Introduction

Welcome to the intricate world of injection molding, where costs can be as complex as the designs themselves. Understanding injection molding costs is crucial for businesses looking to produce high-quality plastic parts efficiently and economically. As we dive into this topic, we’ll explore how much it costs to make a plastic mold and the various elements that contribute to custom plastic molding cost.

Understanding Injection Molding Costs

The overall injection molding costs not only depend on material choices but also on design intricacies and production volumes. By grasping these elements, manufacturers can better estimate how much does custom molding cost and avoid unexpected financial pitfalls.

Key Factors Influencing Pricing

Several key factors influence pricing in the realm of injection molding, including material selection, design complexity, and production volume. Each of these aspects plays a significant role in shaping the total cost; for instance, opting for high-grade materials can elevate your custom plastic molding cost significantly. Additionally, understanding how to calculate moulding cost accurately is essential for making informed decisions that align with your budget.

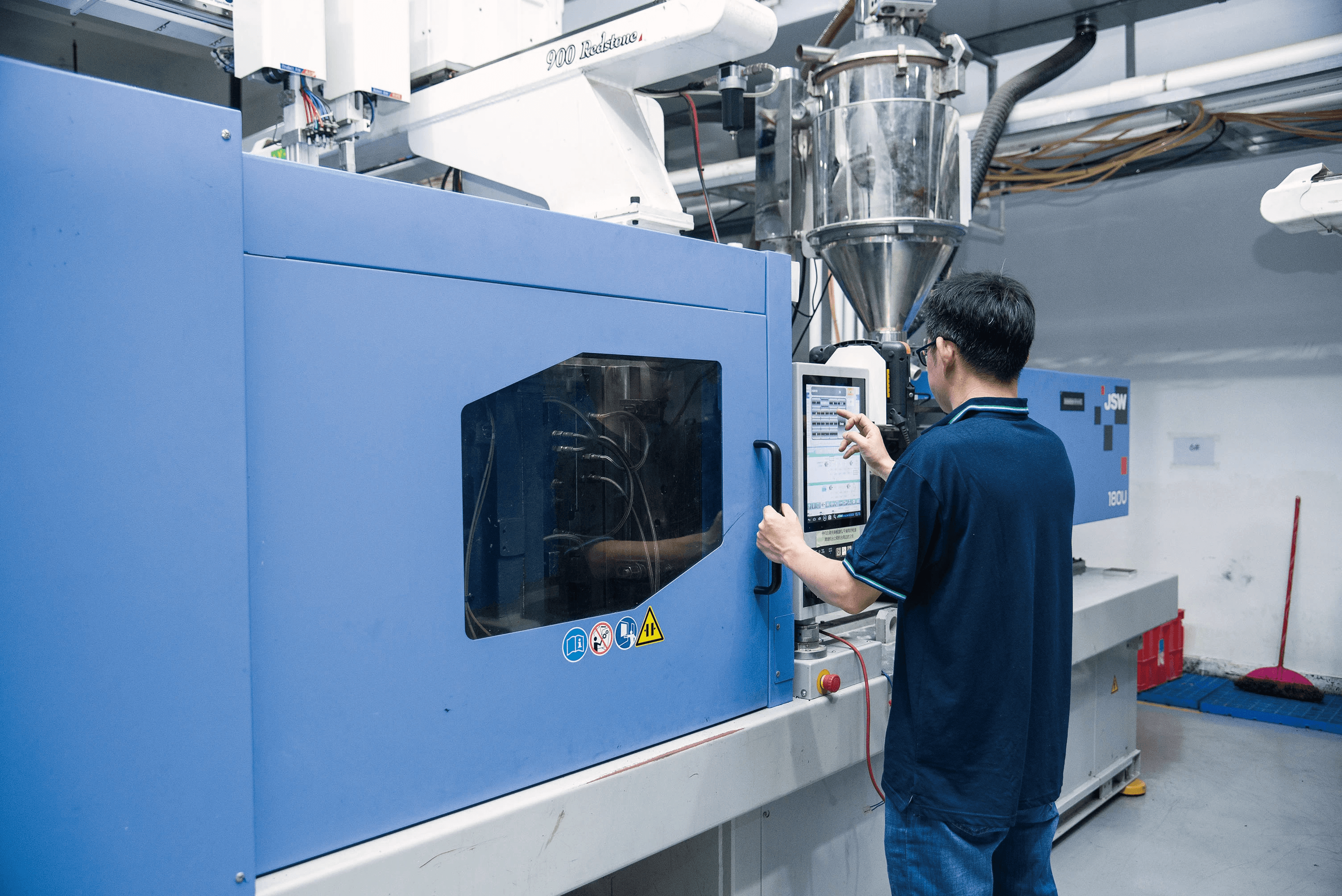

The Role of Technology in Costs

Technology plays an indispensable role in determining injection molding costs today; advancements in machinery can lead to greater efficiency and reduced labor expenses. For instance, knowing how much does a plastic injection molding machine cost per hour can help businesses assess their operational expenditures more effectively. With companies like Baoyuan at the forefront of machine technology innovation, staying updated on these advancements can lead to smarter investments and optimized custom plastic molding processes.

Overview of Injection Molding

Injection molding is a manufacturing process that allows for the creation of complex plastic parts with precision and efficiency. This technique involves melting plastic pellets and injecting them into a mold, where they cool and solidify into the desired shape. Understanding this process is crucial for anyone looking to explore custom plastic molding costs or assess how much it costs to make a plastic mold.

What is Injection Molding?

At its core, injection molding is about efficiency and scalability. The process begins with raw plastic material, which is heated until it becomes liquid and then injected into a precisely designed mold under high pressure. Once cooled, the mold opens to reveal the finished part, making it an ideal solution for mass production while keeping custom molding costs in check.

As for how much does custom molding cost? That depends on various factors including material choice, design complexity, and production volume. By grasping these elements early on, businesses can better estimate their budgets and understand how to calculate moulding cost effectively.

Advantages of Injection Molding

One of the standout advantages of injection molding is its ability to produce high volumes of parts quickly without sacrificing quality. This method ensures uniformity across all pieces, which is essential for industries like automotive or consumer goods where precision matters significantly. Additionally, because it minimizes waste during production, many companies find that injection molding reduces overall manufacturing expenses in terms of both time and materials.

Another benefit lies in the versatility offered by this technology; you can use various materials ranging from thermoplastics to elastomers depending on your specific needs. So when asking How Much Does Plastic Injection Molding Cost? remember that your choice of material can have a significant impact on pricing as well as performance characteristics.

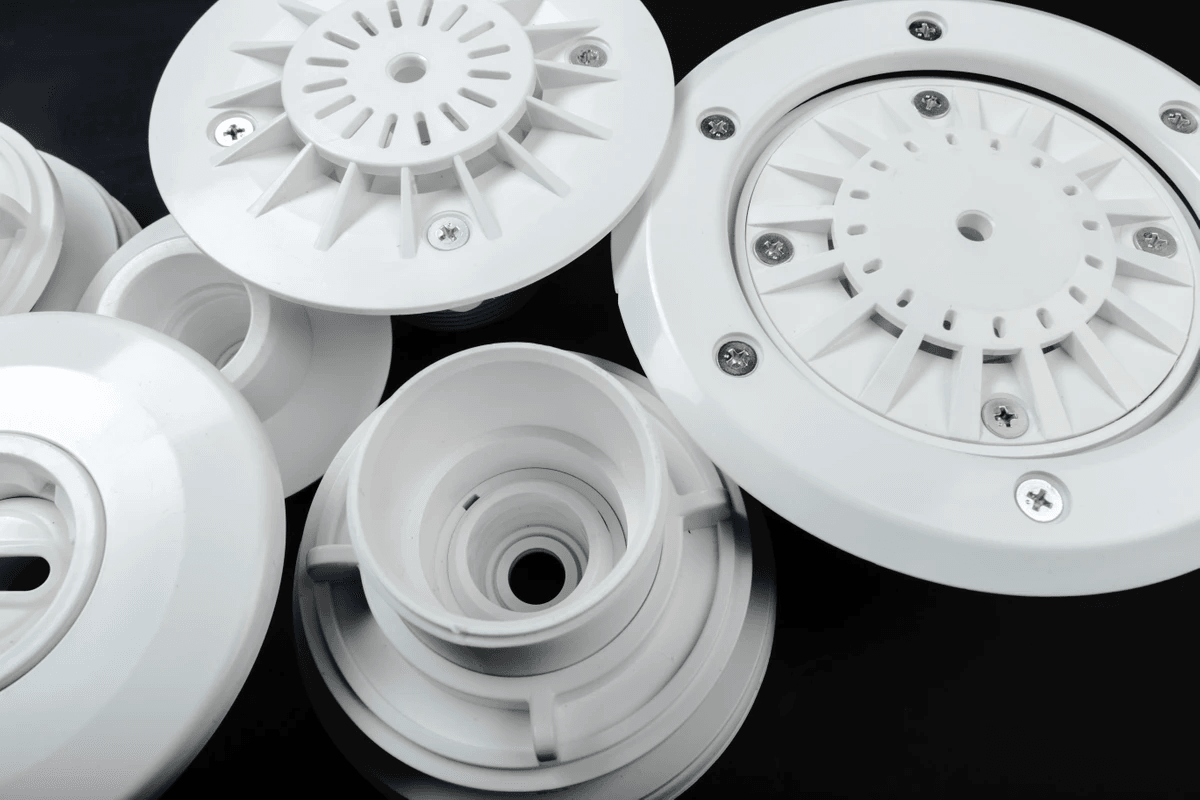

Common Applications for Plastic Parts

Injection molded parts are everywhere—from everyday household items to critical components in medical devices or automotive assemblies. For instance, toy manufacturers often rely on this technique due to its capability for producing intricate designs at scale while keeping custom plastic molding costs manageable. Similarly, sectors like electronics utilize injection molded housings that provide durability without compromising weight.

In addition to toys and electronics, industries such as packaging also benefit from injection molding's efficiency by creating containers tailored specifically for their products. As you begin exploring how much does it cost to make a plastic mold or look into pricing analysis across different sectors, keep in mind that understanding common applications will help contextualize your investment decisions.

Custom Plastic Molding Cost Factors

The overall custom plastic molding cost can vary significantly based on several elements, including material selection, design complexity, and production volume. By breaking down these components, manufacturers can make informed decisions that align with their budget and production needs.

Material Selection and Its Impact

The choice of materials plays a pivotal role in determining custom plastic molding costs. Different plastics have varying price points, properties, and processing requirements; for instance, high-performance polymers tend to be more expensive than standard thermoplastics. Additionally, how much does it cost to make a plastic mold? This often depends on the material selected since certain materials may require specialized molds or processes that drive up costs.

Understanding the implications of material selection not only affects the initial investment but also influences long-term performance and durability of the molded parts. For example, while opting for cheaper materials might reduce upfront expenses, it could lead to higher replacement costs down the line if those materials don’t hold up under stress or environmental conditions. Therefore, evaluating how much does custom molding cost should include a thorough analysis of material properties alongside pricing.

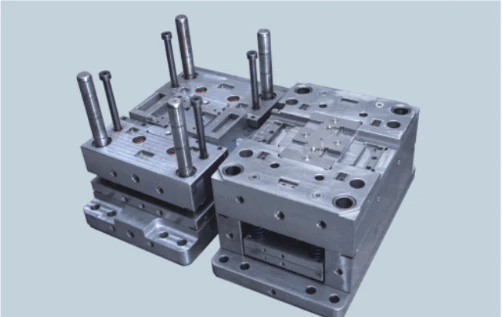

Complexity of Design Considerations

Another significant factor affecting injection molding costs is the complexity of part design. Intricate designs often require more sophisticated molds that take longer to produce and may involve additional engineering work—this translates directly into higher expenses. When asking how to calculate moulding cost accurately, one must account for these complexities as they can dramatically influence both time and labor involved in production.

Moreover, complex designs might necessitate advanced features such as undercuts or thin walls that complicate the mold-making process further. These features not only increase initial mold costs but can also affect cycle times during production; slower cycles mean higher operational costs per unit produced. Thus, businesses must carefully weigh design intricacies against budget constraints when considering their custom plastic molding projects.

Production Volume and Pricing

Production volume is another key component influencing how much does a plastic injection molding machine cost per hour? Generally speaking, larger production runs tend to lower the per-unit cost due to economies of scale; however, this requires an upfront investment in tooling that may not be justified for smaller batches. Understanding your expected volume helps manufacturers gauge whether it's more economical to invest in high-quality molds or opt for quicker solutions with lower initial outlays.

Additionally, fluctuating demand can impact pricing structures significantly; manufacturers need flexibility in their operations while keeping an eye on rising injection molding costs associated with lower volumes. The balancing act between maintaining sufficient stock levels without overcommitting resources is crucial—especially when determining how much does custom molding cost overall within varying market conditions.

In conclusion, grasping these critical factors allows businesses to navigate through the complexities surrounding custom plastic molding effectively while managing their budgets wisely.

Tools of the Trade: Injection Molding Machines

Understanding how much does a plastic injection molding machine cost per hour is essential for any manufacturer looking to optimize their production process. These machines are not just hefty investments; they also influence the quality and speed of production, which directly affects custom plastic molding costs.

How Much Does a Plastic Injection Molding Machine Cost Per Hour?

The hourly cost of operating a plastic injection molding machine can vary widely based on several factors, including machine size, energy consumption, and maintenance requirements. On average, you might expect to pay anywhere from $25 to $150 per hour depending on these variables and how much does it cost to make a plastic mold? This figure can significantly impact your overall custom molding cost if you're running large production runs or using advanced machinery with higher operational efficiencies.

It's important to factor in not just the direct costs but also the potential savings from more efficient machines that reduce cycle times and waste. When evaluating how much does custom molding cost, remember that investing in high-quality equipment often pays off in the long run through reduced operational costs and improved product quality. Therefore, understanding these expenses is crucial for accurate budget planning.

Evaluating Machine Efficiency and Performance

Evaluating machine efficiency is key when considering how to calculate moulding cost effectively. High-performance machines can produce parts faster while consuming less energy, leading to lower overall operational costs over time. Metrics such as cycle time, energy consumption per cycle, and defect rates should be closely monitored as they directly influence the injection molding costs associated with your projects.

Moreover, newer technologies offer enhanced precision that reduces scrap rates—an essential factor in determining custom plastic molding costs. Investing in efficient machinery may seem daunting at first glance due to initial expenses but can yield significant savings by optimizing production processes and minimizing waste over time. Thus, assessing performance metrics becomes indispensable when deciding which machines will best serve your manufacturing needs.

The Role of Baoyuan in Advancing Machine Technology

Baoyuan has emerged as a leader in advancing injection molding technology with innovative solutions designed specifically for enhancing productivity and reducing costs associated with custom plastic molding. Their state-of-the-art machines incorporate features like automation and real-time monitoring systems that help manufacturers keep track of their operations efficiently—making it easier than ever to answer questions like How much does Plastic Injection Molding Cost?

By investing in advanced technology offered by companies like Baoyuan, businesses are better equipped to manage their resources effectively while maintaining high-quality standards across their product lines. This technological edge not only streamlines operations but also plays a significant role in reducing hidden costs often associated with traditional methods of production. Ultimately, embracing such advancements could prove critical for companies looking to thrive within competitive markets where every dollar counts towards achieving optimal custom plastic molding outcomes.

Cost Estimation Techniques

Accurate calculations can save businesses a significant amount of money and time, ensuring that they stay competitive in the market. Let's dive into some effective methods for estimating these costs.

How to Calculate Moulding Cost?

Calculating moulding costs involves several factors that come together like pieces of a puzzle. First, you need to factor in the cost of materials, which can vary widely depending on the type of plastic selected. Additionally, consider the complexity of your design; intricate designs may require more expensive molds and longer production times, ultimately influencing how much does it cost to make a plastic mold? Lastly, don't forget about overhead costs such as machine operation—how much does a plastic injection molding machine cost per hour?

A comprehensive approach will help you determine how much does custom molding cost? By breaking down each component—materials, labor, and machine time—you can arrive at an accurate estimate that reflects your project's unique requirements.

Comparing Quotes from Different Manufacturers

Once you've calculated an initial estimate for your custom plastic molding cost, it's time to shop around! Gathering quotes from different manufacturers allows you to compare not just prices but also services and capabilities. When evaluating these quotes, pay close attention to what each manufacturer includes; some might offer lower prices but exclude essential services or materials.

Understanding how much does plastic injection molding cost across various suppliers helps identify the best value for your investment. Don’t hesitate to ask questions about their pricing structure and any potential hidden fees that could affect your final bill.

Hidden Costs to Watch For

While estimating costs is vital, being aware of hidden costs can make or break your budget in custom plastic molding projects. These sneaky expenses might include tooling charges for molds not included in initial quotes or unexpected shipping fees that arise during delivery. Additionally, if you're working with complex designs or tight tolerances, there may be extra charges related to quality assurance processes.

To avoid surprises down the line when calculating moulding costs, always request a detailed breakdown from manufacturers regarding what’s included in their pricing structures. This way, you'll have a clearer picture of what you’re truly paying for and ensure your project stays within budget.

Pricing Analysis for Different Industries

When it comes to injection molding costs, the financial implications can vary significantly across different industries. Understanding these variations is crucial for businesses looking to optimize their budgets while maintaining quality in production. This section will delve into the specific considerations and pricing structures that define custom plastic molding costs in the automotive, consumer goods, and medical device sectors.

Automotive Industry Injection Molding Costs

The automotive industry is one of the largest consumers of custom plastic molding, utilizing it for everything from interior components to exterior parts. How much does it cost to make a plastic mold in this sector? Typically, initial costs can be high due to stringent safety standards and the need for durable materials; however, these investments often pay off through high-volume production efficiencies. When evaluating injection molding costs in automotive applications, consider factors like material selection and complexity of design—both critical elements that influence overall custom plastic molding cost.

In terms of scale, higher production volumes can significantly reduce per-unit costs; thus, automakers often opt for long-term contracts with manufacturers to secure better pricing. Additionally, how much does a plastic injection molding machine cost per hour? In automotive manufacturing settings where uptime is essential, investing in advanced machinery that offers efficiency and reliability becomes crucial. Ultimately, understanding these dynamics helps companies navigate their budget while ensuring they meet both regulatory requirements and consumer expectations.

Consumer Goods and Their Financial Implications

The consumer goods sector presents unique challenges when assessing how much custom molding cost affects product pricing strategies. Products such as packaging or household items require rapid turnaround times but often come with lower margins compared to other industries like automotive or medical devices. Therefore, understanding how to calculate moulding cost effectively becomes vital for manufacturers aiming to maintain competitiveness without sacrificing quality.

One key factor influencing consumer goods pricing is material choice; cheaper materials may reduce upfront costs but could lead to higher defect rates or shorter product lifespans—ultimately affecting brand reputation and customer satisfaction. How much does custom molding cost can vary widely based on design intricacies; simpler designs generally yield lower prices but may not always align with brand aesthetics or functionality needs. As companies adapt their offerings based on market trends, ongoing evaluation of injection molding costs remains essential.

Medical Device Manufacturing Cost Comparisons

In the realm of medical devices, precision is paramount—not only in product performance but also in manufacturing processes where compliance with strict regulations is required. The question How much does a plastic injection molding machine cost per hour? takes on new significance here as manufacturers must balance operational efficiency with rigorous quality controls that ensure patient safety. Custom plastic molding costs are typically higher in this industry due to specialized materials that meet biocompatibility standards and intricate designs necessary for functionality.

When comparing these costs across various sectors, it's evident that medical device manufacturing requires a more significant investment upfront compared to consumer goods or automotive applications—but this investment pays dividends through reliability and trustworthiness among healthcare providers and patients alike. Furthermore, hidden costs associated with regulatory compliance should be factored into overall estimates when assessing how much does custom molding cost within this field—ensuring no surprises down the line during production runs or market entry phases.

Conclusion

In wrapping up our exploration of injection molding costs, it’s clear that understanding the various elements at play can significantly impact your budget and production strategy. From the initial stages of custom plastic molding cost assessments to evaluating how much does it cost to make a plastic mold, each factor contributes to the overall financial picture. As we look ahead, recognizing these factors will empower businesses to make informed decisions regarding their plastic parts production.

Key Takeaways on Injection Molding Costs

When considering injection molding costs, it's essential to look beyond just the price tag of materials or machinery. The complexity of design and production volume heavily influences how much does custom molding cost, making it crucial for manufacturers to focus on efficiency and scalability. Additionally, understanding how to calculate moulding cost accurately can help avoid unexpected expenses down the line.

Future Trends in Custom Plastic Molding

The landscape of custom plastic molding is evolving rapidly with advancements in technology and sustainability practices. Manufacturers are increasingly exploring eco-friendly materials and energy-efficient processes, which can alter traditional pricing models for custom plastic molding cost. Furthermore, innovations such as 3D printing integration may change how we perceive costs associated with injection molding; after all, who wouldn't want a more streamlined approach?

Making Informed Decisions on Plastic Parts Production

Navigating the world of plastic parts production requires a keen eye on various pricing elements—from machine operation costs (How much does a plastic injection molding machine cost per hour?) to hidden charges that could inflate your budget unexpectedly. By comparing quotes from different manufacturers and understanding industry-specific nuances (like those in automotive or medical sectors), you can make smarter choices regarding your projects. Ultimately, staying informed about injection molding costs will place you in an advantageous position when negotiating contracts or planning future productions.