Introduction

Precision injection molding is a highly specialized manufacturing process that produces intricate and complex plastic components with unparalleled accuracy and consistency. This method offers numerous advantages, including cost-effectiveness, reduced material waste, and the ability to create intricate designs. At Baoyuan, our expertise in precision injection molding ensures that we deliver top-quality products that meet the most demanding industry standards.

Understanding Precision Injection Molding

Precision injection molding involves using advanced machinery and techniques to produce plastic components with incredibly tight tolerances and high levels of repeatability. This process allows for the creation of intricate geometries and complex shapes that would be impossible to achieve through traditional manufacturing methods.

Precision injection molding offers the advantage of producing parts with minimal waste, as the process is highly efficient and precise. This means manufacturers can save on material costs and reduce their environmental impact. Additionally, the high repeatability of precision injection molding ensures consistent quality across large production runs, leading to fewer defects and higher customer satisfaction. These benefits make precision injection molding a cost-effective and sustainable manufacturing solution for various industries.

Advantages of Precision Injection Molding

Precision injection molding offers many advantages that make it a standout manufacturing process. Here's a breakdown of its key benefits:

- Cost-Effective Precision: Reduced material waste translates to significant cost savings. Plus, the high precision of the process minimizes the need for rework or rejects, further enhancing cost efficiency.

- Quality You Can Count On: Tight control over the molding process ensures consistent, high-quality parts every single time. This reliability is crucial for industries with strict quality requirements, like medical device manufacturing.

- Lightweight Champions: Precision injection molding can produce lightweight and incredibly strong parts. This makes it ideal for applications where weight reduction is a priority, such as automotive and aerospace industries.

- Design: (This translates to "without borders" in Hebrew) Unlike some other methods, precision injection molding tackles complex and intricate designs with ease. This opens doors for innovative product development and unique features that can set your product apart from the competition.

- Fast and Furious (Production): High automation keeps production cycles short and efficient. This translates to faster lead times, allowing you to get your products to market quicker and capitalize on emerging trends.

Beyond the Benefits

- Suitable for Diverse Applications: Precision injection molding's versatility makes it applicable across a wide range of industries. This process can be a powerful tool for creating high-quality, functional components, from medical devices and automotive parts to consumer electronics and beyond.

- Scalability for Growth: As your production needs increase, precision injection molding can easily scale up to meet those demands. This makes it a future-proof solution for businesses looking for long-term growth.

By considering these advantages, precision injection molding can be a game-changer for your manufacturing process. It offers a unique combination of cost-effectiveness, quality control, design flexibility, and production speed, making it a compelling choice for businesses across various industries.

Baoyuan Team's Expertise in Precision Injection Molding

At Baoyuan, our team boasts extensive experience in precision plastic molding. We utilize cutting-edge technology and innovative techniques to ensure the highest level of precision in every product we manufacture. We are dedicated to delivering exceptional results that exceed our client's expectations while adhering to strict quality control measures.

Our team at Baoyuan understands the importance of staying ahead of the curve in the rapidly evolving field of precision plastic molding. That's why we invest in ongoing training and development for our staff, ensuring they are equipped with the latest skills and knowledge to tackle even the most complex projects. By staying at the forefront of industry advancements, we can offer our clients innovative solutions that push the boundaries of what is possible in precision injection molding.

The Process of Precision Injection Molding

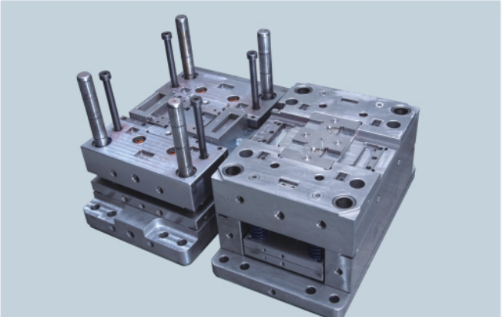

Precision injection molding is a complex process that requires meticulous attention to detail and advanced technology. Baoyuan excels in this area by utilizing cutting-edge software for mold design, ensuring precise and accurate specifications for each product. This enables us to create molds with intricate designs and exact dimensions, producing high-quality precision molded plastics.

Baoyuan's Use of Software in Mold Design

Baoyuan's team utilizes state-of-the-art software to design molds that meet the most demanding specifications. Our skilled engineers create intricate and precise designs, ensuring that every detail is accounted for in the mold. This allows us to produce precision plastic molding with unparalleled accuracy and consistency, meeting the highest industry standards.

Mold Opening and Injection Molding Techniques

Once the mold design is finalized, our expert technicians carefully execute the mold opening and injection molding techniques with precision and expertise. Each step of the process is meticulously monitored to ensure that the plastic material is injected into the mold with exactitude, resulting in flawless precision molded plastics.

After the plastic material is injected into the mold, our technicians carefully monitor the cooling process to ensure that the plastic solidifies and takes on the desired shape. This step is crucial in achieving flawless, precision-molded plastics, as any deviation in temperature or cooling time can result in defects or imperfections. Our team's attention to detail and expertise in mold opening and injection molding techniques ensure that every product meets our high standards for quality and precision.

Ensuring Quality Assurance in Plastic Products

At Baoyuan, quality assurance is paramount in our production process. We employ rigorous testing to guarantee that each plastic product meets our stringent quality standards. Our commitment to delivering high-precision plastic injection molding means that every product leaving our facility undergoes a thorough inspection to ensure durability, longevity, and adherence to customer specifications.

Furthermore, our quality assurance process includes regularly calibrating our manufacturing equipment to ensure consistent and accurate production. This proactive approach helps us identify and address any potential issues before they impact the quality of our plastic products. In addition, we prioritize ongoing training for our staff to keep them updated on the latest industry standards and best practices, contributing to a culture of excellence in every aspect of our operations.

Enhancing Product Quality with Precision Molded Plastics

The Importance of Material Selection

Material selection is the foundation of successful precision injection molding. Here's a breakdown of why it matters and how Baoyuan goes beyond the basics:

The Material Magic: The right material is the backbone of your product. It dictates factors like:

- Strength and Durability: Can it withstand the intended use and environmental conditions?

- Flexibility: Does it possess the required level of bend or give for the application?

- Heat Resistance: Will it perform well under expected temperatures?

Baoyuan's Material Mastery: Their expertise goes beyond just picking a material. They consider:

- Project Specifics: Understanding the product's purpose and function to choose the material that optimizes performance.

- Technical Requirements: Ensuring the material meets all the necessary strength, flexibility, and heat resistance specifications.

Beyond Functionality: Baoyuan takes a holistic approach:

- Aesthetics Matter: They consider how the material's look and feel align with the desired visual appeal of the final product.

- Function Meets Beauty: The material should support technical needs and contribute to the overall user experience and design goals.

Additional Considerations

- Cost Efficiency: Baoyuan likely balances material selection with cost optimization, ensuring the chosen material offers the best performance at a reasonable price point for your project.

- Sustainability: Many manufacturers are environmentally conscious. Baoyuan might explore recyclable or biodegradable materials when possible, considering both performance and environmental impact.

By prioritizing material selection and taking a comprehensive approach that considers function, aesthetics, and even sustainability, Baoyuan sets itself apart. Their team of experts ensures you get a precision injection molded product that is not only technically sound but also meets your specific design goals and exceeds expectations in terms of quality and performance.

Achieving Consistency in Product Dimensions

One of the key advantages of precision molded plastics is the ability to achieve consistent product dimensions. Baoyuan's advanced techniques and state-of-the-art equipment allow for tight tolerances and uniformity across multiple parts, ensuring that every piece meets exact specifications with minimal variation.

In addition to achieving consistent product dimensions, precision molded plastics offer the advantage of high repeatability. This means that once the mold is set up and the process is dialed in, identical parts can be produced with minimal variation. Baoyuan's expertise in high-precision plastic injection molding techniques ensures that every piece produced will meet exact specifications time and time again, providing customers with a reliable and consistent end product.

High Precision Plastic Injection Molding Techniques

At Baoyuan, high precision plastic injection molding techniques are employed to produce intricate and complex components with unparalleled accuracy. From micro-molding to multi-cavity molds, our team utilizes cutting-edge technology to achieve precise results that exceed industry standards.

The Role of a Professional Plastic Injection Company

When it comes to precision injection molding, choosing the right plastic injection company is crucial. Baoyuan boasts extensive experience and expertise in the field, with a proven track record of delivering high-quality precision molded plastics to satisfied clients. Our team's in-depth knowledge and skill set ensure we can meet even the most demanding project requirements.

Baoyuan's Experience and Expertise

With years of experience in precision plastic molding, Baoyuan has honed its expertise in producing top-notch precision molded plastics. Our team's deep understanding of the intricacies involved in precise injection molding allows us to consistently deliver exceptional results, making us a trusted partner for businesses seeking superior plastic products. Furthermore, our commitment to staying updated with the latest technological advancements in the industry ensures that we always utilize the most innovative techniques and materials to meet and exceed customer specifications and requirements. This dedication to continuous improvement sets us apart as a leader in precision plastic molding.

Meeting Customer Specifications and Requirements

At Baoyuan, we understand that every client has unique specifications and requirements for precision plastic injection molding projects. That's why we prioritize open communication and collaboration with our clients to ensure that we fully grasp their needs. Doing so can tailor our approach to meet and exceed their expectations, resulting in highly satisfactory outcomes.

In addition to our commitment to understanding and meeting customer specifications, we also pride ourselves on our ability to offer customization and flexibility in production. We recognize that our clients' needs may evolve, and we are prepared to adapt our manufacturing processes accordingly. Whether it's adjusting production volumes, modifying designs, or accommodating special requests, we are dedicated to providing a personalized experience that aligns with each client's unique requirements.

Customization and Flexibility in Production

One of our service hallmarks is our ability to provide customization and flexibility in production. Whether it's adjusting product dimensions or incorporating specific features into the design, Baoyuan is committed to accommodating our clients' requests with agility and precision. This level of adaptability sets us apart as a premier provider of high-precision plastic injection molding solutions.

By leveraging Baoyuan's experience and expertise, clients can rest assured that their projects are in capable hands. Our commitment to meeting customer specifications through customization underscores our dedication to delivering exceptional results time after time. With Baoyuan as your trusted partner in precise injection molding, you can expect nothing less than superior quality and innovation at every production stage.

Understanding the Significance of Precise Injection Molding

Precision injection molding plays a crucial role in enhancing product durability and longevity. By using high precision plastic injection molding techniques, products are manufactured with consistent dimensions and superior quality, resulting in longer-lasting and durable end products.

Impact on Product Durability and Longevity

Precision-molded plastics are a game-changer when it comes to product durability and longevity. Here's a closer look at how this technology elevates product quality:

1. Durability Built In: Precision injection molding creates parts with exceptional strength and consistency. The controlled molding process eliminates weak points or imperfections that can lead to premature failure, resulting in products that can endure wear and tear for extended periods.

2. A Lifespan Boost: Precision molding extends a product's lifespan by enhancing structural integrity. This translates to a better return on investment for consumers and a positive environmental impact by reducing waste from disposable products.

3. Design for Longevity: Unlike traditional methods, precision molding tackles complex shapes and intricate features with ease. This allows for the incorporation of design elements that specifically enhance durability, such as:

- Reinforced Corners: Extra material strategically placed to absorb impact and prevent cracks.

- Integrated Support Structures: Internal ribbing or bracing for increased rigidity and resistance to stress.

4. Meeting the Standards: Precision molding ensures parts meet industry regulations for durability. This translates to safe and reliable products that comply with established safety protocols, fostering consumer trust and satisfaction.

Beyond Durability

- Material Matters: The choice of material during the precision molding process significantly impacts durability. Baoyuan's expertise in material selection ensures the perfect match between material properties and the product's intended use.

- Process Consistency: Precision injection molding minimizes human error and guarantees consistent quality throughout production. This eliminates inconsistencies that might compromise product durability in traditional manufacturing methods.

By leveraging the precision and control offered by this molding technique, manufacturers can create products that are not only functional but also built to last. This translates to a win-win situation for both businesses and consumers, with businesses benefiting from reduced warranty claims and increased customer satisfaction and consumers enjoying long-lasting, reliable products.

Meeting Industry Standards and Regulations

Meeting industry standards and regulations is essential in ensuring that products are safe for consumer use. Precision injection molding allows for the production of high-quality plastic components that comply with industry standards, providing both manufacturers and consumers peace of mind.

Precision injection molding not only ensures compliance with industry standards but also allows for creating intricate and complex designs that meet the specific needs of manufacturers and consumers. By utilizing advanced technology and expertise, Baoyuan can consistently produce plastic components that meet regulations and exceed expectations in terms of quality and performance. This commitment to precision and excellence sets Baoyuan apart, providing a reliable source of top-notch plastic components.

Baoyuan's Commitment to Precision and Excellence

At Baoyuan, we are committed to upholding the highest precision plastic injection molding standards. Our dedication to excellence ensures that all our products meet rigorous quality control measures and deliver superior results that exceed customer expectations.

At Baoyuan, we are committed to upholding the highest standards of precision plastic injection molding. Our dedication to excellence ensures that all our products meet rigorous quality control measures, delivering superior results that exceed customer expectations. In addition to our stringent quality control measures, we prioritize sustainability in our manufacturing processes. By incorporating eco-friendly materials and reducing waste, we strive to minimize our environmental impact while producing top-notch plastic components.

Baoyuan's Dedication to Quality and Innovation

Precision injection molding has revolutionized the production of plastic products, and Baoyuan is at the forefront of this innovation. Our commitment to delivering superior products through precision injection molding is evident in our attention to detail and dedication to quality.

Delivering Superior Products through Precision Injection Molding

At Baoyuan, we understand the importance of precision injection molding in producing high-quality plastic products. Our expertise in precision molded plastics allows us to deliver superior products that meet and exceed our customers' expectations. With our state-of-the-art equipment and skilled team, we ensure that every product meets the highest quality standards.

As a leading plastic injection company, Baoyuan is dedicated to quality and innovation in all aspects of our operations. We constantly explore new techniques and technologies to enhance our precision plastic molding processes, ensuring we stay ahead of industry trends. Our commitment to innovation sets us apart as a trusted partner for all precision injection molding needs.

The Future of High Precision Plastic Injection Molding

The future of high precision plastic injection molding looks promising, with continuous advancements in technology and materials. Baoyuan is poised to lead this evolution with our unwavering dedication to excellence and customer satisfaction. As we continue to refine our precise injection molding techniques, we are confident that the future holds endless possibilities for creating innovative and durable plastic products.

With Baoyuan's expertise in precision injection molding, you can trust us to deliver top-quality plastic products that meet your specific requirements while adhering to industry standards.