Introduction

In today's automotive industry, the use of injection molding for manufacturing auto parts has become increasingly crucial. Baoyuan's expertise in injection molding for auto parts has positioned them as a leader in this field. The benefits of using injection molded plastic parts in automobiles are vast, making it a preferred method for producing high-quality components.

Importance of Injection Molding in Automotive Industry

Injection molding plays a vital role in the production of automotive parts due to its ability to create complex shapes and intricate designs with precision. This process allows for mass production of parts at a faster rate, meeting the demands of the ever-evolving automotive industry.

Baoyuan's Expertise in Injection Molding for Auto Parts

Baoyuan has honed their skills and expertise in injection molding techniques specifically tailored to meet the stringent requirements of the automotive sector. Their commitment to innovation and quality has made them a trusted partner for many leading automobile manufacturers.

Benefits of Using Injection Molded Plastic Parts in Automobiles

The advantages of using injection molded plastic parts in automobiles are numerous, including cost-effectiveness, lightweight construction, and enhanced durability. These components also offer greater design flexibility and can be customized to meet specific performance requirements.

The Process of Injection Molding Automotive Parts

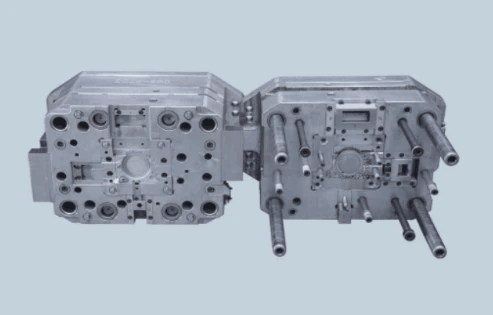

When it comes to manufacturing automotive parts, injection molding is a crucial process. It involves the use of molten plastic material that is injected into a mold, where it cools and solidifies to form the desired part. The process begins with the melting of plastic pellets, which are then injected into a mold cavity under high pressure. Once the plastic has cooled and solidified, the mold opens, and the finished part is ejected.

Steps involved in Injection Molding Process

The injection molding process consists of several key steps. First, the mold is clamped shut, and the plastic material is injected into the mold cavity. Next, the material is allowed to cool and harden inside the mold before it is ejected as a finished part. This process allows for high precision and repeatability in producing automotive parts with complex shapes and intricate details.

After the plastic material is injected into the mold cavity, pressure is applied to ensure that the material fills every crevice and corner of the mold, resulting in a high-quality finished product. This pressure also helps to minimize any defects or imperfections in the final part, ensuring that it meets the required specifications. Once the material has cooled and hardened inside the mold, it is carefully ejected to prevent any damage to the intricate details and complex shapes that have been achieved through this precise process.

Baoyuan's Innovative Techniques in Injection Molding

Baoyuan has been at the forefront of developing innovative techniques in injection molding for automotive parts. Their advanced machinery and technology allow for precise control over every aspect of the molding process, ensuring high-quality parts that meet strict industry standards.

Baoyuan's commitment to innovation in injection molding has led to the development of cutting-edge techniques that set them apart in the automotive industry. Their expertise in using advanced machinery and technology allows them to achieve unparalleled precision and consistency in producing high-quality parts. As a result, their injection molded parts not only meet but exceed the rigorous standards set by the industry, giving automotive manufacturers a competitive edge.

Advantages of Using Injection Molded Parts in Auto Industry

The use of injection molded plastic parts offers numerous advantages in the auto industry. These parts are lightweight yet durable, making them ideal for improving fuel efficiency without sacrificing safety or performance. Additionally, injection molded parts can be produced at a faster rate than traditional manufacturing methods, reducing production time and costs.

Injection molded plastic parts also offer design flexibility, allowing for intricate and complex shapes to be easily achieved. This means that auto manufacturers can create unique and customized components that are tailored to specific vehicle designs and functions. In addition, the use of injection molded parts results in minimal material waste, as the process is highly efficient and precise. This not only contributes to cost savings but also aligns with sustainable manufacturing practices, making it a win-win situation for both auto companies and the environment.

Quality Assurance in Plastic Injection Molding Parts

Baoyuan's Commitment to Quality in Injection Molding

At Baoyuan, we take pride in our commitment to delivering high-quality injection molded plastic parts for the automotive industry. Our team of experts ensures that every part meets strict quality standards before it leaves our facility, giving our clients peace of mind and confidence in our products.

Our dedication to quality assurance extends beyond the manufacturing process. We also prioritize ongoing training and development for our team to ensure they are equipped with the latest knowledge and skills in injection molding technology. This commitment to continuous improvement allows us to stay ahead of industry trends and deliver innovative solutions that meet the evolving needs of our automotive clients.

Importance of Quality Assurance in Automotive Parts Manufacturing

In the automotive industry, quality assurance is crucial to ensure the safety and performance of vehicles. Using inferior injection molded plastic parts can lead to malfunctions and potential hazards on the road. That's why manufacturers like Baoyuan place a strong emphasis on maintaining high standards of quality assurance.

To ensure high-quality injection molded auto parts, Baoyuan employs a strict quality control process at every stage of production. From the selection of raw materials to the final inspection of finished parts, every step is carefully monitored to meet industry standards. This meticulous attention to detail helps prevent defects and ensures that each component meets the performance and safety requirements expected in the automotive industry.

How Baoyuan Ensures High-Quality Injection Molded Auto Parts

To ensure that our injection molded plastic auto parts meet the highest standards, we implement rigorous testing procedures at every stage of production. From material selection to final inspection, we employ advanced techniques and equipment to guarantee the durability, precision, and reliability of our products.

Design and Development of Injection Molded Plastic Auto Parts

Baoyuan's expertise in mold design and development is unmatched in the industry. With years of experience, our team of engineers and designers are adept at creating intricate and efficient molds for injection molding automotive parts.

The importance of proper design for injection molded auto parts cannot be overstated. A well-designed mold ensures that the final product meets all quality standards and functions flawlessly within the automobile.

Baoyuan utilizes cutting-edge software for mold design and development, allowing us to create precise and complex molds for injection molding automotive parts with utmost accuracy.

With our expertise in mold design, understanding of proper design principles, and use of advanced software, Baoyuan ensures that the injection molded plastic auto parts we produce are of the highest quality and precision.

Applications of Injection Molded Plastic Parts in Automobiles

Various Auto Parts Produced Through Injection Molding

Injection molding automotive parts are used in a wide range of automobile components, including bumpers, dashboards, interior panels, and even engine components. The versatility of injection molding allows for the production of complex and intricate parts that are essential for modern vehicles.

Injection molding automotive parts are not only essential for the structural integrity of vehicles but also play a significant role in enhancing their aesthetic appeal. From sleek and stylish exterior components to finely detailed interior panels, injection molding allows for the production of parts that meet the high standards of modern automotive design. This process enables manufacturers to create parts with intricate designs and textures, adding a touch of sophistication to the overall look and feel of the vehicle.

Benefits of Using Injection Molded Plastic Auto Parts

The use of injection molded plastic parts in automobiles offers numerous benefits, such as reduced weight, improved fuel efficiency, and enhanced durability. Additionally, these parts can be manufactured at a lower cost compared to traditional metal components without compromising on quality or performance.

Furthermore, injection molded plastic parts offer greater design flexibility, allowing for intricate and complex shapes that may not be achievable with traditional metal components. This opens up new possibilities for innovative and stylish automotive designs, giving manufacturers a competitive edge in the market. The ability to customize the color and finish of plastic parts also adds to the aesthetic appeal of vehicles, attracting consumers who value both form and function in their automotive choices.

Baoyuan's Specialization in Single-color and Double-color Plastic Products

Baoyuan specializes in producing high-quality single-color and double-color plastic injection molded auto parts. Their expertise in creating multi-material components allows for greater design flexibility and aesthetic appeal in automotive applications.

Furthermore, Baoyuan's commitment to quality and precision in their manufacturing process ensures that their single-color and double-color plastic products meet the highest industry standards. This dedication to excellence results in durable and reliable auto parts that enhance the performance and appearance of vehicles. Customers can trust in Baoyuan's expertise to deliver products that not only meet their functional requirements but also exceed their aesthetic expectations.

Conclusion

The future of injection molding in the auto industry looks promising, with the demand for high-quality, durable plastic parts on the rise. Baoyuan's expertise in shaping the automotive industry through innovative injection molding techniques is evident, as they continue to meet the growing demand for injection molded auto parts.

Future of Injection Molding in Auto Industry

As technology advances, the future of injection molding in the auto industry will see even more efficient and sustainable processes. With a focus on eco-friendly materials and streamlined production methods, injection molded plastic parts will continue to play a crucial role in automobile manufacturing. Additionally, advancements in 3D printing technology will further revolutionize the injection molding process, allowing for more intricate and customized designs to be produced with ease. This will open up new possibilities for innovative car designs and enhanced functionality, giving automakers greater flexibility in their manufacturing processes.

Baoyuan's Role in Shaping the Automotive Industry

Baoyuan has been at the forefront of shaping the automotive industry by providing top-notch injection molded plastic auto parts that meet and exceed industry standards. Their commitment to innovation and quality has solidified their position as a key player in revolutionizing how auto parts are manufactured.

Baoyuan's dedication to staying ahead of the curve has led to the development of cutting-edge injection molded auto parts that are not only durable and reliable but also environmentally friendly. By utilizing advanced materials and manufacturing processes, Baoyuan has set a new standard for sustainability in the automotive industry, reducing waste and energy consumption without sacrificing performance. This commitment to eco-friendly practices not only benefits the environment but also positions Baoyuan as a leader in responsible manufacturing.

The Growing Demand for Injection Molded Auto Parts

The growing demand for injection molded auto parts is a testament to their reliability and cost-effectiveness. As more car manufacturers recognize the benefits of using these durable plastic components, Baoyuan's specialization in single-color and double-color plastic products will continue to meet this increasing demand.