Introduction

Welcome to the world of plastic injection molding automotive parts, where innovation meets excellence. In this article, we will explore the significance of injection molding in the automotive industry and delve into Baoyuan's expertise in plastic injection molding.

Understanding Plastic Injection Molding Automotive Parts

Plastic injection molding automotive parts have revolutionized the manufacturing process, providing a cost-effective and efficient solution for producing intricate components for vehicles. Baoyuan's specialization in this field ensures top-notch quality and precision in every part they produce.

The Importance of Injection Molding in Automotive Industry

Injection molding plays a crucial role in the automotive industry by enabling mass production of complex parts with minimal waste. This process not only enhances efficiency but also contributes to lightweighting, which is essential for improving fuel economy and reducing emissions.

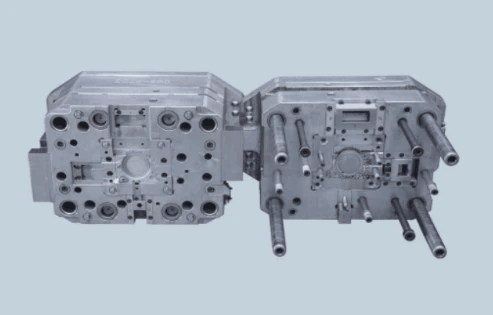

Baoyuan's Expertise in Plastic Injection Molding

As a leader in plastic injection molding, Baoyuan has honed its expertise over the years to meet the demanding requirements of the automotive sector. Their commitment to innovation and quality has made them a trusted partner for top automotive manufacturers worldwide.

The Basics of Plastic Injection Molding Process

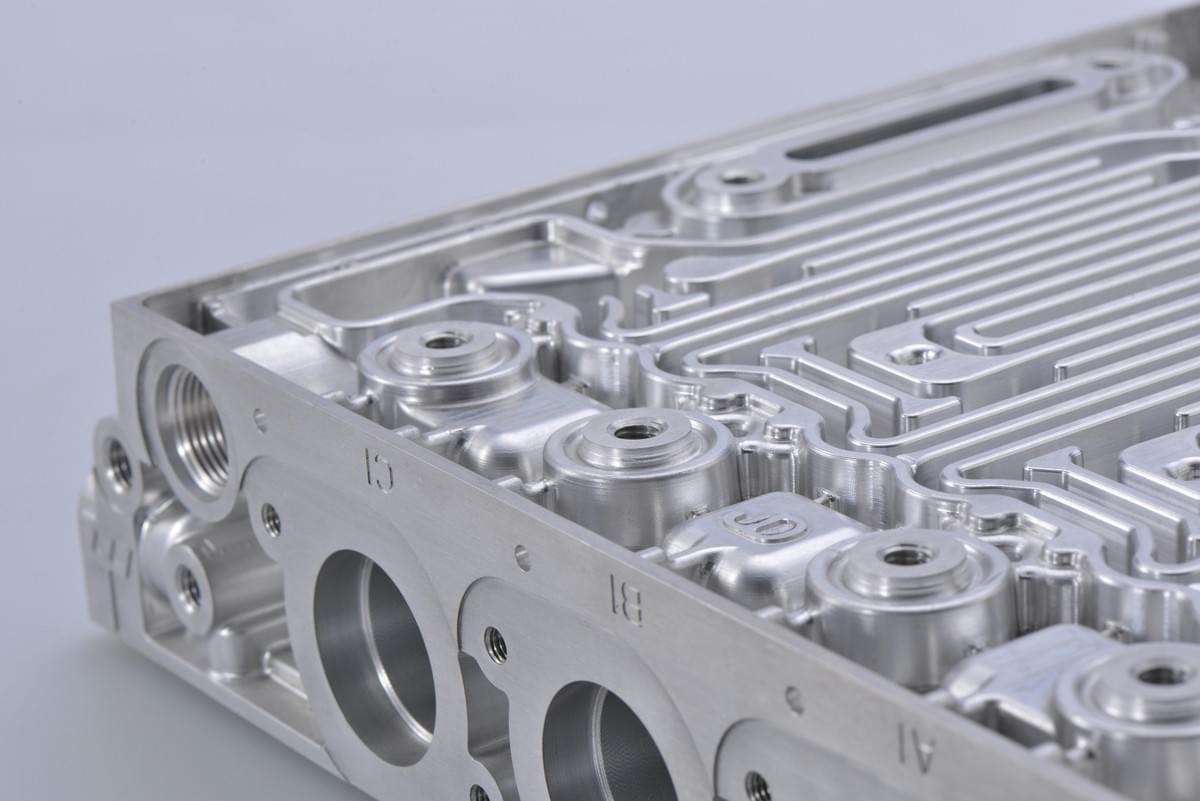

Plastic injection molding automotive parts are manufactured through a precise and efficient process. Baoyuan specializes in this process, ensuring top-quality parts for the automotive industry.

Key Steps in Injection Molding

The key steps in plastic injection molding process include clamping, injection, cooling, and ejection. Baoyuan's expertise lies in carefully executing each step to produce flawless automotive injection molding parts.

Baoyuan's attention to detail begins with the clamping process, where the two halves of the mold are securely closed to prevent any plastic leakage. Once the mold is clamped shut, the injection step begins, during which molten plastic is forced into the mold cavity. This is a critical stage that requires precision and control to ensure the proper distribution of material. Baoyuan's skilled technicians excel at maintaining optimal temperature and pressure levels throughout this stage to achieve consistent and high-quality results.

How Does Injection Molding Work

Injection molding works by melting plastic pellets and injecting the molten material into a mold cavity under high pressure. The material then cools and solidifies, taking the shape of the mold. Baoyuan's state-of-the-art equipment ensures that this process is carried out with precision. With our advanced technology, we are able to achieve intricate designs and tight tolerances, meeting the specific requirements of our clients' projects.

Baoyuan's Specialization in Injection Molding Process

Baoyuan specializes in the intricacies of the injection molding process, from mold design to material selection and production. Their attention to detail and commitment to excellence make them a leader in producing high-quality automotive plastic injection molding parts.

Baoyuan's expertise in injection molding extends beyond just the production process. They are also adept at integrating advanced technologies and innovative techniques to optimize efficiency and reduce production costs. By staying abreast of the latest industry trends, Baoyuan ensures that their automotive plastic injection molding parts meet the highest standards of quality and performance. Their ability to adapt to changing market demands sets them apart as a reliable partner for automotive manufacturers.

Advantages of Using Injection Molded Parts in Automotive Industry

Durability of Injection Molded Parts

When it comes to plastic injection molding automotive parts, durability is a key advantage. The process creates parts that are strong and resistant to wear and tear, making them ideal for the demanding environment of the automotive industry. With Baoyuan's expertise in producing durable injection molded parts, you can trust that your automotive components will stand the test of time.

In addition to durability, plastic injection molding also offers precision and consistency in the production of automotive parts. This means that each part is manufactured with exact specifications, ensuring a perfect fit and seamless integration into the vehicle's design. With Baoyuan's advanced technology and stringent quality control measures, you can be confident that every injection molded part will meet the highest standards of precision and consistency, contributing to the overall performance and reliability of your automotive components.

Precision and Consistency in Injection Molded Parts

The precision and consistency offered by injection molding parts are unmatched. This ensures that each part produced is identical, meeting strict quality standards every time. With Baoyuan's specialization in the injection molding process, you can rely on precise and consistent automotive parts that fit perfectly and function flawlessly within your vehicles. In addition to the uniformity of each part, Baoyuan's injection molding process also ensures a high level of durability and strength in the finished products. This means that your automotive parts will be able to withstand the rigors of everyday use without compromising on performance or safety.

Baoyuan's Excellence in Automotive Injection Molding

Baoyuan has established itself as a leader in automotive injection molding, delivering high-quality plastic injection molding parts for various applications within the industry. With a focus on innovation and advanced technology, Baoyuan consistently exceeds expectations by providing top-notch solutions for automotive plastic injection molding needs.

Baoyuan's reputation for excellence in automotive injection molding is built on a commitment to staying ahead of industry trends and technological advancements. By investing in cutting-edge equipment and continuously improving manufacturing processes, Baoyuan ensures that its plastic injection molding parts meet the highest standards for quality and performance. This dedication to innovation allows Baoyuan to offer customized solutions that address the specific needs of automotive manufacturers, setting them apart as a trusted partner in the industry.

Factors to Consider in Designing Injection Molded Automotive Parts

Design Flexibility in Injection Molded Parts

When it comes to designing injection molded automotive parts, design flexibility is crucial. With plastic injection molding, complex and intricate designs can be easily achieved, allowing for unique and customized automotive components that meet specific requirements. Baoyuan's expertise lies in maximizing the design flexibility of injection molded parts to deliver innovative solutions for the automotive industry.

With plastic injection molding, the material selection is also a key factor in achieving the desired design flexibility. Baoyuan understands the importance of choosing the right materials for injection molded automotive parts, taking into consideration factors such as strength, durability, and heat resistance. By carefully selecting the most suitable materials, Baoyuan is able to ensure that the injection molded parts not only meet design requirements but also perform optimally in the demanding automotive environment.

Material Selection for Injection Molded Automotive Parts

The material selection process for injection molded automotive parts is a critical factor in ensuring the durability and performance of the final product. With a wide range of materials available, including thermoplastics and thermosetting polymers, Baoyuan's team of experts carefully selects the most suitable materials for each application, considering factors such as strength, heat resistance, and impact tolerance.

The selection of materials for injection molded automotive parts is not only crucial for the durability and performance of the final product but also for meeting industry regulations and standards. Baoyuan's team goes beyond just considering strength, heat resistance, and impact tolerance; they also take into account factors such as chemical resistance, electrical properties, and overall cost-effectiveness. By carefully weighing these various factors, Baoyuan ensures that the chosen materials will meet the specific needs of each automotive application.

Baoyuan's Expertise in Designing Injection Molded Parts

Baoyuan has established itself as a leader in designing injection molded parts for the automotive industry. With a deep understanding of the intricacies involved in creating high-quality automotive components, Baoyuan leverages its expertise to optimize designs for manufacturability, cost-effectiveness, and overall performance. The company's commitment to excellence ensures that every injection molded part meets the highest standards of quality and precision.

Baoyuan's expertise in designing injection molded parts for the automotive industry extends beyond just creating high-quality components. The company also focuses on incorporating innovative and sustainable materials into their designs, ensuring that their products are not only durable and reliable but also environmentally friendly. By staying ahead of industry trends and regulations, Baoyuan continues to set the standard for excellence in injection molded parts, providing customers with cutting-edge solutions that meet the demands of today's automotive market.

Quality Assurance in Plastic Injection Molding Parts

Importance of Quality Control in Injection Molding

Quality control is crucial in the production of plastic injection molding automotive parts to ensure that they meet industry standards and customer requirements. By implementing rigorous quality control measures, manufacturers can detect and address any defects or inconsistencies in the injection molding process, ultimately leading to higher customer satisfaction and product reliability.

Implementing quality control measures also helps in reducing waste and rework, as any issues can be identified and resolved early in the production process. This not only saves time and resources but also contributes to a more efficient and cost-effective manufacturing operation. By maintaining consistent quality standards, manufacturers can also build a reputation for reliability and excellence in the industry, which can lead to increased business opportunities and customer trust.

Baoyuan's Quality Assurance Process

At Baoyuan, our quality assurance process is comprehensive and meticulous. We utilize advanced testing equipment and techniques to inspect the integrity, dimensions, and performance of our injection molded plastic parts. Our dedicated quality control team conducts thorough assessments at every stage of production to guarantee that each automotive part meets the highest standards of excellence.

Furthermore, our senior management and technical personnel play a crucial role in upholding the quality assurance process. They provide strategic guidance and support to ensure that our quality control team has the resources and expertise needed to maintain the highest standards. By fostering a culture of continuous improvement, they encourage innovation and excellence in every aspect of our production process, ultimately contributing to the overall success of Baoyuan.

The Role of Senior Management and Technical Personnel at Baoyuan

Senior management and technical personnel at Baoyuan play a pivotal role in upholding our commitment to quality assurance in plastic injection molding parts for the automotive industry. Their expertise and leadership ensure that our manufacturing processes adhere to strict quality guidelines, resulting in reliable, durable, and high-performing injection molded parts that meet the specific needs of our automotive clients.

Furthermore, the senior management and technical personnel at Baoyuan are constantly seeking ways to improve our manufacturing processes and stay ahead of industry trends. By staying abreast of the latest advancements in plastic injection molding technology, they ensure that our products are not only of the highest quality but also incorporate cutting-edge innovations that give our automotive clients a competitive edge in the market.

Conclusion

Achieving Excellence in Plastic Injection Molding Automotive Parts

Baoyuan has mastered the art of producing high-quality plastic injection molding automotive parts, ensuring durability and precision in every product. With a deep understanding of the plastic injection molding process and a commitment to innovation, Baoyuan continues to set the standard for excellence in automotive injection molding.

Baoyuan's dedication to quality and innovation is evident in their continuous investment in cutting-edge technology and equipment. By staying at the forefront of industry advancements, Baoyuan ensures that their automotive parts meet the highest standards of performance and reliability. This commitment to staying ahead of the curve sets them apart as a leader in the field of plastic injection molding for automotive applications.

Baoyuan's Commitment to Quality and Innovation

As a leader in the industry, Baoyuan is dedicated to upholding the highest standards of quality and innovation in plastic injection molding parts. With a focus on design flexibility, material selection, and quality control, Baoyuan ensures that every automotive part meets the strictest requirements for performance and reliability.

With an eye towards the future, Baoyuan is committed to staying at the forefront of technological advancements in automotive plastic injection molding. By investing in research and development, Baoyuan aims to continuously improve its manufacturing processes and explore new materials and techniques to enhance the performance and durability of its parts. This forward-thinking approach ensures that Baoyuan will remain a trusted partner for automotive manufacturers seeking innovative solutions for their molding needs.

The Future of Automotive Plastic Injection Molding

The future of automotive plastic injection molding is bright, with continuous advancements in technology and materials leading to even greater possibilities. Baoyuan remains at the forefront of these developments, constantly pushing the boundaries of what is possible in automotive injection molding.

As the demand for lightweight, durable automotive components continues to grow, Baoyuan is well-positioned to meet the needs of the industry. With a focus on sustainability and efficiency, Baoyuan's injection molding processes are designed to minimize waste and energy consumption, making them an ideal choice for environmentally-conscious manufacturers. By staying ahead of the curve in terms of technology and materials, Baoyuan is able to offer innovative solutions that not only meet current industry standards but also anticipate future trends.