Introduction

Injection molding is a widely used manufacturing process that allows for the mass production of plastic parts with high precision. However, understanding injection molding costs can be a daunting task for many businesses, especially those new to the industry. This guide aims to demystify the various aspects of injection molding costs, offering insights into how to estimate injection molding cost effectively.

Understanding Injection Molding Costs

Injection molding costs encompass various factors including materials, mold design, production volume, and labor. To truly grasp what is involved in calculating these costs, one must consider not only the upfront expenses but also ongoing operational costs that can arise during production. For instance, when asking What is the average cost of an injection mold?, it's essential to remember that this figure can vary significantly based on complexity and material choices.

The Importance of Accurate Cost Estimation

Accurate cost estimation is crucial for any business looking to invest in injection molding processes. Miscalculating these expenses can lead to budget overruns and project delays that could jeopardize profitability. By learning how to calculate injection mold cost effectively and understanding how much does injection molding cost per kg, businesses can make informed decisions that align with their financial goals.

Key Factors Influencing Injection Molding Costs

Several key factors play a significant role in determining overall injection molding costs. Material selection is one such factor; different types of plastics come with varying price tags which directly affect production expense. Additionally, considering 3D printing vs injection molding provides valuable context as it highlights alternative methods and their respective costs—important information when evaluating options for manufacturing needs.

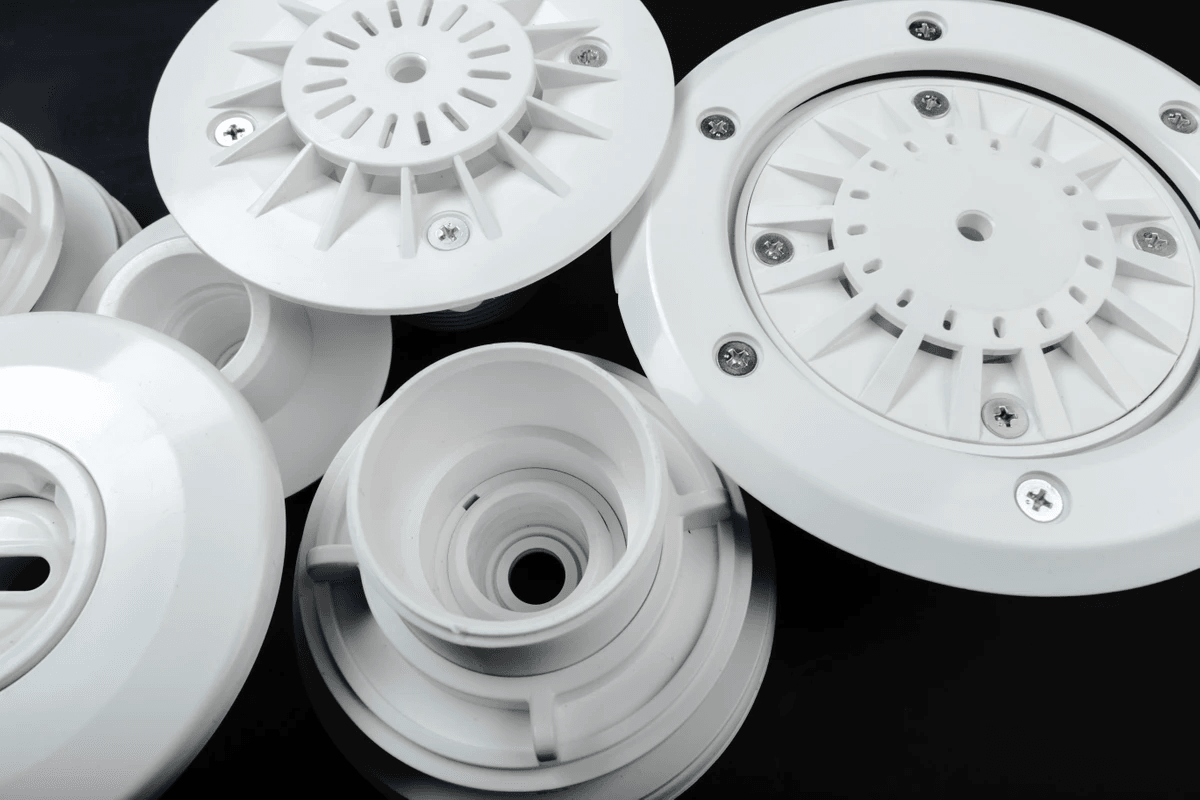

Material Selection

Types of Materials and Their Costs

There are several types of materials commonly used in injection molding, including thermoplastics, thermosetting plastics, and elastomers. Each material comes with its own price tag—thermoplastics like ABS and polycarbonate tend to be more affordable than high-performance materials such as PEEK or nylon. When trying to estimate injection molding costs, it’s essential to consider not only the material price but also how it impacts other factors like mold design and production speed.

Understanding what is the average cost of an injection mold can help you gauge whether your chosen material aligns with your budget. For instance, while cheaper materials may seem attractive initially, they could lead to higher costs down the line if they require more complex molds or additional processing steps. Thus, a thorough analysis of material costs should be part of your strategy when calculating total expenses.

The Role of Resin in Pricing

Resin selection plays a pivotal role in determining injection molding costs because it directly influences both the upfront investment and long-term performance of molded parts. Different resins have varying thermal properties, strength characteristics, and ease of processing that can impact your overall project timeline and expenses. Therefore, understanding how to calculate injection mold cost effectively involves considering resin grades that match both performance requirements and budget constraints.

For example, while specialty resins may offer superior mechanical properties or chemical resistance at a higher upfront cost, they might reduce production waste or improve product lifespan—ultimately saving money over time. This means that when evaluating options for how much does injection molding cost per kg? you must factor in not just the raw material price but also potential savings from enhanced durability or reduced cycle times associated with specific resins.

Comparing Costs of 3D Printing vs Injection Molding

In recent years, 3D printing has emerged as a popular alternative to traditional methods like injection molding due to its rapid prototyping capabilities and lower initial setup costs. However, when comparing 3D printing vs injection molding on an economic scale over larger production runs, the dynamics shift considerably. While 3D printing might save you money on small batches or complex geometries requiring no tooling changes, large-scale production often favors injection molding due to its ability to produce high volumes at lower per-unit costs.

To truly understand how much does injection molding cost in China compared to other countries is vital for businesses looking for competitive pricing without compromising quality. In many cases, overseas manufacturers can leverage economies of scale that significantly reduce labor and material expenses—making them attractive partners for large-scale projects needing precise budgeting strategies around injections molds and resin choices alike.

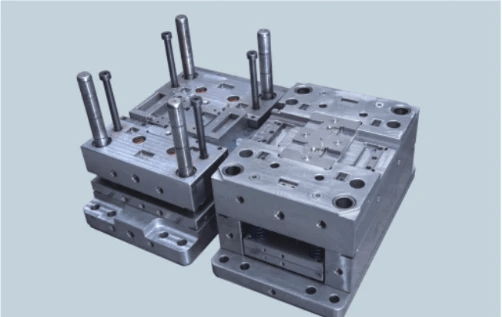

Mold Design and Complexity

How Design Impacts Injection Mold Costs

The complexity of a mold's design directly correlates with its cost, as intricate designs often require more time and resources to manufacture. Factors such as undercuts, draft angles, and surface finishes can complicate the molding process and lead to higher expenses. Moreover, if you’re wondering how much does injection molding cost per kg? The answer often hinges on these design intricacies; simpler molds generally allow for lower material waste and faster cycle times, which ultimately reduces costs.

In addition, when comparing 3D printing vs injection molding, it's essential to consider that while 3D printing offers flexibility in design without high upfront costs, injection molding can be more economical in large-scale production due to its efficiency once the mold is created. Therefore, understanding how to calculate injection mold cost involves not only analyzing material expenses but also factoring in the complexities introduced by your specific design choices.

Average Cost of an Injection Mold Explained

What is the average cost of an injection mold? This question doesn't have a one-size-fits-all answer; however, it typically ranges from $1,000 for simple molds to over $100,000 for highly intricate designs used in specialized applications. The average cost often reflects not just materials but also labor involved in crafting the molds based on their complexity.

In regions like China where manufacturing costs are lower, you may find that prices for similar molds are significantly reduced—how much does injection molding cost in China? It’s often less than half of what you'd pay in many Western countries due to lower labor rates and operational overheads. Thus, evaluating your project’s requirements against these averages is crucial for accurate budgeting.

The Benefits of Efficient Mold Design

Efficient mold design provides several advantages that extend beyond mere cost savings; it enhances production speed and improves product quality as well. By optimizing your mold's layout and mechanics, you can reduce cycle times significantly—leading to increased output without sacrificing quality or incurring additional expenses related to rework or defects.

Moreover, investing time upfront into designing an efficient mold helps mitigate long-term risks associated with high injection molding costs down the line. With a streamlined process that minimizes waste and maximizes productivity during each run, companies can better manage their budgets while ensuring consistent quality across products. Ultimately, making informed decisions about mold complexity will empower manufacturers not just today but well into future projects as well.

Production Volume

Calculating Costs Based on Quantity

Calculating costs based on quantity involves analyzing both fixed and variable expenses associated with injection molding. Fixed costs, such as mold creation and setup fees, remain constant regardless of the number of units produced. Conversely, variable costs fluctuate with production volume—more units typically lead to lower per-unit costs due to economies of scale, making it crucial to know how much does injection molding cost per kg when planning larger runs.

For instance, if you're considering a high-volume order, the upfront investment in mold design may seem daunting at first glance. However, as you produce more units, those initial mold costs get spread out over a larger number of products, reducing the overall cost per item significantly. This is where understanding how to calculate injection mold cost can be invaluable for maximizing profitability while keeping an eye on total injection molding costs.

Fixed vs Variable Costs in Injection Molding

In the realm of injection molding, distinguishing between fixed and variable costs is essential for accurate budgeting and forecasting. Fixed costs encompass expenses that do not change regardless of production levels—these include mold design and manufacturing fees which can be substantial depending on complexity. On the other hand, variable costs are directly tied to production volume; materials used for each unit and labor involved in running machines fall into this category.

A clear grasp of these two types of expenses allows companies to strategize their production more effectively. For example, if you're weighing 3D printing vs injection molding for a short run versus a long-term project, knowing how these costs interplay will guide your decision-making process significantly. Ultimately, effective management of fixed and variable components can lead to reduced overall injection molding costs.

How Much Does Injection Molding Cost per kg?

When asking how much does injection molding cost per kg?, it's important to factor in several variables including material choice and complexity of the part being produced. Generally speaking, prices can vary widely depending on location; for instance, many businesses find that how much does injection molding cost in China tends to be lower than in Western countries due to cheaper labor rates and material sourcing options.

To provide a rough estimate: typical prices might range from $3-$10 per kg depending on various factors such as resin type or design intricacies involved in creating molds—this is why understanding how to estimate injection molding cost accurately is crucial for project planning. Additionally, comparing these figures against alternative methods like 3D printing may reveal surprising insights regarding efficiency versus expense when scaling up production volumes.

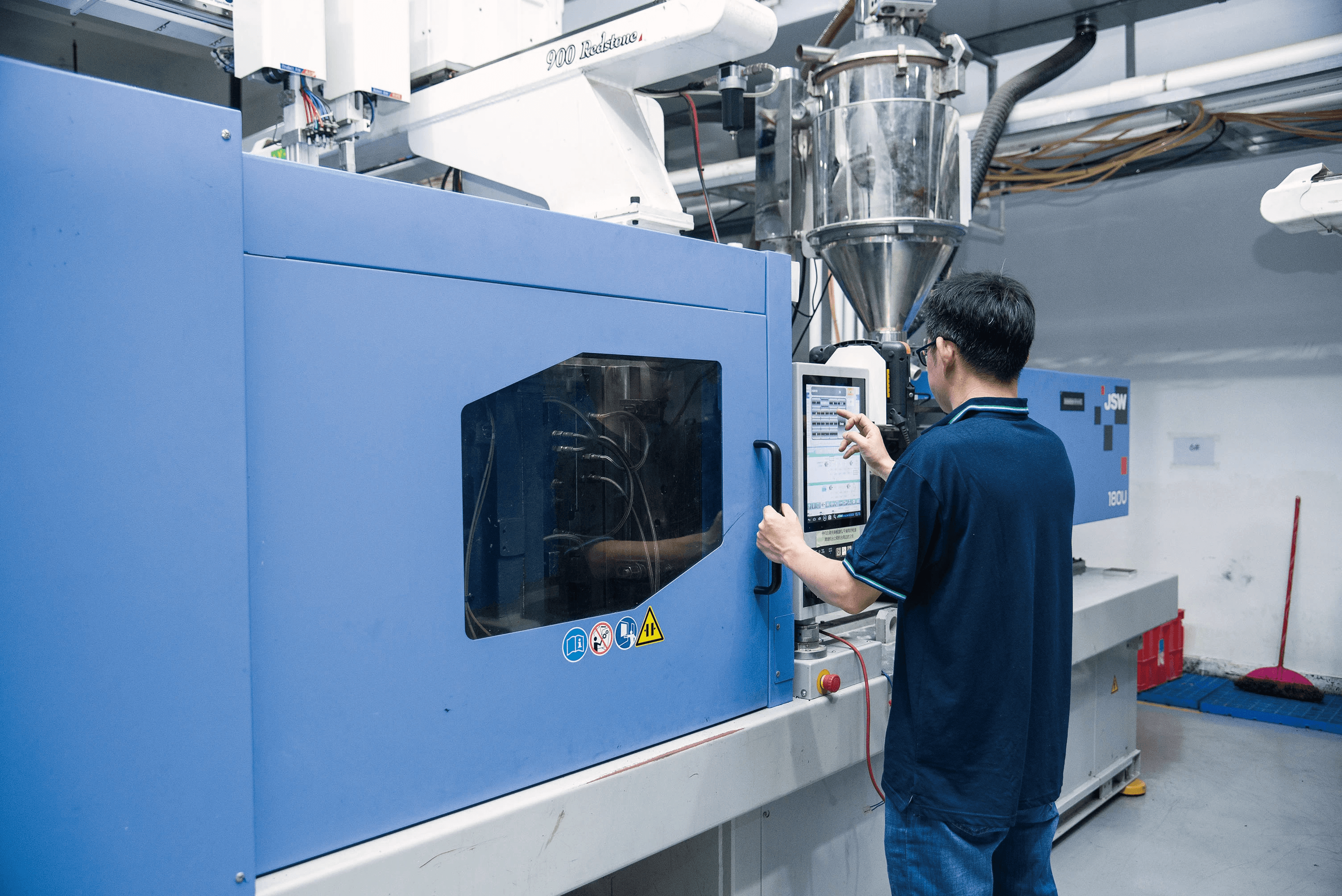

Labor and Overhead Costs

Understanding labor and overhead costs is crucial when estimating injection molding costs. These expenses can significantly influence the overall pricing structure, impacting your project's budget and profitability. By breaking down these factors, you can gain a clearer picture of how to calculate injection mold cost effectively.

Labor Factors That Affect Pricing

Labor costs in injection molding vary based on several factors, including location, skill level, and the complexity of the project. For instance, skilled technicians who operate advanced machinery may command higher wages than those with less experience. Additionally, labor costs in countries like China are typically lower than in Western nations, which can affect how much does injection molding cost per kg when outsourcing production.

When considering labor for your project, it's essential to factor in not just hourly wages but also training time and potential overtime expenses. Delays caused by inexperienced workers can lead to increased production times and ultimately raise your injection molding costs. Therefore, understanding the local labor market is key to making informed decisions about your manufacturing needs.

Understanding Overhead in Injection Molding

Overhead costs encompass all indirect expenses associated with running an injection molding operation that aren't directly tied to production. This includes utilities, rent for manufacturing space, maintenance of machinery, and administrative salaries—essentially anything that keeps the lights on while molds are being crafted. Understanding these overheads is vital for accurate cost estimation; they can add a significant percentage to your overall injection molding costs.

In many cases, overhead is calculated as a percentage of direct labor or material costs—often ranging from 20% to 50%. When evaluating suppliers or facilities for your project, consider how efficient their operations are at managing overhead; this could save you money in the long run. Remember that high-quality work often comes with higher overheads but may yield better results than cheaper alternatives.

How to Estimate Injection Molding Cost?

Estimating injection molding cost requires a comprehensive approach that considers all relevant factors—from material selection to production volume and even geographical considerations like how much does injection molding cost in China versus other regions. A good starting point is calculating the fixed costs associated with mold creation and setup before factoring in variable costs tied to each part produced.

To accurately estimate these expenses, you should also look into specific metrics such as cycle time (the time taken for one complete cycle of injecting resin) and scrap rates (the percentage of defective parts). Additionally, comparing traditional methods like 3D printing vs injection molding will help clarify which option best suits your budgetary constraints while meeting quality standards.

Finally, don't forget about ongoing operational expenses such as maintenance or potential downtime due to equipment failure—these can significantly impact how much you end up spending overall on any given project! By taking a holistic view of these elements together with precise calculations on individual components like what is the average cost of an injection mold? you'll be well-equipped for success.

Location and Supplier Factors

Comparing Injection Molding Cost in China vs Other Countries

How much does injection molding cost in China? Generally, the costs tend to be lower than those in Western countries due to reduced labor expenses and competitive pricing on raw materials. However, while initial quotes may look appealing, hidden costs such as shipping fees, tariffs, and potential delays can add up quickly, making it crucial to conduct a thorough analysis when comparing international suppliers.

In contrast, countries like the United States or Germany may offer higher upfront costs but often provide superior quality assurance and shorter production times. This leads us back to the question of how to estimate injection molding cost accurately—consider not just the price per unit but also factors like reliability and responsiveness of your supplier. Ultimately, understanding these nuances will help you make an informed decision about where to source your injection molded parts.

Baoyuan's Role in Cost Efficiency

Baoyuan has carved out a niche for itself by balancing quality with affordability in the realm of injection molding costs. Their strategic operations allow them to minimize overhead while maximizing efficiency without compromising on product integrity. By leveraging advanced technology and skilled labor, Baoyuan can provide competitive pricing that rivals even the lowest-cost options available globally.

When considering how much does injection molding cost per kg or looking into what is the average cost of an injection mold? Baoyuan’s transparent pricing model makes it easier for clients to understand what they’re paying for at every stage of production. They also excel at helping customers navigate through complexities like 3D printing vs injection molding comparisons by providing tailored solutions that align with specific project needs.

Finding the Right Partner for Your Injection Molding Needs

Choosing a supplier is more than just finding someone who offers low prices; it's about forming a partnership that can adapt as your needs evolve over time. How to calculate injection mold cost effectively involves not only assessing price but also evaluating reliability and communication practices from potential partners. A good partner will help you understand all aspects of injection molding costs while ensuring you receive high-quality products on time.

It's wise to ask potential suppliers about their experience with similar projects and how they handle challenges that may arise during production runs—this can save you headaches down the road! In summary, finding a reliable partner means investing time upfront but pays off significantly when it comes down to managing your overall project budget efficiently.

Conclusion

In summary, understanding injection molding costs is crucial for anyone looking to embark on a manufacturing project. The factors influencing these costs range from material selection to labor and overhead expenses, all of which can significantly affect the final price. By grasping these elements, you can make informed decisions that will ultimately lead to cost-effective production.

Key Takeaways on Injection Molding Costs

When estimating injection molding costs, it's essential to consider multiple variables such as material type, mold design complexity, and production volume. For instance, the average cost of an injection mold can vary widely based on its intricacy and functionality. Additionally, comparing how much does injection molding cost per kg across different suppliers can reveal significant savings opportunities.

Tips for Accurate Cost Calculations

To accurately calculate injection mold cost, begin by assessing your project's specific needs—this includes selecting the right materials and determining the required production volume. Utilize cost estimation tools or consult with experienced professionals who can provide insights tailored to your project’s scale and complexity. Don’t forget to weigh the pros and cons of 3D printing vs injection molding; sometimes opting for one over the other can dramatically alter your overall budget.

Making Informed Decisions for Your Projects

With a clear understanding of how much does injection molding cost in China versus other countries, you can identify potential areas for savings without sacrificing quality. Partnering with reliable suppliers like Baoyuan may also enhance your overall efficiency while keeping costs manageable. Ultimately, making informed decisions based on thorough research will empower you to navigate the complexities of injection molding costs effectively.