Introduction

In today's manufacturing landscape, the demand for precision and efficiency has led to the rise of large part injection molding. This innovative technique allows businesses to produce oversized components with remarkable accuracy, making it a game-changer across various industries. As companies seek reliable solutions for their production needs, understanding the nuances of injection molding large parts becomes essential.

The Rise of Large Part Injection Molding

Large part injection molding has gained significant traction in recent years due to advancements in technology and materials. This process not only meets the growing demand for larger components but also enhances production speed and reduces waste. Industries such as automotive, aerospace, and consumer goods are increasingly turning to this method for its ability to create complex shapes that were once thought impossible.

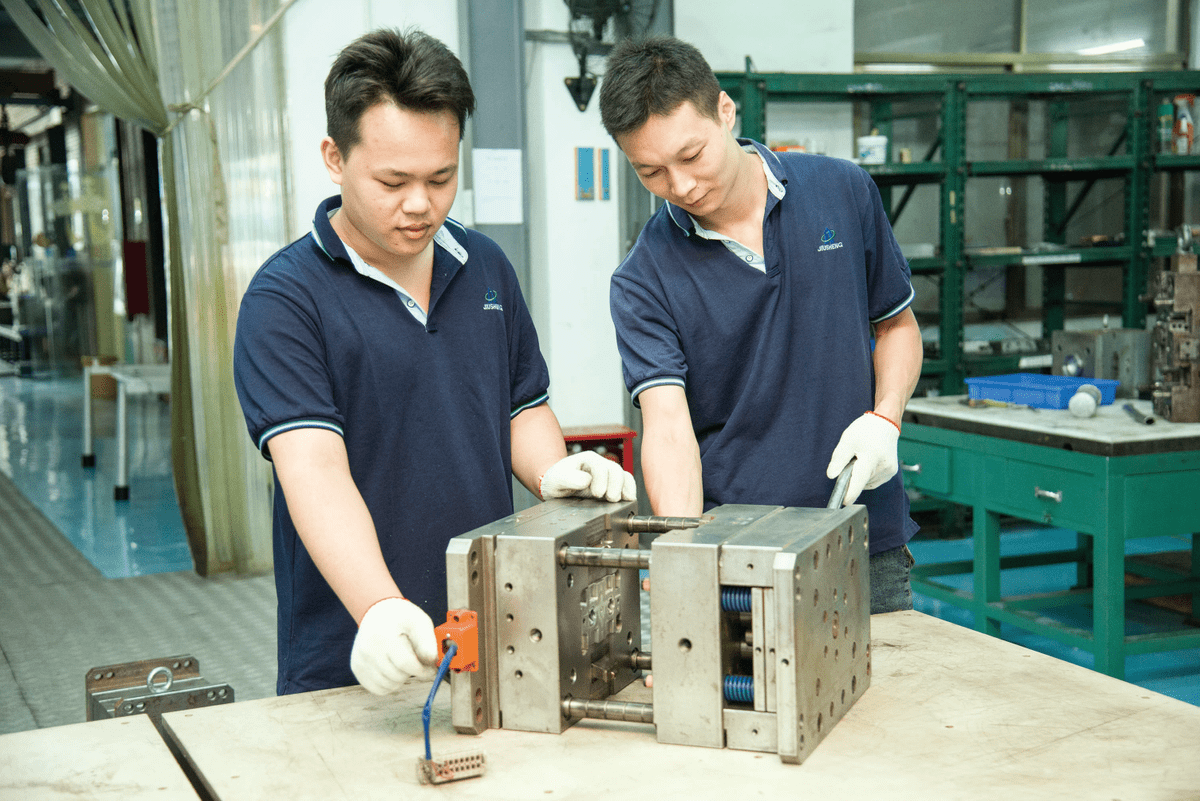

Why Choose Baoyuan for Your Needs

When considering your options for large part injection molding, Baoyuan stands out as a premier choice. With a commitment to quality and innovation, Baoyuan offers tailored solutions that meet diverse manufacturing requirements. Their expertise in handling projects involving large parts ensures that clients receive exceptional service from concept through production.

Understanding Injection Molding Large Parts

To fully appreciate the benefits of injection molding large parts, it's important to grasp how the process works. Essentially, molten material is injected into a mold cavity where it cools and solidifies into the desired shape—perfectly suited for producing sizable components with intricate designs. Moreover, exploring questions like How large can you injection mold? or Can injection molding be used for large parts? will further illuminate its potential applications in modern manufacturing.

What is Large Part Injection Molding?

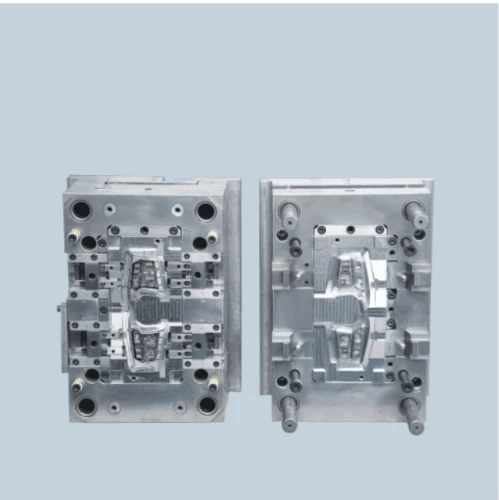

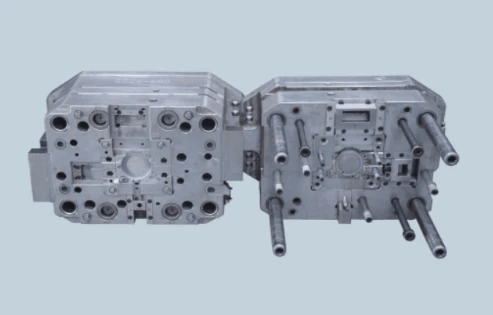

Large part injection molding is a specialized manufacturing process designed to create substantial components with precision and efficiency. This technique utilizes advanced machinery and molds to produce large plastic parts that meet the specific needs of various industries. By leveraging this technology, manufacturers can achieve high-quality results while minimizing waste and production time.

Definition and Overview

At its core, large part injection molding involves injecting molten plastic into a custom-designed mold to create oversized components. Unlike standard injection molding processes, which typically focus on smaller items, this method caters specifically to larger dimensions that require unique considerations in design and production. Understanding how large you can injection mold is crucial for businesses looking to optimize their manufacturing capabilities while ensuring product quality.

Advantages of Large Injection Molding

The advantages of large injection molding are numerous, making it an attractive option for many manufacturers. First and foremost, this process allows for the creation of complex shapes with high precision, which is essential when producing intricate designs or functional parts. Additionally, using injection molding for large parts often results in reduced lead times and lower overall costs compared to traditional manufacturing methods—especially when utilizing injection molding contract manufacturing services offered by companies like Baoyuan.

Another significant benefit is the ability to utilize a wide range of materials suitable for various applications. This versatility means that manufacturers can choose from different plastics based on their specific requirements—such as durability or flexibility—ensuring optimal performance in the final product.

Applications Across Industries

Large part injection molding finds applications across a diverse array of industries due to its adaptability and efficiency. For instance, automotive manufacturers frequently rely on this technique to produce sizable components like bumpers or dashboards that require both strength and aesthetic appeal. Similarly, industries such as aerospace use large injection molded parts for structural elements where lightweight yet durable materials are essential.

Moreover, sectors like consumer goods benefit from the customization options available through large part injection molding—allowing them to create unique designs tailored specifically for their target market. As businesses continue exploring how they can leverage this technology effectively, the demand for innovative solutions in large part production will only grow stronger.

How Large Can You Injection Mold?

When it comes to injection molding large parts, one of the most frequently asked questions is, How large can you injection mold? The answer isn't as straightforward as one might think. While advances in technology have pushed the boundaries of size, various factors come into play that can limit how large a part can be molded effectively.

Exploring Size Limitations

The size limitations for injection molding large parts are influenced by various elements, including machine capacity and mold design. Typically, standard machines can handle parts up to a few hundred pounds in weight and several feet in dimensions; however, specialized equipment can accommodate much larger components. It's essential to understand that while larger molds are possible, they require careful planning and precise engineering to ensure quality and consistency.

Factors Affecting Mold Size

Several factors affect how large you can injection mold successfully. First and foremost is the type of material being used; some materials may not flow well in larger molds or could lead to defects if not processed correctly. Additionally, the complexity of the part design plays a significant role—more intricate designs may necessitate smaller molds to maintain precision and quality during production.

Real-World Examples in Large Molding

There are numerous real-world examples showcasing the capabilities of injection molding for large parts. For instance, automotive manufacturers often utilize large part injection molding for components like bumpers or dashboards that require both size and durability. Another example is in construction equipment manufacturing where oversized panels or housings are produced using advanced techniques that push the limits of traditional methods.

Can Injection Molding Be Used for Large Parts?

When considering the capabilities of injection molding large parts, one might wonder about the compatibility with various materials. The good news is that injection molding can accommodate a wide range of materials, from thermoplastics to composites, making it an ideal choice for large-scale production. This versatility allows manufacturers to select the best material for their specific application, ensuring durability and performance.

Compatibility with Various Materials

Injection molding large parts can utilize a variety of materials including ABS, polycarbonate, nylon, and polypropylene. Each material offers distinct properties such as strength, flexibility, and temperature resistance which can be tailored to meet project requirements. Additionally, advancements in material science have expanded the possibilities even further; now manufacturers can experiment with blends and additives to enhance performance characteristics.

Customization Options Offered by Baoyuan

At Baoyuan, customization is not just a buzzword; it's a commitment to meeting your unique needs in large part injection molding. From mold design to finishing processes, we offer extensive options that allow you to specify dimensions, textures, and colors tailored precisely to your specifications. Whether you're looking for intricate designs or robust structural components, our team works closely with you throughout the process to ensure your vision becomes reality.

Success Stories from Baoyuan Clients

Baoyuan has built a reputation through numerous success stories in large part injection molding across various industries. For instance, we partnered with an automotive manufacturer needing oversized components that required precision engineering and rapid turnaround times—successfully delivering on all fronts! Another client in the aerospace sector benefitted from our expertise in injection molding contract manufacturing by receiving custom parts that exceeded their expectations while reducing lead times significantly.

Injection Molding Contract Manufacturing

In the world of large part production, injection molding contract manufacturing stands out as a game-changer. This approach allows companies to leverage specialized expertise and advanced technology without the overhead costs associated with in-house manufacturing. By outsourcing their large part injection molding needs, businesses can focus on their core competencies while ensuring high-quality production.

Benefits of Contract Manufacturing for Large Parts

One of the primary benefits of injection molding contract manufacturing for large parts is cost efficiency. Companies can avoid hefty investments in machinery and labor while still accessing top-tier equipment and skilled professionals. Additionally, this model provides flexibility, allowing businesses to scale production up or down based on demand without long-term commitments.

Another advantage is the ability to tap into specialized knowledge that comes from seasoned manufacturers like Baoyuan. With extensive experience in handling various materials and complex designs, Baoyuan ensures that even the largest parts are produced with precision and quality assurance. This expertise translates into reduced lead times and enhanced product reliability.

Finally, partnering with a contract manufacturer enables companies to stay ahead of market trends by utilizing cutting-edge technologies that may not be feasible for smaller operations. As industries evolve, having a reliable partner in large injection molding can provide a competitive edge—ensuring your products meet both current standards and future demands.

Baoyuan’s Expertise in the Field

Baoyuan has established itself as a leader in injection molding large parts through its commitment to innovation and quality. With years of experience under its belt, Baoyuan understands how large part injection molding can be optimized for various applications across multiple industries. Their team utilizes state-of-the-art technology combined with deep industry knowledge to deliver exceptional results every time.

The company excels at customizing solutions tailored specifically for client needs, whether they are exploring how large can you injection mold? or seeking specific material compatibility for their projects. Baoyuan's engineers work closely with clients from concept through production, ensuring that every aspect aligns perfectly with project requirements—resulting in products that exceed expectations.

Moreover, Baoyuan’s dedication to continuous improvement means they are always looking for ways to enhance efficiency while minimizing large injection molding costs without sacrificing quality or performance. This proactive approach empowers clients by providing them access to innovative techniques and materials that help streamline processes.

Case Studies Demonstrating Excellence

To illustrate Baoyuan's prowess in injection molding contract manufacturing, let's explore some notable case studies showcasing their success with large parts. In one instance, a prominent automotive manufacturer approached Baoyuan needing custom components weighing several hundred pounds each—a true test of can injection molding be used for large parts? The result was not only successful but also led to significant improvements in assembly line efficiency due to the precision engineering provided by Baoyuan.

Another remarkable case involved a consumer electronics company looking for lightweight yet durable housings for oversized devices—a challenge when considering how size impacts mold design and material selection. By leveraging advanced techniques in large part injection molding, Baoyuan delivered high-quality components that met stringent safety standards while remaining cost-effective.

These examples highlight how partnering with an expert like Baoyuan transforms challenges into opportunities within the realm of large part production—demonstrating excellence through innovation and collaboration at every turn.

Understanding Large Injection Molding Cost

When it comes to injection molding large parts, understanding the associated costs is crucial for businesses looking to optimize their production processes. Several factors can influence these costs, including material selection, mold complexity, and production volume. By gaining insight into these cost drivers, companies can make informed decisions that align with their budget and production goals.

Factors Influencing Cost Estimates

The cost of large injection molding is affected by multiple variables that manufacturers must consider. First and foremost is the type of material used; different plastics vary significantly in price and availability, impacting overall project expenses. Additionally, the complexity of the mold itself plays a critical role—more intricate designs require more time and resources to produce, which can inflate costs considerably.

Another essential factor is the size of the parts being produced—after all, how large can you injection mold? Larger molds not only require more material but also demand specialized machinery capable of handling such dimensions. Furthermore, production volume matters; higher quantities often lead to lower per-unit costs due to economies of scale.

Lastly, labor costs should not be overlooked; skilled technicians are needed to operate machinery and ensure quality control during production. Each of these factors contributes to a comprehensive understanding of what drives injection molding large parts costs.

Cost-Effective Strategies by Baoyuan

Baoyuan employs various strategies aimed at minimizing large injection molding costs while maintaining high-quality output. One approach involves optimizing design for manufacturability (DFM), which helps reduce waste during production while ensuring that molds are easier to create and maintain. This proactive strategy often results in significant savings over time.

Additionally, Baoyuan leverages advanced technology in its manufacturing processes—automated systems help streamline operations and reduce labor expenses without sacrificing quality or precision in producing large parts. These technological investments enable Baoyuan to pass on cost savings directly to clients seeking efficient solutions for their projects.

Moreover, Baoyuan’s expertise in injection molding contract manufacturing allows them to offer flexible pricing models tailored specifically for each client's needs. Whether you’re looking for short-run prototypes or long-term production runs, Baoyuan's adaptability ensures you receive the best value possible when pursuing your large part projects.

Comparing Costs with Traditional Manufacturing

When evaluating your options for producing large components, it's essential to compare the costs associated with injection molding against traditional manufacturing methods like machining or casting. Typically, traditional methods may involve higher labor rates due to manual processes and longer lead times associated with tooling changes or setup adjustments.

In contrast, using injection molding for large parts often leads to faster turnaround times thanks to automated machinery that requires less human intervention once set up correctly. This efficiency translates into reduced overall project timelines and lower labor-related expenses compared with traditional techniques.

Furthermore, when considering long-term projects involving high volumes of similar components—think about how frequently you'll need those parts—large part injection molding generally offers a more economical solution over time due primarily to decreased per-unit costs as volumes increase compared with traditional manufacturing methods which may struggle under similar conditions.

Conclusion

In conclusion, the landscape of manufacturing is evolving, and large part injection molding stands at the forefront of this transformation. Choosing Baoyuan for your injection molding large parts projects not only ensures high-quality results but also offers you access to cutting-edge technology and expertise in the field. With a commitment to excellence and customer satisfaction, Baoyuan is poised to be your partner in navigating the complexities of large injection molding.

Key Benefits of Choosing Baoyuan

Baoyuan brings a wealth of experience in injection molding large parts, making it an ideal choice for businesses seeking reliable solutions. The company’s advanced facilities and skilled workforce enable them to handle a variety of materials while maintaining precision and efficiency. Additionally, Baoyuan's dedication to customization means that they can cater specifically to your project's unique requirements, ensuring that you receive exactly what you need.

The Future of Large Part Injection Molding

The future looks bright for large part injection molding as technological advancements continue to enhance capabilities and expand possibilities. As industries evolve, so too does the demand for innovative solutions that can meet complex design specifications while remaining cost-effective. With companies like Baoyuan leading the charge, we can expect significant strides in how we approach questions like How large can you injection mold?—pushing boundaries further than ever before.

Your Next Steps in Large Injection Projects

If you're considering embarking on a project involving large parts, now is the perfect time to explore your options with Baoyuan’s expertise in injection molding contract manufacturing. Start by assessing your specific needs—whether it's understanding how large you can injection mold or evaluating potential costs associated with large injection molding projects. Reach out today for a consultation; together we can turn your vision into reality!