Introduction

Welcome to the world of precision molded plastics, where innovation meets excellence! Precision injection molding has revolutionized the manufacturing industry, offering unparalleled benefits in product quality and cost-efficiency. At the forefront of this game-changing technology is Baoyuan, a leading expert in precision plastic molding.

The Importance of Precision Molded Plastics

Precision molded plastics play a crucial role in modern manufacturing, offering exceptional strength, durability, and dimensional accuracy. These qualities are essential for producing high-quality products that meet the stringent demands of various industries.

Benefits of Precision Injection Molding

The advantages of precision injection molding are manifold - from intricate design capabilities to rapid production cycles and minimal material wastage. This cutting-edge technology enables manufacturers to create complex components with unmatched precision and consistency.

The Role of Baoyuan in Precision Plastic Molding

Baoyuan stands at the forefront of precision plastic molding, leveraging state-of-the-art equipment and expertise to deliver top-notch solutions for diverse applications. With a commitment to excellence, Baoyuan has earned a stellar reputation as an industry leader in high precision plastic injection molding.

The Advantages of Precision Molded Plastics

Precision molded plastics offer a myriad of advantages that make them a top choice for manufacturers. With the ability to create high-quality, durable products, precision injection molding ensures that the end result is strong, resilient, and built to last. This is crucial for industries where product longevity is a key factor in consumer satisfaction and brand reputation.

High-quality, Durable Products

The precision in the molding process results in products that are consistently high in quality and durability. This means that manufacturers can rely on precision molded plastics to meet their performance standards and customer expectations. Whether it's for automotive components or medical devices, the durability of precision plastic molding plays a significant role in ensuring the safety and reliability of these products.

Precision plastic molding also allows for the creation of complex designs and features that may not be achievable through other manufacturing processes. This means that manufacturers can create intricate and detailed components for a wide range of industries, from consumer electronics to aerospace. The ability to produce complex designs and features adds value to the end product, making it more attractive to consumers and giving manufacturers a competitive edge in the market.

Complex Designs and Features

Another advantage of precision molded plastics is the ability to create intricate designs and incorporate complex features into the final product. This level of detail allows for innovative solutions that may not be achievable through traditional manufacturing methods. From intricate patterns to precise measurements, precision injection molding enables manufacturers to bring their most ambitious designs to life.

Furthermore, precision molded plastics offer the advantage of producing complex features and designs at a cost-effective rate. The ability to incorporate intricate details and precise measurements into the final product allows manufacturers to achieve innovative solutions that may not be achievable through traditional manufacturing methods. This level of detail enables companies to bring their most ambitious designs to life while keeping production costs in check.

Cost-Effective Production Processes

Precision plastic molding also offers cost-effective production processes that can help businesses save on manufacturing expenses without compromising on quality or design complexity. By streamlining production through efficient mold design and injection molding techniques, manufacturers can achieve higher output rates while minimizing material waste, ultimately leading to significant cost savings.

Furthermore, precision plastic molding allows for the production of intricate and complex designs with high accuracy and consistency. This means that businesses can create products with intricate details and unique shapes without incurring additional costs for specialized tooling or manual labor. The ability to produce such complex designs at a lower cost gives businesses a competitive edge in the market, allowing them to offer innovative products without breaking the bank.

Stay tuned for Part III where we will delve into Baoyuan's expertise in precision injection molding!

Baoyuan's Expertise in Precision Injection Molding

Senior Management with Years of Experience

At Baoyuan, our team is led by senior management with decades of experience in precision injection molding. Their expertise and industry knowledge allow us to provide innovative solutions and superior quality products to our clients.

Our senior management team's proficiency in mold design and injection molding is unmatched in the industry. Their extensive experience allows us to tackle complex projects with ease, delivering high-quality products on time and within budget. With their guidance, we are able to stay ahead of the curve in terms of technology and innovation, ensuring that our clients receive cutting-edge solutions for their needs.

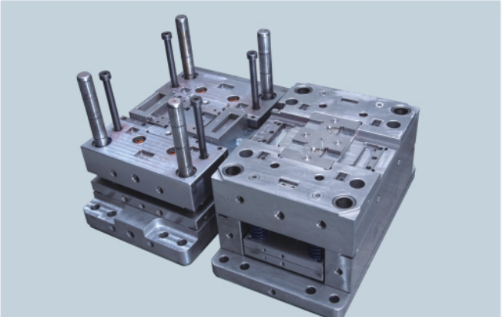

Proficiency in Mold Design and Injection Molding

Our proficiency in mold design and injection molding sets us apart as leaders in the industry. We utilize cutting-edge technology and advanced techniques to ensure the precision and accuracy of every plastic product we manufacture.

Our commitment to quality assurance extends beyond the manufacturing process. We conduct rigorous testing and inspection procedures to guarantee that every plastic product meets our high standards for durability, functionality, and aesthetic appeal. Our attention to detail and dedication to excellence ensure that our clients receive top-notch plastic products that exceed their expectations.

Quality Assurance of Plastic Products

Quality assurance is at the core of our operations at Baoyuan. We have rigorous quality control measures in place to guarantee that every precision molded plastic product meets the highest standards for durability, functionality, and aesthetic appeal.

At Baoyuan, we understand that quality assurance is not just about meeting industry standards; it's about exceeding them. Our team of experienced engineers and technicians are dedicated to continuously improving our quality control measures to ensure that every plastic product we produce is of the highest quality. We invest in state-of-the-art technology and equipment to conduct thorough inspections and tests at every stage of the production process, from raw material sourcing to final product assembly.

The Impact of Precision Plastic Molding on Product Quality

Consistency and Precision in Manufacturing

Precision molded plastics play a crucial role in ensuring consistency and precision in manufacturing processes. With high-tech injection molding techniques, every product is produced with exact specifications, reducing the risk of defects and ensuring uniformity throughout the production cycle.

Precision molded plastics are essential for meeting industry standards and regulations, as they ensure that every product adheres to specific guidelines and requirements. This level of precision is particularly important in industries such as aerospace, automotive, and medical devices, where even the slightest deviation can have significant consequences. By using advanced injection molding techniques, manufacturers can confidently produce components that meet the strictest quality standards, giving them a competitive edge in their respective markets.

Meeting Industry Standards and Regulations

The use of precision injection molding allows manufacturers to meet stringent industry standards and regulations. This ensures that products are not only of high quality but also compliant with safety and environmental requirements, giving customers peace of mind when using or purchasing these items.

Precision injection molding also allows manufacturers to consistently produce products with high levels of accuracy and repeatability, reducing the likelihood of defects or inconsistencies. This level of precision not only meets industry standards but also contributes to overall customer satisfaction by delivering products that perform as expected. By meeting these standards, manufacturers can build a strong brand reputation for reliability and quality.

Customer Satisfaction and Brand Reputation

The impact of precision plastic molding on product quality extends to customer satisfaction and brand reputation. By delivering consistently high-quality products, manufacturers can build trust with their customers, leading to positive brand recognition and long-term loyalty in the market.

By consistently delivering high-quality products through precision plastic molding, manufacturers can build trust with their customers. This trust leads to positive brand recognition in the market, as satisfied customers are more likely to recommend the brand to others. Additionally, long-term loyalty is established as customers continue to choose the brand over competitors due to the reliability and quality of the products.

Precision Injection Molding in California

California is renowned for its industry leadership in high precision plastic injection molding. With a focus on innovation and cutting-edge technologies, the state has established itself as a hub for precision plastic molding.

Industry Leadership in High Precision Plastic Injection Molding

California leads the way in high precision plastic injection molding, with a multitude of companies at the forefront of this technology. The state's commitment to excellence and quality has positioned it as a key player in the industry, setting high standards for precision molded plastics.

California's leadership in high precision plastic injection molding is further solidified by its innovative technologies and sustainable practices. Companies in the state are constantly pushing the boundaries of what is possible in plastic injection molding, developing new techniques and processes to achieve even greater precision and quality. Additionally, California-based manufacturers are committed to sustainable practices, utilizing eco-friendly materials and reducing waste to minimize their environmental impact while still delivering exceptional products.

Innovative Technologies and Sustainable Practices

The injection molding industry in California is characterized by its embrace of innovative technologies and sustainable practices. Companies are constantly pushing the boundaries of what's possible, while also prioritizing environmentally friendly processes that minimize waste and energy consumption.

Furthermore, the injection molding industry in California has seen a surge in the adoption of advanced materials and technologies to improve product quality and efficiency. From high-performance polymers to cutting-edge 3D printing techniques, companies are constantly seeking out new ways to stay ahead of the competition. This commitment to innovation not only drives the industry forward but also ensures that California remains a hub for groundbreaking manufacturing processes.

Baoyuan's Contribution to the Injection Molding Industry

Baoyuan has made significant contributions to the injection molding industry in California, leveraging its expertise in precision plastic injection molding to deliver top-notch products. As a trusted partner for businesses seeking high-quality plastic components, Baoyuan plays an integral role in shaping the future of precision molded plastics.

Furthermore, Baoyuan's commitment to innovation and continuous improvement has led to the development of cutting-edge technology and processes in the injection molding industry. By investing in state-of-the-art machinery and staying abreast of the latest advancements in materials and design, Baoyuan remains at the forefront of delivering high-performance plastic components that meet the evolving needs of its clients. This dedication to staying ahead of the curve sets Baoyuan apart as a leader in the injection molding industry.

Conclusion

Precision molded plastics have revolutionized the manufacturing industry, offering high-quality, durable products with complex designs and cost-effective production processes. Baoyuan has solidified its position as a trusted partner for precision injection molding, with expertise in mold design and quality assurance. The future of precision plastic molding in California looks promising, with industry leadership and innovative technologies driving sustainable practices.

Achieving Quality Products with Precision Molded Plastics

The use of precision molded plastics ensures the production of high-quality products that are durable and reliable. With complex designs and features, these plastics offer a level of versatility that traditional manufacturing methods cannot match. The cost-effective production processes also make precision injection molding a preferred choice for many industries.

Precision molded plastics offer a level of consistency and uniformity that is difficult to achieve with other manufacturing methods. This ensures that each product meets the same high standards of quality and performance, leading to greater customer satisfaction and loyalty. In addition, the ability to create intricate and detailed designs with precision molding allows for the production of products with unique features and functionality, setting them apart from the competition.

Baoyuan: A Trusted Partner for Precision Injection Molding

Baoyuan's expertise in precision plastic molding is unmatched, with senior management boasting years of experience in the industry. Their proficiency in mold design and injection molding ensures the delivery of top-notch products that meet industry standards and regulations. As a result, Baoyuan has become a trusted partner for businesses seeking high precision plastic injection molding solutions.

With a focus on continuous improvement and innovation, Baoyuan stays ahead of the curve in precision plastic molding. Their commitment to investing in the latest technology and machinery ensures that they can offer cutting-edge solutions to their clients. By staying at the forefront of industry trends, Baoyuan remains a reliable partner for businesses looking for advanced and high-quality injection molding services.

The Future of Precision Plastic Molding

The future of precision plastic molding in California is bright, with the industry leading the way in high precision plastic injection molding technologies and sustainable practices. As companies like Baoyuan continue to innovate and contribute to the injection molding industry, we can expect even greater advancements in product quality and manufacturing efficiency.

As companies like Baoyuan continue to innovate and contribute to the injection molding industry, we can expect even greater advancements in product quality and manufacturing efficiency. The integration of advanced technologies such as 3D printing and automation will further streamline the production process, reducing lead times and costs while maintaining high precision standards. Additionally, the industry's commitment to sustainable practices will drive the development of eco-friendly materials and processes, ensuring that precision plastic molding remains a responsible and forward-thinking manufacturing solution.

With a focus on achieving quality products through precision molded plastics, Baoyuan's expertise as a trusted partner for precision injection molding will continue to shape the future of the industry in California and beyond.