Introduction

In the fast-paced world of healthcare, precision and reliability are paramount, making medical injection molding a crucial process in the production of medical devices. A medical plastic injection molding company plays a key role in ensuring that these devices meet stringent safety and quality standards. By understanding the nuances of medical injection molding, stakeholders can make informed decisions when selecting partners to bring their innovative ideas to life.

Understanding Medical Injection Molding

Medical injection molding is a specialized manufacturing process used to create intricate components for various healthcare applications. This technique involves injecting molten plastic into molds to produce high-quality parts with exceptional accuracy and repeatability. The versatility of medical injection molding makes it ideal for everything from syringes and surgical instruments to complex diagnostic equipment.

Importance of Choosing a Reliable Partner

Selecting a reliable partner in the realm of medical injection molding companies is essential for ensuring product quality and compliance with industry regulations. The right medical injection molding company not only brings technical expertise but also an understanding of the unique challenges faced by healthcare manufacturers. A strong partnership can lead to enhanced innovation, reduced time-to-market, and ultimately better patient outcomes.

Key Players in the Industry

The landscape of medical injection molding is populated by several key players who have established themselves as leaders in this niche market. Companies like Nordson Medical, Phillips-Medisize, and RMF Medical are known for their innovative approaches and comprehensive solutions tailored specifically for the healthcare sector. Understanding who these top-tier companies are can help businesses identify potential partners that align with their specific needs in plastic injection molding contract manufacturing.

What is Medical Injection Molding?

Medical injection molding is a specialized manufacturing process tailored for the healthcare sector, where precision and reliability are paramount. This technique involves injecting molten plastic into molds to create intricate components used in medical devices and equipment. By partnering with a reputable medical plastic injection molding company, manufacturers can ensure high-quality products that meet stringent regulatory standards.

Definition and Process Overview

At its core, medical injection molding is about creating parts with exceptional accuracy and consistency. The process begins with the selection of appropriate thermoplastic materials, which are then heated until they become pliable enough to be injected into custom molds. Once cooled, these parts retain their shape and can be further processed or assembled into final products.

The efficiency of this method allows for mass production without compromising quality, making it a preferred choice among medical injection molding companies. Each step—from material selection to mold design—requires expertise to ensure that the final product meets the rigorous demands of the healthcare industry. In essence, it’s not just about making parts; it's about crafting reliable solutions that enhance patient care.

Applications in Healthcare

Medical injection molding finds its applications across a wide range of healthcare products, from simple syringes to complex surgical instruments. For instance, disposable components like IV bags and drug delivery systems rely heavily on this technology for their production. Additionally, diagnostic devices such as blood glucose meters also benefit significantly from the precision offered by medical injection molding.

The versatility of this process means it can cater to both high-volume production runs and custom orders for unique devices—a key advantage for any plastic injection molding shop targeting the medical sector. Furthermore, as advancements in technology continue to evolve, we see an increasing number of innovative applications emerging within healthcare settings thanks to these sophisticated manufacturing processes.

Benefits of Medical Injection Molding

One of the primary benefits of choosing a medical injection molding company is the ability to produce complex geometries with minimal waste—a crucial factor in cost management within healthcare manufacturing. This method also allows for rapid prototyping and design iterations, enabling companies to bring new products to market faster than traditional manufacturing methods would allow.

Moreover, when it comes to quality assurance, many leading medical injection molding companies implement rigorous testing protocols throughout production cycles. This ensures that every component not only meets but often exceeds industry standards for safety and efficacy—vital attributes when dealing with patient-related products. Ultimately, leveraging plastic injection molding contract manufacturing opens up opportunities for enhanced efficiency while maintaining high-quality outputs essential in today’s competitive landscape.

Why Choose Baoyuan as Your Medical Injection Molding Company

Expertise and Experience in the Field

Baoyuan boasts years of expertise in medical plastic injection molding, making us well-equipped to handle complex projects with precision. Our team consists of seasoned professionals who understand the nuances of medical device manufacturing, ensuring that every product meets regulatory standards. This extensive experience positions us as a reliable choice for companies seeking a reputable medical injection molding company.

Our deep-rooted knowledge allows us to navigate challenges effectively, whether they involve material selection or production techniques. At Baoyuan, we believe that expertise is not just about years in the business; it's also about understanding our clients' unique needs and delivering tailored solutions. This customer-centric approach has solidified our reputation as one of the leading medical injection molding companies in the industry.

Advanced Technology and Equipment

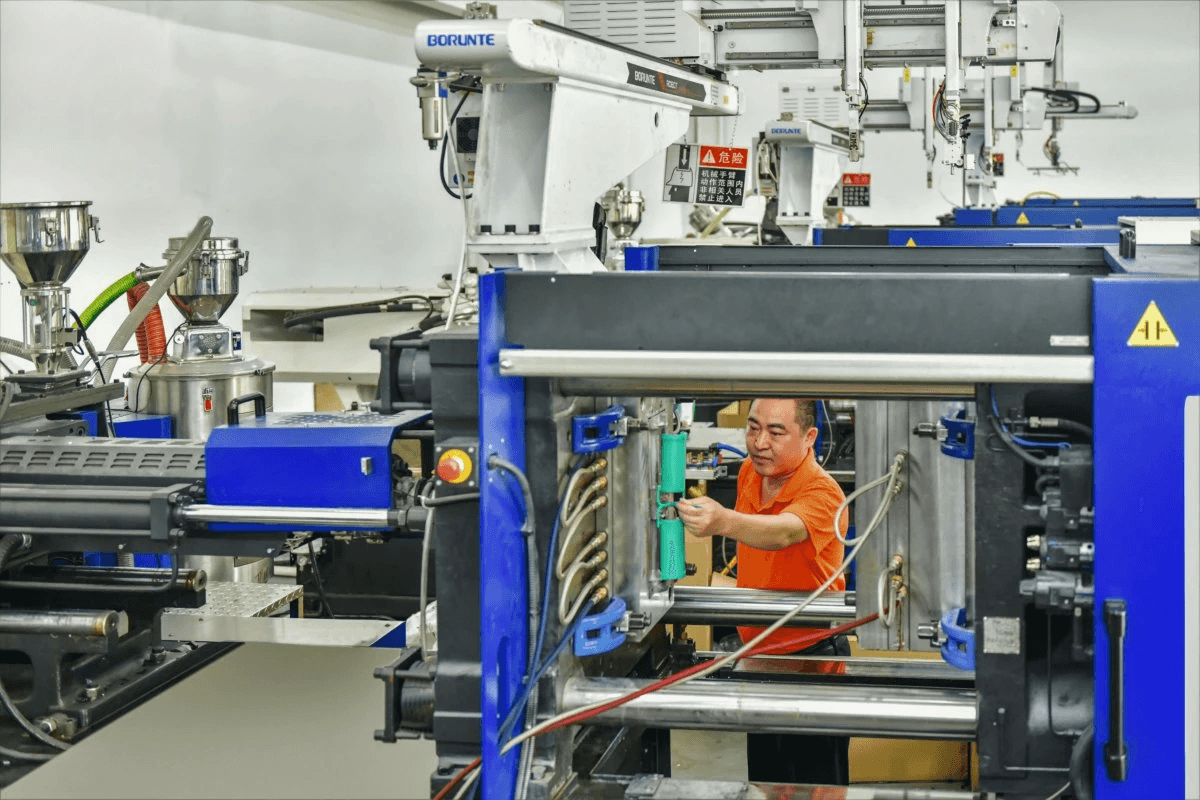

In today’s fast-paced world, staying ahead means investing in advanced technology and equipment—and that's precisely what we do at Baoyuan. Our state-of-the-art facilities are equipped with cutting-edge machinery designed specifically for medical injection molding applications. This investment ensures that we can produce high-quality components efficiently while maintaining strict adherence to industry regulations.

Moreover, our technology enables us to explore innovative materials and processes that enhance product performance and reliability. By leveraging automation and precision engineering, we minimize waste and optimize production times without compromising quality—a critical factor for any plastic injection molding contract manufacturing partner you choose. When you work with Baoyuan, you're not just getting a service; you're gaining access to advanced capabilities that set your products apart from competitors.

Comprehensive Quality Control Measures

Quality control is paramount in the realm of healthcare products where safety cannot be compromised. At Baoyuan, we implement comprehensive quality control measures throughout our production process to ensure every item meets rigorous standards before it reaches your hands. From raw material inspection to final product testing, our protocols guarantee consistency and reliability—hallmarks of any top-tier medical plastic injection molding company.

Our dedicated quality assurance team employs both automated systems and manual inspections to catch any discrepancies early on—because when it comes down to patient safety, there’s no room for error! Additionally, we continuously review and refine our processes based on feedback from clients and advancements in technology so you can trust that your products are manufactured under best practices at all times. Choosing Baoyuan means choosing a partner committed not only to meeting but exceeding quality expectations within the competitive landscape of medical injection molding companies.

Top Medical Injection Molding Companies to Consider

Nordson Medical's Innovative Approaches

Nordson Medical has established itself as a leader in the realm of medical injection molding by embracing innovation at every turn. This medical injection molding company specializes in developing advanced technologies that streamline production processes and enhance product performance. Their commitment to research and development allows them to stay ahead of industry trends while providing clients with cutting-edge solutions tailored specifically for healthcare applications.

One of Nordson's standout features is its ability to integrate diverse manufacturing processes, which results in high-quality components that meet stringent regulatory standards. Their expertise ensures that products are not only efficient but also safe for use in critical healthcare environments. With a focus on continuous improvement and customer satisfaction, Nordson Medical exemplifies what it means to be a top-tier player among medical injection molding companies.

Phillips-Medisize's End-to-End Solutions

Phillips-Medisize takes pride in offering end-to-end solutions that cater to various aspects of the plastic injection molding contract manufacturing process. This medical plastic injection molding company provides services ranging from product design and prototyping to full-scale production and logistics management. By streamlining these processes under one roof, they enable clients to save time and resources while ensuring consistent quality across all stages of development.

Their extensive experience in both drug delivery systems and diagnostic devices positions them as a versatile partner for any organization looking for reliable medical injection molding services. Phillips-Medisize’s investment in state-of-the-art technology further enhances their capabilities, allowing them to deliver complex designs with precision and efficiency. For those seeking an all-encompassing solution within the realm of medical injection molding companies, Phillips-Medisize is hard to beat.

RMF Medical's Custom Capabilities

RMF Medical shines as a go-to option for organizations needing custom capabilities within the plastic injection molding landscape. This innovative medical injection molding company focuses on tailoring solutions that meet specific client needs while adhering strictly to industry regulations and standards. Their flexibility allows them to handle projects ranging from small batch productions to large-scale runs without compromising quality or timelines.

What sets RMF apart is its collaborative approach; they work closely with clients throughout the entire process—from initial concept through final production—to ensure alignment with expectations at every stage. With an emphasis on delivering unique products designed specifically for demanding applications, RMF Medical demonstrates why it remains a formidable contender among leading medical injection molding companies today. If customization is key for your project, RMF Medical should definitely be on your radar.

Plastic Injection Molding Contract Manufacturing Explained

In the realm of medical devices, plastic injection molding contract manufacturing has emerged as a pivotal strategy for companies looking to optimize their production processes. This approach allows businesses to outsource their manufacturing needs to specialized medical plastic injection molding companies, ensuring that they can focus on innovation and market growth. By leveraging the expertise of a dedicated plastic injection molding shop, medical device manufacturers can enhance efficiency while maintaining high standards.

The Concept of Contract Manufacturing

Contract manufacturing in the context of medical injection molding involves partnering with an external manufacturer to produce components or products according to specified requirements. This arrangement is particularly beneficial for companies that may not have the resources or capabilities to handle large-scale production internally. By collaborating with experienced medical injection molding companies, businesses can access advanced technology and skilled labor without the overhead costs associated with running their own facilities.

Advantages for Medical Device Companies

One of the most significant advantages of engaging in plastic injection molding contract manufacturing is cost-effectiveness. Medical device companies can reduce expenses related to equipment acquisition, maintenance, and labor by outsourcing production tasks to a specialized medical injection molding company. Additionally, this approach allows for greater flexibility in scaling operations up or down based on market demand, enabling firms to respond swiftly without compromising quality.

Furthermore, working with established medical injection molding companies often means gaining access to cutting-edge technology and expertise that might not be available in-house. These partners typically invest heavily in state-of-the-art machinery and adhere strictly to industry regulations, ensuring that products meet stringent quality standards. Ultimately, this partnership can lead to faster time-to-market for new devices while maintaining compliance with rigorous healthcare industry requirements.

Key Considerations When Selecting a Partner

When selecting a partner for plastic injection molding contract manufacturing, several key considerations must be taken into account. First and foremost is the company's experience within the specific niche of medical device manufacturing; familiarity with regulatory compliance and quality assurance protocols is crucial for success in this field. Prospective partners should also demonstrate a robust track record of delivering high-quality products consistently.

Another critical factor is the technological capabilities of the potential partner's facility; advanced equipment and innovative techniques are essential for producing complex components efficiently and accurately. Companies should inquire about the range of services offered by each medical injection molding company they consider—some may provide design assistance or prototyping services that could streamline development processes further.

Lastly, communication plays an integral role in any successful partnership; establishing clear lines of dialogue ensures that both parties remain aligned throughout production cycles. A reliable partner will prioritize transparency regarding timelines, costs, and any potential challenges that may arise during manufacturing efforts.

The Future of Medical Injection Molding

As the healthcare landscape continues to evolve, medical injection molding is poised for significant advancements. The demand for innovative medical devices and components is driving a shift in how medical plastic injection molding companies operate. This evolution will not only enhance production efficiency but also improve patient outcomes through better-designed products.

Trends Shaping the Industry

One of the most notable trends shaping the medical injection molding industry is the increasing integration of automation and smart manufacturing technologies. Many leading medical injection molding companies are adopting Industry 4.0 principles, which leverage data analytics and IoT to optimize production processes. This trend allows plastic injection molding contract manufacturing to become more efficient, reducing lead times while maintaining high-quality standards.

Another emerging trend is the personalization of medical devices, as healthcare becomes more tailored to individual patient needs. Medical plastic injection molding companies are developing customizable solutions that can adapt to specific requirements, enhancing functionality and user experience. This shift towards personalization not only improves device effectiveness but also fosters greater patient engagement and satisfaction.

Finally, regulatory changes are influencing how medical injection molding is approached across the industry. Companies must stay ahead of evolving compliance requirements, ensuring their processes align with new standards while still delivering innovative products on time. As a result, collaboration between manufacturers and regulatory bodies will be crucial in navigating these changes effectively.

Advances in Materials and Techniques

The materials used in medical injection molding are continuously evolving, with a strong focus on biocompatibility and performance enhancement. New polymer formulations are being developed that offer improved mechanical properties while being safer for patients—essential for any reputable medical plastic injection molding company looking to stay competitive in this space. These advancements enable manufacturers to create lighter yet stronger components that can withstand rigorous use in various healthcare applications.

Additionally, additive manufacturing techniques are starting to complement traditional methods like plastic injection molding contract manufacturing. By integrating 3D printing technologies into their workflows, companies can produce complex geometries that were previously difficult or impossible to achieve through conventional means alone. This synergy not only accelerates prototyping phases but also allows for rapid iterations based on real-world feedback—a game changer for many medical device developers.

Moreover, advancements in processing techniques such as multi-material injection molding are opening new avenues for innovation within the industry. By combining different materials within a single component, manufacturers can create products with unique properties tailored specifically for their intended applications—offering enhanced functionality without sacrificing quality or performance.

The Role of Sustainability in Manufacturing

Sustainability has become an essential consideration within the realm of medical injection molding as environmental awareness rises among consumers and regulators alike. Medical plastic injection molding companies are increasingly implementing eco-friendly practices throughout their operations—from material sourcing to waste management strategies—to minimize their environmental footprint while meeting market demands for greener products. This commitment not only helps protect our planet but also enhances brand reputation among environmentally conscious clients.

In addition, many organizations are exploring bio-based polymers as alternatives to traditional plastics used in manufacturing processes—an exciting development that could revolutionize how we approach product design within this sector! By utilizing renewable resources instead of fossil fuels when creating these materials, businesses can significantly reduce greenhouse gas emissions associated with production activities—a win-win situation all around!

Lastly, recycling initiatives play a crucial role as well; forward-thinking companies recognize that embracing circular economy principles can lead them toward long-term sustainability goals while simultaneously cutting costs associated with raw material procurement! Through partnerships with recycling facilities or investing directly into recycling technology themselves (like those found at top-tier plastic Injection Molding shops), they open doors towards reducing waste generated during each phase—from design through end-of-life disposal!

Conclusion

In the ever-evolving landscape of healthcare, the importance of selecting the right medical plastic injection molding company cannot be overstated. Your choice can significantly impact product quality, compliance with regulations, and ultimately patient safety. As you navigate through various medical injection molding companies, consider not only their capabilities but also their alignment with your specific needs.

Choosing the Right Medical Injection Molding Partner

Look for a company that demonstrates a proven track record in medical injection molding, showcasing successful projects and satisfied clients. This ensures that your chosen plastic injection molding contract manufacturing partner understands both industry standards and the intricacies involved in creating high-quality medical devices.

Additionally, consider the level of communication and collaboration offered by potential partners. A responsive plastic injection molding shop will keep you informed throughout the process, ensuring that any adjustments or innovations align seamlessly with your project goals. Ultimately, choosing a reliable partner can streamline production timelines while enhancing overall product quality.

The Impact of Technology on Quality

The role of technology in modern medical injection molding cannot be ignored; it is a game changer for quality assurance and efficiency. Advanced machinery and software tools allow for precise control over every aspect of the manufacturing process within medical plastic injection molding companies. This results in consistent output that meets stringent regulatory requirements while minimizing waste—a win-win for both manufacturers and clients alike.

Moreover, innovations like automation and real-time monitoring systems have elevated production capabilities to new heights. Medical injection molding companies employing these technologies can offer faster turnaround times without sacrificing quality standards or compliance measures. In this fast-paced industry where precision is critical, leveraging cutting-edge technology is essential for maintaining competitive advantage.

Looking Ahead in Medical Device Manufacturing

As we peer into the future of medical device manufacturing, several trends are poised to reshape how we approach medical plastic injection molding processes. The integration of sustainable practices will likely become a priority as consumers demand environmentally friendly products—this includes everything from materials used to energy-efficient manufacturing techniques within plastic injection molding shops. Companies that embrace sustainability will not only meet regulatory demands but also attract eco-conscious clients.

Additionally, advancements in materials science promise exciting possibilities for innovation in design and functionality within medical devices produced by leading medical injection molding companies. From biocompatible polymers to smart materials capable of real-time monitoring, staying ahead means being open to change and adaptation within this dynamic field. As we look ahead, it's clear that strategic partnerships combined with technological advancements will drive success in this vital sector.