Introduction

Are you curious about the wonders of ABS plastic material and its moldable properties? If so, you're in for a treat! In this comprehensive guide, we'll delve into the basics of plastic molding and explore how to choose the right techniques for molding ABS plastic.

Understanding ABS Plastic Material

ABS plastic, also known as acrylonitrile butadiene styrene, is a versatile thermoplastic polymer that boasts exceptional strength and durability. Its moldable nature makes it an ideal choice for a wide range of applications, from automotive parts to consumer electronics.

ABS plastic is known for its high impact resistance, making it a popular choice for products that require durability and strength. Its ability to withstand high temperatures also makes it suitable for use in various engineering applications. In addition, ABS plastic can be easily painted or coated, allowing for customization and aesthetic appeal in a wide range of products.

The Basics of Plastic Molding

Plastic molding is a manufacturing process that involves shaping molten plastic material into a desired form. It encompasses various techniques such as injection molding, blow molding, and compression molding, each with its unique advantages for producing ABS parts. Injection molding, for example, is ideal for creating complex and intricate shapes with high precision, making it perfect for producing intricate ABS parts with fine details. On the other hand, blow molding is well-suited for manufacturing hollow objects such as bottles and containers, offering a cost-effective solution for producing large quantities of ABS parts.

Choosing the Right Techniques for ABS Plastic

When it comes to molding ABS plastic, selecting the appropriate technique is crucial for achieving high-quality results. Factors such as part complexity, production volume, and cost considerations play a pivotal role in determining the most suitable method.

Considering the part complexity, intricate designs with undercuts or tight tolerances may require injection molding to achieve the desired results. This technique allows for precise and detailed features to be replicated consistently, making it ideal for complex parts. On the other hand, simpler geometries may be better suited for techniques such as thermoforming or 3D printing, which can offer cost-effective solutions for low-volume production.

The Properties of ABS Plastic

ABS plastic material is known for its exceptional durability and flexibility, making it a popular choice for a wide range of applications. Its ability to withstand impact and bending without breaking makes it ideal for manufacturing car parts and other products that require resilience and strength.

Durability and Flexibility

ABS plastic exhibits remarkable durability, allowing it to withstand heavy use and harsh environmental conditions without deteriorating. Its flexibility also makes it easy to mold into complex shapes, providing designers with the freedom to create innovative products with intricate details.

Furthermore, ABS plastic's heat resistance is a key feature that sets it apart from other materials. Its ability to withstand high temperatures without deforming or losing its structural integrity makes it an ideal choice for applications that involve exposure to heat, such as automotive components and electronic enclosures. This heat resistance also contributes to the material's long-term durability, ensuring that products made from ABS plastic can maintain their performance even in challenging environments.

Heat Resistance and Impact Strength

One of the key properties of ABS material is its impressive heat resistance, enabling it to maintain its structural integrity even at high temperatures. In addition, ABS plastic boasts exceptional impact strength, making it highly resistant to physical damage from external forces. This combination of heat resistance and impact strength makes ABS an ideal choice for a wide range of applications, from automotive components to consumer electronics.

Choosing the Right ABS Sheet for Molding

When selecting an ABS sheet for molding, it's essential to consider factors such as thickness, color, and texture to ensure that the final product meets your specific requirements. With a wide range of options available, choosing the right ABS sheet is crucial for achieving optimal results in plastic molding processes. Additionally, it's important to take into account the impact resistance and heat deflection temperature of the ABS sheet to ensure that it can withstand the intended application without compromising its structural integrity. Moreover, considering the environmental conditions in which the molded parts will be used can help in selecting an ABS sheet with suitable UV resistance and weatherability for long-term durability.

Now let's dive into some techniques for effectively molding ABS plastic parts that meet high-quality standards.

Techniques for Molding ABS Plastic

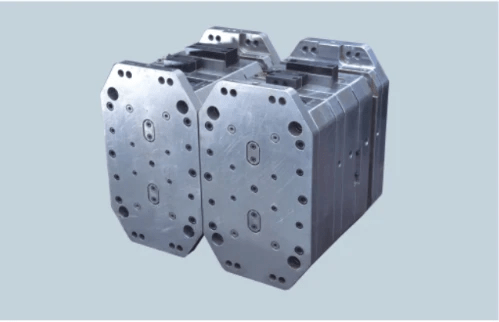

When it comes to molding ABS plastic, the injection molding process is the most commonly used technique. This involves heating the ABS material to a molten state and injecting it into a mold cavity under high pressure. The mold is then cooled, allowing the plastic to solidify into the desired shape. This process is ideal for mass-producing parts with complex geometries, making it a popular choice for manufacturing ABS car parts.

Injection Molding Process

The injection molding process begins with feeding small ABS plastic pellets into a hopper, which then feeds into a heated barrel. Inside the barrel, the pellets are melted and mixed before being injected into the mold cavity. Once inside the mold, the plastic is allowed to cool and harden before being ejected as a finished part. This method ensures high precision and repeatability in producing ABS parts, making it an efficient and cost-effective option for manufacturers.

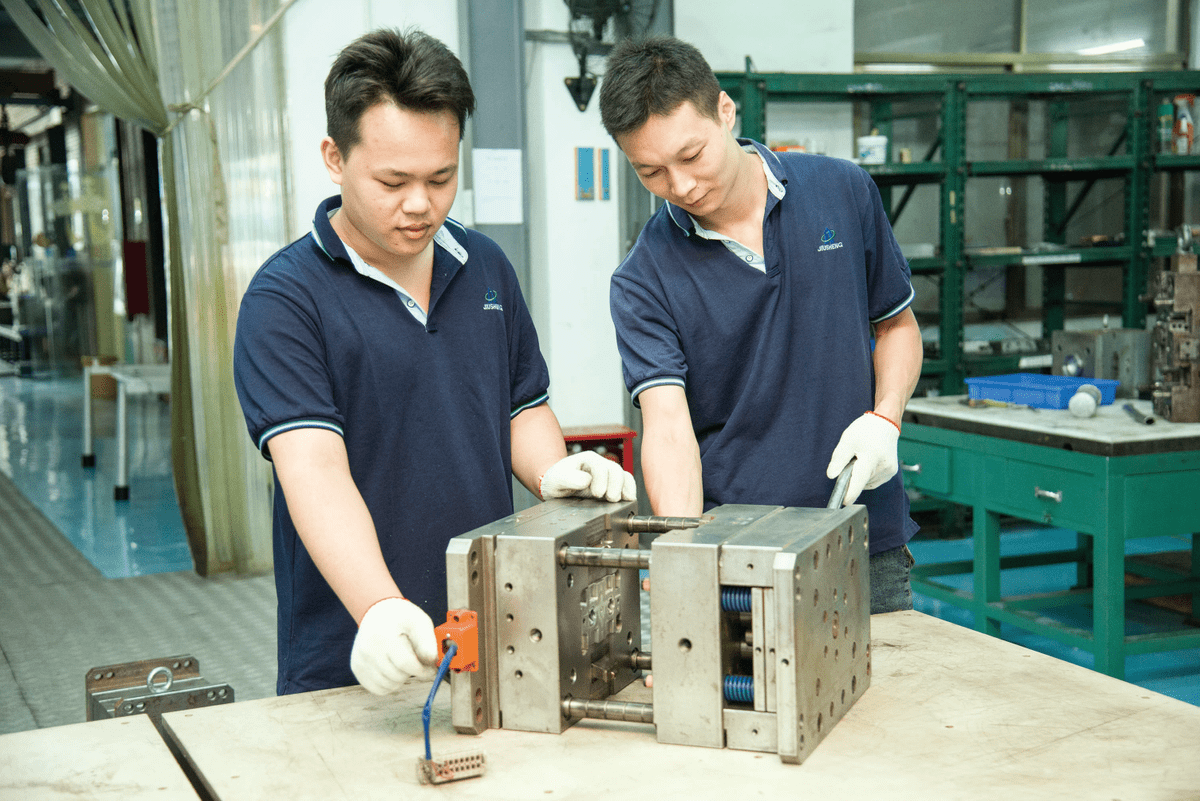

After the plastic has cooled and hardened, the mold opens to release the finished part. The design of the mold is crucial in ensuring that the final product meets the required specifications. Mold design involves careful consideration of factors such as part geometry, material flow, and cooling time to achieve optimal results. The mold opening process must be carefully timed and controlled to prevent any damage to the newly formed part.

Mold Design and Mold Opening

The design of the mold plays a crucial role in achieving quality ABS plastic parts. Mold design considerations include wall thickness, gate location, and cooling channels to ensure even distribution of heat during the molding process. Additionally, proper mold opening mechanisms are essential for safely removing finished parts from the mold without causing damage or distortion. Baoyuan's expertise in mold design and opening ensures that each ABS part meets strict quality standards.

Baoyuan's Expertise in ABS Plastic Molding

Baoyuan has extensive experience in molding ABS plastic parts for various industries, including automotive manufacturing. With state-of-the-art facilities and advanced injection molding technology, Baoyuan can produce high-quality ABS components with tight tolerances and superior surface finishes. Our team of skilled engineers is dedicated to optimizing every aspect of the molding process to deliver exceptional results for our clients.

Baoyuan's expertise in ABS plastic molding extends to providing customized solutions for specific industry needs. Our team collaborates closely with clients to understand their unique requirements and design molds that meet their exact specifications. This personalized approach ensures that the final products are tailored to the specific application, resulting in enhanced performance and efficiency for our clients.

Tips for Successful ABS Plastic Molding

Temperature Control for Quality Results

To achieve high-quality results when molding ABS plastic, it's crucial to maintain precise temperature control throughout the process. ABS material requires specific temperature ranges for melting and cooling to ensure proper flow and solidification. By carefully monitoring and adjusting the temperatures, you can avoid defects and achieve consistent, high-quality molded parts.

Avoiding Warping and Shrinkage

One of the key challenges in molding ABS plastic is preventing warping and shrinkage during the cooling phase. Proper mold design, including uniform wall thickness and adequate venting, can help minimize these issues. Additionally, controlling the cooling rate and using appropriate injection speed can contribute to reducing warping and shrinkage, resulting in dimensionally stable molded parts.

Baoyuan's Quality Assurance in Molding ABS Parts

At Baoyuan, we understand the importance of maintaining strict quality standards when molding ABS parts. Our experienced team utilizes advanced techniques to ensure precise temperature control, minimize warping and shrinkage, and produce consistently high-quality ABS plastic products. With our commitment to excellence, you can trust that your ABS parts will meet your specifications and performance requirements.

Remember that achieving successful results when molding ABS plastic requires careful attention to temperature control, prevention of warping/shrinkage issues, and a commitment to quality assurance from your manufacturing partner like Baoyuan!

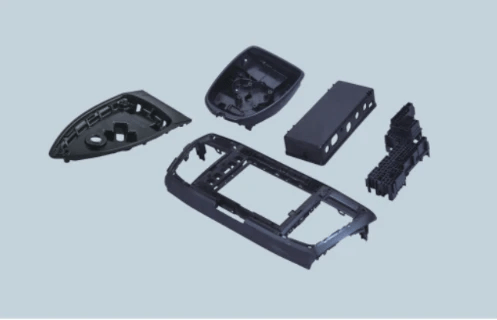

Advantages of Using ABS Material for Car Parts

When it comes to car parts, using ABS material offers several advantages. Firstly, ABS plastic is lightweight, which contributes to better fuel efficiency and overall vehicle performance. Its design flexibility allows for the creation of intricate and aesthetically appealing car parts that enhance the overall look of the vehicle. Baoyuan's extensive experience in producing high-quality car parts using ABS material ensures that you will receive durable and reliable components for your vehicles.

Lightweight and Fuel Efficiency

Using ABS material for car parts significantly reduces the overall weight of the vehicle, resulting in improved fuel efficiency and reduced emissions. This makes ABS an ideal choice for manufacturers looking to enhance their vehicles' environmental impact while maintaining high performance standards.

Design Flexibility and Aesthetic Appeal

ABS plastic's moldable nature allows for intricate designs and shapes that can be tailored to specific aesthetic requirements. This flexibility in design opens up a world of possibilities for creating unique and visually appealing car parts that stand out from the competition, giving your vehicles a competitive edge in the market.

Baoyuan's Experience in Producing High-Quality Car Parts

Baoyuan has a proven track record of producing high-quality car parts using ABS material. With our expertise in molding ABS plastic, we ensure that every part meets stringent quality standards, offering durability, reliability, and precision engineering for all your automotive needs.

Finishing and Polishing ABS Plastic Parts

When it comes to finishing and polishing ABS plastic parts, achieving the right surface texture and gloss is crucial for a professional look. The smoothness and shine of the surface can greatly enhance the overall aesthetic appeal of the product, making it more attractive to customers.

Surface Texture and Gloss

To achieve the desired surface texture and gloss for ABS plastic parts, various techniques such as sanding, buffing, or using chemical treatments can be employed. These methods help to smoothen out any imperfections on the surface and bring out a glossy finish that is visually appealing. Baoyuan's expertise in finishing ensures that every ABS plastic part meets high-quality standards in terms of texture and gloss.

Painting and Coating Techniques

In addition to achieving a smooth surface texture, painting and coating techniques are also essential for enhancing the appearance of ABS plastic parts. These processes involve applying layers of paint or protective coatings to not only add color but also provide durability and resistance to external elements. Baoyuan's advanced painting and coating technologies ensure that ABS plastic parts are not only visually appealing but also long-lasting.

Baoyuan's Proficiency in Finishing ABS Plastic Products

Baoyuan's proficiency in finishing ABS plastic products is unmatched, thanks to years of experience in molding and refining various types of plastics. With a keen eye for detail, Baoyuan's team ensures that every ABS plastic part undergoes meticulous finishing processes to meet customer specifications with precision and excellence.

With Baoyuan's expertise in finishing techniques, you can trust that your ABS plastic parts will not only meet industry standards but exceed them in terms of quality, durability, and visual appeal.

Conclusion

As you can see, Baoyuan is your go-to partner for high-quality ABS plastic car parts. With our expertise in molding ABS plastic and our commitment to precision and durability, we ensure that your car design is elevated to the next level. Trust Baoyuan to deliver top-notch ABS plastic parts that meet your exact specifications.

Baoyuan: Your Partner for Quality ABS Plastic Car Parts

At Baoyuan, we specialize in producing top-notch ABS plastic car parts that are durable, lightweight, and aesthetically appealing. With our expertise in molding ABS plastic material, we guarantee the highest quality products that meet your specific requirements. Choose Baoyuan as your trusted partner for all your ABS plastic needs.

Achieving Precision and Durability with ABS Molding

With our advanced techniques for molding ABS plastic and our focus on temperature control and quality assurance, Baoyuan ensures that every part we produce meets the highest standards of precision and durability. Our commitment to excellence sets us apart as a leader in the industry when it comes to moldable plastic materials like ABS.

Elevate Your Car Design with Baoyuan's Expertise

When it comes to creating innovative car designs, trust Baoyuan to provide the expertise you need to elevate your project. Our proficiency in finishing and polishing ABS plastic parts ensures that your car design stands out with its superior surface texture and gloss. Let Baoyuan take your car design to new heights with our extensive knowledge of abs material.