Introduction

When it comes to plastic injection molding, PVC (Polyvinyl Chloride) is a popular material choice. It offers a wide range of applications and benefits, making it a go-to option for many industries. However, understanding the intricacies of PVC material for injection molding is crucial to achieving successful results. In this comprehensive guide, we will explore the basics of PVC molding, its advantages, and how to overcome common problems in PVC injection molding.

What is PVC Molding?

PVC molding refers to the process of using Polyvinyl Chloride as the primary material in injection molding. This versatile plastic resin is known for its durability, chemical resistance, and cost-effectiveness, making it ideal for a variety of products and components.

PVC molding is a popular choice for manufacturing due to its versatility and ability to be molded into various shapes and sizes. Its durability makes it suitable for use in products that require long-term performance, such as piping, window frames, and electrical insulation. Additionally, PVC's chemical resistance makes it an excellent option for products that may come into contact with corrosive substances, such as industrial equipment or medical devices. Its cost-effectiveness also makes it a preferred material for manufacturers looking to produce high-quality products at a reasonable price point.

Understanding PVC Material for Injection Molding

In Plastic Injection Molding Polyvinyl Chloride (PVC), understanding the unique properties and characteristics of PVC material is essential for achieving high-quality results in injection molding processes. From its flexibility to its thermal stability, knowing how to work with PVC effectively can make all the difference in product quality.

PVC injection molding can present several challenges, including issues with flowability and mold release. Understanding how to properly adjust processing parameters such as temperature, pressure, and injection speed can help mitigate these issues and ensure a smooth production process. Additionally, selecting the right PVC grade for the specific application is crucial for achieving the desired mechanical properties and surface finish of the final product.

Common Problems in PVC Injection Molding

Injection molding pvc problems can arise from factors such as temperature control, mold design, or material impurities. By identifying these common issues and learning how to address them effectively, manufacturers can improve their overall success rate in producing top-notch PVC material products through injection molding.

Injection molding PVC problems can also stem from issues related to material drying and preparation. Moisture in the PVC resin can lead to defects in the final product, such as bubbles or surface imperfections. Properly drying the material before injection molding is crucial to ensuring a high-quality end result. Additionally, using a dehumidifying hopper or dryer can help to remove any excess moisture from the resin, preventing potential defects and improving overall product quality.

Now let's dive into the basics of rigid PVC injection molding and explore Baoyuan's expertise in this field!

The Basics of Rigid PVC Injection Molding

PVC Injection Molding 101

PVC injection molding, also known as plastic injection molding polyvinyl chloride (PVC), is a manufacturing process used to produce a wide range of PVC material products. It involves melting the rigid PVC injection molding plastic resin and injecting it into a mold to create the desired shape. This versatile process is widely used in various industries for producing durable and cost-effective products.

PVC material offers numerous advantages for injection molding. Firstly, it is a highly versatile material that can be easily molded into various shapes and sizes, making it suitable for a wide range of products. Additionally, PVC is known for its durability and resistance to chemicals, making it ideal for applications where strength and longevity are crucial. Moreover, PVC injection molding is a cost-effective process, as the material itself is relatively inexpensive and the production process is efficient, resulting in lower manufacturing costs.

Advantages of Using PVC Material for Injection Molding

One of the key advantages of using PVC material for injection molding is its excellent chemical resistance, making it suitable for applications where exposure to harsh chemicals is expected. Additionally, rigid PVC injection molding offers high impact strength, good dimensional stability, and low moisture absorption, making it ideal for outdoor and high-impact applications.

Moreover, PVC material is known for its excellent weatherability, meaning it can withstand prolonged exposure to sunlight and extreme temperatures without degrading. This makes it a top choice for outdoor applications such as construction materials, window profiles, and outdoor furniture. The ability of PVC to maintain its structural integrity in harsh environmental conditions adds to its appeal for injection molding.

Key Considerations in PVC Injection Molding Process

When it comes to rigid PVC injection molding processing guide, there are several key considerations to keep in mind. These include the need for precise temperature control during the melting and injection stages, as well as the importance of using molds designed specifically for PVC material. Proper venting is also crucial to avoid air entrapment during the injection process.

In addition to temperature control and proper venting, it is essential to consider the impact of PVC's corrosive nature on the molds and injection equipment. Specialized materials and coatings may be necessary to protect the machinery and ensure long-term durability. Furthermore, the high viscosity of molten PVC requires careful attention to injection speed and pressure to achieve optimal results. Finding the right balance in these parameters is key to producing high-quality PVC products consistently.

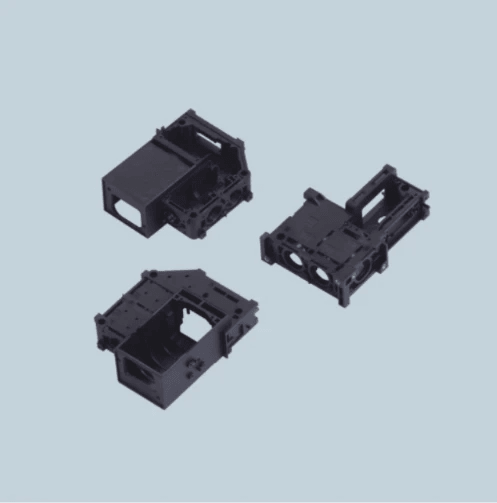

The Baoyuan team has a senior management/technical personnel who have been engaged in the industry for many years, and can skillfully use software to design molds, mold opening, and injection molding. Proficient in the production and quality assurance of single-color and double-color plastic products.

Now that we've covered the basics of rigid PVC injection molding, let's dive into Baoyuan’s expertise in this field.

Baoyuan’s Expertise in PVC Injection Molding

Baoyuan’s Senior Management and Technical Personnel

The Baoyuan team consists of seasoned professionals with extensive experience in the plastic injection molding industry. They possess a deep understanding of PVC material products injection molding and are adept at overcoming common injection molding PVC problems. With their expertise, they ensure that every project meets the highest standards of quality and precision.

The Baoyuan team's proficiency in designing molds and injection molding is unmatched in the industry. Their ability to create intricate and precise molds for PVC material products sets them apart from their competitors. This attention to detail ensures that each project is executed with the highest level of accuracy and efficiency, resulting in top-quality finished products that exceed client expectations.

Proficiency in Designing Molds and Injection Molding

Baoyuan's technical personnel are proficient in using state-of-the-art software to design molds for rigid PVC injection molding. They have a keen eye for detail, ensuring that every mold is precisely tailored to meet the unique requirements of each project. Their expertise extends to mold opening and the entire injection molding process, guaranteeing superior results for clients.

Quality Assurance of PVC Products at Baoyuan

At Baoyuan, quality assurance is paramount in every step of the PVC injection molding process. The team meticulously inspects each product to ensure that it meets the highest standards of durability, functionality, and aesthetics. With their commitment to excellence, clients can trust that their PVC material products will be delivered with uncompromising quality.

Furthermore, Baoyuan's quality assurance process includes regular equipment maintenance and calibration to ensure the precision and consistency of the PVC injection molding. This proactive approach helps to minimize defects and variations in product quality, ultimately leading to a more reliable and uniform end result. By upholding these high standards, Baoyuan demonstrates its unwavering dedication to delivering PVC products that consistently meet or exceed customer expectations.

Tips for Successful PVC Injection Molding

Best Practices for Rigid PVC Injection Molding

When it comes to PVC injection molding, it's crucial to ensure that the mold temperature is well-controlled to prevent warping and shrinkage. Additionally, using a high screw speed and low back pressure can help improve the flow of the PVC material during the injection process, resulting in high-quality finished products.

In addition to controlling mold temperature and optimizing screw speed and back pressure, it's important to carefully select the right PVC material for injection molding. Different grades of PVC have varying properties, such as impact resistance, chemical resistance, and heat stability. By choosing the appropriate grade for your specific application, you can ensure that the finished products meet the required performance standards. This proactive approach can prevent issues such as brittleness or poor surface finish, resulting in higher quality and more durable end products.

Overcoming Challenges in PVC Material Injection Molding

One common challenge in PVC material injection molding is dealing with its high viscosity, which can lead to uneven filling of the mold cavity and potential air traps. To overcome this, it's important to carefully adjust the injection speed and pressure while also ensuring that the mold design allows for proper venting to release any trapped air.

Another important factor to consider when overcoming the challenges of PVC material injection molding is the temperature control during the process. PVC has a narrow processing window, so it's crucial to maintain precise temperatures in the barrel, mold, and hot runner system to prevent degradation of the material and ensure consistent quality in the finished product. Implementing advanced heating and cooling technologies can help to achieve more stable and uniform temperature control throughout the injection molding process.

Improving Efficiency in PVC Injection Molding Process

To improve efficiency in PVC injection molding, consider using a specialized screw design and barrel configuration tailored for processing PVC material. This can help minimize shear heating and reduce energy consumption during the molding process, ultimately leading to higher productivity and cost savings.

Remember that successful PVC injection molding requires careful attention to detail and expertise in handling the unique properties of this plastic resin. By following best practices, overcoming challenges, and improving efficiency, you can achieve excellent results in your PVC material products injection molding endeavors.

Conclusion

When it comes to achieving quality results in PVC injection molding, it's essential to understand the basics of PVC material and the injection molding process. By following the rigid PVC injection molding processing guide and implementing best practices, manufacturers can overcome common problems in PVC injection molding and improve efficiency.

Achieving Quality Results in PVC Injection Molding

By focusing on the key considerations in PVC injection molding and leveraging the expertise of experienced professionals like Baoyuan, manufacturers can achieve high-quality results in their PVC material products injection molding. With a thorough understanding of rigid PVC injection molding, it's possible to produce durable and precise plastic products that meet industry standards.

By paying close attention to the temperature and pressure settings during PVC injection molding, manufacturers can ensure that the material is processed properly and consistently. This level of precision is essential for creating high-quality PVC products that meet industry standards for durability and performance. With the expertise of professionals like Baoyuan, manufacturers can optimize their injection molding processes to achieve the best results with PVC materials.

Key Takeaways for PVC Injection Molding Success

The key takeaways for PVC injection molding success include understanding the advantages of using PVC material for injection molding, overcoming challenges in the process, and continuously improving efficiency. By following these key takeaways, manufacturers can ensure consistent quality and performance in their PVC injection molded products.

Understanding the advantages of using PVC material for injection molding is crucial for manufacturers looking to achieve success in this process. PVC offers excellent durability, chemical resistance, and cost-effectiveness, making it a popular choice for a wide range of products. By leveraging these advantages, manufacturers can create high-quality, long-lasting PVC injection molded products that meet the needs of their customers.

Choosing the Right Partner for PVC Injection Molding Success

Selecting the right partner for PVC injection molding is crucial for success. Baoyuan stands out as a reliable partner with its senior management and technical personnel who excel in designing molds, mold opening, and injection molding. Their proficiency in production and quality assurance ensures that manufacturers can trust them to deliver exceptional results.

Furthermore, Baoyuan's commitment to continuous improvement and innovation sets them apart as a leader in the PVC injection molding industry. Their investment in state-of-the-art technology and equipment ensures that they can meet the evolving needs of manufacturers and deliver cutting-edge solutions. With Baoyuan as a partner, manufacturers can be confident that they are staying ahead of the curve and maintaining a competitive edge in the market.