an injection mold cost. Different materials come with varying price tags; for instance, high-grade steel may be more expensive but offers durability and longevity compared to lower-grade options. Additionally, the type of plastic used in the molding process can also influence costs—certain resins are pricier than others due to their properties or availability.

Moreover, using specialized materials for specific applications can add another layer of expense. When considering what is the average cost of an injection mold, it’s crucial to factor in not just the mold itself but also the material's compatibility with your production needs. Ultimately, a well-thought-out material selection can lead to savings in both short-term costs and long-term performance.

Complexity of the Design

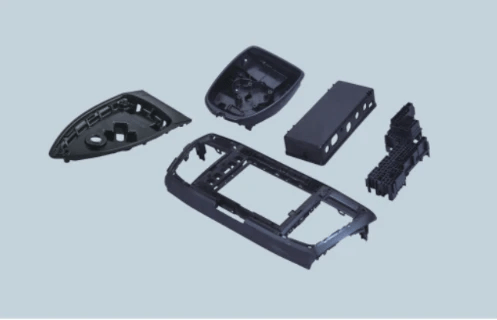

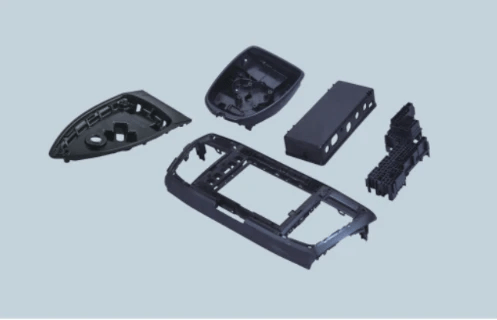

Another key element that drives up costs is the complexity of your design. Intricate designs require more detailed molds, which means increased machining time and higher labor costs—both contributors to why are injection molds so expensive? Simple shapes may be easier and cheaper to produce, but if you need advanced features like undercuts or multi-cavity designs, expect your expenses to rise accordingly.

Design complexity also plays a role in manufacturing efficiency; more complicated molds could lead to longer cycle times during production. Therefore, when asking how much does injection molding cost in China or elsewhere, consider how design intricacies will affect not only initial investment but also operational efficiency down the road. The balance between creating innovative products and keeping costs manageable often hinges on this very factor.

Production Volume Considerations

Finally, production volume considerations significantly influence how much does an injection mold cost overall. High-volume production typically allows manufacturers to spread out initial mold expenses over a larger number of units, reducing per-unit costs considerably—a concept known as economies of scale. Conversely, low-volume runs may result in higher per-unit prices since fixed costs are divided among fewer parts.

Additionally, if you're looking into how much does an injection molding machine cost alongside your mold investment, keep in mind that machines designed for high-volume output often carry higher upfront prices as well—yet they might save money over time through increased efficiency and reduced labor needs. Therefore, understanding your projected production volume is critical when calculating total expenses related to both molds and machines alike.

What is the Average Cost of an Injection Mold?

When diving into the world of injection molding, a burning question often arises: what is the average cost of an injection mold? The answer isn't straightforward, as costs can vary dramatically based on several factors. However, understanding these variables will help manufacturers gauge how much does an injection mold cost for their specific needs.

Typical Price Ranges in the Market

In the market, typical price ranges for injection molds can fluctuate widely from a few thousand dollars to over $100,000. For simple molds used in low-volume production, costs might start around $2,000 to $5,000. Conversely, complex molds designed for high-volume production can easily exceed $50,000 or more—demonstrating why many ask why are injection molds so expensive?

Comparison of Costs Across Industries

Comparing costs across different industries reveals fascinating insights into how much does injection molding cost overall. For example, automotive and medical industries often require high precision and stringent quality standards; thus their mold costs tend to be on the higher end of the spectrum. In contrast, consumer goods may employ simpler designs that keep their mold expenses relatively lower—showing that industry demands directly influence pricing.

Insights from Baoyuan on Pricing Trends

According to Baoyuan’s observations on pricing trends in the injection molding sector, there has been a noticeable shift toward more competitive pricing due to advancements in technology and manufacturing processes. As companies seek efficiency and reduced lead times, understanding how to calculate injection mold cost becomes crucial for maintaining profitability. Furthermore, Baoyuan emphasizes that while initial costs might seem daunting—especially when considering how much does an injection molding machine cost—the long-term savings from efficient production can outweigh these upfront expenses.

How Much Does Injection Molding Cost in China?

When considering the question of how much does injection molding cost in China?, it’s essential to recognize that the financial landscape is quite favorable for many manufacturers. The overall lower labor costs, coupled with efficient production capabilities, create a compelling case for businesses looking to cut expenses while maintaining quality. Many companies find that manufacturing in China can significantly reduce their overall injection mold cost, making it an attractive option for large-scale production.

Cost Benefits of Manufacturing in China

One of the primary reasons businesses flock to China is the substantial cost benefits associated with injection molding. Labor costs are considerably lower than in many Western countries, allowing manufacturers to save on production expenses without sacrificing quality. Additionally, China's robust supply chain and established infrastructure contribute to reduced logistics and material costs, further lowering how much does an injection mold cost.

Moreover, Chinese manufacturers often offer competitive pricing due to their ability to produce molds at scale. This means that when asking what is the average cost of an injection mold? you might find that prices are significantly lower compared to other regions. Thus, if you're looking at how much does injection molding cost in China versus other countries, you'll likely see a clear financial advantage.

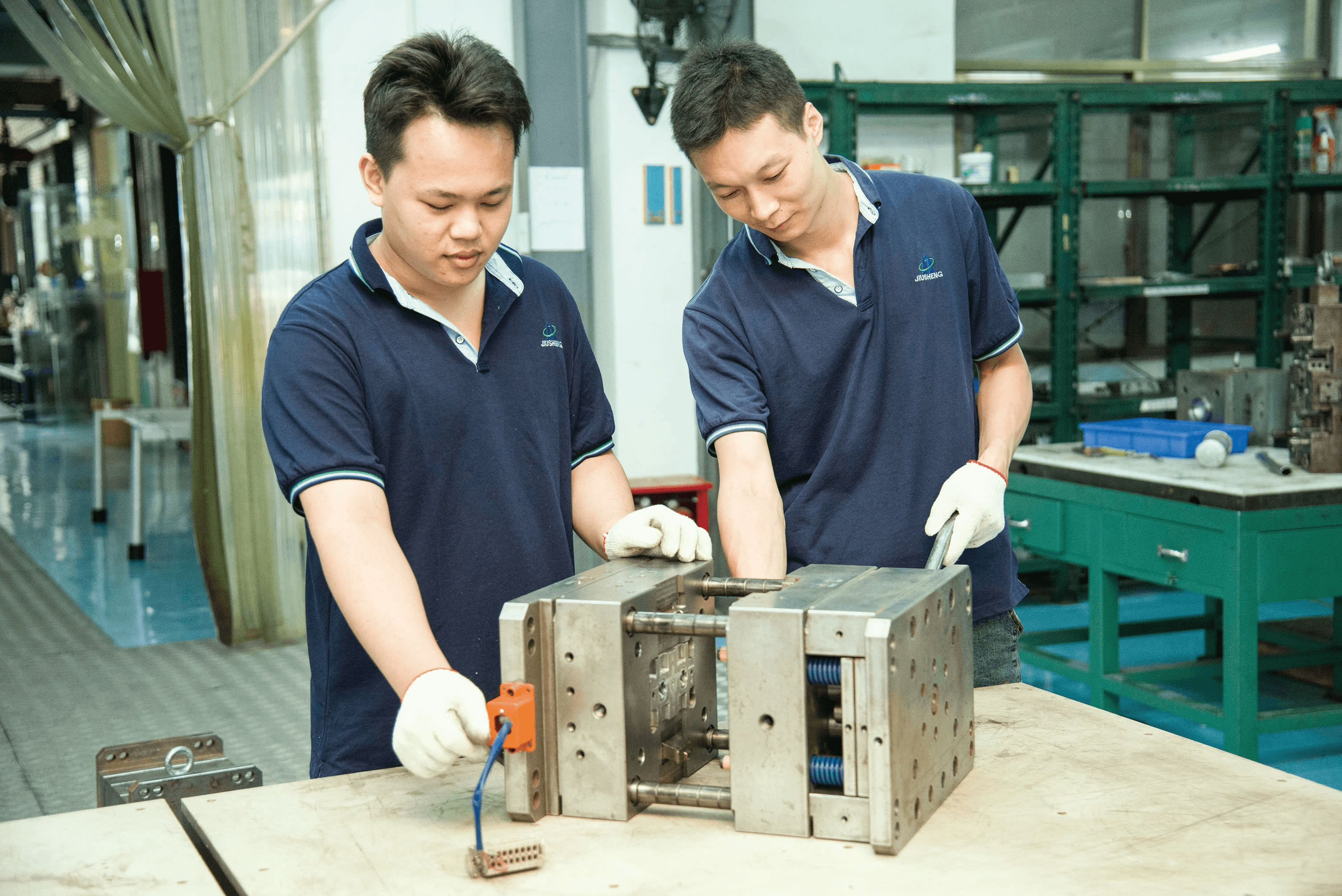

Quality vs. Cost: A Balancing Act

While it’s tempting to focus solely on price when evaluating how much does an injection mold cost, quality must also be part of the equation. Many companies worry about compromising product integrity when opting for cheaper manufacturing options abroad; however, this isn’t always the case with Chinese suppliers. The key lies in choosing reputable manufacturers who prioritize precision engineering and quality control alongside competitive pricing.

It's crucial for businesses to conduct thorough research and vet potential partners carefully before diving into contracts based solely on low costs. After all, understanding why injection molds can be expensive often leads back to the importance of investing in high-quality materials and skilled labor—factors that can sometimes be overlooked when fixated on price alone. Therefore, while exploring how much does injection molding cost in China offers significant savings potential, maintaining a balance between quality and affordability is essential.

Baoyuan’s Perspective on Chinese Market Pricing

At Baoyuan, we understand that navigating the complexities of how much does an injection mold cost requires both market insights and practical experience within the Chinese landscape. Our perspective emphasizes not only competitive pricing but also our commitment to delivering high-quality molds tailored to client specifications—because we believe that long-term value trumps short-term savings every time.

When we analyze current trends regarding how much does injection molding cost in China today, it's evident that ongoing advancements in technology are driving down expenses while enhancing precision and efficiency across production lines. It’s not just about cutting corners; it’s about smart investments that yield better products at lower prices over time—an approach we wholeheartedly endorse at Baoyuan as part of our mission.

In conclusion, understanding what influences pricing dynamics within China's injection molding sector helps businesses make informed decisions regarding their manufacturing strategies while ensuring they don’t sacrifice quality for savings alone.

Why Are Injection Molds So Expensive?

When delving into the world of injection molding, one question often arises: Why are injection molds so expensive? Understanding the cost structure is crucial for manufacturers and businesses looking to optimize their production processes. The expense associated with injection molds stems from various factors, including material selection, labor costs, and the precision required in engineering.

Breakdown of Material and Labor Costs

The first step in understanding how much does an injection mold cost is to examine the materials involved. High-quality steel or aluminum is typically used for mold construction, which can significantly drive up costs due to their durability and ability to withstand high pressures during production. Additionally, labor costs play a vital role; skilled technicians are needed for both the design and manufacturing processes, making labor a significant portion of the overall expenses.

Labor also encompasses maintenance and adjustments required throughout the mold's lifecycle. As molds undergo wear and tear from repeated use, ongoing maintenance becomes necessary to ensure consistent quality in production runs. Therefore, when calculating how much does an injection molding machine cost or assessing overall expenses, it's essential to factor in both material quality and skilled labor contributions.

Importance of Precision Engineering

Precision engineering is another critical factor that contributes to why injection molds are so expensive. The intricacy involved in designing molds demands advanced technology and expertise to achieve exact specifications tailored to specific products. Any minor error can lead to defects that compromise product integrity or functionality, which could result in costly reworks or scrapped batches.

Moreover, achieving tight tolerances requires sophisticated machinery capable of producing complex geometries with high accuracy. This level of precision not only elevates initial mold costs but also influences long-term operational efficiency by minimizing waste during production runs. Thus, when asking what is the average cost of an injection mold?, remember that precision engineering is a pivotal element driving those numbers upward.

Long-Term Investment in Quality

Investing in high-quality injection molds may seem daunting at first glance; however, it’s crucial for long-term success in manufacturing operations. High-quality molds tend to have longer lifespans and require less frequent replacements or repairs than cheaper alternatives—saving money over time despite higher upfront costs. This aspect makes understanding how to calculate injection mold cost not just about immediate financial outlay but also future savings potential.

Additionally, well-crafted molds contribute directly to product quality assurance by ensuring consistency across production runs—an invaluable asset for brands looking to maintain their reputation and customer satisfaction levels. Companies often find that opting for higher-quality molds leads them down a path where they can produce superior products more efficiently while reducing operational hiccups associated with inferior designs or materials.

In summary, while it may be tempting to seek out lower-cost options when considering how much does an injection mold cost?, investing wisely upfront pays off significantly down the line through enhanced quality control and reduced operational issues.

How to Calculate Injection Mold Cost?

Calculating the cost of an injection mold can seem like a daunting task, but with the right tools and knowledge, it becomes manageable. Understanding how much does an injection mold cost requires a careful examination of various factors that contribute to the overall pricing. By using an injection mold cost calculator and considering key metrics, manufacturers can make informed decisions that align with their budget and production goals.

Using an Injection Mold Cost Calculator

An injection mold cost calculator is a handy tool that helps estimate the expenses associated with creating an injection mold. These calculators typically require inputs such as material type, mold complexity, and production volume to generate a cost estimate. Knowing how much does injection molding cost in China or elsewhere can also influence your calculations, as prices may vary significantly based on location and market conditions.

To get started, simply input your project specifications into the calculator, which will then provide you with a breakdown of costs associated with each component of the process. This not only helps in understanding what is the average cost of an injection mold but also assists in budgeting for future projects more accurately. Remember that while these calculators provide valuable insights, they are still estimates; actual costs may vary depending on specific requirements and unforeseen factors.

Key Metrics and Variables to Consider

When calculating injection mold costs, several key metrics need to be considered for accurate results. First off is material selection—how much does an injection molding machine cost will depend on whether you choose high-grade materials or more economical options. Additionally, design complexity plays a critical role; intricate designs often require specialized molds which can drive up costs significantly.

Production volume is another crucial variable; higher volumes typically lead to lower per-unit costs due to economies of scale—this means knowing how many units you'll need can help refine your calculations further. Lastly, labor costs should not be overlooked; skilled labor may be required for precision engineering tasks which adds another layer to your overall expenses when determining why are injection molds so expensive.

Expert Tips from Baoyuan’s Technical Team

Baoyuan’s technical team offers some expert tips that could save you both time and money when calculating your injection mold costs. Firstly, always gather multiple quotes from different manufacturers—this allows you to compare prices effectively while also getting insights into what is the average cost of an injection mold across various suppliers. Secondly, don’t shy away from discussing design modifications; sometimes small changes can lead to significant savings without compromising quality.

Additionally, consider long-term partnerships with suppliers who understand your needs well—this could result in reduced rates over time as they become familiar with your projects and requirements related to how much does injection molding cost in China versus other regions. Lastly, keep abreast of market trends through resources like Baoyuan’s reports on pricing trends; this knowledge empowers you when negotiating contracts or making purchasing decisions regarding new equipment like how much does an injection molding machine cost.

Conclusion

As we wrap up our exploration of injection mold costs, it's clear that understanding the various factors is essential for making informed manufacturing decisions. The question of how much does an injection mold cost? can be complex, influenced by materials, design intricacies, and production volume. Additionally, recognizing why injection molds can be so expensive helps manufacturers appreciate the long-term value they provide.

Key Takeaways on Injection Mold Costs

To summarize, when pondering what is the average cost of an injection mold?, remember that prices can vary widely based on several elements. Material selection plays a significant role; high-quality resins may drive costs up but ensure durability and performance. Moreover, the complexity of your design and anticipated production volume will further impact your overall investment in injection molding.

Understanding the Long-Term Value

Investing in an injection mold isn't just about immediate costs; it’s a long-term investment in quality and efficiency. While you might wonder how much does injection molding cost in China compared to local alternatives, the balance between cost and quality should always guide your choices. Quality molds lead to fewer defects and lower production costs over time—essentially saving money in the long run.

Making Informed Decisions in Manufacturing

When it comes to how to calculate injection mold cost accurately, utilizing an injection mold cost calculator can streamline your budgeting process significantly. It's crucial to consider all variables—material types, labor costs, and machine expenses—to arrive at a realistic figure for your project needs. As you navigate these waters, remember that being informed about how much does an injection molding machine cost will also play a vital role in your overall manufacturing strategy.