Introduction

Injection moulding is a manufacturing process that has gained immense popularity due to its efficiency and versatility. However, understanding the injection moulding cost per kg can be quite a puzzle for many businesses looking to leverage this technology. Factors such as material selection, labor expenses, and equipment maintenance all play significant roles in determining how much does injection molding cost per kg.

Understanding Injection Moulding Costs

To grasp the intricacies of injection moulding costs, one must first consider the various elements that contribute to the overall expense. The average cost of an injection mold can vary significantly based on design complexity and material choices, making it crucial to have a clear understanding before diving into production. Additionally, knowing how to calculate injection mold cost effectively can save businesses from unexpected budget overruns.

Factors Influencing Cost Per Kg

Several factors influence the cost per kg in injection moulding, ranging from raw material prices to labor costs associated with production. For instance, sourcing materials from different regions can lead to variations in pricing; how much does injection molding cost in China? This question often arises when comparing regional manufacturing capabilities and their associated costs. Furthermore, understanding these factors helps companies estimate their overall investment accurately and avoid common pitfalls.

The Role of Injection Moulding Providers

Choosing the right injection moulding service is crucial for ensuring quality and efficiency while keeping costs manageable. Experienced providers understand the nuances of pricing structures and can offer insights into how to estimate injection molding cost based on specific project requirements. By collaborating with knowledgeable partners like Baoyuan, businesses can navigate the complexities of injections moulding costs more effectively.

What Is Injection Moulding?

Injection moulding is a manufacturing process that has revolutionized the way products are created, particularly in the plastic industry. This technique allows for the mass production of complex shapes and designs with high precision and efficiency. Understanding how this process works can provide valuable insights into factors like injection moulding cost per kg, which is crucial for businesses looking to optimize their production budgets.

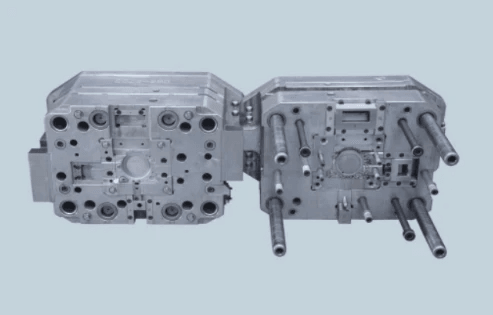

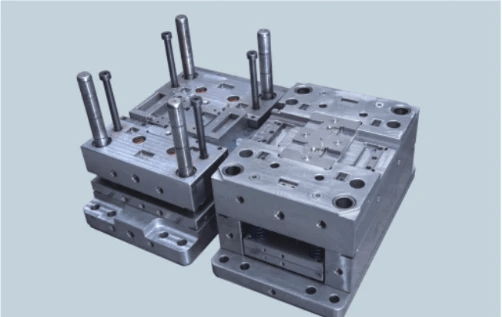

Overview of the Process

The injection moulding process begins with melting raw plastic material, which is then injected into a mold under high pressure. Once cooled, the mold opens to reveal a finished part that often requires little to no further processing. This method not only speeds up production but also minimizes waste, making it an attractive option for manufacturers focused on cost-effective solutions.

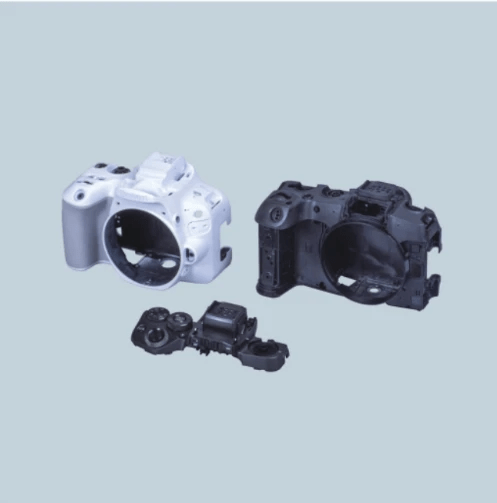

Key Applications in Industry

Injection moulding finds its place across various industries due to its versatility and efficiency. From automotive parts and consumer electronics to medical devices and packaging materials, this technique serves as a backbone for many production lines. As companies increasingly seek to lower their costs—like understanding how much does injection molding cost per kg—it's clear why injection moulding remains a go-to choice for product development.

Benefits of Injection Moulding

The benefits of injection moulding extend beyond just speed; they include enhanced design flexibility and reduced labor costs compared to traditional manufacturing methods. The ability to produce intricate designs without significant manual intervention allows businesses to innovate rapidly while keeping an eye on their bottom line—especially relevant when considering what is the average cost of an injection mold? Additionally, using this method can lead to consistent quality across large batches, making it easier for companies to maintain standards while estimating costs effectively.

Breakdown of Injection Moulding Cost Per Kg

Material Costs Explained

Material costs are one of the primary factors influencing injection moulding cost per kg. The type of plastic resin selected for your project significantly affects pricing; for instance, high-performance polymers often come with a heftier price tag than standard thermoplastics. Additionally, fluctuations in global market prices can impact how much does injection molding cost per kg at any given time, making it crucial to stay updated on material trends.

In China and other manufacturing hubs, sourcing materials can also vary in price based on local availability and demand. For example, if you're wondering how much does injection molding cost in China compared to other regions, be aware that local suppliers may offer competitive rates due to lower transport costs. Therefore, when estimating material costs for your project, consider both the type of resin needed and its market fluctuations.

Finally, factoring in waste during production is vital—inevitably some material will be lost or scrapped during the process. Understanding these nuances helps you better estimate injection moulding cost per kg while ensuring that you select the right materials for your needs without breaking the bank.

Labor and Overhead Expenses

Labor and overhead expenses are another key component of calculating overall injection moulding costs. Skilled workers are needed for setup and operation of machinery as well as quality control throughout production runs—these labor costs must be factored into your final budget. If you're curious about how to calculate injection mold cost accurately, don't overlook these human elements that contribute significantly to pricing.

Overhead expenses include everything from utilities like electricity to facility maintenance—essentially all those hidden costs that keep a manufacturing operation running smoothly but aren’t directly tied to production output. These overheads can vary widely depending on location; thus understanding regional differences is crucial when estimating overall project expenses or comparing how much does injection molding cost in China versus elsewhere.

Moreover, efficient labor practices can lead to reduced cycle times and improved productivity levels—ultimately lowering your total investment in an injection molding service. So while labor might seem like just another line item on your budget sheet, it has far-reaching implications on both quality and overall cost-effectiveness.

Equipment and Maintenance Contributions

The machinery used in the injection moulding process also contributes significantly to the overall cost per kg of molded parts. High-quality machines tend not only to produce better products but also require regular maintenance—this ongoing upkeep adds another layer of expense that manufacturers must account for when considering their pricing structure. Understanding what is the average cost of an injection mold will help clarify how equipment impacts your budget as well.

Additionally, advanced technologies such as robotics or automated systems may raise initial capital expenditures but could ultimately save money by increasing efficiency over time—a classic case where spending more upfront pays off later down the line! When evaluating how much does injection molding cost per kg based solely on machine capabilities versus long-term operational savings becomes essential.

Lastly, don’t forget about depreciation! As machines age or become obsolete due to technological advancements or changing industry standards; their value decreases over time which should be included in any comprehensive costing strategy related specifically back towards those all-important molds themselves!

How to Calculate Injection Mold Cost?

Calculating the cost of an injection mold can feel like deciphering a secret code, but with the right approach, it becomes much clearer. Understanding how to calculate injection mold cost involves several factors that contribute to the overall price. By breaking down these elements, you can gain insight into how much does injection molding cost per kg and make informed decisions for your project.

Essential Calculating Factors

When determining the injection moulding cost per kg, several essential factors come into play. First and foremost is the material type; different plastics have varying costs that significantly impact your overall budget. Additionally, mold complexity and design intricacies will affect pricing—more complex molds require more time and resources to produce.

Labor costs also play a critical role in calculating injection mold expenses. Skilled labor is necessary for both setup and operation, which can vary based on location—this is particularly relevant when considering how much does injection molding cost in China versus other regions. Lastly, overhead expenses such as utilities and facility maintenance should not be overlooked; they contribute directly to the total cost of production.

Estimating Mold Lifespan

Estimating the lifespan of an injection mold is crucial for understanding its long-term value and return on investment (ROI). A well-designed mold can last anywhere from thousands to millions of cycles, depending on its construction materials and usage conditions. By assessing how long you expect your product line to run, you can better gauge what is the average cost of an injection mold relative to its expected output over time.

To accurately estimate this lifespan, consider factors such as material wear-and-tear during production runs and maintenance schedules that may prolong or shorten a mold’s life. The longer a mold lasts without needing replacement or significant repairs, the lower your effective injection moulding cost per kg becomes over time. Therefore, investing in high-quality molds initially may save money in the long run.

Tools for Cost Calculation

To simplify your calculations for estimating costs associated with injection molding services, various tools are available online that can help streamline this process. Many software programs allow users to input specific parameters like material types, weight per part, cycle times, and labor rates—providing an estimated total based on these inputs. This makes it easier than ever to answer questions like How to estimate Injection Molding Cost? accurately.

Moreover, some companies offer specialized calculators designed specifically for determining costs related to different aspects of injection molding projects—these tools often take regional variations into account as well! Utilizing these resources not only saves time but also minimizes errors that could lead you astray when managing budgets effectively.

Average Injection Moulding Cost in Various Regions

Comparing Costs in China vs. Other Regions

China has emerged as a dominant player in the injection moulding market due to its competitive pricing and vast manufacturing capabilities. The average cost of an injection mold produced in China can be significantly lower than that of similar molds made in Western countries, primarily due to lower labor costs and material availability. However, while the initial costs may be enticing, it's essential to consider factors such as quality control and shipping that could affect the overall injection moulding cost per kg.

In contrast, countries like Germany or the USA may have higher upfront costs but often provide superior quality assurance and faster turnaround times for complex projects. This can lead some companies to ask how to estimate injection molding cost accurately when sourcing from different regions. Ultimately, businesses must weigh their priorities—cost versus quality—when deciding where to procure their injection molding services.

Regional Material Sourcing Impacts

Material sourcing is another critical factor influencing the injection moulding cost per kg across various regions. In areas where raw materials are readily available and locally sourced, manufacturers can reduce transportation expenses significantly; this directly impacts overall pricing for clients looking for affordable solutions. Conversely, if a region relies heavily on imported materials, this could inflate costs substantially.

For example, if you’re asking yourself how much does injection molding cost per kg when using specialized materials like high-performance plastics or composites? The answer will vary greatly depending on local availability and market conditions affecting those materials' prices. Companies should also consider regional suppliers’ reliability and consistency when determining how to calculate injection mold cost effectively.

How Labor Costs Affect Overall Pricing

Labor costs are perhaps one of the most significant contributors to the variation in injection moulding costs globally. In countries with high wage standards such as Japan or Switzerland, manufacturers face increased operational expenses that inevitably translate into higher prices for consumers seeking an efficient injection molding service. On the other hand, nations with lower labor costs—like China or India—can offer more competitive rates without compromising production volume.

However, it's crucial not just to look at wage levels but also at workforce skill sets when evaluating how labor affects overall pricing for your project’s needs. Skilled labor can lead to more efficient production processes and fewer errors during assembly; thus lowering long-term costs even if initial rates seem high at first glance! Understanding these dynamics is vital for anyone trying to navigate how to estimate injection molding cost accurately.

Estimating Costs for Your Project

Estimating costs for your injection moulding project can feel like navigating a maze, but with the right approach, you can find your way to accurate figures. Understanding the various components that contribute to injection moulding cost per kg is essential. This section will guide you through tips, pitfalls to avoid, and useful software tools for effective cost calculations.

Tips for Accurate Cost Estimation

When it comes to estimating injection moulding costs accurately, start by gathering detailed information about your project requirements. Consider factors such as material type, part complexity, and production volume; these elements significantly influence how much does injection molding cost per kg? Additionally, consult with experienced injection molding service providers who can provide insights based on their expertise and past projects. Having a clear understanding of these factors will empower you to create a more precise budget.

Common Pitfalls to Avoid

One common pitfall in estimating costs is underestimating material requirements or overestimating production efficiency. It's crucial not only to ask how much does injection molding cost in China but also to compare it with other regions while factoring in local sourcing dynamics. Additionally, failing to account for potential design changes during production can lead to increased costs down the line; always plan for contingencies!

Another mistake is relying solely on online calculators without cross-referencing with industry standards or expert opinions. While these tools are handy for getting a ballpark figure on how to calculate injection mold cost quickly, they may not capture all nuances specific to your project needs.

Using Software for Cost Calculations

In today's digital age, using specialized software can streamline your estimation process significantly when figuring out how to estimate injection molding cost accurately. There are numerous applications tailored specifically for calculating injection moulding costs that take into account various parameters like material type and machine settings. These tools often come with built-in databases that provide real-time updates on market prices—ensuring you're working with accurate data.

Moreover, many of these software solutions allow you to run different scenarios by adjusting variables such as volume or material choice—helping you see how changes impact your overall budget and giving insight into what is the average cost of an injection mold under different circumstances.

By utilizing technology alongside sound strategies and avoiding common pitfalls in estimation processes, you'll be well-equipped not only to understand but also manage your project's financial aspects effectively.

Conclusion

In the world of manufacturing, understanding injection moulding costs is crucial for businesses seeking efficiency and quality. The injection moulding cost per kg can vary significantly based on a multitude of factors such as material selection, labor expenses, and equipment maintenance. By grasping these variables, companies can make informed decisions that align with their budget and production goals.

Factors Impacting Injection Moulding Costs

When considering how much does injection molding cost per kg?, several elements come into play. Material costs are often at the forefront, as different polymers have varying price points that can greatly affect overall expenses. Additionally, labor costs and overhead expenses contribute to the final tally; thus, understanding these factors is essential for accurate budgeting.

Another critical aspect is the complexity of the design and mold requirements. The average cost of an injection mold can fluctuate based on intricacies in design or specific industry standards that need to be met. This means that when estimating costs for your project, all these considerations should be factored in to avoid unexpected financial surprises.

How to Find the Right Injection Moulding Service

Finding a reliable injection molding service involves more than just searching for low prices; it's about value and expertise too. Begin by assessing potential providers' experience in handling projects similar to yours while also evaluating their reputation in terms of quality and delivery timelines. Asking questions like “How to calculate injection mold cost?” or “How to Estimate Injection Molding Cost?” during consultations can help gauge their knowledge base.

Don’t overlook customer reviews or case studies either; they provide insight into how previous clients have fared with particular services. Additionally, consider geographical factors—how much does injection molding cost in China?—as this may influence your decision if you're sourcing internationally or locally.

The Importance of Experienced Providers like Baoyuan

Choosing an experienced provider like Baoyuan can significantly impact your project’s success when it comes to managing injection moulding costs effectively. With a deep understanding of both market dynamics and technical expertise, they ensure that you receive not only competitive pricing but also high-quality results tailored to your specifications. Their ability to navigate complexities associated with different materials and designs means you won't just get an injection mold; you'll get one optimized for performance and durability.

Furthermore, experienced providers often have established relationships with suppliers which may lead to better material pricing—ultimately reducing your overall injection moulding cost per kg! In conclusion, investing time in selecting the right partner will pay off immensely through smoother processes and superior end products.