Introduction

One innovative approach that has been gaining traction is tunnel gate injection molding, a technique that offers numerous advantages. Baoyuan, with its expertise in tunnel gate design, has been at the forefront of this cutting-edge technology, providing superior solutions for clients in various industries.

Understanding Tunnel Gate Injection Molding

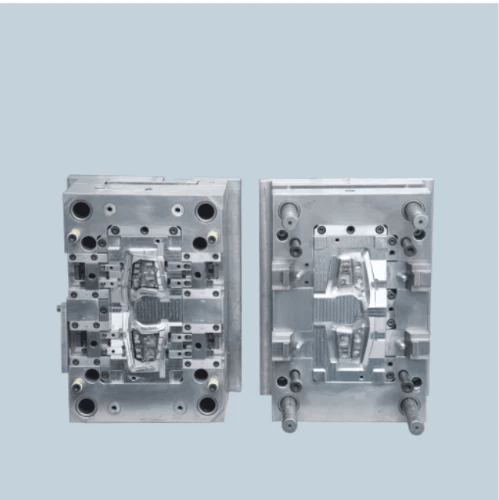

Tunnel gate injection molding involves creating a small tunnel-like channel through which the molten plastic is injected into the mold cavity. This technique allows for precise control over the flow of plastic and minimizes visible gate marks on the final product, resulting in a superior surface finish.

Advantages of Tunnel Gates in Injection Molding

One of the key advantages of tunnel gates is their ability to ensure exceptional surface quality on molded parts. By minimizing visible gates and reducing parting lines, tunnel gates help produce high-quality products with minimal post-processing required.

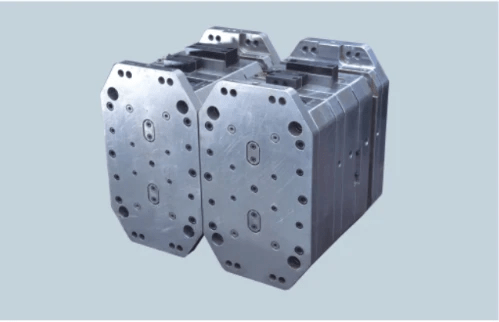

Baoyuan's Expertise in Tunnel Gate Design

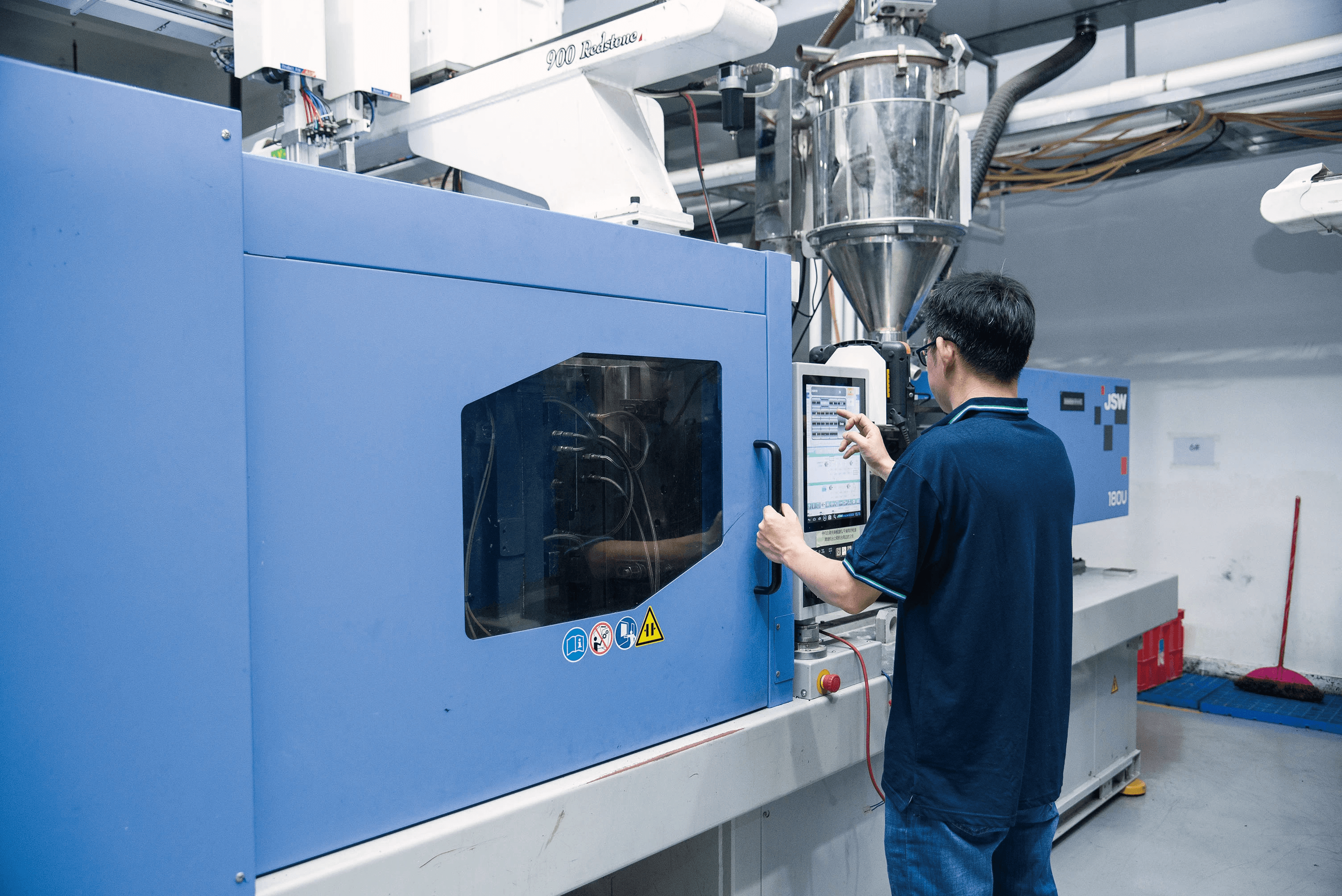

The Baoyuan team boasts senior management and technical personnel who have honed their skills over many years in the industry. Proficient in mold design and injection molding, they leverage advanced software to create innovative tunnel gate designs that optimize product quality and production efficiency.

The Importance of Gate Selection in Injection Molding

When it comes to injection molding, gate selection plays a crucial role in determining the surface quality and overall success of the process. Baoyuan understands the significance of this decision and offers a range of innovative gate options to meet diverse production needs.

Ensuring Surface Quality with Tunnel Gates

Tunnel gate injection molding is a preferred choice for many manufacturers due to its ability to ensure superior surface quality. By utilizing tunnel gates, Baoyuan can effectively minimize visible gate marks on the final product, resulting in a flawless finish that meets high-quality standards.

By incorporating tunnel gates into the injection molding process, Baoyuan can also reduce the need for additional finishing processes, saving time and resources. This innovative approach not only ensures a flawless surface quality but also streamlines production, leading to increased efficiency and cost-effectiveness. As a result, Baoyuan's tunnel gate injection molding stands out as a cutting-edge solution that meets the demands of high-quality manufacturing.

Baoyuan's Innovative Approach to Gate Selection

Baoyuan takes an innovative approach to gate selection by offering various types of gates for injection molding, including submarine gate injection molding, edge gate injection molding, and sprue gate injection-molding. This diverse range allows Baoyuan to cater to specific project requirements and achieve optimal results for clients.

In addition to offering a diverse range of gate options, Baoyuan also provides expert consultation and guidance to help clients determine the most suitable gate type for their specific project needs. This personalized approach ensures that clients are able to make informed decisions that will ultimately lead to the best possible outcomes for their injection molding projects. By taking into account factors such as material type, part design, and production volume, Baoyuan is able to recommend the most effective gate solution for each unique situation.

Types of Gates For Injection Moulding

Exploring Submarine Gate Injection Molding

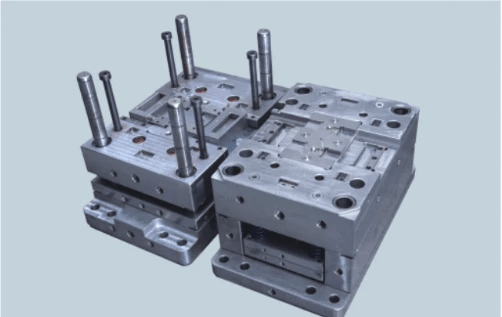

Submarine gate injection molding is a type of gate where the gate is located beneath the surface of the part, allowing for a seamless finish. Baoyuan's expertise in this area ensures that the submarine gate is strategically placed to maintain product integrity and surface quality throughout the injection molding process.

Submarine gate injection molding offers significant advantages in terms of product quality and surface finish. By strategically placing the gate beneath the surface of the part, Baoyuan ensures that the final product maintains its integrity and appearance. This approach also minimizes the need for additional finishing processes, saving time and costs in production. Additionally, the seamless finish achieved with submarine gate injection molding enhances the overall aesthetic appeal of the final product, making it a preferred choice for high-quality manufacturing.

Maximizing Quality with Edge Gate Injection Molding

Edge gate injection molding involves placing the gate at the edge of the part, allowing for easy removal and minimizing any visible marks on the final product. Baoyuan's innovative approach to edge gate selection ensures that product quality is maximized while maintaining an efficient production process.

Edge gate injection molding is a cost-effective method that allows for easy removal of the part from the mold, reducing production time and labor costs. By strategically placing the gate at the edge of the part, Baoyuan ensures that any visible marks on the final product are minimized, resulting in a high-quality finish that meets customer expectations. This innovative approach to edge gate selection not only maximizes product quality but also streamlines the production process, making it an ideal choice for manufacturers looking to optimize their operations.

The Benefits of Sprue Gate Injection-Molding

Sprue gate injection-molding involves a simple and cost-effective method where the plastic material enters through a small opening called a sprue. This method allows for easy control of material flow and minimizes waste. Baoyuan's expertise in sprue gate design ensures efficient production and high-quality plastic products.

Additionally, sprue gate injection-molding allows for easy removal of the finished product, reducing the need for additional finishing processes. This results in faster production times and lower labor costs. Baoyuan's commitment to precision and attention to detail ensures that every product manufactured using sprue gate injection-molding meets the highest standards of quality and consistency.

Advantages of Tunnel Gate Injection Molding

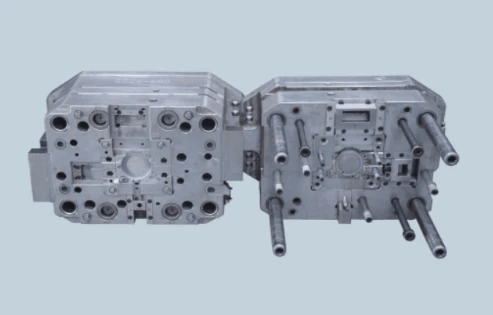

Tunnel gate injection molding offers numerous advantages, including the ability to enhance product quality with fan gate injection molding. This method allows for precise control over the flow of molten plastic, resulting in superior surface finish and reduced waste. Baoyuan's expertise in tunnel gate design ensures that products are consistently produced with high quality and reliability.

Enhancing Product Quality with Fan Gate Injection Molding

Fan gate injection molding is a key advantage of tunnel gates, as it allows for the creation of intricate and detailed parts with minimal visible marks or defects. By utilizing this method, Baoyuan can achieve a high level of precision and consistency in the production of plastic products, ensuring that every item meets strict quality standards. This approach also minimizes material waste, making it a cost-effective solution for manufacturers.

Fan gate injection molding also allows for the production of parts with uniform wall thickness, reducing the risk of warping and distortion. This ensures that the final products not only meet aesthetic standards but also functional requirements. By optimizing the design and manufacturing process, Baoyuan can deliver high-quality plastic products that are durable and reliable, meeting the needs of various industries and applications.

Optimizing Design with Ring Gate Injection Molding

Ring gate injection molding is another innovative technique that Baoyuan leverages to optimize design and improve overall product performance. By using this method, the team can ensure that plastic parts are free from imperfections while maintaining structural integrity and dimensional accuracy. This results in durable and reliable products that meet or exceed customer expectations.

Furthermore, ring gate injection molding allows Baoyuan to achieve a higher level of precision and consistency in the production of plastic parts. This means that each product will have the same high-quality finish, reducing variation and ensuring uniformity across the entire product line. As a result, customers can trust that they are receiving a reliable and consistent product every time they purchase from Baoyuan.

Baoyuan's Success Stories with Tunnel Gates

Baoyuan has a proven track record of success with tunnel gates, showcasing their ability to consistently deliver high-quality plastic products using this advanced injection molding technology. With a team of experienced technical personnel who specialize in mold design and injection molding, Baoyuan has achieved remarkable results for clients across various industries. Their expertise in tunnel gate design has enabled them to produce complex components with exceptional precision and reliability.

By utilizing tunnel gates, they have been able to minimize the appearance of gate marks on the finished products, enhancing the overall aesthetic appeal. This attention to detail and commitment to delivering flawless plastic components sets Baoyuan apart as a leader in the injection molding industry.

With Baoyuan's commitment to excellence and their proficiency in leveraging tunnel gates for superior surface finish, it's clear that they are at the forefront of the future of injection molding technology.

The Key Role of Gate Design in Injection Molding

Tunnel gate injection molding is a critical aspect of the injection molding process, and Baoyuan's expertise in mold design and injection molding sets them apart. With a team of experienced technical personnel, they excel in utilizing software to design molds and ensure top-quality production.

Baoyuan's Expertise in Mold Design and Injection Molding

Baoyuan's senior management and technical personnel have years of industry experience, allowing them to skillfully design molds, handle mold opening, and execute precise injection molding. Their proficiency extends to the production and quality assurance of both single-color and double-color plastic products.

With their expertise in mold design and injection molding, Baoyuan's team is able to consistently achieve quality assurance in plastic product production. Their attention to detail and commitment to precision ensure that every single-color and double-color plastic product meets the highest standards of durability and functionality. This dedication to quality sets Baoyuan apart as a leader in the industry, providing customers with reliable and top-notch plastic products.

Achieving Quality Assurance in Plastic Product Production

Baoyuan's innovative approach to gate selection plays a crucial role. By leveraging tunnel gates for superior surface finish, they ensure that each product meets the highest standards of quality. In addition to gate selection, Baoyuan also emphasizes the importance of experienced technical personnel in their production process. With skilled and knowledgeable staff overseeing every step of the manufacturing process, they are able to identify and address any potential issues before they impact product quality. This commitment to expertise sets them apart in the industry and ensures top-notch results for their clients.

The Importance of Experienced Technical Personnel

Experienced technical personnel are indispensable when it comes to gate design in injection molding. Baoyuan's team possesses the expertise needed to optimize gate selection, ensuring that every product meets or exceeds customer expectations. With their in-depth knowledge of materials and processes, they are able to anticipate potential issues and make necessary adjustments to prevent defects or production delays. Their ability to troubleshoot and problem-solve on the fly is a valuable asset in the fast-paced world of manufacturing.

Experienced technical personnel also play a crucial role in ensuring the overall efficiency and cost-effectiveness of the injection molding process. By leveraging their expertise, Baoyuan's team is able to identify opportunities for streamlining production, reducing waste, and improving cycle times. This not only leads to significant cost savings for the company but also allows for faster turnaround times, ultimately benefiting the customer by delivering high-quality products in a timely manner.

Conclusion

Baoyuan's commitment to quality tunnel gate design is unparalleled in the industry. With a team of experienced technical personnel and innovative software tools, Baoyuan excels in mold design, mold opening, and injection molding. Their expertise in producing single-color and double-color plastic products ensures superior surface finish and product quality.

Leveraging tunnel gates for superior surface finish is a game-changer in injection molding. Baoyuan's innovative approach to gate selection, including submarine gate injection molding, edge gate injection molding, and sprue gate injection-molding, maximizes the quality of plastic products. Their success stories with fan gate injection molding and ring gate injection molding demonstrate their dedication to excellence.

The future of injection molding is bright with Baoyuan's expertise leading the way. By prioritizing quality assurance and leveraging experienced technical personnel, Baoyuan ensures that every plastic product meets the highest standards. Their commitment to innovation and superior surface finish sets them apart as industry leaders.