Introduction

Understanding Injection Mold Costs

Injection mold costs can vary widely based on numerous factors, including complexity, size, and production volume. Many manufacturers find themselves asking, What is the average cost of an injection mold? This question leads to a deeper exploration of how different components influence pricing and what businesses can expect when planning their projects.

Key Factors Influencing Prices

Several key factors play a significant role in determining how much does it cost to make an injection mold. These include design intricacies, material choices, and even labor expenses associated with the molding process. Additionally, understanding regional variations and market trends can provide valuable insight into how much are injection moulds in different areas.

Common Misconceptions About Costs

Despite the vast information available about injection molds, many misconceptions persist regarding their costs. For instance, some believe that all molds are prohibitively expensive or that custom designs always break the bank; however, this isn't necessarily true. By utilizing tools like an injection mould cost calculator or an injection moulding part cost calculator, manufacturers can gain clarity on what they should realistically expect when budgeting for their projects.

How Much Do Injection Molds Cost?

Breaking Down the Expenses

To truly grasp what is the average cost of an injection mold, we need to look at its core components. First off, material costs play a significant role; high-quality steel or aluminum will drive up your initial investment but may save money in longevity and durability later on. Then there are labor and overhead costs, which encompass everything from machine operation to maintenance and even facility expenses—each contributing to how much it costs to make an injection mold.

Additionally, design and engineering fees should not be overlooked; if you're opting for custom molds tailored specifically for your product needs, expect these services to add considerably to your total bill. Lastly, don’t forget about ancillary expenses like shipping and handling—these can sneak up on you if you're not careful! Keeping track of all these factors can help you utilize tools like an injection mould cost calculator effectively.

Average Prices in the Industry

So how much are injection moulds typically priced? On average, standard molds can range from $1,000 to $100,000 depending on size and complexity. Custom molds tend to be on the higher end of that spectrum but offer unique features tailored precisely for specific applications.

For instance, smaller production runs might only require simpler designs that could be produced at lower costs—think around $5,000 or so for basic models. Conversely, larger-scale operations with intricate designs may find themselves facing prices upwards of $50k or more! This variability makes it crucial for anyone asking What is the average cost of an injection mold? to consider their specific needs carefully.

Factors That Affect Pricing

Several key factors influence how much do injection molds cost beyond just materials and labor—timeliness is one of them! If you need a quick turnaround time for your project, manufacturers may charge a premium fee for expedited services or rush orders. Additionally, geographical location plays a role; regions with higher living costs generally see inflated prices due to increased labor rates.

Another significant factor is production volume: higher quantities often lead manufacturers to offer discounts per unit due to economies of scale—the more you order at once means less hassle per item produced! Lastly, technological advancements in machinery can also affect pricing; newer machines that produce better quality parts faster may have higher upfront costs but ultimately save money over time through efficiency gains.

What is the Average Cost of an Injection Mold?

Understanding what is the average cost of an injection mold can be a bit tricky, as it varies significantly based on several factors. Generally, injection molds can range from a few thousand dollars to over $100,000. The price you end up paying often reflects the complexity of the mold and the materials used, so let's dive deeper into those typical price ranges.

Exploring Typical Price Ranges

When asking how much do injection molds cost, you’ll find that typical prices can start around $1,000 for simple designs and go up to $50,000 for more intricate molds. High-end custom molds designed for specific applications may reach upwards of $100,000 or more. Factors such as size, material selection, and production volume all play significant roles in determining these costs.

For instance, a basic mold for small plastic parts may cost between $3,000 and $10,000 while larger components could easily push that figure beyond $20,000. Understanding these typical price ranges helps businesses budget effectively when considering how much does it cost to make an injection mold.

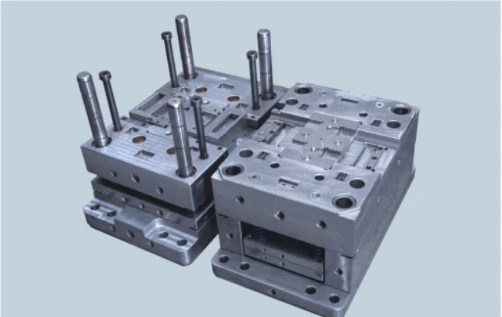

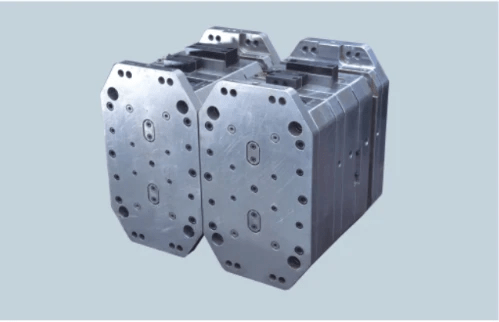

Comparing Standard vs. Custom Molds

The distinction between standard and custom molds is crucial when evaluating how much are injection moulds in general. Standard molds are typically less expensive due to their mass production capabilities and simpler designs; they might average between $5,000 to $15,000 depending on size and complexity. Custom molds cater to specific needs or unique part designs and can significantly inflate costs—often ranging from $20,000 to over $100,000.

In addition to initial pricing differences, maintenance costs should also be considered when comparing these two types of molds. Custom molds may require specialized care due to their unique features which can add further expenses down the line; thus understanding how to calculate injection mold cost accurately becomes essential for long-term financial planning.

Case Studies of Real-World Costs

To put things into perspective regarding what is the average cost of an injection mold in real-world scenarios—let's examine a few case studies! Company A needed a simple mold for a plastic cap; after thorough research using an injection moulding part cost calculator they found quotes ranging from $3,500 to $6,500 from various manufacturers.

On the other hand, Company B required a complex automotive part which led them down a rabbit hole of quotes averaging around $45,000 after consulting with multiple suppliers about how much does it cost to make an injection mould specifically designed for high-volume production runs. These examples illustrate that while averages provide insight into potential costs associated with manufacturing processes like these—actual expenses can vary widely based on specific requirements.

How to Calculate Injection Mold Cost?

Calculating the cost of an injection mold can feel like trying to solve a Rubik's cube blindfolded. However, with a clear understanding of essential components and the right tools, you can simplify this process significantly. In this section, we’ll break down how to calculate injection mold cost effectively while keeping your budget in check.

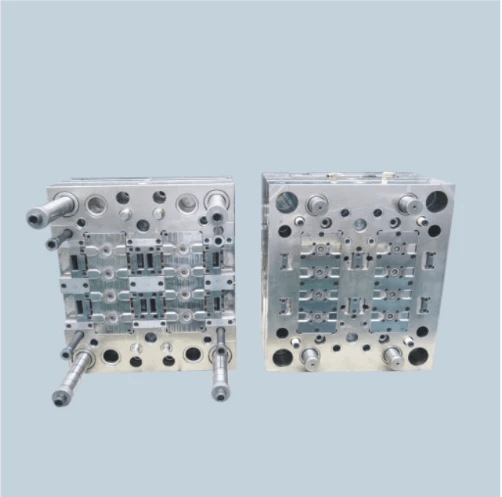

Essential Cost Components

To grasp how much do injection molds cost, it’s crucial to identify the essential components that contribute to the overall price. First up are material costs; these vary based on the type of resin or metal you choose for your mold. Next, there are labor costs associated with designing and manufacturing the mold, which can fluctuate depending on complexity and production time.

Additionally, overhead expenses such as utilities and equipment maintenance should be factored into your calculations. Don't forget about tooling costs—these are often overlooked but play a significant role in determining what is the average cost of an injection mold. Finally, consider any additional features or modifications that may be needed for specialized applications; these could add substantial amounts to your final invoice.

Tools for Cost Calculation

When it comes to calculating how much does it cost to make an injection mould, having the right tools at your disposal can make all the difference. One popular option is an injection mould cost calculator; these online tools allow you to input various parameters such as material type and labor hours for a more accurate estimate.

Another useful resource is an injection moulding part cost calculator; this tool helps assess costs based on specific parts you intend to produce rather than just generic molds. Additionally, software solutions designed for manufacturing costing can provide comprehensive insights into both direct and indirect expenses involved in producing injection molds.

Sample Calculations Using the Injection Mould Cost Calculator

Let’s put theory into practice with some sample calculations using an injection mould cost calculator! For instance, if you're looking at a standard two-cavity mold made from steel with a projected production run of 10,000 parts, inputting relevant data might yield initial estimates around $20,000–$30,000 depending on design intricacies.

If we apply varying factors like material choice or production volume adjustments within our calculations—say switching from steel to aluminum—you might see significant shifts in total costs as well as changes in durability and longevity of the molds themselves. Remember that understanding these nuances will help clarify how much are injection moulds really worth in terms of investment versus return over time!

How Much Does It Cost to Make an Injection Mold?

When considering how much it costs to make an injection mold, several factors come into play that can significantly affect the overall price. The design complexity, material selection, and production volume all contribute to the final figure. Understanding these aspects can help you navigate through the murky waters of injection mold costs and avoid unexpected expenses.

Material Costs and Their Impact

Material costs are one of the most significant components when calculating how much do injection molds cost. The type of material used for both the mold and the parts being produced can vary widely in price, affecting your budget considerably. For instance, high-quality steel molds may seem pricey upfront but often result in lower long-term costs due to durability and longevity compared to cheaper alternatives.

When asking what is the average cost of an injection mold, it's essential to consider that premium materials may increase initial expenses but can lead to better performance and fewer defects down the line. Additionally, if you're using specialized materials for your products—like high-temperature plastics or bio-resins—this will also impact your overall material costs significantly. Therefore, carefully selecting materials is crucial for effective cost management.

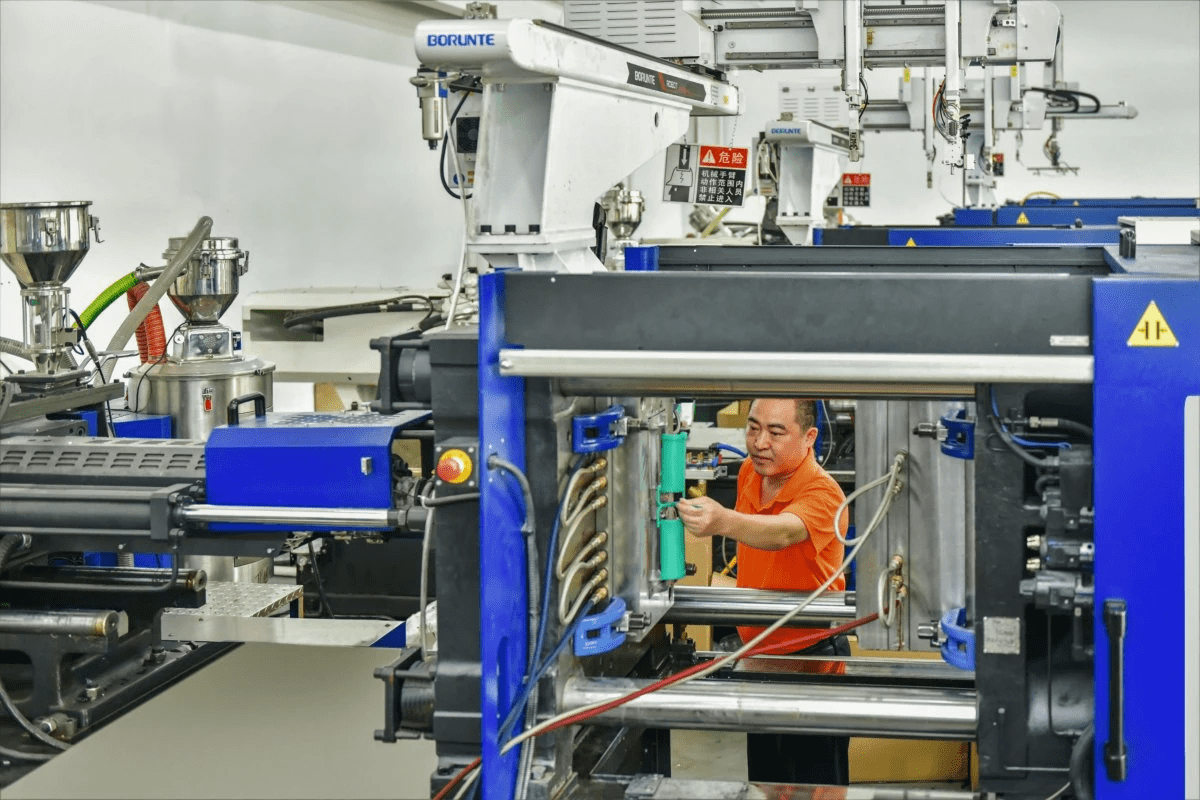

Labor and Overhead Considerations

Labor costs are another critical factor in determining how much does it cost to make an injection mold. Skilled labor is required for both design and manufacturing processes; thus, wages can add up quickly if you're not careful with project management. Furthermore, overhead expenses such as facility maintenance, utilities, and equipment depreciation must be factored into your calculations as well.

Understanding how these labor dynamics fit into your project helps you better grasp how much are injection moulds in a real-world context. If you’re outsourcing work or dealing with international suppliers, fluctuating labor rates can further complicate matters—making it imperative to keep a close eye on these variables during budgeting phases.

Cost-saving Tips from the Baoyuan Team

The Baoyuan team has some valuable insights on minimizing expenses while ensuring quality when asking how much does it cost to make an injection mold? First off, consider using standard designs instead of custom ones whenever possible; this often leads to lower tooling costs and faster production times without sacrificing functionality.

Additionally, utilizing an injection moulding part cost calculator can help streamline your budgeting process by providing estimates based on specific parameters like material type and complexity level. Lastly, don't shy away from negotiating quotes with manufacturers; many are open to discussing terms that could lead to significant savings over time while still delivering a quality product.

How Much Are Injection Moulds?

When it comes to understanding how much are injection moulds, the answer isn't straightforward. Prices can vary significantly based on several factors, including complexity, materials, and manufacturing location. This section will help you navigate the murky waters of injection mold pricing while answering the burning question: how much do injection molds cost?

Assessing Market Rates

Market rates for injection molds can fluctuate widely depending on industry demand and technological advancements. On average, a standard mold may range from a few thousand to tens of thousands of dollars. To get a clearer picture of what is the average cost of an injection mold in your specific sector, it's crucial to consult industry reports and recent market studies.

Moreover, certain materials and specialized features can drive up costs significantly. For instance, molds designed for high-volume production or intricate designs will naturally command higher prices. Therefore, assessing market rates involves not only looking at base costs but also understanding the added value that specific features bring to your project.

Regional Price Variations

Understanding regional price variations is essential when determining how much does it cost to make an injection mold. Different countries have varying labor costs, material availability, and manufacturing regulations that can influence overall pricing structures. For example, molds produced in countries with lower labor costs might be cheaper than those manufactured in regions with higher wages.

Additionally, local demand for molds can also impact prices; areas with a booming manufacturing sector may see inflated costs due to increased competition for resources. It's wise to research local suppliers as well as international options before making decisions based solely on initial quotes. This way, you’ll have a comprehensive understanding of how much are injection moulds in different markets.

Understanding Quotes from Manufacturers

When you're ready to dive into obtaining quotes from manufacturers, knowing how to calculate injection mold cost is key to deciphering these figures effectively. Manufacturers often provide detailed breakdowns that include material costs, labor charges, overhead expenses, and any additional fees related to design or modifications needed during production.

Be prepared for variability in quotes; some manufacturers might offer lower upfront prices but include hidden fees later on—so always ask for clarification on each component of their quote! Utilizing tools like an injection mould cost calculator can help you compare offers more accurately by providing standardized metrics across different manufacturers’ proposals.

In summary, understanding how much do injection molds cost involves assessing market rates carefully while considering regional variations and being savvy about manufacturer quotes. With this knowledge at hand—alongside tools like the injection moulding part cost calculator—you’ll be better equipped to manage your budget effectively without compromising quality.

Conclusion

Navigating the world of injection mold costs can feel like trying to solve a Rubik's Cube blindfolded. From understanding how much do injection molds cost to exploring what is the average cost of an injection mold, it's crucial to grasp the nuances that influence pricing. As we've discussed, factors like material choice, labor, and regional variations significantly affect your bottom line.

Recap of Injection Mold Cost Factors

In summary, several key factors determine how much are injection moulds in today’s market. Material costs play a pivotal role in shaping the overall price, while labor and overhead considerations can add unexpected expenses. Additionally, understanding how to calculate injection mold cost accurately will help you avoid common pitfalls and ensure you get the best value for your investment.

Final Thoughts on Cost Management

Managing costs effectively is essential for any business looking to succeed in manufacturing. By keeping tabs on how much does it cost to make an injection mold and leveraging tools such as the injection mould cost calculator, you can make informed decisions that align with your budgetary constraints. Remember, a well-planned approach not only saves money but also enhances production efficiency.

Resources for Further Cost Calculations

To dive deeper into understanding your specific needs, consider utilizing resources like an injection moulding part cost calculator or consulting industry experts who can provide tailored insights. Online platforms often have calculators that help break down costs based on your unique project specifications—making it easier than ever to assess how much does an injection molding machine cost in relation to your production goals. With these tools at hand, you're well-equipped to tackle any costing challenges that come your way.