Introduction

When it comes to plastic sheets for various applications, understanding the differences between polycarbonate and acrylic glass sheets is crucial. While both materials offer durability and versatility, they have distinct properties that make them suitable for different uses. Whether you're considering using plexiglass acrylic sheets or polycarbonate panels, knowing their key differences and applications is essential to make an informed choice.

Understanding Polycarbonate and Acrylic Sheets

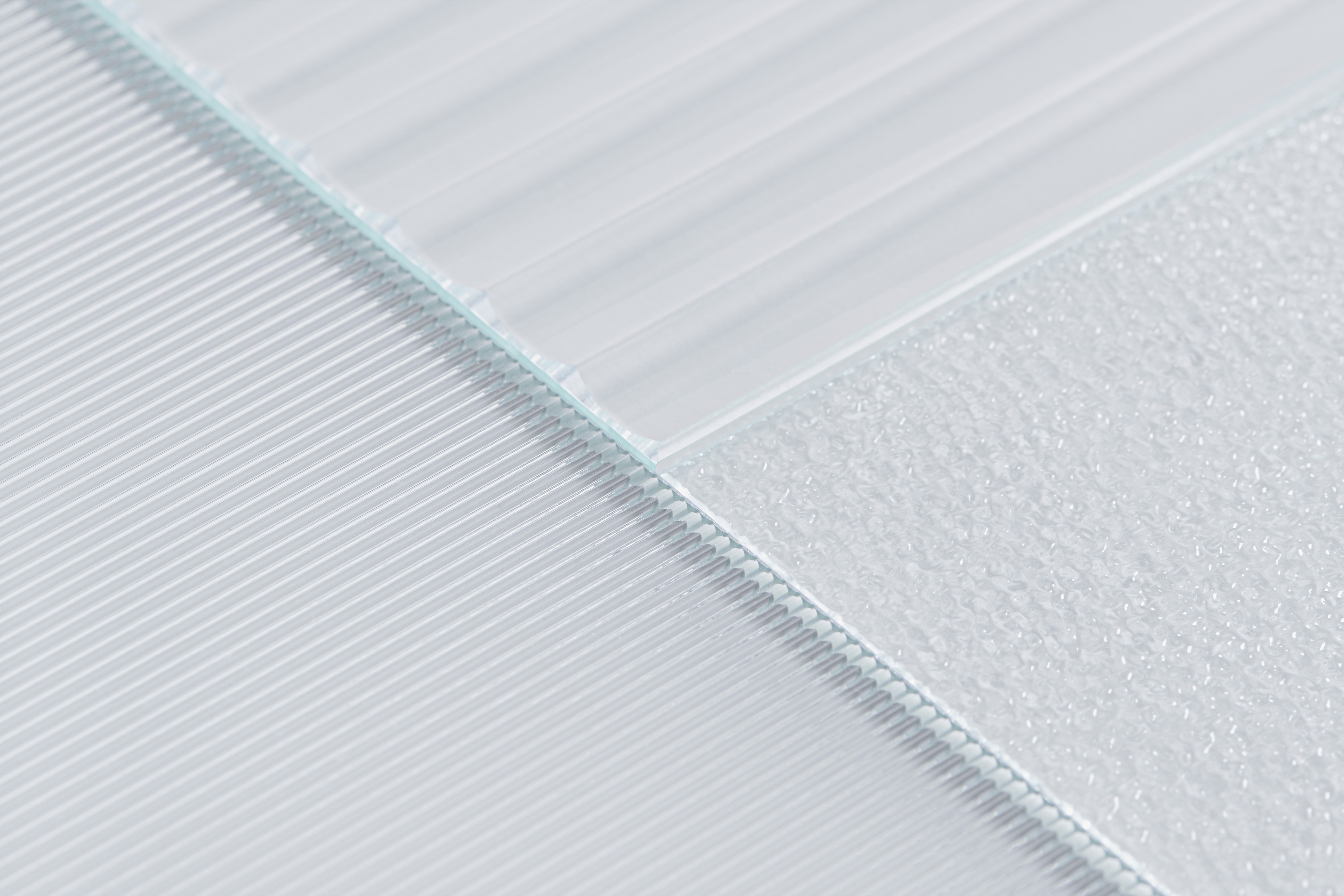

Polycarbonate sheets are known for their exceptional impact resistance and flexibility, making them ideal for applications where durability is paramount. On the other hand, acrylic sheets, also known as plexiglass, offer superior optical clarity and UV resistance, making them a popular choice for transparent barriers and displays.

Key Differences Between Polycarbonate and Acrylic

Choosing between polycarbonate and acrylic can be tricky. They are both clear, lightweight plastics with a wide range of applications. However, they have some key differences:

- Impact Resistance: Polycarbonate is significantly more impact-resistant than acrylic. It is virtually unbreakable, making it ideal for applications that require high levels of protection, such as bullet-resistant windows or riot shields.

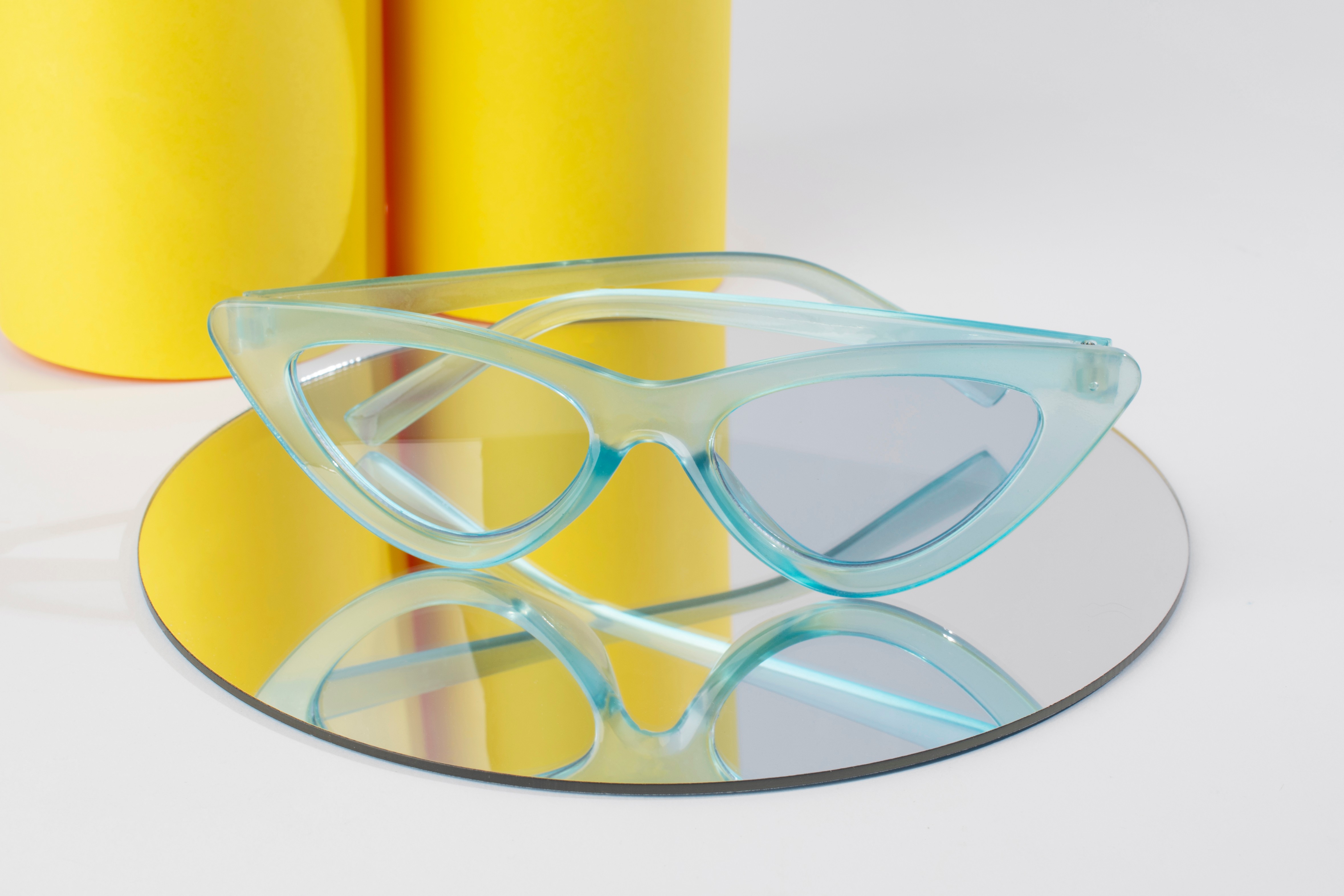

- Optical Clarity: Acrylic offers superior optical clarity. It has a higher light transmittance and a clearer view, making it a better choice for applications where visibility is critical, such as display cases or eyeglasses.

- Scratch Resistance: Acrylic is more scratch-resistant than polycarbonate. Polycarbonate is more susceptible to scratches from everyday wear and tear.

- Cost: Acrylic is typically less expensive than polycarbonate.

Polycarbonate is the tougher choice, while acrylic provides a clearer view. When choosing between polycarbonate and acrylic, consider the material's primary function. If durability is a significant concern, polycarbonate might be the better option. On the other hand, if optical clarity is essential, acrylic might be a better fit.

Applications of Polycarbonate vs. Acrylic Sheets

Polycarbonate panels, such as machine guards and safety barriers, are commonly used in industrial settings due to their strength and impact resistance. Acrylic sheets are favored for residential projects like windows, picture frames, and DIY crafts where transparency is essential.

The Composition and Properties of Polycarbonate and Acrylic Sheets

When comparing polycarbonate vs acrylic glass sheets, it's essential to understand their composition and properties. Polycarbonate sheets are made from a thermoplastic polymer known for its high impact resistance and durability. On the other hand, acrylic, or plexiglass, is a transparent thermoplastic known for its exceptional optical clarity and UV resistance.

Chemical Makeup and Durability

Polycarbonate panels comprise bisphenol A (BPA) and phosgene, resulting in a tough material that can withstand extreme weather conditions and physical impacts. Acrylic sheets, also known as plastic sheets, are made from polymethyl methacrylate (PMMA), offering excellent chemical resistance and durability.

Impact Resistance and Flexibility

Polycarbonate sheets are renowned for their exceptional impact resistance, making them ideal for applications requiring high protection against breakage or vandalism. In contrast, acrylic glass sheets offer flexibility and shatter resistance but may not be as durable in high-impact scenarios.

Polycarbonate sheets are also known for their superior optical clarity, providing a high level of transparency, making them an excellent choice for applications where visibility is crucial. In contrast, acrylic glass sheets may have slight distortions in their clarity, which could affect the overall aesthetic and functionality of the application. Additionally, polycarbonate sheets offer excellent UV resistance, making them suitable for outdoor use without the risk of yellowing or degradation over time. This UV resistance ensures that the material maintains its optical clarity and structural integrity even when exposed to harsh sunlight.

Optical Clarity and UV Resistance

Acrylic sheeting provides superior optical clarity to polycarbonate panels, making it an excellent choice for applications where transparency is crucial. Additionally, acrylic offers excellent UV resistance, making it suitable for outdoor use in various industries.

In addition to its optical clarity and UV resistance, acrylic sheeting offers excellent weatherability, maintaining its transparency and strength over time in harsh outdoor conditions. This makes it an ideal choice for greenhouse glazing, skylights, and outdoor signage where prolonged exposure to the elements is a concern. Acrylic's ability to withstand UV radiation without yellowing or becoming brittle ensures that it remains a reliable material for transparent structures in various industries.

Uses and Applications of Polycarbonate Sheets

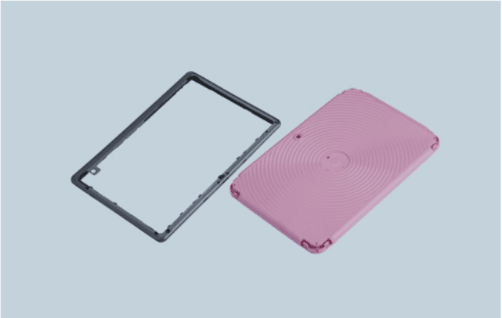

Polycarbonate sheets are widely used in industrial and commercial applications due to their exceptional durability and impact resistance. Polycarbonate panels, from machine guards to safety barriers, provide a reliable solution for protecting workers and equipment in high-risk environments. Their versatility also makes them suitable for construction, where they can be used as roofing materials or as protective barriers for machinery.

Industrial and Commercial Applications

In addition to industrial settings, polycarbonate sheets are also popular for residential and DIY projects. Their lightweight nature makes them easy to handle, making them ideal for DIY enthusiasts looking to add a durable yet transparent material to their projects. Polycarbonate sheets offer an affordable and practical solution for various home improvement projects, whether it's a greenhouse, shed window, or even a custom aquarium.

Residential and DIY Projects

At Baoyuan, our expertise in polycarbonate sheet production ensures that our products meet the highest quality standards. With state-of-the-art manufacturing processes and stringent quality assurance measures, we guarantee that our polycarbonate panels are reliable, long-lasting, and suitable for various applications.

Baoyuan's Expertise in Polycarbonate Sheet Production and Quality Assurance

Baoyuan's expertise in polycarbonate sheet production and quality assurance is unmatched in the industry. With years of experience and a commitment to excellence, Baoyuan has perfected the art of manufacturing high-quality polycarbonate sheets that meet the strictest standards. Their skilled professionals ensure that every sheet is produced with precision and attention to detail, guaranteeing superior performance and durability for any application. Customers can trust Baoyuan's expertise to deliver top-notch products that exceed expectations and stand the test of time.

Advantages and Disadvantages of Acrylic Sheets

Transparency and Scratch Resistance

Acrylic glass sheets, commonly known as plexiglass acrylic sheets, offer exceptional transparency, allowing maximum light transmission. This makes them an ideal choice for applications where optical clarity is essential, such as display cases or picture frames. Additionally, acrylic sheets are highly resistant to scratches, ensuring long-lasting durability in high-traffic areas.

Brittleness and Weather Resistance

One drawback of acrylic panels is their tendency to be more brittle than polycarbonate sheets. While strong and impact-resistant, they may not withstand heavy impacts, and neither can polycarbonate panels. Furthermore, acrylic sheets may experience some weathering over time when exposed to harsh environmental conditions, which can affect their longevity in outdoor applications.

Baoyuan's Skilled Use of Software for Acrylic Sheet Design and Production

Baoyuan takes pride in its ability to deliver exceptional acrylic sheet solutions. Their advanced software capabilities ensure:

- Precision Design: Meticulous software allows for creating intricate and flawless designs.

- Accurate Production: Advanced cutting and shaping techniques guarantee each sheet meets the highest standards of craftsmanship and accuracy.

- Customization: Their expertise allows them to tailor acrylic solutions to your project requirements.

Combining

these elements, Baoyuan ensures your project receives the perfect acrylic solution.

Comparing the Cost and Maintenance of Polycarbonate and Acrylic

Initial Investment and Long-Term Durability

When comparing the initial investment for polycarbonate vs. acrylic glass sheets, it's essential to consider each material's long-term durability. While plexiglass acrylic sheets may have a lower upfront cost, polycarbonate sheets offer superior impact resistance. They are virtually unbreakable, making them a cost-effective choice in the long run for applications that require durability.

In addition to durability, the cleaning and maintenance requirements of polycarbonate and acrylic glass sheets should also be considered when deciding. While acrylic sheets are known for being easy to clean and maintain, polycarbonate sheets are also relatively simple to care for, requiring only regular washing with soap and water. This means that both materials offer convenience in terms of upkeep, ensuring that they remain in good condition for an extended period without requiring excessive time or effort.

Cleaning and Maintenance Requirements

Both polycarbonate and acrylic panels are easy to clean and maintain. However, polycarbonate sheets are more resistant to scratching, making them ideal for high-traffic areas or outdoor use. While acrylic sheets are more prone to scratches, they can be easily buffed out with a specialized cleaner, offering versatility in maintenance options.

Additionally, polycarbonate and acrylic panels are resistant to UV radiation, ensuring they do not turn yellow or degrade when sunlight exposes them. This makes them suitable for outdoor applications without frequent maintenance or replacement. In terms of cleaning, both materials can be easily washed with mild soap and water, making them a low-maintenance option for various settings.

Baoyuan's Experience with Cost-Effective Production and Quality Control

At Baoyuan, we understand the importance of cost-effective production without compromising quality. Our expertise in manufacturing polycarbonate and acrylic sheets allows us to offer competitive pricing while ensuring strict quality control measures are in place throughout production. This results in high-quality plastic sheets that meet industry standards for durability and performance.

In addition to our commitment to cost-effective production and quality control, Baoyuan is also dedicated to minimizing the environmental impact of our manufacturing processes. Both polycarbonate and acrylic sheets are recyclable, reducing waste and promoting sustainability. We strive to use eco-friendly materials and energy-efficient technologies in our production facilities, demonstrating our dedication to environmental responsibility. By choosing Baoyuan for your plastic sheet needs, you can trust that you are supporting a company prioritizing quality and sustainability.

Environmental Impact: Polycarbonate vs. Acrylic Sheets

Recyclability and Sustainability

When comparing polycarbonate vs acrylic glass sheets, it's important to consider their recyclability and sustainability. Polycarbonate sheets are known for being fully recyclable, making them an environmentally friendly option for various projects. On the other hand, plexiglass acrylic sheets also have recycling capabilities, but they are not as widely recycled as polycarbonate panels, which may impact their sustainability in the long run.

Carbon Footprint and Eco-Friendly Options

The carbon footprint of polycarbonate vs acrylic sheets is another crucial factor to consider regarding environmental impact. Polycarbonate has a lower carbon footprint than acrylic glass sheets due to its longer lifespan and durability, making it a more eco-friendly option in the long term. While plexiglass acrylic sheets can be energy-intensive, they offer eco-friendly options with recycled content that can help reduce their environmental impact.

Baoyuan's Commitment to Sustainable Manufacturing Practices

At Baoyuan, we are committed to sustainable manufacturing practices when producing polycarbonate and acrylic sheets. We prioritize using recycled materials in our production processes whenever possible to minimize waste and reduce our environmental footprint. By choosing Baoyuan as your trusted partner for high-quality plastic solutions, you can rest assured that you support a company dedicated to environmentally responsible practices.

Furthermore, we are constantly investing in research and development to find innovative ways to improve our manufacturing processes and make them even more sustainable. We aim to lead the industry in eco-friendly production methods, setting a new standard for environmental responsibility. By choosing Baoyuan as your supplier, you are getting top-quality products and contributing to a greener future for the planet.

Make the Best Choice for Your Project

When choosing between polycarbonate and acrylic glass sheets for your project, it is essential to weigh the pros and cons of each material. While polycarbonate sheets offer superior impact resistance and durability, acrylic sheets are known for their transparency and scratch resistance. Understanding the versatility of polycarbonate and acrylic will help you make the best choice for your specific needs.

Ultimately, deciding between polycarbonate and acrylic will depend on your project requirements. Polycarbonate panels may be the better option if you need high-impact resistance and flexibility. On the other hand, if optical clarity and scratch resistance are crucial, plexiglass acrylic sheets could be more suitable. Consider factors such as environmental impact, maintenance requirements, and cost-effectiveness when deciding.

Exploring the Versatility of Polycarbonate and Acrylic

Both plastic sheets have various applications in various industries, from industrial to residential projects. Polycarbonate is commonly used in construction, automotive, and security applications due to its strength and durability. Acrylic is often chosen for signage, display cases, and DIY projects because of its optical clarity and ease of fabrication.

Baoyuan: Your Trusted Partner for High-Quality Plastic Solutions

Are you looking for high-quality polycarbonate or acrylic sheets? Baoyuan can be your trusted partner. Here's why:

- Production and Quality Expertise: Baoyuan boasts extensive experience in manufacturing plastic sheets. Their commitment to quality ensures you receive top-notch products.

- Customization Options: Do you need something specific? Baoyuan offers custom-designed plastic sheets alongside standard panels to meet your unique requirements.

- Sustainable Manufacturing: Baoyuan prioritizes eco-friendly practices so you can feel good about your purchase.

With Baoyuan, you get the perfect combination of quality, customization, and sustainability.