Introduction

Navigating the world of injection mold cost can feel like deciphering a complex puzzle. With numerous factors influencing the price, it’s crucial to understand what drives these costs and how they can impact your manufacturing decisions. Whether you’re asking, “How much does a mold for injection cost?” or pondering the expenses associated with production in different regions, grasping these elements is essential for effective budgeting.

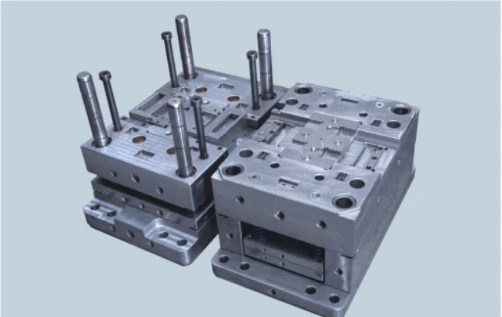

Understanding Injection Mold Cost Factors

Injection mold cost is influenced by several key factors that range from material selection to design complexity. For instance, the choice of materials can significantly affect both quality and price, while intricate designs may require more advanced techniques and time-consuming processes, raising costs further. Additionally, understanding how labor costs integrate into the overall injection molding process will provide you with a clearer picture of what to expect when budgeting for your project.

Key Questions About Mold Pricing

When considering injection molding, it's important to address some fundamental questions about mold pricing: How much does injection molding cost in China compared to domestic options? Why is injection mold so expensive? And how do you effectively calculate these costs? By tackling these inquiries head-on, you'll not only clarify your financial expectations but also empower yourself to make informed decisions that align with your project goals.

The Importance of Cost Calculation

Accurate cost calculation is vital in ensuring that your investment in an injection mold yields optimal returns. Utilizing tools like an injection mold cost calculator can streamline this process and help you identify areas where savings might be possible without compromising quality. Ultimately, understanding how to calculate injection mold cost effectively will enable you to plan better and maximize efficiency throughout your production cycle.

What Influences Injection Mold Cost?

When it comes to understanding injection mold cost, several factors come into play that can significantly affect the final price. These include material selection, design complexity, and labor costs associated with the injection molding process. By delving into these elements, you can gain a clearer picture of how to calculate injection mold cost effectively.

Material Selection and Its Impact

The choice of materials is one of the most significant factors influencing injection mold cost. Different materials have varying prices, properties, and processing requirements that can drastically alter your budget. For instance, high-performance plastics may be more expensive upfront but could save costs in durability and performance over time—so when asking “How much does injection molding cost in China?” or elsewhere, consider the material as a key player.

Moreover, using specialized or reinforced materials can increase both the initial mold price and the overall production costs due to their unique handling requirements. An effective way to estimate these expenses is by utilizing an injection mold cost calculator that takes material specifics into account. Remember that while cheaper materials might lower your immediate costs, they could lead to higher expenses down the line if they don’t meet quality standards.

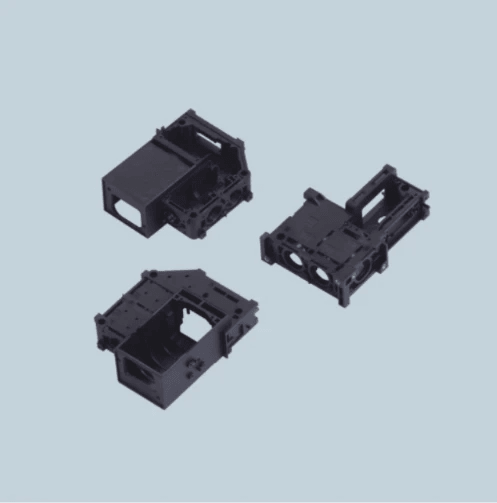

Design Complexity and Its Role

Design complexity plays a pivotal role in determining injection mold cost as well. The more intricate your design is—think detailed features or multi-part assemblies—the more time-consuming and costly it will be to create an effective mold for it. This complexity not only increases labor hours but may also require advanced machinery; thus raising questions like “How much does an injection molding machine cost?”

Additionally, complex designs might necessitate additional engineering work during both the design phase and manufacturing process, further inflating costs. If you're wondering why injection molds are so expensive overall, this aspect certainly contributes significantly; simpler designs often translate into lower production times and reduced costs across the board.

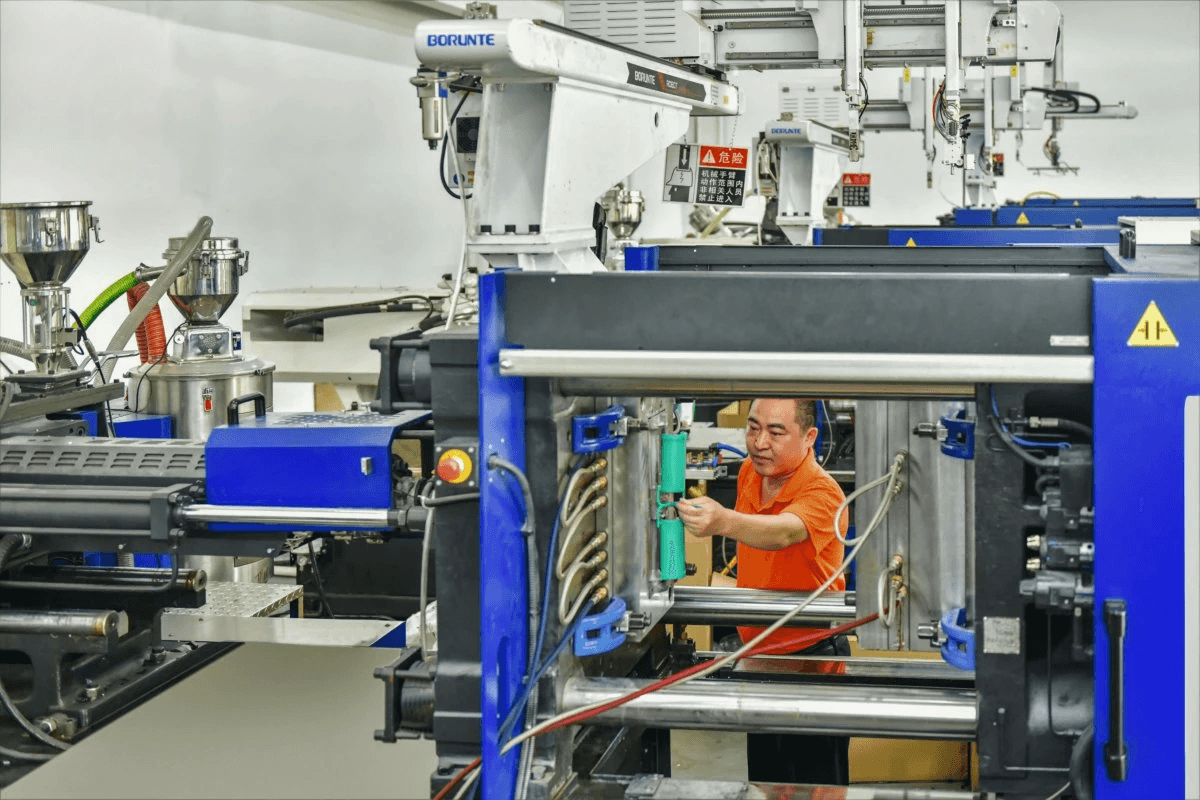

Labor Costs in the Injection Molding Process

Labor costs are another crucial factor affecting overall injection mold cost that shouldn’t be overlooked. The skill level required for designing molds or operating machinery can vary widely based on project complexity and technology used in production processes. As such, regions with higher wage standards will naturally see increased labor expenses impacting total pricing.

In countries like China where labor may be less expensive than domestic options, many companies weigh their decisions carefully when considering “How much does injection molding cost in China?” versus local manufacturing alternatives. However, it's essential to balance these savings against potential compromises on quality or delivery timelines which can ultimately affect your bottom line in unforeseen ways.

Understanding all these influences helps you navigate through questions about how to calculate injection mold cost accurately while ensuring you make informed decisions about your production needs.

How to Calculate Injection Mold Cost?

Calculating injection mold cost can feel like trying to solve a Rubik's Cube blindfolded; it’s complex but entirely doable with the right tools and knowledge. Understanding the various factors involved will help you answer the burning question: How much does a mold for injection cost? With that in mind, let's dive into some practical methods and considerations for estimating your costs accurately.

Using an Injection Mold Cost Calculator

An injection mold cost calculator is your best friend when it comes to estimating expenses quickly and efficiently. These calculators take into account various parameters such as material type, mold complexity, and production volume to provide a ballpark figure for your injection mold cost. However, while these tools can give you a rough estimate, they should be complemented with detailed analysis for precision.

When using an injection mold cost calculator, it's crucial to input accurate data regarding your project specifications. The more precise your information—like the type of plastic used or the intricacy of the design—the better the result you'll get from the calculator. Keep in mind that while these calculators are useful, they can't replace professional consultation if you're dealing with larger projects or unique requirements.

Key Metrics to Consider

To truly understand how to calculate injection mold cost effectively, you need to consider several key metrics beyond just material prices. First off is design complexity; intricate designs typically require more time and expertise, which translates into higher costs. Additionally, factors such as production volume play a significant role; larger runs usually mean lower per-unit costs due to economies of scale.

Another vital metric is labor costs associated with both creating and operating an injection molding machine. How much does an injection molding machine cost? This question often leads back to labor since skilled technicians are necessary for setup and maintenance—adding another layer of expense you must account for in your overall calculations. Lastly, don’t forget about overhead costs like facility expenses or utilities that can also impact your final numbers.

Steps to Estimate Your Costs

Estimating your injection mold costs involves several straightforward steps that can make this daunting task much easier. Start by gathering all necessary project specifications—this includes dimensions, materials needed, and any special features required in the design phase. Once you've compiled this information, input it into an injection mold cost calculator or consult with experts who can help refine those estimates further.

Next up is breaking down each component: analyze material selection carefully since high-quality materials often come at a premium price but may save you money long-term through durability and reduced waste during production runs. After that step comes evaluating labor requirements; consider how much skilled labor will be needed based on complexity and volume demands.

Finally, compile all these elements into a comprehensive budget plan that includes potential contingencies for unexpected expenses—because let’s face it: surprises happen! By following these steps methodically on how to calculate injection mold cost effectively, you'll be well on your way toward making informed decisions about your manufacturing process.

Comparing Costs: China vs. Domestic

When it comes to injection mold cost, businesses often find themselves weighing the benefits of offshore manufacturing against local production. Understanding how much does injection molding cost in China compared to domestic options is crucial for making informed decisions. This section will explore the financial implications, benefits, and quality considerations involved in choosing between these two manufacturing landscapes.

How Much Does Injection Molding Cost in China?

The question How much does injection molding cost in China? is frequently asked by companies looking to optimize their production budgets. Typically, costs can be significantly lower than domestic prices due to lower labor costs and material expenses in China. However, while initial figures may seem attractive, it’s essential to consider additional factors such as shipping fees and potential tariffs that can inflate the overall injection mold cost.

Moreover, using an injection mold cost calculator can help provide a clearer picture of total expenses when sourcing from overseas. Many manufacturers offer competitive prices for molds; however, understanding how much does a mold for injection cost requires scrutinizing quotes closely and factoring in hidden costs that might arise later on. Ultimately, while Chinese manufacturing may present lower upfront costs, the complexities involved necessitate thorough analysis.

Benefits of Offshore vs. Local Manufacturing

Offshore manufacturing offers numerous advantages beyond just price; however, comparing these benefits with local options is vital for businesses concerned about overall efficiency and quality control. One significant benefit of offshore production is reduced labor costs which directly affect the injection mold cost—allowing companies to allocate funds elsewhere within their operations. Additionally, many Chinese manufacturers have advanced technology that can streamline production processes.

On the flip side, local manufacturing provides advantages such as quicker turnaround times and easier communication with suppliers—elements that can enhance project efficiency significantly. Furthermore, when considering how much does an injection molding machine cost domestically versus abroad, it's essential to factor in maintenance support and service availability that often favors local suppliers due to proximity and established relationships within the industry. Thus, weighing both options carefully will help businesses make more informed choices regarding their manufacturing strategies.

Quality Considerations Beyond Price

While price plays a crucial role when evaluating where to produce your products—especially concerning injection mold cost—quality should never be overlooked in this equation. The adage you get what you pay for rings particularly true when discussing overseas manufacturing; cheaper molds may lead to higher defect rates or inferior materials affecting product longevity and performance over time. Therefore, it’s vital for companies to assess not just how much does an injection molding machine cost but also its reliability and durability.

Moreover, technical expertise varies greatly between suppliers; thus understanding why is injection mold so expensive often ties back into the level of craftsmanship involved in creating high-quality molds that meet rigorous standards. Investing slightly more upfront into reliable domestic partners could yield long-term savings through reduced waste and improved product consistency—a factor that ultimately enhances brand reputation among consumers.

In summary, while evaluating your options between Chinese manufacturers versus local producers regarding your next project’s needs involves crunching numbers with tools like an injection mold cost calculator; it equally requires considering quality implications that could affect your bottom line down the road.

Why Is Injection Mold So Expensive?

When considering the overall injection mold cost, one might be surprised to discover the myriad factors contributing to its price tag. From the raw materials used to construct molds to the sophisticated machinery required for production, understanding these elements can shed light on why many ask, How much does a mold for injection cost? The intricacies of this manufacturing process often lead to higher expenses than initially anticipated, making it crucial for businesses to grasp these dynamics.

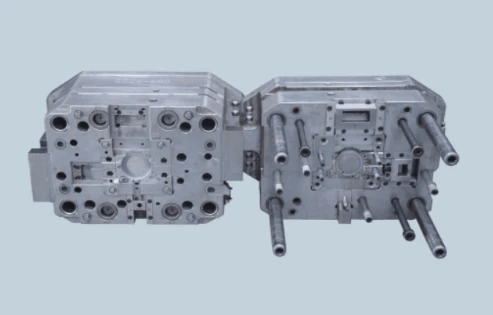

Analyzing Material and Machine Costs

The choice of materials significantly influences injection mold cost. High-quality steel and aluminum are commonly used due to their durability and ability to withstand high-pressure conditions, but they come with a hefty price. Additionally, how much does an injection molding machine cost? The investment in advanced machinery is substantial; cutting-edge machines designed for precision can run into hundreds of thousands of dollars, further driving up costs.

Moreover, the specific requirements of your project can dictate material selection and machine capabilities. For instance, specialized molds may require unique materials that are more expensive than standard options. Consequently, when pondering how to calculate injection mold cost accurately, it’s essential to account for both material quality and machine specifications.

The Role of Technical Expertise

Another vital component that contributes significantly to why injection mold is so expensive is technical expertise. Skilled engineers and technicians are necessary not only for designing intricate molds but also for optimizing production processes. This expertise comes at a premium; thus, labor costs can escalate quickly when you factor in the need for experienced professionals who understand how much does injection molding cost in China compared to domestic options.

Furthermore, complex designs require advanced knowledge in areas such as CAD software and material science—skills that are not easily acquired or cheap to hire out. As a result, companies must invest considerably in human resources alongside their machinery and materials if they wish to achieve high-quality outcomes without incurring excessive delays or errors during production.

Understanding Production Time and Efficiency

Production time plays a critical role in determining overall injection mold costs as well. Longer production runs lead not only to increased labor costs but also affect machine utilization rates—if machines sit idle waiting on parts or designs that aren’t optimized efficiently, expenses balloon even further. When assessing how much does an injection molding machine cost over its lifespan, one must consider its operational efficiency alongside initial purchase price.

Additionally, any downtime due to maintenance or design modifications can hinder productivity significantly; this inefficiency translates directly into higher costs per unit produced. Therefore, streamlining operations while maintaining quality becomes paramount if businesses want their investment in molds—and ultimately their bottom line—to pay off effectively.

Practical Tips for Cost-Efficient Injection Molding

When it comes to managing injection mold cost, practical strategies can make a significant difference. By understanding various factors and implementing smart practices, you can optimize your budget without sacrificing quality. Here are some tips to help you navigate the complexities of injection molding while keeping costs in check.

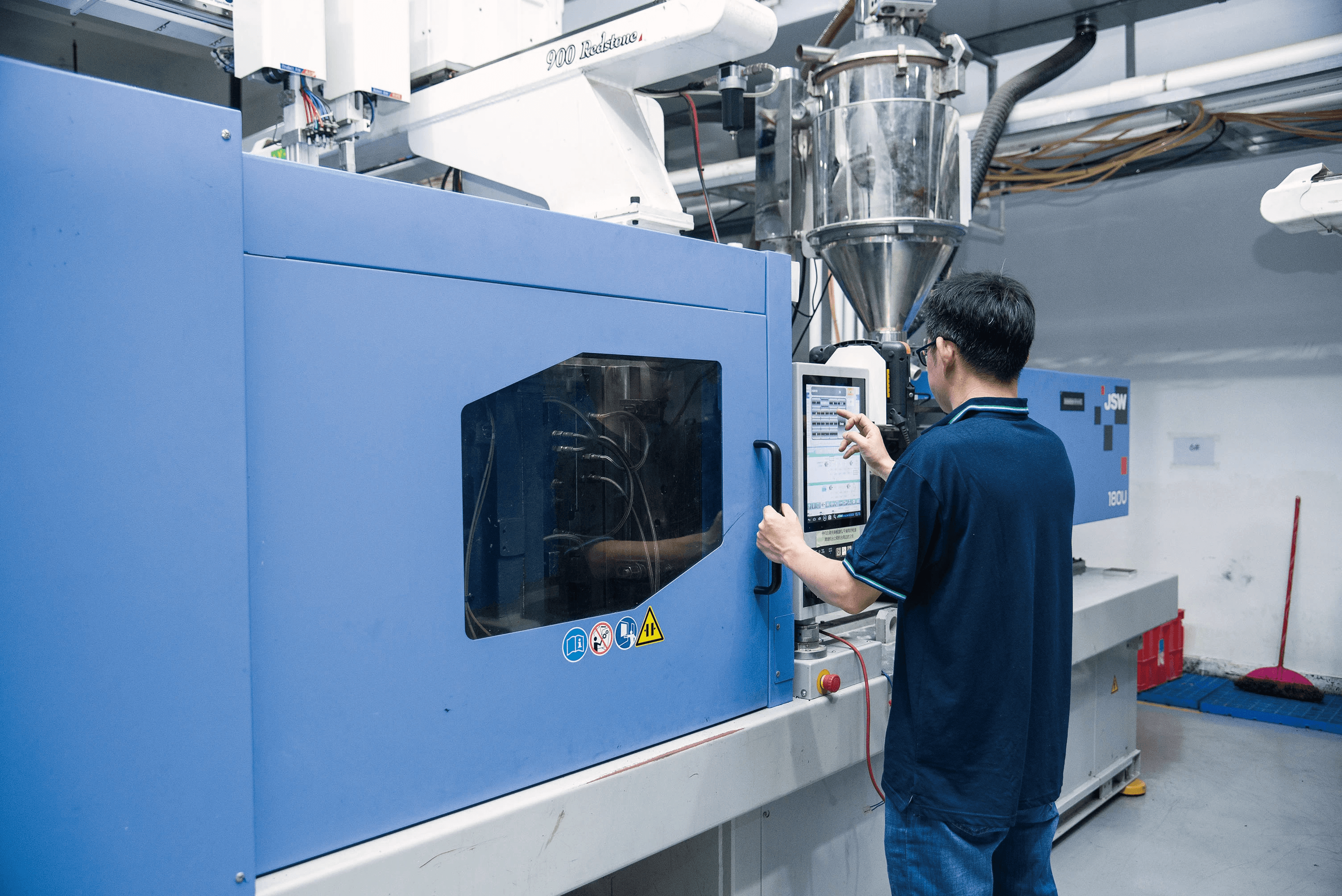

Partnering with Experienced Teams Like Baoyuan

Choosing the right partner for your injection molding projects can drastically influence your overall costs. Companies like Baoyuan bring years of expertise and a wealth of knowledge to the table, helping you avoid common pitfalls that lead to increased injection mold cost. With their experience, they can guide you on how much does an injection molding machine cost and recommend the best materials and designs that align with your budget.

Additionally, working with seasoned professionals means faster turnaround times and fewer errors during production. This efficiency translates into lower labor costs, which is a significant factor when calculating how to calculate injection mold cost effectively. Ultimately, partnering with experienced teams not only reduces initial expenses but also ensures long-term savings through optimized processes.

Streamlining Design for Cost Savings

Design complexity plays a crucial role in determining how much does a mold for injection cost. By simplifying your design where possible, you can significantly cut down on both material usage and production time—two key contributors to overall expenses. A well-thought-out design can lead to reduced cycle times and less wear on machinery, ultimately lowering the question of why is injection mold so expensive?

Employing design software or consulting with experts during the early stages can help identify potential inefficiencies before they become costly issues down the line. Moreover, using an injection mold cost calculator during this phase will give you insight into how different design choices impact pricing. Streamlining your design not only benefits your budget but also enhances product performance.

Long-Term Savings Through Quality Assurance

Investing in quality assurance may seem like an added expense at first glance; however, it pays off significantly over time by minimizing defects and rework costs associated with poor-quality molds. Understanding how much does injection molding cost in China versus domestic options often leads businesses astray; focusing on quality should be paramount regardless of location or initial price point.

By ensuring that every aspect of production meets high standards from the outset, you're more likely to enjoy smoother operations down the road—reducing wasteful expenditures linked to corrections or replacements due to faulty products or molds. Furthermore, maintaining rigorous quality checks helps clarify why is injection mold so expensive; it’s all about ensuring reliability and longevity in every piece produced.

Conclusion

In the world of manufacturing, understanding injection mold cost is crucial for making informed decisions that impact your bottom line. As we’ve explored, various factors influence how much does a mold for injection cost, from material selection to design complexity and labor expenses. Navigating these elements effectively can lead to significant savings and enhanced production efficiency.

Finding the Right Injection Mold Solutions

Finding the right injection mold solutions involves more than just comparing prices; it’s about ensuring quality and efficiency in your production process. Companies must consider how much does injection molding cost in China versus domestic options while weighing the benefits of both. By partnering with experienced teams, such as Baoyuan, you can streamline the process and ensure that your investment yields long-term benefits.

Assessing Your Injection Mold Cost Needs

When assessing your injection mold cost needs, it’s essential to utilize tools like an injection mold cost calculator to get a clear picture of potential expenses. Understanding how to calculate injection mold cost accurately will help you make better budgeting decisions and avoid unexpected financial pitfalls later on. Remember that while initial costs may seem high, investing in quality molds often results in lower overall costs due to increased durability and efficiency.

Making Informed Decisions for Production Efficiency

Making informed decisions about production efficiency requires a thorough understanding of why is injection mold so expensive and what factors contribute to those costs. Knowing how much does an injection molding machine cost can also influence your choices regarding equipment investments or partnerships with manufacturers who have their machinery in place. Ultimately, being well-informed allows you to optimize your operations while keeping an eye on both quality and costs.