Introduction

In today's automotive industry, the use of injection molded plastic auto parts has become increasingly vital. From custom automotive components to car interiors, injection molding offers a cost-effective and efficient solution for producing high-quality parts. With the demand for lightweighting and fuel efficiency, plastic injection molding has emerged as a game-changer in automotive manufacturing. And at the forefront of this innovation is Baoyuan, a trusted expert in injection molded plastic auto parts.

Importance of Plastic Injection Molding for Automotive Parts

The significance of plastic injection molding in the automotive industry cannot be overstated. Injection-molded car components have revolutionized the way vehicles are designed and manufactured, offering unparalleled versatility and precision in creating complex geometries and intricate details for various automotive applications.

The use of injection-molded plastic auto parts also contributes to the overall lightweighting of vehicles, which is crucial for improving fuel efficiency and reducing emissions. By utilizing plastic materials, automotive manufacturers can achieve significant weight savings compared to traditional metal components, without sacrificing strength or durability. This allows for the production of more eco-friendly vehicles that meet stringent regulatory standards while providing enhanced performance and handling for drivers.

Advantages of Using Injection Molded Plastic Auto Parts

The advantages of using injection molded plastic auto parts are numerous. From enhanced design flexibility to reduced production costs, these parts offer unmatched durability and reliability while contributing to overall lightweighting and fuel efficiency in modern automobiles.

In addition to the aforementioned benefits, injection molded plastic auto parts also offer exceptional resistance to corrosion and chemicals, making them ideal for withstanding harsh environmental conditions and exposure to various substances on the road. This durability ensures that the parts have a longer lifespan, reducing the need for frequent replacements and maintenance, ultimately saving both time and money for vehicle owners. Furthermore, the smooth surface finish achieved through injection molding enhances aerodynamics, contributing to improved vehicle performance and fuel efficiency.

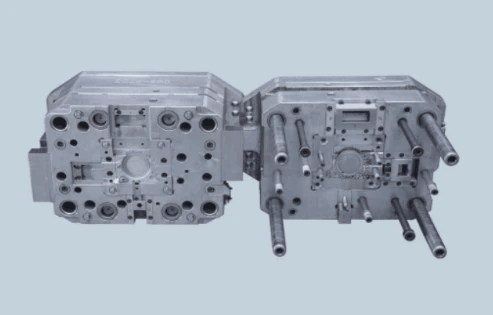

Baoyuan: Expert in Injection Molded Plastic Auto Parts

As a leading manufacturer specializing in plastic automotive mold design & manufacturing, Baoyuan has solidified its reputation as an industry leader in producing top-quality injection molded parts for automotive use. With a commitment to innovation and sustainability, Baoyuan continues to set new standards for excellence in this field.

With a state-of-the-art facility and a team of experienced engineers and technicians, Baoyuan is able to deliver precision-engineered plastic automotive parts that meet the highest standards of quality and performance. By leveraging the latest technology and manufacturing processes, Baoyuan ensures that each injection molded part is not only durable and reliable but also lightweight and cost-effective. This dedication to excellence has earned Baoyuan the trust of leading automotive manufacturers worldwide, cementing its position as a go-to provider for injection molded plastic auto parts.

Baoyuan's Expertise in Plastic Injection Molding

Baoyuan's extensive expertise in plastic injection molding is evident through its highly skilled senior management and technical personnel, who possess years of experience in the automotive industry. Their in-depth knowledge and innovative approach make Baoyuan a top choice for injection-molded car components.

Baoyuan's Senior Management and Technical Personnel

Led by a team of industry veterans, Baoyuan boasts a group of senior management and technical personnel with a wealth of knowledge in plastic automotive mold design & manufacturing. Their collective expertise ensures that every aspect of the injection molding process is handled with precision and care, resulting in high-quality plastic automotive parts.

In addition to their extensive knowledge in plastic automotive mold design and manufacturing, Baoyuan's senior management and technical personnel are also well-versed in the latest technological advancements in the industry. This allows them to stay ahead of the curve and implement innovative solutions to improve the efficiency and quality of the injection molding process. By staying abreast of new developments, Baoyuan's team ensures that they are always equipped to meet the evolving needs of their clients and deliver cutting-edge plastic automotive parts.

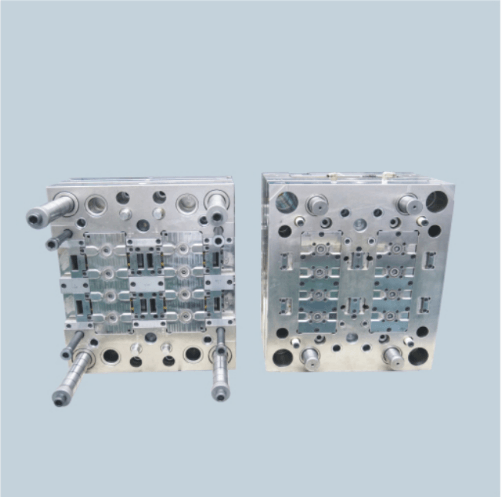

Baoyuan's Proficiency in Designing Molds and Injection Molding

Baoyuan's proficiency in designing molds and injection molding is unmatched, allowing for the creation of custom automotive components that meet the highest standards of quality and performance. With state-of-the-art technology and advanced techniques, Baoyuan delivers precision-engineered injection molded parts for automotive applications.

Furthermore, Baoyuan's expertise in designing molds and injection molding extends beyond automotive components to include a specialization in single-color and double-color plastic products. This allows for the creation of a wide range of custom plastic parts for various industries, from consumer electronics to household appliances. By leveraging their advanced techniques and state-of-the-art technology, Baoyuan is able to deliver high-quality, precision-engineered plastic products that meet the unique specifications and requirements of each client.

Baoyuan's Specialization in Single-color and Double-color Plastic Products

Specializing in both single-color and double-color plastic products, Baoyuan offers versatile solutions for a wide range of automotive needs. Whether it's creating intricate details or complex geometries, Baoyuan's expertise in plastic injection molding for automotive parts ensures that every product meets the highest standards of excellence.

Baoyuan's specialization in single-color and double-color plastic products allows for the creation of automotive parts with intricate details and complex geometries, ensuring that every product meets the highest standards of excellence. With a focus on versatility, Baoyuan offers solutions for a wide range of automotive needs, from interior components to exterior trim. This expertise in plastic injection molding enables Baoyuan to produce durable, high-quality auto parts that meet the demanding requirements of the automotive industry.

Benefits of Using Injection Molded Plastic Auto Parts

Cost-effectiveness of Injection Molded Plastic Auto Parts

Injection molded plastic auto parts offer a cost-effective solution for automotive manufacturers, as the production process is highly efficient and requires minimal labor. The use of automated injection molding machines also reduces the need for manual intervention, further cutting down on production costs. This cost-effectiveness translates to more affordable automotive components for consumers, making it a win-win situation for both manufacturers and end-users.

Durability and Reliability of Injection Molded Plastic Auto Parts

Injection-molded car components are known for their exceptional durability and reliability, making them ideal for the demanding conditions of the automotive industry. The high-quality materials used in injection molding ensure that the parts can withstand harsh environmental factors, heavy loads, and constant wear and tear without compromising their performance. This durability not only enhances the overall longevity of vehicles but also minimizes maintenance and replacement costs for consumers.

Contribution to Lightweighting and Fuel Efficiency in Automotive Industry

Plastic injection molding plays a crucial role in lightweighting vehicles, which is essential for improving fuel efficiency and reducing carbon emissions. By utilizing lightweight yet robust plastic auto parts, manufacturers can significantly decrease the overall weight of vehicles without sacrificing structural integrity or safety standards. This reduction in weight directly translates to improved fuel economy, making injection-molded plastic components instrumental in creating more environmentally friendly automobiles.

Design Flexibility in Injection Molded Plastic Auto Parts

Customization Options for Automotive Parts

Injection molding offers endless possibilities for customizing automotive parts to meet specific requirements. With Baoyuan's expertise in plastic injection molding, clients can easily tailor the design, color, and material of their auto components. Whether it's a unique shape or a personalized logo, Baoyuan ensures that each part is customized to perfection, providing a competitive edge in the automotive industry.

Furthermore, Baoyuan's advanced technology and state-of-the-art equipment allow for the production of automotive parts with complex geometries and intricate details. This means that clients can achieve designs that were previously thought to be unattainable, giving them the freedom to push the boundaries of innovation in their products. With Baoyuan's expertise, clients can rest assured that even the most intricate details will be faithfully replicated in the final injection molded parts.

Complex Geometries and Intricate Details in Injection Molded Parts

The versatility of injection molding allows for the creation of intricate and complex geometries that are otherwise impossible with traditional manufacturing methods. Baoyuan's precision and attention to detail ensure that even the most intricate designs are faithfully replicated in their injection molded parts. From sleek curves to fine details, Baoyuan excels in producing high-quality components with exceptional precision.

Baoyuan's Innovative Design Capabilities

Baoyuan prides itself on its innovative approach to design, constantly pushing the boundaries of what is possible with injection molded plastic auto parts. Their team of experienced designers and engineers collaborate closely with clients to bring their visions to life, offering creative solutions and cutting-edge designs that set their products apart from the competition. With Baoyuan, clients can expect nothing less than groundbreaking innovation in every aspect of their injection molded automotive components.

Baoyuan's commitment to innovation extends beyond just design capabilities. They are also dedicated to environmental sustainability, constantly seeking ways to reduce the environmental impact of their injection molded plastic auto parts. By utilizing eco-friendly materials and implementing efficient production processes, Baoyuan ensures that their products not only meet high performance standards but also contribute to a greener future for the automotive industry. Clients can trust that Baoyuan's innovative designs are not only cutting-edge but also environmentally responsible, making them a top choice for sustainable auto components.

Environmental Sustainability of Injection Molded Plastic Auto Parts

Recyclability and Reusability of Injection Molded Plastic Auto Parts

Injection molded plastic auto parts are highly recyclable and reusable, contributing to a more sustainable automotive industry. Baoyuan's expertise in producing durable and long-lasting injection molded parts ensures that they can be easily recycled and repurposed for future use, reducing waste and environmental impact.

In addition to their recyclability and reusability, injection molded plastic auto parts also contribute to a reduced carbon footprint in automotive manufacturing. By utilizing these durable and long-lasting parts, manufacturers can decrease the need for new raw materials, leading to less energy consumption and lower greenhouse gas emissions during production. This sustainable approach not only benefits the environment but also helps companies reduce their overall operational costs, making it a win-win situation for both the industry and the planet.

Reduced Carbon Footprint in Automotive Manufacturing

The use of injection molded plastic auto parts significantly reduces the carbon footprint in automotive manufacturing. With lightweight materials and efficient production processes, Baoyuan's injection-molded car components contribute to lower fuel consumption and emissions, aligning with global efforts towards environmental conservation.

With a focus on sustainability, Baoyuan is committed to using eco-friendly materials and implementing energy-efficient manufacturing processes. By reducing the environmental impact of automotive production, Baoyuan sets an example for other manufacturers to follow suit in embracing sustainable practices. The company's dedication to minimizing its carbon footprint demonstrates a proactive approach towards addressing the global climate crisis and promoting a greener future for the automotive industry.

Baoyuan's Commitment to Sustainable Production Practices

Baoyuan is dedicated to sustainable production practices, including the responsible use of resources and energy-efficient manufacturing processes. By prioritizing eco-friendly materials and reducing waste in production, Baoyuan upholds its commitment to environmental sustainability while delivering high-quality plastic injection-molded automotive components.

Quality Assurance in Injection Molded Plastic Auto Parts

Baoyuan's Stringent Quality Control Measures

Baoyuan takes pride in its rigorous quality control measures, ensuring that every injection molded plastic auto part meets the highest standards of excellence. From raw material inspection to final product testing, Baoyuan employs advanced quality control techniques to guarantee the durability and reliability of its automotive components.

Furthermore, Baoyuan's commitment to quality extends beyond the manufacturing process. The company also prioritizes continuous improvement and innovation, constantly seeking new ways to enhance the performance and longevity of its auto parts. By staying ahead of industry trends and technological advancements, Baoyuan ensures that its products not only meet current standards but also anticipate future needs in the automotive market.

Compliance with Industry Standards and Regulations

As a leader in plastic injection molding for automotive parts, Baoyuan adheres to all industry standards and regulations to deliver products that meet or exceed the expectations of its clients. By staying updated with the latest automotive manufacturing requirements, Baoyuan ensures that its injection-molded car components are of top-notch quality.

Reliability and Longevity of Baoyuan’s Injection Molded Products

With a commitment to excellence, Baoyuan's injection molded parts for automotive applications are designed for unparalleled reliability and longevity. Customers can trust in the durability of Baoyuan's plastic automotive mold design & manufacturing, knowing that they are investing in high-quality products that will stand the test of time.

Customers can also take comfort in the fact that Baoyuan's injection molded parts are rigorously tested for performance and durability. Through extensive quality control measures, Baoyuan ensures that each automotive part meets or exceeds industry standards, providing peace of mind to customers who rely on these products for their vehicles. This dedication to thorough testing and quality assurance further solidifies the reputation of Baoyuan as a trusted provider of long-lasting injection molded products.

Conclusion

Baoyuan is the top choice for high-quality injection molded plastic auto parts, offering unparalleled expertise in custom automotive components. With our innovative design capabilities and commitment to sustainability, Baoyuan is your partner in harnessing the benefits of injection molded parts for the automotive industry.

Choosing Baoyuan for High-Quality Injection Molded Auto Parts

When it comes to injection molded plastic auto parts, Baoyuan stands out as a leader in design and manufacturing. Our dedication to quality and precision ensures that you receive only the best-in-class automotive components for your vehicles.

Harnessing the Benefits of Injection Molded Plastic Auto Parts

By choosing Baoyuan's injection-molded car components, you are tapping into the cost-effectiveness, durability, and lightweighting advantages that our products offer. Experience the difference with our high-performing plastic automotive mold design & manufacturing solutions.

Embracing Innovation and Sustainability with Baoyuan

At Baoyuan, we are not just focused on creating exceptional injection molded parts for automotive use; we are also committed to sustainable production practices that reduce environmental impact. Embrace innovation and sustainability with Baoyuan as your partner in plastic injection molding for automotive parts.