Introduction

Injection molding is a fascinating process that plays a pivotal role in modern manufacturing, but how much does injection molding cost? Understanding the various components that contribute to injection molding costs can help businesses make informed decisions, especially when it comes to small production runs. In this guide, we'll explore not only the intricacies of pricing but also why small runs are essential for many companies today.

Understanding Injection Molding Costs

When diving into the world of injection molding, one of the first questions that arises is: what is the average cost of an injection mold? The costs can vary significantly based on numerous factors such as design complexity, material selection, and production volume. Therefore, understanding these components will arm you with knowledge to ask the right questions and negotiate better deals.

The Importance of Small Runs

Small production runs are becoming increasingly popular in industries ranging from automotive to consumer goods. These smaller batches allow businesses to test new products or respond quickly to market demands without incurring massive upfront costs. However, understanding how much does injection molding cost for these small runs is crucial for budgeting and financial planning.

Key Factors Influencing Pricing

Several key factors influence pricing in injection molding beyond just material and labor costs. Geographical location plays a significant role; for instance, how much does injection molding cost in China compared to domestic options? Additionally, considerations such as mold design complexity and machine operational efficiency must be factored into any comprehensive cost analysis.

What is Injection Molding?

Injection molding is a manufacturing process that involves creating parts by injecting molten material into a mold. This technique is widely used in various industries due to its efficiency and ability to produce high volumes of identical products. As we delve deeper, you'll discover how much does injection molding cost and the various factors influencing that price.

Definition and Process Overview

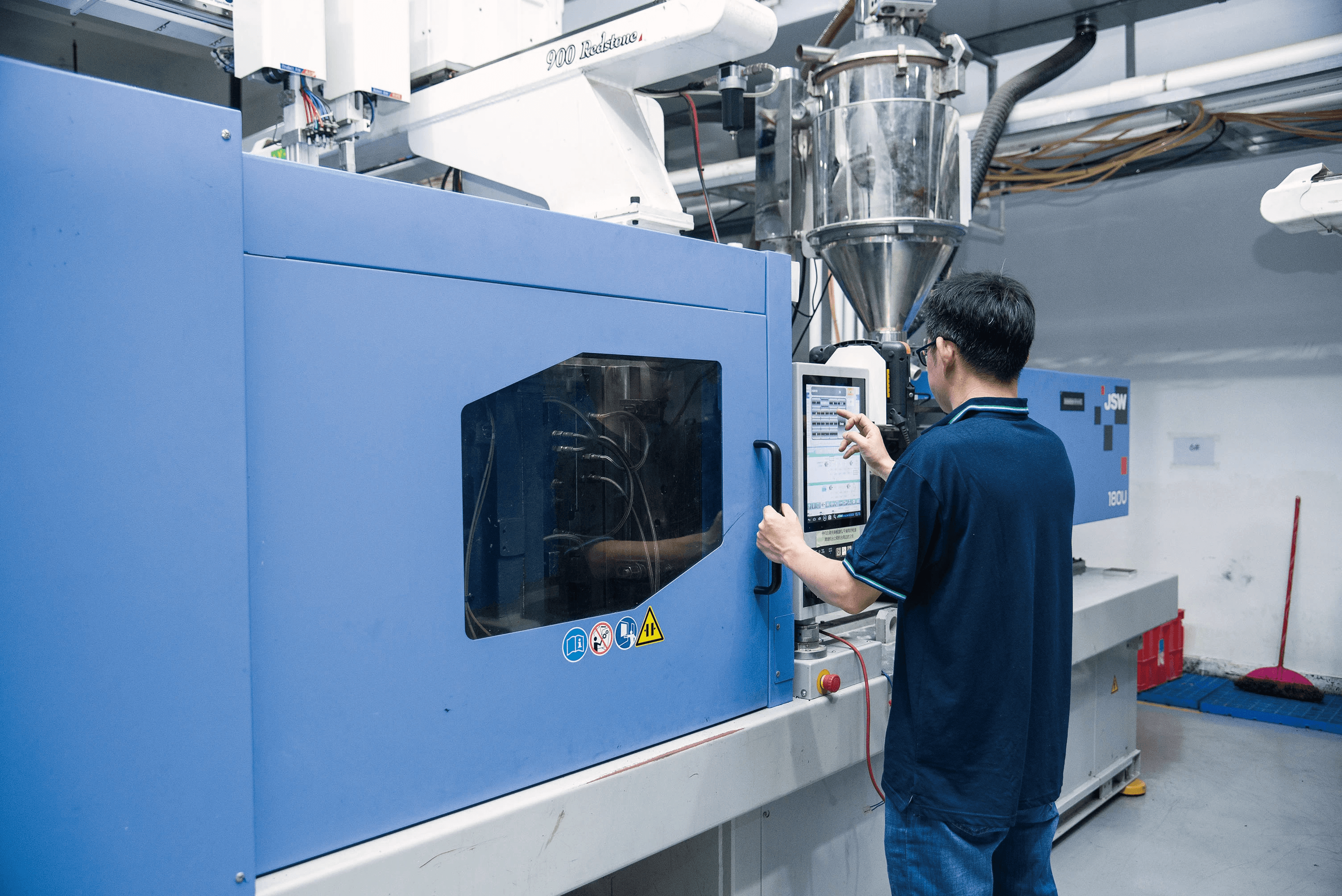

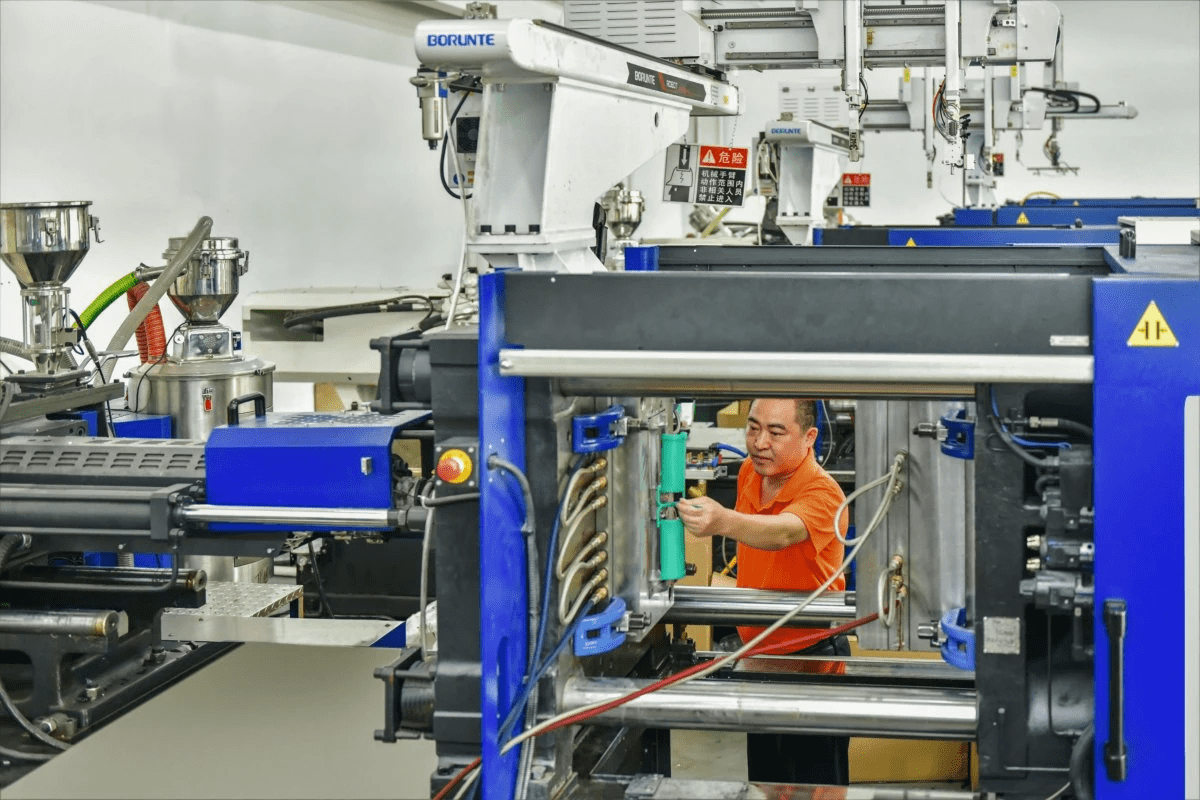

At its core, injection molding consists of melting plastic or other materials and forcing them into a pre-designed mold under high pressure. Once cooled, the material solidifies, taking on the shape of the mold cavity. This process allows manufacturers to create complex geometries with precision, making it a go-to method for producing everything from small components to large assemblies.

The machinery involved in this process includes an injection unit and a clamping unit, which work in tandem to ensure efficiency and accuracy. The operator must consider several variables like temperature, pressure, and cooling time during production to achieve optimal results. Understanding how much does injection molding cost starts with recognizing these foundational elements of the process.

Benefits of Injection Molding

One significant advantage of injection molding is its ability to produce large quantities of parts quickly without sacrificing quality. This efficiency translates directly into cost savings for businesses looking to scale production—an essential factor when considering how much does injection molding cost per part. Moreover, the consistency achieved through this method minimizes waste and maximizes resource utilization.

Another benefit lies in the versatility of materials used; from thermoplastics to elastomers, manufacturers have numerous options at their disposal based on project requirements. The design flexibility allows for intricate details that would be challenging or impossible with other manufacturing techniques. These advantages make it clear why many industries favor this method over others.

Common Applications in Industry

Injection molding serves as the backbone for many sectors including automotive, consumer goods, medical devices, and electronics—each demanding precision-engineered components tailored for specific functions. For instance, automotive manufacturers rely on this process for producing dashboards and interior parts efficiently while ensuring durability and aesthetics are maintained throughout production runs.

In consumer goods, everything from toys to kitchen utensils can be created using injection molds due to their affordability and adaptability across different designs. Additionally, medical device companies leverage this technology for producing sterile components essential for healthcare applications—demonstrating just how integral injection molding is across diverse fields.

As we explore further sections like “What is the average cost of an injection mold?” or “How much does injection molding cost in China?”, it's vital to appreciate not only what goes into creating these parts but also their real-world implications on industries worldwide.

How Much Does Injection Molding Cost?

Analyzing Average Costs of Production

To truly grasp what is the average cost of an injection mold, one must consider various components that contribute to the total expense. Generally, the average costs for injection molding production can range anywhere from $1,000 to $100,000 depending on the intricacies of the mold and the materials used. For small runs specifically, it’s crucial to analyze these costs closely since they can often be higher per unit than larger production runs.

Regional Variations: Injection Molding Costs in China

Now let’s dive into how much does injection molding cost in China compared to other regions. Due to lower labor and material costs, many companies find that manufacturing in China can significantly reduce expenses—often by 20-50% compared to domestic production. However, while initial savings may seem attractive, it’s essential to factor in shipping times and potential tariffs when calculating total expenses.

Comparing Costs: Domestic vs. Overseas Production

When comparing costs between domestic and overseas production for injection molding projects, several factors come into play that affect how much does injection molding cost overall. While overseas options may offer lower prices initially, hidden fees such as shipping delays or quality control issues could inflate final expenses—especially for smaller runs where precision matters most. Ultimately, businesses must weigh these considerations against their specific needs; sometimes paying a bit more domestically ensures better quality and faster turnaround.

What is the Average Cost of an Injection Mold?

Breakdown of Mold Design Costs

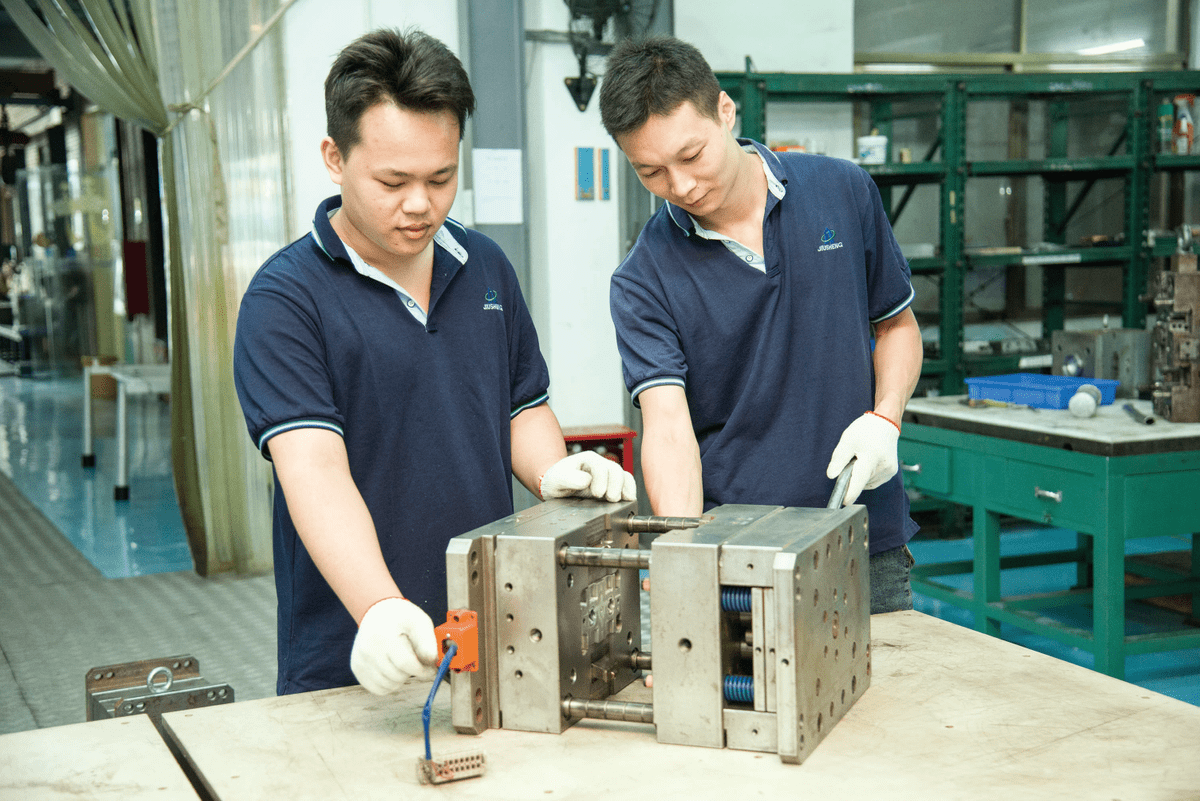

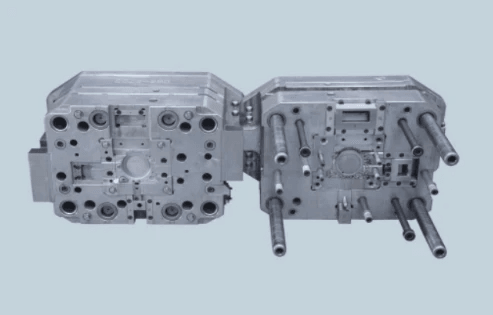

The design phase of an injection mold is where a substantial portion of your budget will be allocated. Depending on the complexity and precision required for your specific application, mold design can range from a few thousand to tens of thousands of dollars. Factors such as whether you're using 3D modeling software or traditional drafting techniques also impact how much does injection molding cost in terms of initial mold expenses.

Additionally, specialized features like cooling channels or intricate geometries can further increase costs. It's essential to weigh these design aspects against production goals to determine how to calculate injection mold cost effectively. Remember that investing in a well-designed mold upfront can lead to savings in production efficiency later on.

Material Choices and Their Impact

Material selection plays a pivotal role in determining not just the quality but also how much does injection molding cost overall. Different materials come with varying price tags; for instance, high-performance thermoplastics typically command higher prices than standard resins. The choice between metal alloys for durability versus plastic materials for lighter applications can significantly affect both initial costs and long-term performance.

Moreover, some materials may require specialized processing conditions that could elevate operational expenses—think about how much does injection molding cost per part when you factor in these variables! Choosing the right material not only influences upfront costs but also impacts maintenance and longevity throughout the mold's lifespan.

Lifespan and Maintenance Expenses

Understanding the lifespan and maintenance expenses associated with an injection mold is vital for calculating its total cost-effectiveness over time. A well-maintained mold can last for years, potentially producing millions of parts before requiring replacement or significant repairs—this longevity helps mitigate initial investment concerns regarding how much does injection molding cost per part produced over time.

However, neglecting regular maintenance can lead to increased wear and tear that shortens this lifespan dramatically while inflating repair costs unexpectedly. Therefore, it's wise to incorporate routine inspections and upkeep into your budgeting plans if you want to avoid future headaches—and additional costs!

Ultimately, by considering all these factors—design complexities, material choices, and maintenance requirements—you'll have a clearer picture of what is the average cost of an injection mold tailored specifically for your needs.

How to Calculate Injection Mold Cost?

Calculating the cost of injection molds can seem daunting, but breaking it down into manageable steps can simplify the process. Understanding how much does injection molding cost requires a thorough assessment of various factors that contribute to the overall expense. This section will guide you through a step-by-step calculation process, consider design complexities, and address how production volume impacts costs.

Step-by-Step Calculation Process

To answer the question, How to calculate injection mold cost?, start by identifying all components involved in the mold's creation. Begin with the initial design costs, which include engineering time and any necessary 3D modeling work. Next, factor in material costs for both the mold itself and any prototypes needed for testing before full production begins.

Once you've established those figures, consider additional expenses such as machining time and labor costs associated with creating the mold. Don't forget to include overheads like utilities or facility costs if applicable; they can add up quickly! Finally, tally these expenses together to arrive at your total injection mold cost estimate.

Considerations for Design Complexity

When pondering What is the average cost of an injection mold?, remember that design complexity plays a significant role in determining overall expenses. Intricate designs often require more advanced engineering and manufacturing techniques, which can drive up costs considerably. For instance, if your product features undercuts or intricate geometries, expect higher machining times and possibly more expensive materials.

Moreover, complex designs might necessitate additional testing and validation phases before production kicks off—further increasing your budgetary requirements. If you're working on a tight budget but still want quality results, consider simplifying your design where possible; this could lead to significant savings without sacrificing functionality.

Impact of Production Volume on Cost

The volume of parts you plan to produce has a substantial impact on how much does injection molding cost per part. Generally speaking, higher production volumes lead to lower per-unit costs due to economies of scale—more parts mean you spread out fixed costs over a larger quantity! Conversely, smaller runs often result in higher per-part expenses since setup fees remain constant regardless of output.

In addition to fixed costs being distributed over more units with high-volume runs, recurring operational expenses also diminish per unit as production increases. However, if you're considering small runs purely for prototyping or testing purposes—like asking how much does injection molding cost in China—you might find that overseas production offers competitive pricing even for lower quantities due to reduced labor rates.

How Much Does Injection Molding Cost Per Part?

When it comes to determining how much does injection molding cost per part, several factors come into play that can significantly influence the final price. These include the complexity of the part design, the type of materials used, and the production volume. Understanding these variables can help businesses make informed decisions and optimize their budget for small runs.

Factors Affecting Cost Per Unit

The first major factor affecting cost per unit is design complexity. Intricate designs often require more advanced molds and longer production times, which drive costs up. Additionally, materials play a crucial role; premium materials will raise expenses compared to standard options, making it essential to choose wisely based on your project needs.

Another consideration is production volume; higher quantities typically lead to lower costs per unit due to economies of scale. However, for small runs where only a limited number of parts are needed, manufacturers may impose higher prices since the initial setup costs are distributed over fewer items. This means that understanding how much does injection molding cost in China or elsewhere can vary significantly based on these factors.

Lastly, operational expenses like labor and machine time must be factored in when calculating your total costs per part. For example, if you're wondering about injection molding machine cost per hour, it's essential to consider how this impacts your overall budget as well as your profit margins.

Estimating Costs for Small Runs

Estimating costs for small runs in injection molding requires a careful analysis of all contributing factors discussed earlier. Typically, small production runs will have higher per-part costs than larger batches due to fixed overhead expenses being spread over fewer pieces. To get an accurate estimate, you should gather quotes from multiple manufacturers and consider both tooling and material expenses.

Moreover, understanding what is the average cost of an injection mold can guide you in budgeting effectively for smaller projects. While custom molds can be expensive upfront—often ranging from thousands to tens of thousands—this investment may pay off if you plan for future production runs or larger quantities later on.

To further refine your estimates for small runs, it's advisable to conduct a thorough analysis based on specific project requirements such as lead times and material specifications. This ensures that you have a clear picture of how much does injection molding cost per part while maintaining quality standards throughout the process.

Case Studies of Small Production Runs

To illustrate how much does injection molding cost per part in practical scenarios, let’s look at some case studies involving small production runs across different industries. In one instance involving automotive components with complex geometries, a company found that producing 100 units resulted in an average cost per part of $8 due to high mold setup fees and specialized materials used.

Conversely, another case study focused on simple consumer goods demonstrated that by optimizing design simplicity and selecting standard polymers led to an average unit price drop down to $2 for 500 parts produced in one run—a significant savings achieved through strategic planning!

These examples highlight not only how much does injection molding cost but also emphasize the importance of choosing appropriate designs and materials tailored specifically for smaller volumes without compromising quality or performance standards.

Injection Molding Machine Cost Per Hour

When considering the overall expenses associated with injection molding, one critical component is the cost of operating the injection molding machine per hour. Understanding how much does injection molding cost in terms of machine operation can significantly impact your budget, especially for small runs. This section will delve into the various factors influencing these costs, providing a clearer picture for manufacturers and businesses alike.

Equipment Costs and Their Implications

The initial investment in injection molding machinery can be substantial, often running into hundreds of thousands of dollars depending on the size and capabilities of the machine. However, this equipment is essential for determining how much does injection molding cost over time since it directly influences production efficiency and quality output. Additionally, the type of machinery selected—whether new or used—can greatly affect your operational budget; newer machines typically offer enhanced energy efficiency but come at a higher price tag.

Operational Costs to Consider

Beyond just acquiring the machinery, operational costs must also be factored into your calculations when assessing how much does injection molding cost per hour. These include electricity consumption, maintenance expenses, labor costs, and materials used during production runs. It's crucial to evaluate these ongoing expenses as they can accumulate quickly; for instance, older machines may require more frequent repairs that could inflate overall operational costs.

Efficiency Factors in Production

Efficiency plays a significant role in determining how much does injection molding cost per part produced. Factors such as cycle time—the duration it takes to complete one production cycle—can affect both labor and energy costs significantly; shorter cycle times typically lead to lower costs per part due to increased throughput. Moreover, optimizing machine settings and choosing suitable materials can enhance productivity further while reducing waste and minimizing downtime.

Conclusion

In summary, understanding the costs associated with injection molding is crucial for businesses considering this manufacturing method. Whether you're asking yourself how much does injection molding cost or wondering about the average cost of an injection mold, knowing the various factors at play can help you make informed decisions. From equipment expenses to material choices and production volumes, every detail contributes to the overall price tag.

Key Takeaways on Costs

When evaluating how much does injection molding cost, it's essential to break down each component of the process. The average cost of an injection mold can vary significantly based on design complexity and material selection, which directly impacts your budget. Additionally, regional variations—like how much does injection molding cost in China versus domestic production—can lead to significant savings or additional expenses depending on your specific needs.

Making Informed Decisions for Small Runs

For smaller production runs, understanding how to calculate injection mold cost becomes vital in ensuring profitability. Factors such as design intricacy and anticipated production volume play a pivotal role in determining how much does injection molding cost per part. By weighing these considerations carefully, you can optimize your budget and achieve a balance between quality and expense.

Where to Get Help: Baoyuan's Expertise

If you're still feeling overwhelmed by questions like “how much does injection molding cost?” or need guidance on what is the average cost of an injection mold, look no further than Baoyuan's expertise in this field. Our team is dedicated to helping businesses navigate their unique challenges while providing insights into efficient manufacturing practices and competitive pricing strategies. With our support, you'll be well-equipped to tackle any project confidently.