Introduction

Understanding Injection Molding Costs

At its core, the injection molding cost encompasses various components such as materials, labor, machinery, and tooling. Each of these factors plays a significant role in determining how much does injection molding cost? For instance, the choice of material can dramatically influence both the quality and expense of the final product.

Common Misconceptions About Pricing

One prevalent misconception is that lower initial costs always equate to savings in the long run; however, this isn't always true when considering injection molding costs. Often, opting for cheaper materials or less experienced labor can lead to higher defect rates and increased rework expenses down the line. Additionally, many people underestimate how much does injection molding cost per kg when evaluating their options.

The Importance of Accurate Estimates

Accurate estimates are essential not only for budgeting but also for setting realistic timelines and expectations in any manufacturing project involving injection molding. Without proper calculations on how much does an injection molding machine cost or what typical prices look like in China or elsewhere, businesses may find themselves facing unexpected financial challenges later on. In a competitive landscape where every dollar counts, understanding these nuances can make all the difference between success and failure.

Breakdown of Injection Molding Costs

Material Costs Explained

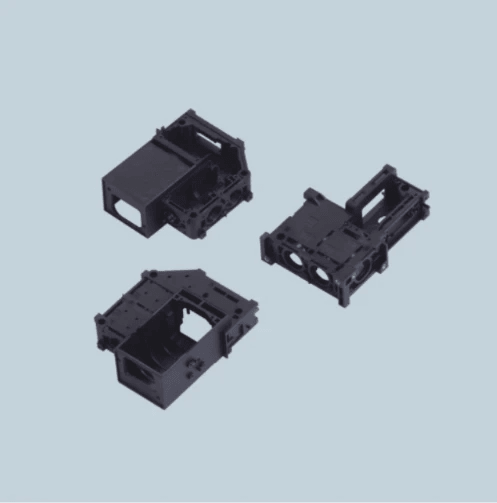

Material costs are often the most significant portion of your injection molding cost. The type of resin you choose will greatly influence the price; for instance, high-performance polymers tend to be pricier than standard thermoplastics. Additionally, fluctuations in raw material prices can lead to variability in how much does injection molding cost per kg, making it crucial for manufacturers to stay updated on market trends.

Selecting the right materials isn't just about cost; it's also about performance and suitability for your project requirements. Different applications demand different qualities, from flexibility and strength to heat resistance and chemical stability. Therefore, understanding these nuances can help ensure that you're not only getting a good deal but also achieving optimal results.

Labor and Overhead Factors

Labor and overhead are often overlooked when discussing how much does injection molding cost, but they play a vital role in the equation. Skilled labor is necessary for operating machinery efficiently while ensuring quality control throughout production processes. Moreover, overhead costs such as facility maintenance, utilities, and administrative expenses can add up quickly.

These factors collectively contribute to why does injection molding cost so much compared to simpler manufacturing methods. It's not just about the hands-on work; it's also about managing an entire ecosystem that supports production efforts effectively. By factoring in these elements early in your budgeting process, you can achieve more accurate estimates.

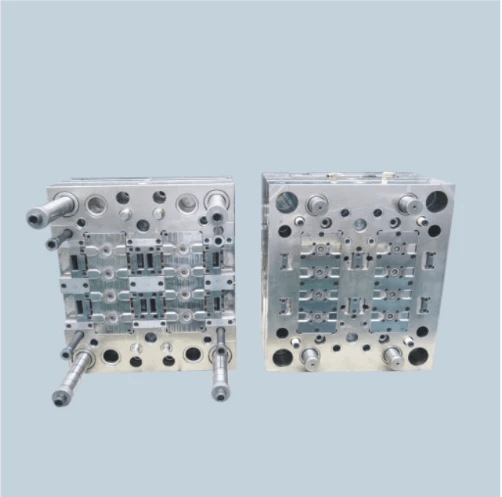

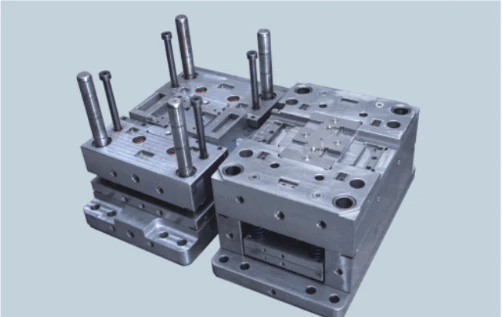

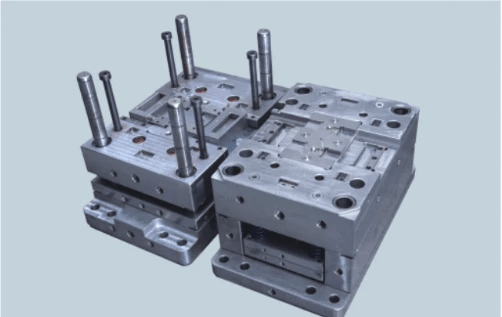

Tooling and Mold Expenses

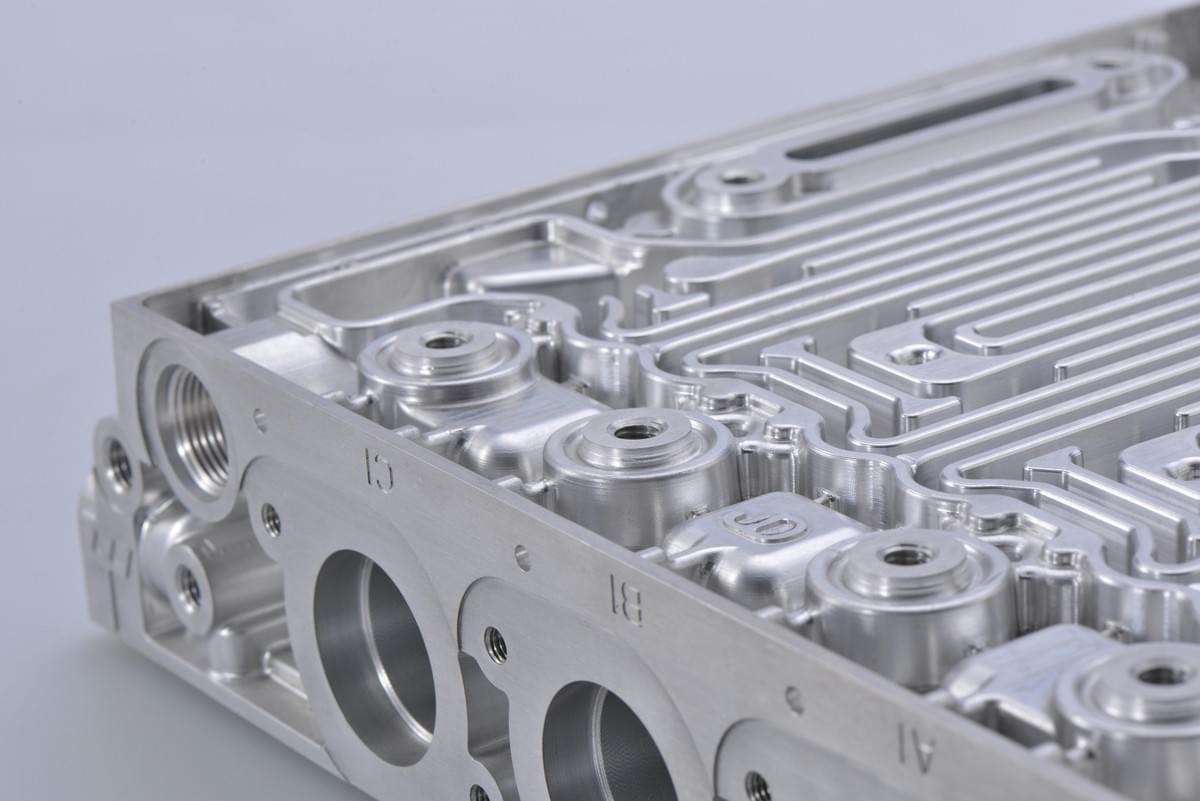

Tooling and mold expenses are perhaps the most significant upfront costs associated with injection molding projects. Creating molds requires precision engineering and high-quality materials—both of which add substantial value but also come at a steep price tag. Depending on complexity and durability requirements, tooling can range from thousands to tens of thousands of dollars.

Understanding how much does an injection molding machine cost is crucial here because it directly impacts tooling expenses as well; specialized machines may require custom molds that elevate initial investments further still. However, once produced, molds can yield thousands or even millions of parts over their lifespan—making them an investment rather than merely an expense in many cases.

In summary, while tooling might seem expensive initially when evaluating how much does injection molding cost overall, its long-term benefits often outweigh those upfront burdens significantly.

How Much Does Injection Molding Cost?

When considering the question, How much does injection molding cost? it's essential to understand that pricing can vary significantly based on various factors. From project size to material choice, each element plays a role in determining the overall expenditure. In this section, we’ll break down average costs for small projects, large volume production, and the variability that comes with unique project requirements.

Average Costs for Small Projects

For small projects, injection molding cost typically ranges from a few thousand dollars to tens of thousands depending on complexity and material used. Generally speaking, you might expect to pay around $2,000 to $10,000 for initial setup and production runs of smaller batches. However, keep in mind that while these costs may seem manageable upfront, they can quickly escalate if additional modifications or tooling are required.

When asking How much does injection molding cost per kg? for small projects, the answer often hovers around $5 to $15 per kilogram of finished product. This range can fluctuate based on specific materials and design intricacies involved in your project. So while it’s tempting to cut corners on costs when dealing with smaller runs, remember that quality should never be compromised.

Costs for Large Volume Production

On the flip side of the coin lies large volume production where economies of scale come into play—this is where things get interesting! The injection molding cost per unit decreases significantly as quantities increase; think along the lines of $1 to $5 per unit depending on materials and design specifications. For high-volume orders exceeding 100,000 units or more, you could see substantial savings over smaller batch productions.

If you’re pondering “How much does injection molding cost in China?” for mass production purposes—well—you’re likely looking at even lower prices due to reduced labor costs and competitive manufacturing practices there. It’s not uncommon for companies sourcing from China to find prices slashed by 30-50% compared to local manufacturing options in developed countries! However, always weigh these potential savings against quality control issues and shipping times.

Variability in Project Requirements

One thing is certain: when it comes down to “Why does injection molding cost so much?”, variability plays a significant role! Each project comes with its own set of requirements—whether it’s intricate designs requiring specialized molds or unique materials that demand higher prices—the possibilities are endless! As such, costs can vary widely even between similar products.

Additionally, other factors such as lead times and urgency can also impact your total expenses; rushing a job could lead you down a costly rabbit hole if you're not careful! If you're exploring options like metal injection molding cost versus traditional plastic methods—be prepared for differences that reflect their respective complexities as well. Ultimately understanding these variables will help you make informed decisions about your project's budget.

Injection Molding Cost per Kilogram

Calculating Costs Based on Weight

Calculating the injection molding cost per kilogram involves considering various elements such as material expenses, labor, and overheads associated with production. To get an accurate figure, you take the total production costs and divide that by the total weight of the parts produced in kilograms. This method not only gives you a clear picture of how much does injection molding cost per kg but also aids in budgeting for future projects.

For instance, if your total costs amount to $10,000 for producing 1,000 kg of product, your injection molding cost would be $10/kg. This straightforward calculation is essential for comparing different suppliers or methods when asking how much does injection molding cost in China versus local options.

Factors Influencing Cost per kg

Several factors can influence the injection molding cost per kg beyond just materials and labor. The complexity of the part design plays a crucial role; intricate designs may require more expensive molds and longer production times, thus driving up costs. Additionally, fluctuations in raw material prices and changes in labor rates can significantly affect overall pricing.

Another aspect to consider is the volume of production; larger orders typically reduce costs due to economies of scale. However, it's essential to remember that while asking Why does injection molding cost so much? often leads back to these variables—complexity and volume—there are many hidden expenses that can creep into your calculations.

Comparisons with Other Manufacturing Methods

When evaluating how much does injection molding cost compared to other manufacturing methods like CNC machining or 3D printing, it's crucial to consider not just initial costs but also long-term value and efficiency. While CNC machining might have lower upfront expenses for small runs, it often becomes more costly as volumes increase due to longer processing times and higher labor requirements.

On the other hand, metal injection molding offers unique advantages when discussing metal injection molding costs versus traditional plastic methods; it allows for complex geometries while maintaining strength at lower weights—ideal for specific industries like automotive or aerospace. Ultimately, understanding these comparisons will empower businesses looking at their options while keeping an eye on their budget.

Examining Injection Molding Costs in China

Benefits of Sourcing from China

One of the primary benefits of sourcing injection molding from China is the significant reduction in overall costs. Labor rates are generally lower than in Western countries, which translates to savings on production expenses. Additionally, China's robust supply chain and access to a variety of materials can streamline your project timelines and reduce lead times.

Another advantage is the scale at which Chinese manufacturers operate; they often have the capacity to handle large volume production at reduced rates. This means if you're asking yourself, How much does injection molding cost? you'll likely find that Chinese manufacturers can provide attractive pricing for bulk orders. Furthermore, many companies have invested heavily in modern technology and equipment, improving both efficiency and quality.

However, it's essential to consider potential communication barriers and cultural differences when dealing with overseas suppliers. Establishing clear expectations regarding quality standards will help mitigate risks associated with sourcing from abroad. Ultimately, weighing these factors against potential savings is crucial for making an informed decision about where to manufacture your products.

Typical Price Ranges and Expectations

So how much does injection molding cost in China? Generally speaking, prices can vary widely depending on several factors including material type, complexity of design, and order volume. For small projects or prototypes, you might expect costs ranging from $1 to $10 per part depending on these variables.

For larger production runs—think thousands or even millions of units—the price per unit typically decreases significantly due to economies of scale. On average, businesses may see costs drop below $1 per part with high-volume orders when working with reliable Chinese manufacturers who specialize in injection molding processes. However, it’s essential to keep an eye on additional fees that might arise during shipping or customs clearance.

Understanding how much does injection molding cost per kg is another critical aspect when evaluating overall expenses. In many cases, the weight-based pricing model helps facilitate comparisons between different manufacturing methods—like metal injection molding cost versus traditional plastic options—allowing companies to choose what best fits their budgetary constraints.

Quality vs. Cost: Making the Right Choice

While lower prices are enticing when considering how much does injection molding cost in China, quality should never take a back seat to savings alone. Many manufacturers offer competitive rates but may compromise on material quality or manufacturing practices that ultimately affect product performance and longevity. It's crucial to conduct thorough research into potential partners before signing any contracts.

One way to gauge quality is by requesting samples before committing to large orders; this allows you firsthand experience with what you can expect regarding craftsmanship and consistency over time. Additionally, consider visiting factories if possible—nothing beats seeing operations up close when determining whether a supplier meets your standards for quality control.

In conclusion, while understanding why does injection molding cost so much involves various elements such as technology investment and labor dynamics within each country’s economy; evaluating these alongside potential savings from sourcing abroad will help ensure you strike the right balance between price point and product integrity without sacrificing either side too heavily.

Why Does Injection Molding Cost So Much?

Understanding the Complexity of Production

Injection molding is not just about pouring plastic into a mold and calling it a day; it’s an intricate process that requires precision and expertise. The production involves multiple stages, including design, prototyping, tooling, and actual manufacturing. Each stage demands time and resources, leading many to ask: “Why does injection molding cost so much?” The answer lies in this complexity; more steps mean more costs.

Moreover, the need for skilled labor adds another layer of expense. Trained professionals are required to operate machines and manage quality control throughout the production cycle. This expertise ensures that products meet stringent quality standards but also contributes significantly to overall injection molding costs.

The Role of Technology and Equipment

Modern injection molding relies heavily on advanced technology and equipment designed for high efficiency and accuracy. High-quality machinery can be quite pricey—so when considering how much does an injection molding machine cost?—the answer can range significantly based on functionality and capacity. Investing in state-of-the-art equipment often translates into higher initial costs but can lead to improved production rates over time.

Additionally, technology such as computer-aided design (CAD) software streamlines the design process but requires ongoing software licenses and updates that add to expenses. This reliance on cutting-edge tools is crucial for maintaining competitiveness in today’s market but also raises questions about how much does injection molding cost per kg? When you factor in these technological investments, it's clear why prices may soar.

Long-Term Value vs. Initial Investment

While upfront costs for injection molding might seem daunting at first glance, it's essential to consider long-term value versus initial investment when evaluating these expenses. The durability and consistency of products produced through injection molding often lead companies to see significant returns over time despite high starting costs. In essence, understanding how much does injection molding cost should involve looking beyond immediate figures toward future benefits.

Moreover, when comparing different manufacturing methods or sourcing options like “How much does injection molding cost in China?”, it's vital to weigh potential savings against quality outcomes over time. A lower price tag may not always equate to better value if it compromises product integrity or leads to increased waste down the line—something particularly relevant with metal injection molding costs as well.

In conclusion, while many factors contribute to why does injection molding cost so much?, understanding these complexities helps demystify pricing structures within this industry.

How Much Does an Injection Molding Machine Cost?

When diving into the world of injection molding, one of the first questions that pops up is, “How much does an injection molding machine cost?” The price can vary widely depending on several factors, including the type of machine and its specifications. Understanding these costs is crucial for anyone looking to enter the injection molding market, whether for small-scale projects or large production runs.

Types of Machines and Their Costs

There are several types of injection molding machines available on the market today, each with its own price range. For instance, a standard hydraulic machine might cost anywhere from $20,000 to $150,000 based on size and capabilities. In contrast, electric machines tend to be more expensive due to their advanced technology and energy efficiency—ranging from $50,000 to over $200,000. Additionally, specialized machines like those used in metal injection molding cost even more due to their intricate design and functionality.

Factors Influencing Machine Pricing

Several factors influence how much does an injection molding machine cost beyond just the type. The size of the clamping force required for your projects will significantly affect pricing; larger clamping forces lead to higher costs. Other considerations include automation features (like robotics), brand reputation, warranty options, and whether you’re purchasing new or used equipment—all pivotal when calculating your overall investment in injection molding.

Financing Options for New Buyers

For those wondering how they can manage the hefty price tag associated with purchasing an injection molding machine, financing options abound! Many manufacturers offer leasing programs that allow buyers to spread out payments over time rather than paying upfront—making it easier for startups or smaller companies to enter this competitive field without breaking the bank. Additionally, traditional loans from banks or specialized equipment financing companies can provide another avenue for acquiring machinery while keeping cash flow in check.

Exploring Metal Injection Molding Costs

Metal injection molding (MIM) represents a fascinating alternative to traditional plastic injection molding, offering unique advantages and challenges. At its core, the process involves combining metal powders with a binder material, which is then injected into molds to create complex parts. Understanding the differences between plastic and metal molding is essential for businesses looking to optimize their production processes while keeping an eye on injection molding costs.

Differences Between Plastic and Metal Molding

When comparing plastic and metal injection molding, several key distinctions come into play that affect overall costs. For starters, the raw materials differ significantly; while plastics are often less expensive and more readily available, metals can carry a higher initial cost due to sourcing and processing complexities. Additionally, the machinery used in metal injection molding tends to be more specialized and costly—raising questions like How much does an injection molding machine cost? when considering investments in this area.

The production cycles also vary; plastic molds can typically be produced faster than metal molds due to their simpler design requirements. However, once established, metal molds can produce high-precision parts with excellent surface finishes that are difficult to achieve with plastics alone. This precision comes at a price—many manufacturers wonder Why does injection molding cost so much? when it comes to investing in MIM processes.

Cost Benefits of Metal Injection Molding

Despite the higher initial investment associated with metal injection molding costs, there are several long-term benefits that may offset these expenses. For one, MIM allows for the mass production of intricate components that would otherwise require extensive machining or assembly processes in traditional manufacturing methods—saving both time and labor costs over time. Moreover, because MIM produces near-net-shape parts, there is less waste generated during production compared to subtractive machining techniques.

Another significant advantage is durability; products made through metal injection molding often boast superior strength and resistance properties compared to their plastic counterparts. This makes them ideal for industries where performance under stress is crucial—ultimately leading businesses to ask not just How much does injection molding cost? but also What value do we gain from this investment? The potential for reduced long-term maintenance costs further enhances the appeal of MIM.

Industries That Benefit from Metal Injection Molding

Various industries stand to gain tremendously from adopting metal injection molding techniques due to its unique capabilities and efficiencies. The automotive sector frequently utilizes MIM for producing components like gears or brackets where strength-to-weight ratios are paramount—a perfect example of how understanding How much does injection molding cost per kg? can lead companies toward smarter material choices that enhance product performance without breaking the bank.

Similarly, electronics manufacturers benefit from the precision offered by metal injection molded parts for items such as connectors or housings—where tight tolerances make all the difference in functionality and reliability. Even medical device companies leverage this technology for creating intricate components that meet stringent regulatory standards while managing overall production costs effectively.

In conclusion, while exploring metal injection molding costs reveals some challenges related to initial investments and equipment pricing (like asking How much does an injection molding machine cost?), it simultaneously uncovers numerous advantages across diverse industries eager for innovation without sacrificing quality or performance.

Conclusion

In summary, understanding injection molding costs is crucial for anyone looking to engage in this manufacturing process. From the intricacies of material and labor expenses to the impact of tooling and machinery, these factors collectively shape the question: how much does injection molding cost? Whether you’re a small business owner or part of a large corporation, grasping these elements will empower you to make informed decisions.

Key Takeaways on Injection Molding Costs

The first takeaway is that injection molding costs can vary significantly based on project size and complexity. Small projects may have higher per-unit costs compared to large volume productions, but they also require less upfront investment in tooling. Additionally, understanding how much does injection molding cost per kg can help you budget effectively and compare it with other manufacturing methods.

Another critical point is the role of location in determining costs; for instance, how much does injection molding cost in China? Typically lower labor rates and material sourcing options can lead to substantial savings, but quality control must not be overlooked. Lastly, recognizing why does injection molding cost so much involves appreciating the advanced technology and skilled labor required for high-quality production.

Strategies for Cost-Effective Production

To achieve cost-effective production in injection molding, consider optimizing your design for manufacturability. This means simplifying components where possible to reduce both material waste and machining time—ultimately lowering your overall injection molding cost. Additionally, bulk purchasing materials can lead to discounts that further decrease expenses.

Another strategy involves conducting thorough research on suppliers; knowing how much does an injection molding machine cost is vital when planning your budget. Investing in high-quality machinery may seem expensive upfront but often results in lower maintenance costs and better efficiency over time. Furthermore, leveraging partnerships with experienced manufacturers can help you navigate complexities while keeping expenses manageable.

How Baoyuan Can Help with Your Needs

At Baoyuan, we understand the nuances of managing injection molding costs while delivering top-notch quality products tailored to your specifications. Our expertise allows us to provide accurate estimates that answer common questions like how much does injection molding cost? We also specialize in sourcing materials efficiently and competitively priced machinery—ensuring you get value without compromising on quality.

Additionally, if you're exploring metal options, we can guide you through metal injection molding costs compared to traditional plastic methods—helping you make an informed choice based on your unique needs. With our commitment to excellence and customer service, Baoyuan stands ready as your partner in navigating the world of manufacturing efficiently.