Introduction

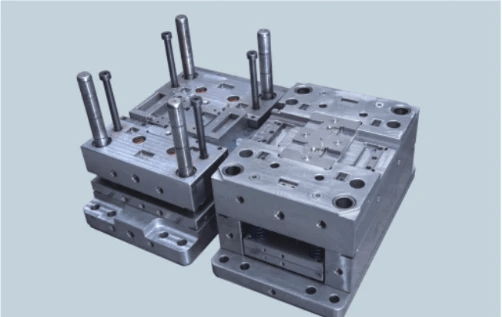

Injection molding is a fascinating process that transforms raw materials into intricate plastic parts through a series of well-coordinated steps. At the heart of this process lies the injection molding valve gate, a crucial component that significantly influences the quality and efficiency of molded products. Understanding how these gates function and their design implications can make all the difference in achieving optimal results in your projects.

Understanding Injection Molding Valve Gates

So, what is a gate in injection molding? In simple terms, it’s the entry point for molten plastic to flow into the mold cavity. The injection molding valve gate specifically controls this flow with precision, allowing for better management of material distribution and cooling times, which are vital for producing high-quality parts.

Importance of Gate Design in Molding

The design of a gate can greatly affect not only the aesthetics but also the mechanical properties of the final product. An effective gate design minimizes defects such as warping or sink marks while maximizing efficiency during production cycles. This brings us to an important question: what is the difference between open gate and valve gate? Each type has its pros and cons that can impact your project's outcome.

Key Terms for Molding Beginners

For those new to this field, familiarizing yourself with key terms related to injection molding is essential for effective communication and understanding processes. Terms like flow rate, cooling time, and gate location will become part of your everyday vocabulary as you delve deeper into how do valve gates work? Additionally, understanding variations like tab gates versus edge gates will equip you with knowledge necessary to make informed decisions on which designs best suit your needs.

What is a Gate in Injection Molding?

In the world of injection molding, the term gate refers to a crucial component that plays a significant role in the production process. Essentially, it acts as the entry point through which molten plastic flows into the mold cavity. Understanding what a gate is in injection molding helps clarify its importance and functionality within various molding systems.

Defining Injection Molding Gates

An injection molding gate is a small opening that allows molten material to enter the mold cavity during the injection process. It serves as both a conduit and control point, managing how and when plastic fills the mold. Without properly designed gates, you could face issues like uneven filling or defects in your final product.

Types of Gates Overview

There are several types of gates used in injection molding, each with its unique characteristics and purposes. Common types include open gates, valve gates, tab gates, and edge gates. Understanding these different types will help you answer questions like What is the difference between open gate and valve gate? or What is the difference between tab gate and edge gate?

Importance of Gates in Mold Design

Gates are pivotal in mold design because they directly influence product quality, cycle time, and overall efficiency of manufacturing processes. The choice of gate type can affect how well materials fill cavities and how easily they can be removed post-molding. Thus, selecting an appropriate gating system—like an injection molding valve gate—can make all the difference between success and failure in your project.

Valve Gate Technology Explained

How Do Valve Gates Work?

So, how do valve gates work? Essentially, they utilize a mechanism that opens and closes at strategic points during the injection process. When the molten plastic is injected into the mold, the valve gate remains closed until the right moment; this helps prevent premature filling and minimizes defects like short shots or sink marks. By controlling the timing of when material enters the mold cavity, these systems ensure an even fill and reduce pressure fluctuations.

Benefits of Valve Gate Systems

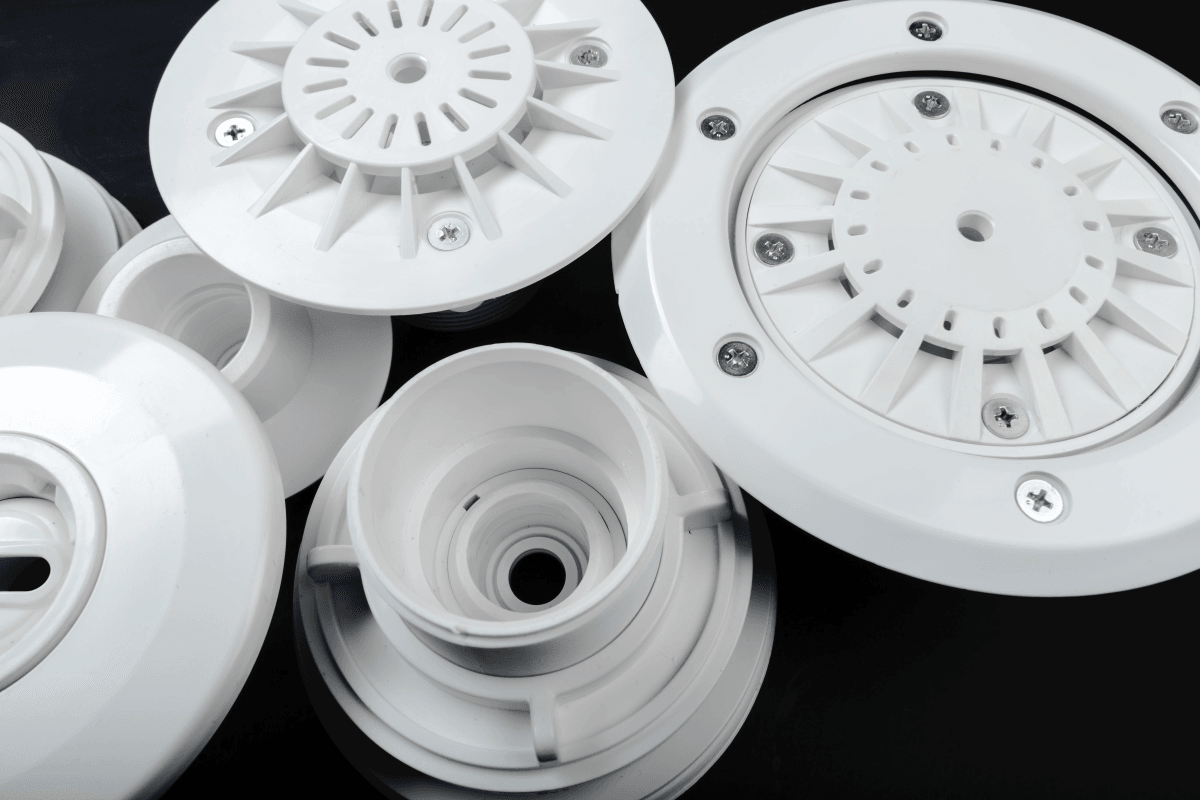

The benefits of utilizing an injection molding valve gate system are numerous and can significantly impact production efficiency. First off, these gates allow for better control over material flow, which leads to improved part consistency and reduced scrap rates—who doesn’t love less waste? Additionally, valve gates can enhance surface finish quality by minimizing knit lines and other imperfections that often plague traditional open gates. In terms of flexibility, they can be tailored for various applications across industries—from automotive to consumer goods.

Real-world Applications of Valve Gates

Real-world applications of valve gates demonstrate their versatility in diverse sectors. For instance, in automotive manufacturing where precision is paramount, these systems help produce intricate parts with tight tolerances while maintaining structural integrity—essentially what every car manufacturer dreams about! Similarly, in consumer electronics where aesthetics matter just as much as functionality, injection molding valve gates can create sleek designs without compromising on performance or durability. This adaptability makes them ideal for any project requiring a reliable solution to complex molding challenges.

Open Gate vs. Valve Gate Comparison

When diving into the world of injection molding, understanding the differences between various gate types is crucial for achieving optimal results. In this section, we will explore the nuances of open gates and valve gates, shedding light on their functionalities and applications. This knowledge will help you make informed decisions for your molding projects.

What is the Difference Between Open Gate and Valve Gate?

To grasp what is a gate in injection molding, it's essential to differentiate between open gates and valve gates. An open gate allows molten plastic to flow freely into the mold cavity without any obstruction, while a valve gate controls this flow through a mechanism that can open or close as needed. This fundamental difference affects everything from cycle times to part quality, making it vital to understand how do valve gates work compared to their open counterparts.

Open gates are often simpler in design and easier to manufacture, but they can lead to issues like excess material at the parting line or visible gate marks on finished products. On the other hand, injection molding valve gates provide more control over material flow and can significantly reduce cosmetic defects, which is particularly beneficial for high-precision applications. Ultimately, choosing between these two options hinges on your specific project requirements and desired outcomes.

Pros and Cons of Each Type

Both open gates and valve gates come with their unique sets of advantages and disadvantages that cater to different needs in injection molding processes. One of the primary pros of an open gate system is its straightforward design; it simplifies setup and maintenance while also being cost-effective for many applications. However, one must consider that this simplicity may come at the cost of potential surface defects or inconsistent fill patterns.

Conversely, while injection molding valve gates offer superior control over material flow—allowing for cleaner parts with less risk of defects—they often require more complex machinery and higher initial investment costs due to their intricate designs. The advantages gained from using valve gates can outweigh these costs when precision is paramount or when dealing with high-value components where aesthetics matter significantly.

When to Choose Valve Gates

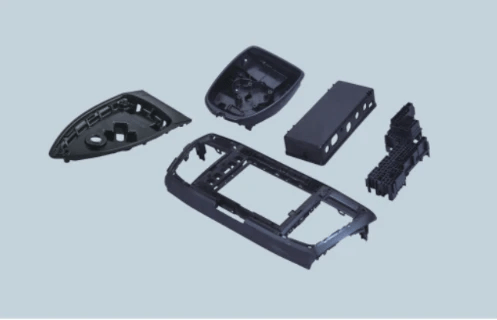

Deciding when to choose valve gates over open ones involves assessing your project's specific needs against each type's capabilities. If you're working on intricate parts requiring tight tolerances or those that are highly visible in end-use applications—think automotive components or consumer electronics—opting for an injection molding valve gate might be your best bet due to its enhanced control over flow dynamics.

Additionally, if you anticipate needing multiple colors or materials within a single part (such as multi-material injections), valve gates provide flexibility by allowing for controlled transitions between different materials without compromising quality. Ultimately, understanding what is the difference between tab gate and edge gate designs can also play a role in making an informed choice regarding which type of gating system best suits your project requirements.

Exploring Tab Gate and Edge Gate Designs

When diving into the world of injection molding valve gates, two popular designs that often come up are the tab gate and edge gate. Understanding the differences between these gate types can significantly impact your molding process and product quality. So, let’s break down what sets them apart and how they each play a role in injection molding.

What is the Difference Between Tab Gate and Edge Gate?

To start off, what is the difference between tab gate and edge gate? A tab gate typically features a flat, raised section that connects to the molded part, allowing for precise control over material flow during injection. In contrast, an edge gate is positioned along the edge of the mold cavity, allowing molten plastic to enter from one side rather than directly into the part itself. This fundamental difference influences how each type interacts with the overall design of your injection molding valve gate system.

The choice between a tab gate and an edge gate may also affect surface finish and aesthetics of your final product. While tab gates can create a clean entry point for material flow, edge gates might leave marks or blemishes depending on their placement and design. Thus, understanding these differences not only helps clarify what is a gate in injection molding but also aids in making informed decisions during production.

Applications of Each Gate Type

Now that we’ve established what sets tab gates apart from edge gates, let’s explore their applications in real-world scenarios. Tab gates are often favored in applications where precision is crucial—think intricate designs like medical devices or consumer electronics where aesthetics matter greatly. The controlled flow provided by tab gates can minimize defects such as sink marks or warping.

On the other hand, edge gates are commonly used for larger parts where speed of production takes precedence over fine details—such as automotive components or large containers. Their straightforward design allows for faster cycle times due to less complex mold structures which can be beneficial when producing high volumes of similar products. By knowing when to apply each type based on your project needs, you’ll be better equipped to navigate through “what is a gate in injection molding?”

Advantages in Different Scenarios

Each type of gate offers unique advantages depending on your specific project requirements—let's take a closer look at those benefits! Tab gates excel when it comes to achieving superior surface quality because they minimize material shear during filling; this leads to fewer defects which means less time spent on post-processing tasks like sanding or painting.

Conversely, edge gates shine in terms of efficiency; they allow for quicker mold filling due to their larger cross-sectional area compared to tab gates which can help reduce overall cycle times significantly—especially important when dealing with high-volume runs! Additionally, since they don’t require as much precision in terms of placement within the mold cavity structure compared to other designs like valve gates or open gates (so what is the difference between open gate and valve gate?), they can simplify manufacturing processes while still delivering satisfactory results.

In conclusion, understanding both tab and edge gates provides valuable insights into choosing the right injection molding valve gate design for your projects based on specific needs such as aesthetics versus efficiency!

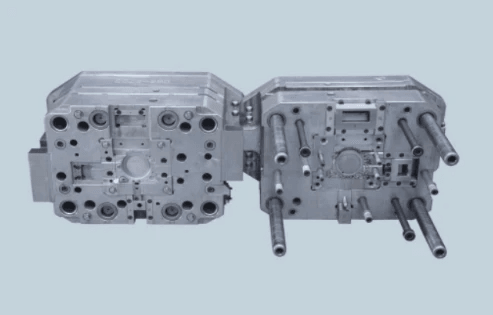

The Role of Baoyuan in Valve Gate Innovation

Baoyuan is at the forefront of innovation in injection molding valve gate technology, leveraging years of expertise to enhance production efficiency and product quality. Their deep understanding of what a gate is in injection molding allows them to design systems that optimize flow and reduce waste. By focusing on advanced gate designs, Baoyuan has set new standards for industries relying on precision plastic components.

Baoyuan’s Expertise in Gate Systems

Baoyuan’s expertise in gate systems stems from a commitment to research and development, which has led to cutting-edge solutions in the realm of injection molding valve gates. They understand the nuances of different gate types, including the essential differences between open gates and valve gates, ensuring that clients receive tailored solutions for their specific needs. With a team dedicated to continuous improvement, Baoyuan remains a key player in developing innovative technologies that push the boundaries of traditional molding practices.

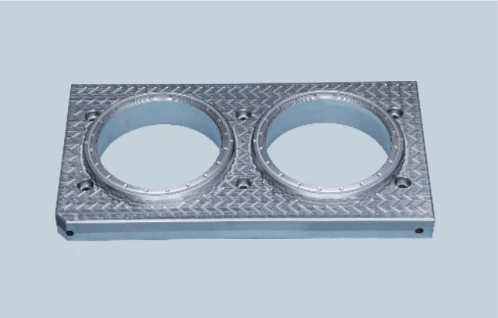

Advanced Techniques in Injection Molding

When it comes to advanced techniques in injection molding, Baoyuan employs state-of-the-art machinery and methodologies that significantly improve how valve gates work. Their focus on automation and precision engineering allows for faster cycle times while maintaining high-quality output—an essential factor when considering what is the difference between tab gate and edge gate designs. By integrating smart technologies into their processes, they not only enhance product quality but also streamline production workflows for greater efficiency.

Quality Assurance in Plastic Products

Quality assurance is paramount at Baoyuan; every injection molding valve gate system undergoes rigorous testing before it reaches customers' hands. They ensure that each component meets stringent industry standards while addressing common concerns about durability and reliability—key factors when evaluating various gate types like tab gates versus edge gates. With a robust quality control system in place, Baoyuan guarantees that its products not only meet expectations but exceed them, fostering trust among clients across diverse sectors.

Conclusion

In wrapping up our exploration of injection molding valve gates, it's clear that understanding this technology is crucial for anyone involved in the molding process. The intricacies of gate design, from what a gate in injection molding is to the differences between various types like open gates and valve gates, can significantly impact production efficiency and product quality. As we anticipate future developments in this field, it’s essential to consider how these innovations will shape the industry.

Key Takeaways on Valve Gates

To summarize, injection molding valve gates offer distinct advantages over traditional open gates by allowing for more precise control over material flow and minimizing defects such as weld lines. Understanding how do valve gates work is fundamental; they operate by using a mechanism that opens and closes at specific times during the injection cycle, ensuring optimal filling patterns. Additionally, recognizing what is the difference between tab gate and edge gate designs can help mold designers choose the most effective options based on their specific application needs.

Future Trends in Injection Molding

Looking ahead, future trends in injection molding are leaning towards increased automation and smart technologies integrated into valve gate systems. Innovations such as real-time monitoring and adaptive control systems will likely emerge to enhance efficiency further while reducing waste. Furthermore, advancements in materials science may lead to new applications for injection molding valve gates that were previously unimaginable.

Choosing the Right Gate for Your Project

When it comes to choosing the right gate for your project, it's essential to weigh factors such as part geometry, material type, and production volume against the benefits of different gating systems. Understanding what is the difference between open gate and valve gate can help you make an informed decision tailored to your project's requirements. Ultimately, whether opting for a tab gate or an edge gate design will depend on your specific needs; thus careful consideration of each option's advantages will lead you toward a successful outcome.