Introduction

In the ever-evolving landscape of manufacturing, the debate of 3D printing vs injection molding cost has become increasingly relevant. As businesses seek to optimize production processes, understanding the nuances of these two technologies is crucial for making informed decisions. This exploration will illuminate not only the cost factors involved but also how each method stacks up against the other in terms of strength, durability, and real-world applications.

Understanding the Cost Factors

When evaluating whether injection molding is more expensive than 3D printing, it’s essential to consider various cost factors that influence overall expenses. Initial setup costs for injection molding can be substantial due to tooling and equipment requirements, while 3D printing often has lower entry costs but variable material expenses. Additionally, long-term production runs may reveal surprising insights into which method truly offers better value—after all, is 3D printing cheaper than manufacturing in bulk?

Key Differences Between Technologies

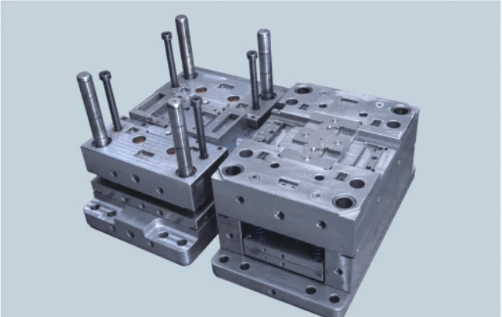

The key differences between injection molding and 3D printing extend beyond just cost; they encompass speed, scalability, and material versatility as well. Injection molding excels in high-volume production with consistent quality but requires significant upfront investment and time for mold creation. On the other hand, 3D printing provides flexibility and rapid prototyping capabilities—leading many to wonder: will 3D printing replace injection molding in certain sectors?

Real-World Applications and Examples

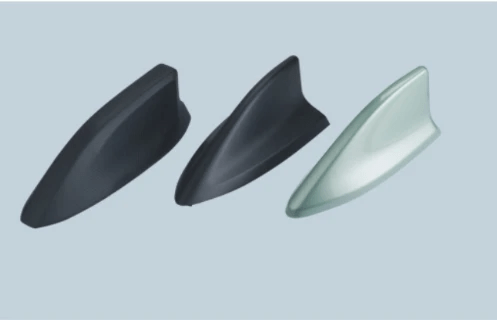

Real-world applications highlight how each technology serves distinct needs within various industries—from automotive to consumer goods. For example, while injection molding is favored for mass-producing durable components like automotive parts due to its strength advantages (think: injection molding vs 3D printing strength), 3D printing shines in creating intricate prototypes or custom designs on demand. By examining these examples closely, we can better understand what is cheaper than injection molding when considering specific project requirements.

Overview of Injection Molding Costs

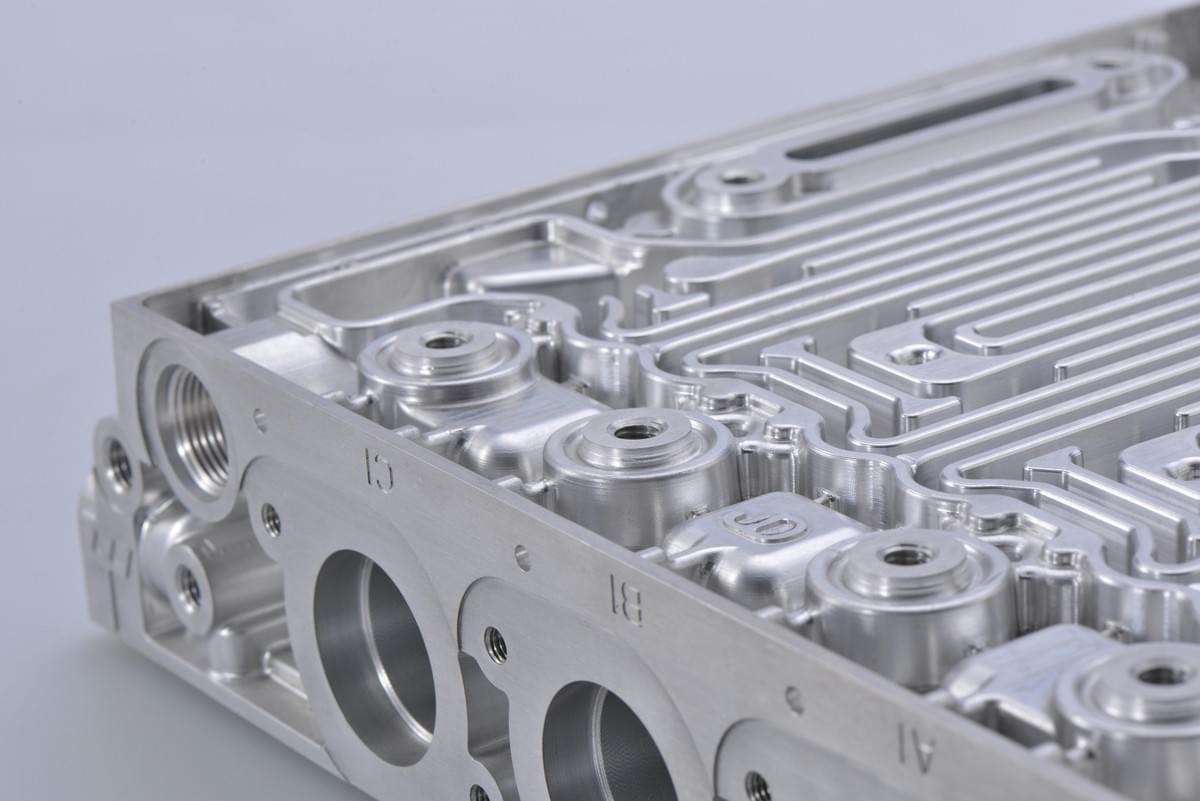

Initial Setup and Equipment Expenses

The initial setup costs for injection molding can be quite substantial, often requiring a hefty investment in specialized machinery and molds. These expenses can range from tens of thousands to millions of dollars depending on the complexity and scale of production desired. This upfront investment raises the question: Is injection molding more expensive than 3D printing? While 3D printing may have lower initial costs due to minimal equipment needs, injection molding's efficiency kicks in once production ramps up.

Per Part Cost Breakdown

Once your molds are created and machinery is operational, per part costs in injection molding can be surprisingly low—often just a few cents per unit when producing large quantities. This significant reduction in cost per part makes it a go-to option for high-volume production runs compared to 3D printing’s variable pricing structure based on material usage and time required for each print. So when pondering whether 3D printing is cheaper than manufacturing through injection molding, remember that volume plays an essential role; as order sizes increase, the cost advantages of injection molding become more pronounced.

Long-Term Cost Efficiency

In terms of long-term cost efficiency, injection molding typically shines brightest in mass production scenarios where consistent quality is paramount. The ability to produce large quantities at low per-part costs means businesses can achieve economies of scale that are hard to match with 3D printing methods—especially for intricate designs or durable components where strength matters (think injection molding vs 3D printing strength). However, if your project requires frequent design changes or smaller runs, you might find yourself asking: what is cheaper than injection molding? In such cases, embracing additive manufacturing could provide better flexibility without breaking the bank.

Analyzing 3D Printing Costs

Material and Equipment Cost Analysis

The material costs for 3D printing can fluctuate significantly based on the type of filament or resin used. Common materials like PLA or ABS may seem affordable, but specialty materials can drive prices up quickly. Additionally, the initial investment in a quality 3D printer can range from a few hundred dollars for hobbyist models to thousands for industrial-grade machines, raising questions like Is injection molding more expensive than 3D printing?

While many enthusiasts find joy in creating prototypes at low costs, businesses often face challenges when scaling production. The equipment needed for consistent quality and speed adds another layer of expense that must be factored in when comparing injection molding vs 3D printing strength and durability. Ultimately, understanding these costs is crucial before deciding which method suits your project's needs.

Cost Variability in Production Runs

One of the standout features of 3D printing is its ability to adapt easily to changes in design without incurring significant retooling expenses. However, this flexibility comes with a caveat: cost variability during production runs can be unpredictable. For small batches or unique designs, you might find that Is 3D printing cheaper than manufacturing? has a resounding yes; but as quantities increase, traditional methods like injection molding often become more economical.

In contrast, with injection molding's upfront costs spread over larger production volumes, it typically leads to lower per-unit prices once set up—making it hard not to ask if Will 3D printing replace injection molding? for mass production scenarios. Therefore, evaluating your project's scale is vital; what starts as an affordable option could spiral out of control if not managed wisely.

Is 3D printing cheaper than manufacturing?

Determining whether Is 3D printing cheaper than manufacturing? involves looking at both short-term and long-term perspectives on cost efficiency. While initial setups for traditional manufacturing methods may seem daunting due to high tooling costs and setup times, they often pay off considerably over large production runs compared to their additive counterparts.

However, when considering niche products or rapid prototyping needs—especially where customization is key—the answer might lean toward yes regarding affordability with 3D printing solutions over time. In many cases where small batches are involved or designs are subject to frequent revisions, companies might find themselves asking What is cheaper than injection molding? as they explore alternative methods like additive manufacturing.

Ultimately, weighing these factors against project requirements will help you navigate through the complexities of both technologies effectively while keeping an eye on overall budget constraints.

Comparing Strength and Durability

3D Printing vs Injection Molding Strength

In terms of strength, injection molding typically holds the upper hand due to its ability to produce parts from high-performance thermoplastics that can withstand significant stress and strain. On the other hand, 3D printing can create complex geometries that might be lighter yet still strong, depending on the material used—think carbon fiber reinforced filaments or nylon composites. This leads us to ponder: Is injection molding more expensive than 3D printing? While injection molding offers superior strength in many cases, its cost-effectiveness comes into play only when producing large quantities.

Real-world Strength Test Comparisons

Real-world tests reveal interesting insights into the strength capabilities of both methods—think tensile tests or impact resistance trials. For example, a recent study showed that while injection-molded parts could handle higher loads before failure, certain 3D printed components showed remarkable resilience under specific conditions due to their unique layer-by-layer construction. This raises another question: Will 3D printing replace injection molding? While not likely in all applications, it's clear that both methods have their place in modern manufacturing.

Applications Suited for Each Method

When considering applications suited for each method, it's essential to evaluate factors like production volume and required part performance. Injection molding excels in high-volume production where uniformity and strength are critical—think automotive components or consumer goods where durability is non-negotiable. Conversely, 3D printing shines in prototyping or low-volume runs where flexibility and rapid iteration are paramount; after all, who wouldn't want a quicker turnaround? So what is cheaper than injection molding? In scenarios requiring customization and lower quantities, 3D printing often proves more cost-effective.

Evaluating Production Speed and Scalability

When considering production methods, speed and scalability play crucial roles in determining the best choice for your project. Both 3D printing and injection molding offer unique advantages, but their effectiveness varies significantly based on the specific application. Understanding these differences can help you make an informed decision about whether to lean towards 3D printing or stick with traditional injection molding.

Speed Differences in Prototyping

In the realm of prototyping, speed is often a decisive factor. 3D printing excels in this area, allowing for rapid iterations and quick adjustments to designs without the need for extensive tooling changes—this is particularly beneficial when testing multiple concepts or designs. In contrast, injection molding requires a longer lead time due to the setup of molds, which can delay initial production phases while you wait for those shiny new tools to arrive.

That said, once production ramps up, injection molding can produce parts at a remarkable speed compared to 3D printing. The initial time investment may be higher with injection molding due to mold creation costs; however, once set up, it churns out parts faster than you can say 3D printing vs injection molding cost. For projects that require rapid prototyping followed by large-scale production, understanding these speed differences is essential.

Large Batch Production and Scaling

When it comes to large batch production and scalability, injection molding often takes the cake. The efficiency of producing thousands of identical parts makes it a go-to choice for manufacturers looking to scale operations quickly and cost-effectively. In contrast, while 3D printing offers flexibility in design changes without additional tooling costs, its slower output rate means that scaling up production can become costly.

Is 3D printing cheaper than manufacturing when considering large quantities? Often not—especially if you're looking at unit economics over thousands of parts where the per-part cost drops significantly with injection molding due to its high-speed capabilities. Therefore, if your project involves mass-producing items where consistency is key, understanding how each method scales will influence your final decision.

Will 3D printing replace injection molding?

The question on everyone's lips: Will 3D printing replace injection molding? While advancements in technology have made 3D printing more viable for certain applications—including low-run productions and complex geometries—the reality is that both methods have their place in modern manufacturing landscapes. Injection molding remains dominant for high-volume runs due to its efficiency and lower per-part costs.

However, it's essential not to overlook scenarios where specific applications might benefit from using both methods in tandem—like using 3D printed prototypes before transitioning into full-scale injection molded products. So instead of pitting them against each other as rivals in a battle royale over Is injection molding more expensive than 3D printing?, consider how they complement each other within different stages of product development.

Choosing the Right Method for Your Project

When it comes to selecting the ideal manufacturing method for your project, understanding the nuances between 3D printing and injection molding is crucial. Factors such as production volume, material requirements, and design complexity play significant roles in determining which method will be more cost-effective. Additionally, evaluating the specific needs of your project can help clarify whether 3D printing or injection molding aligns better with your goals.

Factors Influencing Cost Decisions

Several factors influence cost decisions when comparing 3D printing vs injection molding costs. First, initial setup costs can vary greatly; injection molding often requires a hefty investment in molds and machinery upfront, while 3D printing typically has lower startup expenses due to its flexibility and reduced tooling requirements. Furthermore, production volume plays a pivotal role—if you’re producing small quantities, 3D printing may emerge as the cheaper option; however, for large-scale production runs, injection molding usually becomes more economical over time.

Another essential factor is material selection. The cost of materials can fluctuate significantly between both methods; while some high-end plastics are expensive for injection molding, they might be more accessible in terms of pricing for 3D printing applications. Additionally, design complexity impacts both time and cost—intricate designs are often easier to achieve with 3D printing without incurring extra costs associated with complex molds used in traditional methods.

What is cheaper than injection molding?

When pondering what is cheaper than injection molding? it's essential to consider various alternatives beyond just 3D printing. For low-volume production or one-off prototypes where speed matters most, additive manufacturing (like FDM or SLA) tends to be less expensive than creating custom molds for injection molding processes. Moreover, other techniques like CNC machining or vacuum forming may prove beneficial depending on specific project requirements and material choices.

However, it's important to note that while some methods might initially appear cheaper than injection molding when looking at short-term costs or prototypes—over time and with larger batches—the narrative often shifts back toward traditional methods like injection molding for their long-term efficiency and reduced per-part costs. In essence, understanding how various options stack up against each other requires a comprehensive analysis of both upfront investments and ongoing operational expenses.

Baoyuan’s Expertise in Cost-Effective Solutions

At Baoyuan, we pride ourselves on offering tailored solutions that navigate the complexities of is injection molding more expensive than 3D printing? Our team understands that every project is unique; therefore we analyze your needs meticulously before recommending whether you should lean towards additive manufacturing or traditional methods based on cost-effectiveness and efficiency metrics. With our expertise in both realms—injecting innovation into traditional practices while harnessing cutting-edge technology—we guide clients through their decision-making process seamlessly.

Moreover, we provide insights into current market trends surrounding will 3D printing replace injection molding? While advancements in additive manufacturing continue to make waves across industries, we believe that each method has its rightful place depending on application specifics such as strength requirements (think 3D printing vs injection molding strength). At Baoyuan, our goal remains clear: empower you with knowledge so you can make informed decisions that align perfectly with your project's demands.

Conclusion

In the grand showdown of 3D printing vs injection molding cost, it’s clear that each method has its merits and ideal applications. While injection molding typically shines in large-scale production with lower per-part costs, 3D printing offers flexibility and rapid prototyping benefits that can’t be overlooked. As we delve deeper into the nuances of these technologies, it becomes essential to weigh not only the financial implications but also the specific needs of your project.

Summarizing Cost Comparisons

When comparing 3D printing vs injection molding cost, it's important to consider initial setup expenses alongside long-term efficiencies. Injection molding generally incurs higher upfront costs due to equipment and mold creation, but its per-part price decreases significantly with larger production runs. Conversely, while 3D printing may have lower initial costs for small batches or prototypes, its material and operational expenses can add up quickly—leading some to wonder: is injection molding more expensive than 3D printing?

The question of whether 3D printing is cheaper than manufacturing isn't straightforward; it often depends on the scale and complexity of the parts being produced. For low-volume runs or intricate designs, 3D printing may emerge as a more economical choice. However, for mass production where uniformity is key, injection molding typically prevails due to its efficiency in scaling.

Future of 3D Printing and Injection Molding

Looking ahead, will 3D printing replace injection molding? The answer isn't a simple yes or no; rather, both technologies are likely to coexist and complement each other in various sectors. As advancements in materials and processes continue to evolve for both methods, we can expect a future where hybrid approaches leverage the strengths of each technology.

The increasing demand for customization in industries such as automotive and healthcare suggests that 3D printing will play an increasingly vital role alongside traditional manufacturing methods like injection molding. Meanwhile, improvements in speed and cost-effectiveness for both processes could lead to innovative applications we haven’t even imagined yet!

Making an Informed Decision for Your Needs

Ultimately, making an informed decision about which method suits your project best involves considering several factors beyond just cost—like material properties and production volume requirements. If you're still pondering what is cheaper than injection molding or how the strength stacks up between these two giants (think: 3D printing vs injection molding strength), take time to evaluate your specific needs thoroughly.

Consulting with experts like Baoyuan can provide valuable insights tailored specifically for your project’s demands—ensuring you choose wisely between these two powerful manufacturing techniques. Remember that understanding your unique requirements will guide you toward the most efficient solution without breaking the bank!