Introduction

When it comes to versatile and durable materials, polycarbonate stands out as a top contender. Whether you're familiar with poly carbonate or not, this brief overview will shed some light on its unique properties and applications. From polycarbonate sheets to plastic panels, we'll explore the many facets of this remarkable material.

Understanding Polycarbonate: A Brief Overview

Polycarbonate, often referred to as Lexan sheet, is a type of thermoplastic known for its exceptional strength and transparency. This versatile material is commonly used in various industries for its impact resistance and UV protection. From plastic boards to polycarbonate panels, the applications are endless.

Differentiating Polycarbonate from Other Plastics

While it's easy to categorize polycarbonate as just another plastic, it sets itself apart with its superior durability and lightweight nature. Unlike traditional plastic sheets, polycarbonate offers unmatched impact resistance and weatherability, making it a popular choice for outdoor applications.

Exploring the Advantages and Disadvantages of Polycarbonate

As we delve deeper into the world of polycarbonate, we'll uncover the advantages of using this material in different industries. However, we'll also address the potential drawbacks such as vulnerability to scratching and cost considerations that come with using polycarbonate sheets.

Is Polycarbonate a Plastic?

Defining Polycarbonate and its Composition

Polycarbonate is indeed a type of plastic, known for its exceptional strength and versatility. It is a thermoplastic polymer that is derived from bisphenol A (BPA) and phosgene, resulting in a durable material that can be easily molded into various shapes, making it ideal for a wide range of applications.

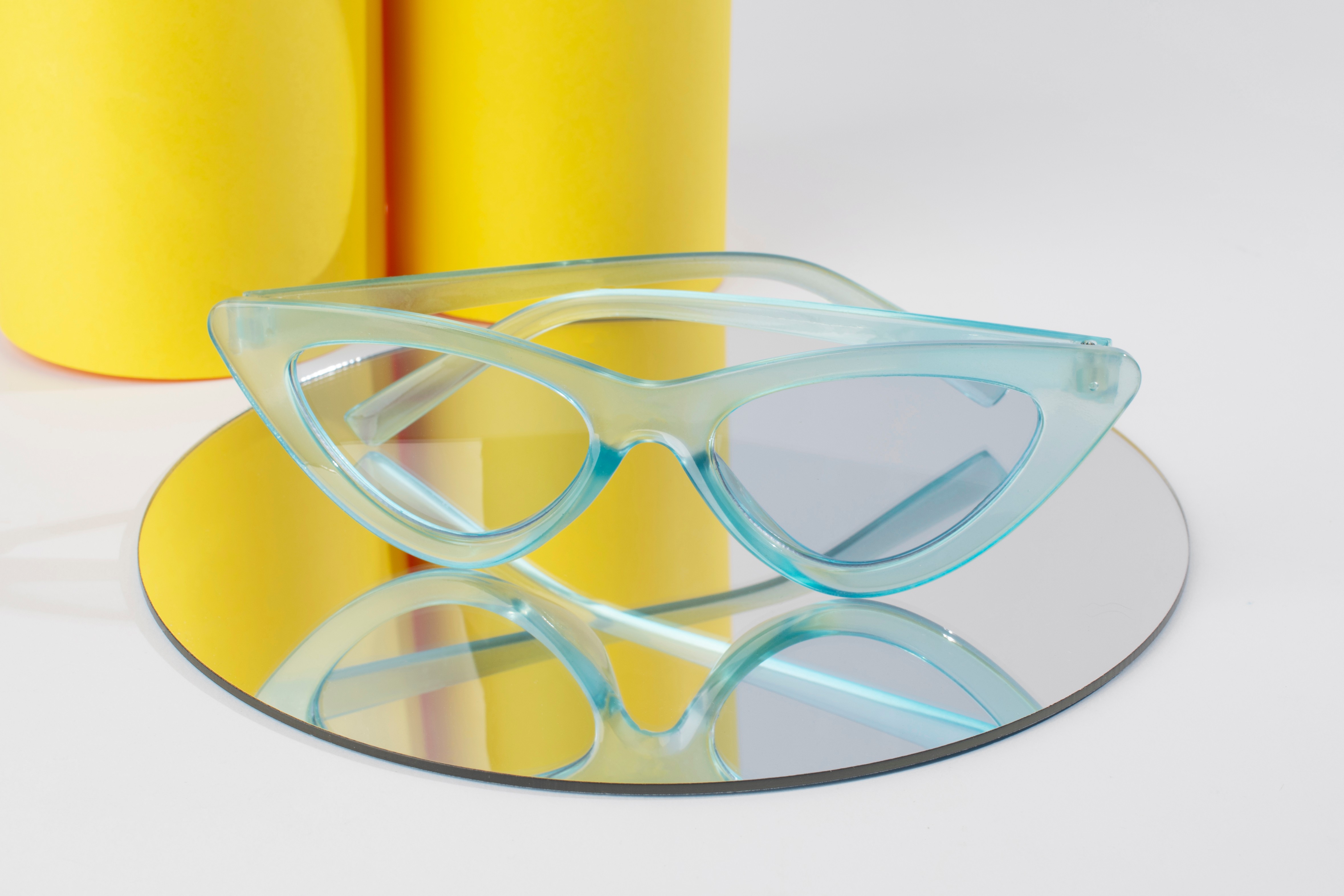

Polycarbonate stands out from other plastics due to its exceptional impact resistance, making it virtually unbreakable. This sets it apart from traditional plastics such as acrylic or PVC, which are more prone to cracking or shattering upon impact. Additionally, polycarbonate offers superior optical clarity, making it an ideal choice for applications that require transparency and visibility, such as eyewear or safety shields. Its ability to withstand high temperatures without warping or melting further distinguishes it from other plastics, allowing for use in demanding environments.

Comparing Polycarbonate to Other Plastics

When comparing polycarbonate to other plastics, it stands out due to its superior impact resistance and clarity. Unlike traditional plastics, polycarbonate has the ability to withstand high levels of force without shattering or breaking, making it an excellent choice for safety equipment and protective barriers.

Furthermore, polycarbonate is also resistant to heat and flame, making it a suitable choice for applications where exposure to high temperatures is a concern. This added durability and resistance to extreme conditions set polycarbonate apart from other plastics, making it an ideal option for a wide range of industrial and commercial uses. In addition, its exceptional optical clarity allows for the transmission of light without compromising on strength, making it a versatile material for various transparent applications.

Addressing Common Misconceptions about Polycarbonate

One common misconception about polycarbonate is that it is similar to acrylic or plexiglass. While they may look similar at first glance, polycarbonate offers greater impact resistance and toughness compared to these other plastic materials. Additionally, some people mistakenly believe that all plastic sheets are the same, but in reality, polycarbonate sheets are in a league of their own when it comes to durability and performance.

Another common misconception about polycarbonate is that it is not suitable for outdoor use. In reality, polycarbonate sheets are UV resistant and can withstand exposure to the elements without yellowing or deteriorating over time. This makes them an excellent choice for outdoor applications such as skylights, greenhouses, and patio covers. So, if you're looking for a durable material that can stand up to the rigors of outdoor use, polycarbonate is a top contender.

Remember that when choosing the right material for your project, understanding the unique properties of polycarbonate will ensure you make an informed decision about whether it's the best fit for your needs.

Advantages of Polycarbonate

Durability and Impact Resistance

When it comes to durability, polycarbonate is in a league of its own. Its exceptional impact resistance makes it virtually unbreakable, making it a top choice for safety and security applications. Whether it's polycarbonate sheets or panels, this material can withstand heavy impacts without cracking or shattering, providing long-lasting protection in high-traffic areas.

UV Protection and Weatherability

Unlike other plastics, polycarbonate offers built-in UV protection, making it ideal for outdoor use. Its ability to withstand harsh weather conditions without yellowing or deteriorating sets it apart from traditional plastic sheets. Whether you're looking for a reliable lexan sheet or plastic panels that can stand the test of time, polycarbonate is the go-to choice for outdoor applications.

Lightweight Nature and Ease of Fabrication

One of the key advantages of polycarbonate is its lightweight nature, which makes handling and installation a breeze. Despite being light in weight, polycarbonate sheets and panels are incredibly strong, offering the perfect balance between strength and ease of fabrication. This makes them an excellent choice for projects where weight is a concern but durability cannot be compromised.

Disadvantages of Polycarbonate

Vulnerability to Scratching

While polycarbonate sheets and panels are known for their durability, they are susceptible to scratching, especially when compared to glass or acrylic. This can be a concern in applications where the material is exposed to high traffic or abrasive conditions, requiring extra care and maintenance to preserve its appearance.

Flammability and Heat Resistance

One of the drawbacks of polycarbonate is its limited resistance to high temperatures, making it less suitable for use in environments with extreme heat or open flames. This characteristic also affects its fire rating, which may limit its application in certain building codes and safety regulations.

Cost Considerations and Environmental Impact

In comparison to other plastic sheets, polycarbonate tends to be more expensive due to its advanced manufacturing process and superior properties. Additionally, while it is a recyclable material, the environmental impact of polycarbonate production should be carefully considered when weighing its benefits against other alternatives.

Now you have a comprehensive understanding of both the advantages and disadvantages of using polycarbonate as a plastic material. Let's move on to exploring the various applications and versatility of polycarbonate sheets and panels in different industries.

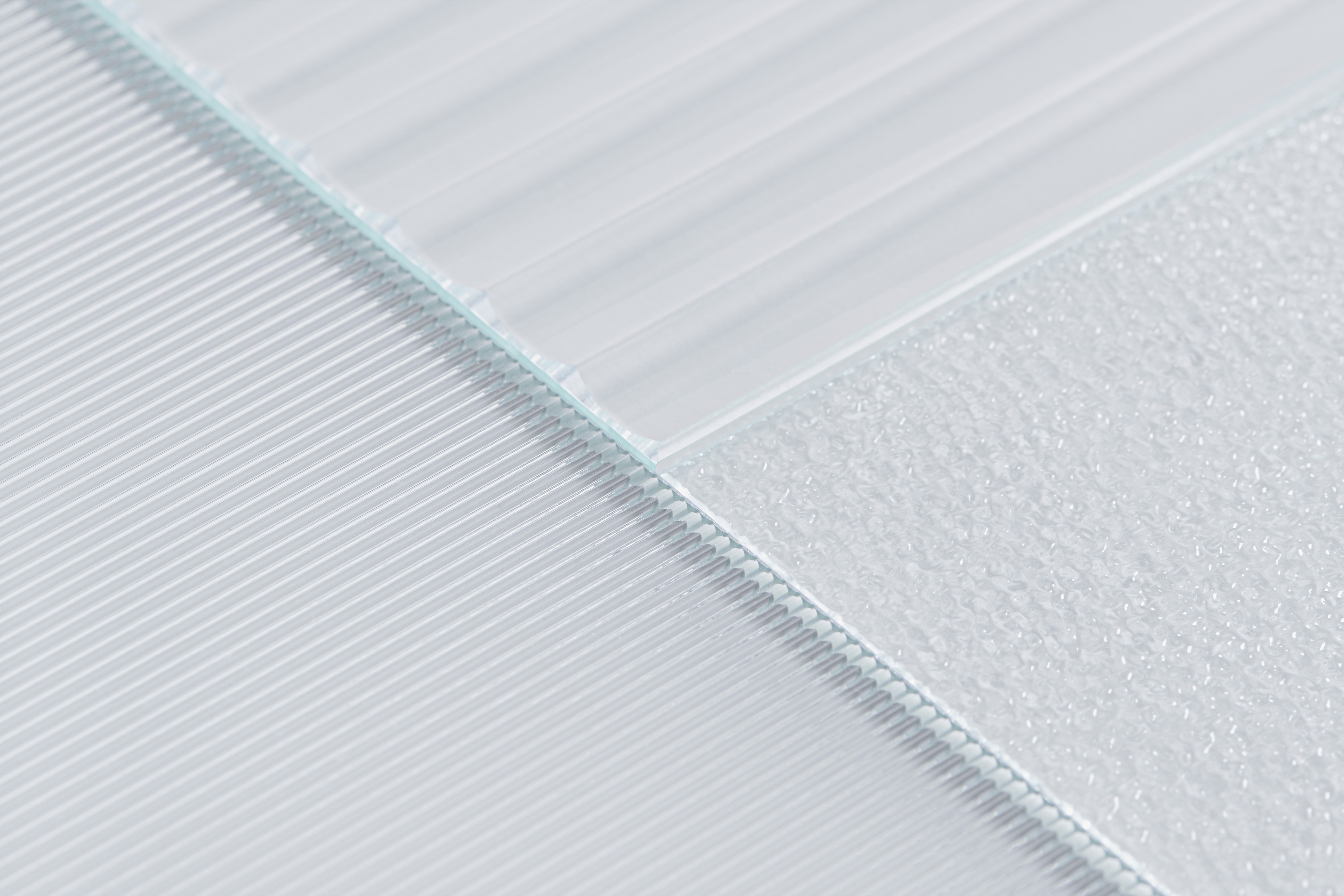

Polycarbonate Sheets and Panels

Applications and Versatility in Various Industries

Polycarbonate sheets and panels have a wide range of applications across different industries, including construction, automotive, agriculture, and signage. These versatile materials are used for roofing, skylights, greenhouse panels, machine guards, and more due to their exceptional impact resistance and durability. With its lightweight nature and ease of fabrication, polycarbonate is the top choice for projects requiring a balance of strength and flexibility.

Polycarbonate sheets and panels are often compared to other sheet materials such as acrylic and glass. While acrylic is known for its clarity and transparency, it lacks the impact resistance and durability of polycarbonate. Glass, on the other hand, is heavy and fragile compared to polycarbonate, making it less suitable for applications requiring flexibility and lightweight materials. In comparison, polycarbonate stands out as the ideal choice for projects that demand a combination of strength, durability, and versatility.

Comparison to Other Sheet Materials like Acrylic and Glass

When comparing polycarbonate sheets to other materials like acrylic or glass, it's clear that polycarbonate outperforms in terms of impact resistance and durability. Unlike traditional glass or acrylic panels that are prone to shattering upon impact, polycarbonate sheets offer unmatched strength without sacrificing clarity. Additionally, polycarbonate is much lighter than glass, making it easier to handle during installation.

Furthermore, polycarbonate sheets have a higher level of UV resistance compared to acrylic and glass, making them ideal for outdoor applications. This means that polycarbonate panels are less likely to yellow or become brittle over time when exposed to sunlight, providing long-lasting performance and aesthetic appeal. In addition, the flexibility of polycarbonate allows for easier customization and shaping, giving designers more creative freedom compared to rigid glass or acrylic materials.

Baoyuan's Expertise in Polycarbonate Product Manufacturing

Baoyuan has established itself as a leader in the production of high-quality polycarbonate sheets and panels. With state-of-the-art manufacturing facilities and a commitment to innovation, Baoyuan offers a wide range of polycarbonate products tailored to meet the specific needs of various industries. From standard clear sheets to specialty Lexan sheet options with enhanced UV protection or fire resistance, Baoyuan's expertise ensures top-notch performance for any application.

Baoyuan's commitment to excellence extends beyond its product offerings. The company also places a strong emphasis on customer service, ensuring that clients receive the support and guidance they need to select the right polycarbonate solutions for their specific requirements. Whether it's providing technical specifications, offering custom fabrication options, or delivering timely logistics support, Baoyuan goes the extra mile to ensure customer satisfaction at every step of the process.

The Future of Polycarbonate

Innovations in Polycarbonate Technology

As technology advances, so does the innovation in polycarbonate materials. Manufacturers are constantly developing new formulations and processing techniques to enhance the strength, durability, and versatility of polycarbonate products. These innovations have led to breakthroughs in impact resistance, UV protection, and flame retardancy, making polycarbonate an even more attractive choice for various applications.

Sustainable Practices and Recycling Initiatives

In response to growing environmental concerns, the polycarbonate industry is embracing sustainable practices and recycling initiatives. Companies are investing in eco-friendly production processes and promoting the recycling of polycarbonate materials to reduce waste and minimize their carbon footprint. This commitment to sustainability ensures that polycarbonate remains a responsible choice for both manufacturers and consumers.

As the demand for sustainable materials continues to grow, Baoyuan is at the forefront of advancing polycarbonate solutions that prioritize environmental responsibility. By investing in cutting-edge technologies and innovative production processes, Baoyuan is able to offer eco-friendly polycarbonate products that meet the highest standards of sustainability. Additionally, Baoyuan actively promotes the recycling of polycarbonate materials, working with partners and stakeholders to create a closed-loop system that minimizes waste and reduces the industry's overall carbon footprint.

Baoyuan's Role in Advancing Polycarbonate Solutions

As a leading manufacturer of polycarbonate sheets and panels, Baoyuan is at the forefront of advancing polycarbonate solutions. With a focus on research and development, Baoyuan continues to push the boundaries of what is possible with polycarbonate technology. By collaborating with industry partners and investing in cutting-edge manufacturing capabilities, Baoyuan is driving innovation in the use of polycarbonate as a sustainable, high-performance material.

Furthermore, Baoyuan's commitment to sustainability is evident in its efforts to reduce the environmental impact of polycarbonate production. By implementing eco-friendly manufacturing processes and using recycled materials, Baoyuan is leading the way in promoting the use of sustainable materials in construction and design. This focus on sustainability not only benefits the environment but also enhances the overall appeal of polycarbonate solutions to environmentally conscious consumers and businesses.

Now that we've explored the future of polycarbonate through technological advancements and sustainability efforts, let's delve into how these developments will shape the landscape of this versatile material for years to come.

Conclusion

When it comes to making informed choices about materials, the verdict on polycarbonate is clear: it is a versatile and durable option for various applications. Navigating the uses and limitations of polycarbonate requires understanding its unique properties and considering factors like cost and environmental impact. Baoyuan's commitment to quality and innovation in polycarbonate production ensures that customers can trust in the reliability of their products.

Making Informed Choices: The Verdict on Polycarbonate

As we've explored, polycarbonate is indeed a type of plastic, known for its strength and impact resistance. It offers a range of benefits, from UV protection to lightweight nature, making it a popular choice for numerous industries. Understanding these advantages allows consumers to make informed decisions when considering polycarbonate for their specific needs.

Polycarbonate's versatility extends beyond its physical properties, as it can also be easily molded and shaped into various forms, making it an ideal material for a wide range of applications. From eyeglass lenses to bulletproof windows, the uses of polycarbonate are diverse and far-reaching. This adaptability allows consumers to explore creative solutions for their specific needs, whether it's for automotive parts or greenhouse panels.

Navigating the Uses and Limitations of Polycarbonate

While polycarbonate sheets and panels have many advantages, they also have limitations that should be considered. Vulnerability to scratching and flammability are important factors to keep in mind when choosing between polycarbonate, other plastic sheets, or alternatives like glass or acrylic. By weighing these considerations, individuals can determine if polycarbonate is the right fit for their project.

While vulnerability to scratching and flammability are important considerations, polycarbonate sheets and panels offer exceptional impact resistance, making them ideal for applications where durability is a priority. Additionally, their lightweight nature makes them easier to handle and install compared to glass or other materials. This combination of strength and ease of use can make polycarbonate a compelling choice for a wide range of projects.

Baoyuan's Commitment to Quality and Innovation in Polycarbonate Production

Baoyuan's expertise in manufacturing polycarbonate products ensures that customers receive high-quality materials designed to meet their specific requirements. With a focus on sustainable practices and recycling initiatives, Baoyuan plays an essential role in advancing the use of polycarbonate while minimizing environmental impact.