Introduction

In the realm of manufacturing, understanding injection mold pricing is crucial for businesses aiming to optimize production costs and enhance profitability. The question How much does an injection mold cost? often arises, as it directly impacts project feasibility and budgeting. By delving into the intricacies of injection mold price, we can uncover the essential factors that shape these costs.

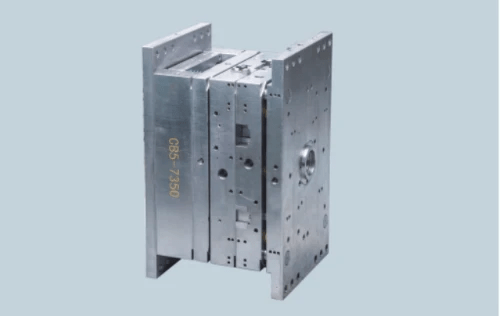

Understanding Injection Mold Pricing

Injection mold pricing isn't just a straightforward number; it's a complex interplay of materials, design specifications, and production quantities. Each element contributes uniquely to the overall cost structure, making it vital for manufacturers to grasp how these components affect their bottom line. As we explore this topic further, we'll answer key questions like How much does injection molding cost per kg? and highlight the significance of precise pricing strategies in achieving competitive advantage.

Factors Influencing Mold Costs

Several factors influence mold costs, including material selection, design complexity, and anticipated production volume. For instance, premium materials can elevate the injection mold price significantly while intricate designs may require more sophisticated manufacturing techniques. Additionally, understanding how production volume correlates with costs will help businesses make informed decisions when planning their budgets.

The Importance of Accurate Cost Estimation

Accurate cost estimation is paramount in ensuring that projects remain financially viable and profitable over time. Miscalculating expenses can lead to budget overruns or missed opportunities; therefore, knowing how to calculate injection mold cost? becomes essential for any manufacturer looking to thrive in today's competitive market. By honing in on reliable estimation methods and tools, companies can effectively manage risks associated with their molding projects.

Key Components of Injection Mold Price

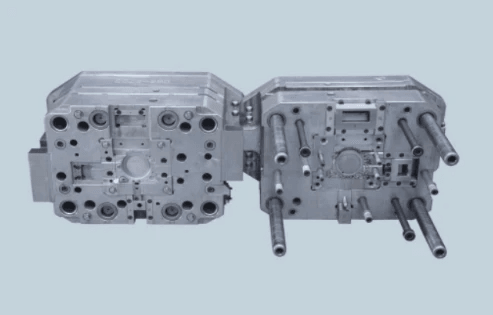

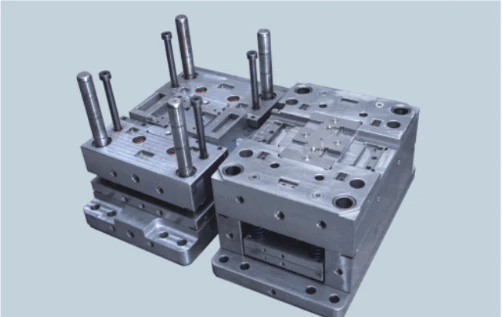

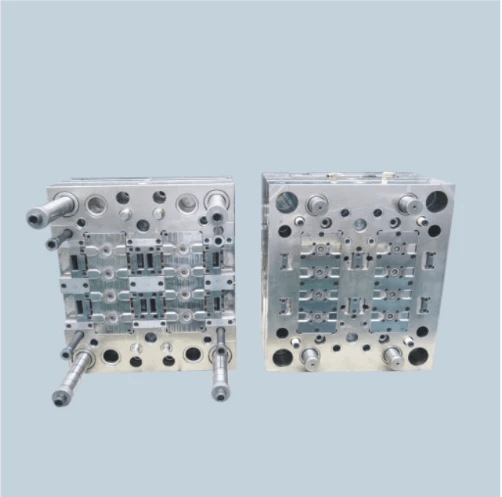

When it comes to understanding injection mold pricing, several key components come into play. These elements can significantly influence the final cost, making it essential for manufacturers and buyers alike to grasp their implications. By examining material selection, design complexity, and production volume correlation, you can better navigate the question: How much does an injection mold cost?

Material Selection's Impact

The choice of materials is a crucial factor in determining injection mold price. Different materials not only vary in cost but also affect the durability and functionality of the molded parts. For instance, using high-performance thermoplastics may increase initial costs but can lead to savings in long-term production due to reduced wear and tear—an important consideration when asking how much does injection molding cost per kg?

Additionally, material selection impacts processing conditions and cycle times during manufacturing—factors that ultimately contribute to overall expenses. If you’re wondering how to estimate injection molding cost accurately, remember that premium materials often require specialized equipment or techniques that can further elevate costs. Thus, selecting the right material is not just about immediate pricing; it’s about balancing performance with long-term value.

Complexity of Design Considerations

Design complexity plays a significant role in shaping injection mold price as well. Intricate designs often necessitate more sophisticated molds which demand higher precision during fabrication—this translates directly into increased costs. When evaluating how much does an injection mold cost?, consider that complex geometries may require additional features like undercuts or multi-cavity configurations that complicate the manufacturing process.

Moreover, design considerations extend beyond aesthetics; they impact functionality too. Designs that are easier to manufacture typically result in lower production costs and quicker turnaround times—key factors for businesses looking at profitability metrics like how profitable is injection molding? Therefore, investing time upfront in optimizing designs can yield substantial savings down the line.

Production Volume and Cost Correlation

The relationship between production volume and injection mold price cannot be overstated; it’s a classic case of “the more you make, the less each one costs.” High-volume production spreads fixed costs over many units, resulting in lower per-unit prices—a critical aspect when analyzing how much does injection molding cost per kg? Conversely, low-volume runs may incur higher average costs due to setup expenses being amortized over fewer pieces.

Furthermore, understanding this correlation helps manufacturers strategize their operations effectively. For those wondering how to calculate injection mold cost accurately, factoring in expected production volumes provides a clearer picture of potential financial outcomes. Ultimately, aligning your production strategy with market demand will enhance profitability while keeping an eye on overall expenses related to mold creation.

How Much Does an Injection Mold Cost?

When it comes to understanding the injection mold price, many factors play a role in determining how much you will ultimately pay. The cost of an injection mold can vary significantly based on design complexity, material selection, and production volume. So, how much does an injection mold cost? Let's delve into the details.

Typical Price Ranges Explained

Typical price ranges for injection molds can vary widely, often falling between $1,000 to $100,000 or even more for highly specialized molds. The lower end usually applies to simple designs made from less expensive materials and intended for low-volume production runs. On the other hand, intricate designs or molds made from high-quality steel for mass production can command prices that reach into six figures.

To get a clearer picture of how to estimate injection molding cost effectively, consider that the average price for a medium-complexity mold might hover around $10,000 to $30,000. This range reflects not just the physical materials but also labor costs and overhead associated with creating a functional mold that meets industry standards. Understanding these typical price ranges sets a solid foundation for anyone looking into how much does an injection mold cost?

Cost Variation by Industry

Cost variation by industry is another crucial factor influencing the overall injection mold price. Industries such as automotive or medical devices often require more stringent quality controls and higher precision in their molds than consumer goods or packaging sectors do. Consequently, this demand results in higher costs due to specialized materials and advanced manufacturing techniques employed.

For example, while a basic consumer product might see an injection molding cost per kg at around $2-$5 depending on material choice and volume, automotive components could easily push that figure up to $10-$20 per kg due to additional safety features and regulatory compliance requirements. This disparity highlights why understanding how profitable is injection molding can vary dramatically across different sectors and applications.

Examples from Real-World Projects

Real-world projects provide valuable insights into how much does an injection mold cost in practical scenarios. For instance, one company specializing in consumer electronics reported spending approximately $15,000 on a multi-cavity mold designed to produce smartphone cases at high volumes—showing just how quickly costs can escalate with added complexity.

In contrast, another case involved producing simple plastic toys where the entire project was completed with a single-cavity mold costing around $3,500—demonstrating that not all projects require deep pockets for successful implementation. These examples underline why it’s essential for businesses to know not only how to calculate injection mold cost but also what factors contribute most significantly based on their specific needs.

How Much Does Injection Molding Cost Per Kg?

When considering how much injection molding costs per kg, it’s essential to break down the various components that contribute to the overall price. The injection mold price can vary significantly based on material selection, labor input, and overhead costs associated with production. Understanding these elements will help you navigate the often complicated landscape of manufacturing expenses.

Analyzing Material Costs

Material costs are a significant factor in determining how much does an injection mold cost? Different types of polymers and resins can dramatically affect the overall cost per kilogram of molded products. For instance, high-performance materials may offer superior properties but come with a higher price tag compared to standard plastics; therefore, selecting the right material is crucial for balancing quality and budget.

Additionally, fluctuations in raw material prices can impact your project’s bottom line. If you're looking to estimate injection molding cost accurately, keeping an eye on market trends for materials is vital. Remember that sustainable options may also be available at competitive prices, so it's worth exploring eco-friendly alternatives as part of your material analysis.

Labor and Overhead Contributions

Labor and overhead are often overlooked when calculating how much does injection molding cost per kg; however, they play a critical role in shaping the final price. Labor costs include not only wages for workers directly involved in production but also expenses related to training and management oversight. Overhead encompasses everything from facility maintenance to utilities, which can add up quickly if not accounted for properly.

To get a clearer picture of how to calculate injection mold cost effectively, consider both direct labor hours and indirect overhead expenses associated with your specific project requirements. An efficient production process can help mitigate these costs; thus investing in automation or skilled labor could yield long-term savings that enhance profitability over time. Ultimately, understanding labor dynamics is key when evaluating overall manufacturing expenses.

Profit Margins in Manufacturing

When assessing how profitable is injection molding?, profit margins should be carefully calculated by considering all associated costs outlined above—material costs, labor inputs, and overhead contributions included. A healthy profit margin typically ranges from 20% to 50%, depending on various factors such as industry standards and competition levels within your niche market. This margin ensures that your business remains sustainable while allowing room for reinvestment into technology or workforce development.

Moreover, keeping track of operational efficiency can further enhance your profit margins by reducing waste during production processes or optimizing supply chain logistics. By focusing on improving quality control measures alongside effective pricing strategies based on accurate estimations of injection mold prices per kg—and knowing how much does an injection mold cost—you create a robust framework for financial success in this competitive field.

In conclusion, understanding the intricacies behind how much injection molding costs per kg is essential for any manufacturer aiming for success in this sector. By analyzing material costs thoroughly while factoring in labor contributions and profit margins diligently—alongside knowing how to estimate injection molding cost accurately—you set yourself up for not just survival but thriving within the marketplace.

How to Calculate Injection Mold Cost?

Calculating the cost of an injection mold can seem like a daunting task, but breaking it down into manageable steps makes it much easier. Understanding how to calculate injection mold cost is essential for manufacturers and businesses looking to budget effectively for their projects. With accurate estimates, you can avoid unpleasant surprises and ensure your production runs smoothly.

Step-by-Step Calculation Guide

To start with, determining the injection mold price involves several key factors. First, assess the complexity of the design; more intricate molds require more time and resources to produce, which significantly affects costs. Next, consider material selection—different materials come with varying price tags that directly impact how much does an injection mold cost?

Once you have these basics down, factor in production volume; higher volumes generally lead to lower per-unit costs due to economies of scale. Don’t forget labor costs—skilled workers may be necessary for intricate designs or quality assurance processes. Finally, add in overhead costs such as equipment maintenance and facility expenses for a comprehensive view of your total investment.

Tools and Software Recommendations

In today's digital age, various tools and software can simplify the process of estimating injection molding costs. Programs like SolidWorks or Autodesk can help visualize designs while providing insights into material requirements and potential manufacturing issues that might affect the final price tag. Additionally, specialized costing software such as Costimator or Moldex3D can offer detailed breakdowns tailored specifically for calculating injection mold prices.

Using these tools not only speeds up the estimation process but also helps you make informed decisions about design modifications that could save money without sacrificing quality or functionality. Many of these programs even include features that allow users to simulate production scenarios—this is invaluable when trying to determine how profitable is injection molding over different runs.

Common Mistakes to Avoid

When calculating how much does injection molding cost per kg or overall project expenses, several common pitfalls can skew your estimates dramatically. One frequent error is underestimating material waste; during production runs, some materials inevitably go unused due to sprue systems or defective parts—failing to account for this can inflate your perceived profitability later on.

Another mistake involves neglecting tooling maintenance costs; molds wear out over time and require replacement or refurbishment which adds hidden expenses not initially considered in your calculations on how profitable is injection molding? Lastly, always double-check your labor estimates; assuming all workers are equally skilled may lead you astray when budgeting for complex projects requiring specialized expertise.

How Profitable Is Injection Molding?

Injection molding can be a lucrative venture, but its profitability hinges on several factors. Understanding how to assess the return on investment (ROI) is crucial for manufacturers looking to thrive in this competitive landscape. By analyzing costs associated with injection molds and production processes, businesses can determine if their strategies are financially sound.

Assessing Return on Investment

To gauge the profitability of injection molding, one must first understand how much an injection mold costs and what it takes to maintain it. The ROI can be calculated by comparing the total revenue generated from molded products against the total costs incurred, including initial mold price and ongoing production expenses. This calculation will reveal whether your investment is yielding satisfactory returns or if adjustments are needed.

Additionally, when considering how much does injection molding cost per kg, it's important to factor in material quality and production efficiency. Higher-quality materials might push up initial costs but can lead to better product performance and customer satisfaction in the long run. A well-executed ROI analysis helps businesses make informed decisions about scaling operations or exploring new markets.

Case Studies of Successful Projects

Examining real-world examples provides valuable insights into how profitable injection molding can be when done right. For instance, a company that specialized in automotive parts invested in high-precision molds which initially seemed expensive; however, they quickly recouped their investment due to increased demand for their durable products. This scenario illustrates that understanding how to calculate injection mold cost accurately can lead to significant long-term profits.

Another case involved a startup that focused on consumer electronics accessories; they utilized advanced technologies like 3D printing for prototype development before committing to full-scale production with traditional molds. By carefully estimating injection molding cost at each stage of development, they minimized waste and maximized efficiency—ultimately leading them toward profitability faster than anticipated.

These examples underscore the importance of strategic planning and accurate cost estimation when venturing into injection molding projects.

Market Trends Impacting Profitability

The landscape of manufacturing is ever-evolving, with market trends significantly influencing injection mold pricing and overall profitability. As industries shift towards sustainability, eco-friendly materials are becoming more popular—often altering the typical price ranges associated with both molds and finished products. Companies that adapt quickly by incorporating these trends may find themselves at an advantage over competitors who cling to outdated methods.

Moreover, advancements in technology continue to reshape how much does an injection mold cost? Innovations like automation and improved design software enable manufacturers to produce more complex designs efficiently while reducing labor costs—a key component of overall expenses in this field. Staying informed about these trends not only helps businesses remain competitive but also allows them to forecast potential shifts in profit margins effectively.

Understanding these market dynamics is essential for anyone interested in evaluating the profitability of their injection molding endeavors.

Conclusion

Navigating the world of injection molding can seem daunting, especially when it comes to understanding injection mold price and how it affects your overall production costs. However, by employing a few strategic approaches, you can significantly reduce expenses while maintaining quality. Whether you're asking yourself, How much does an injection mold cost? or How to estimate injection molding cost? the right strategies can lead to substantial savings.

Strategies for Cost-Effective Molding

To achieve cost-effective molding, start by selecting materials wisely; some materials are more affordable than others and can still meet your design specifications. Additionally, simplifying your design can lower complexity-related costs—remember that intricate designs often require more expensive molds. Finally, consider optimizing production volume; larger runs typically reduce the per-unit cost of injection molding and improve profitability.

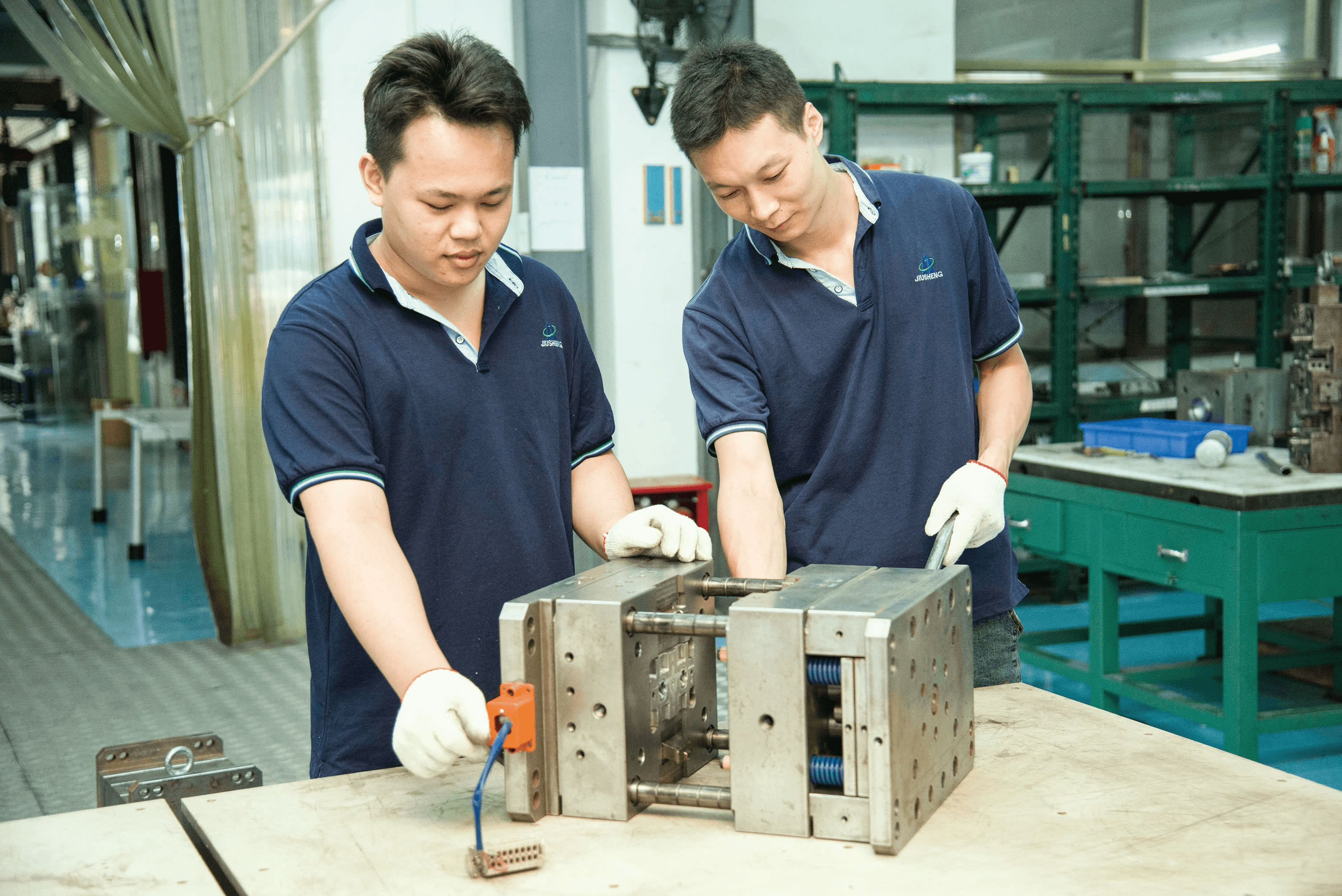

The Role of Experts Like Baoyuan

Engaging with industry experts like Baoyuan can be invaluable in navigating the complexities of injection mold pricing and understanding how much does an injection mold cost? Their experience allows them to provide tailored recommendations that align with your specific needs and budget constraints. Moreover, they can guide you through the intricacies of calculating injection mold costs accurately, ensuring you avoid common pitfalls that could inflate overall expenses.

Future Trends in Injection Mold Pricing

As technology continues to evolve, so too will the landscape of injection molding costs. We're likely to see advancements in automation and material science that could lead to reduced labor costs and enhanced material performance—both critical factors when considering how much does injection molding cost per kg? Additionally, sustainability trends may influence pricing structures as manufacturers seek eco-friendly materials without sacrificing profitability; thus understanding how profitable is injection molding will become increasingly important for future investments.