Introduction

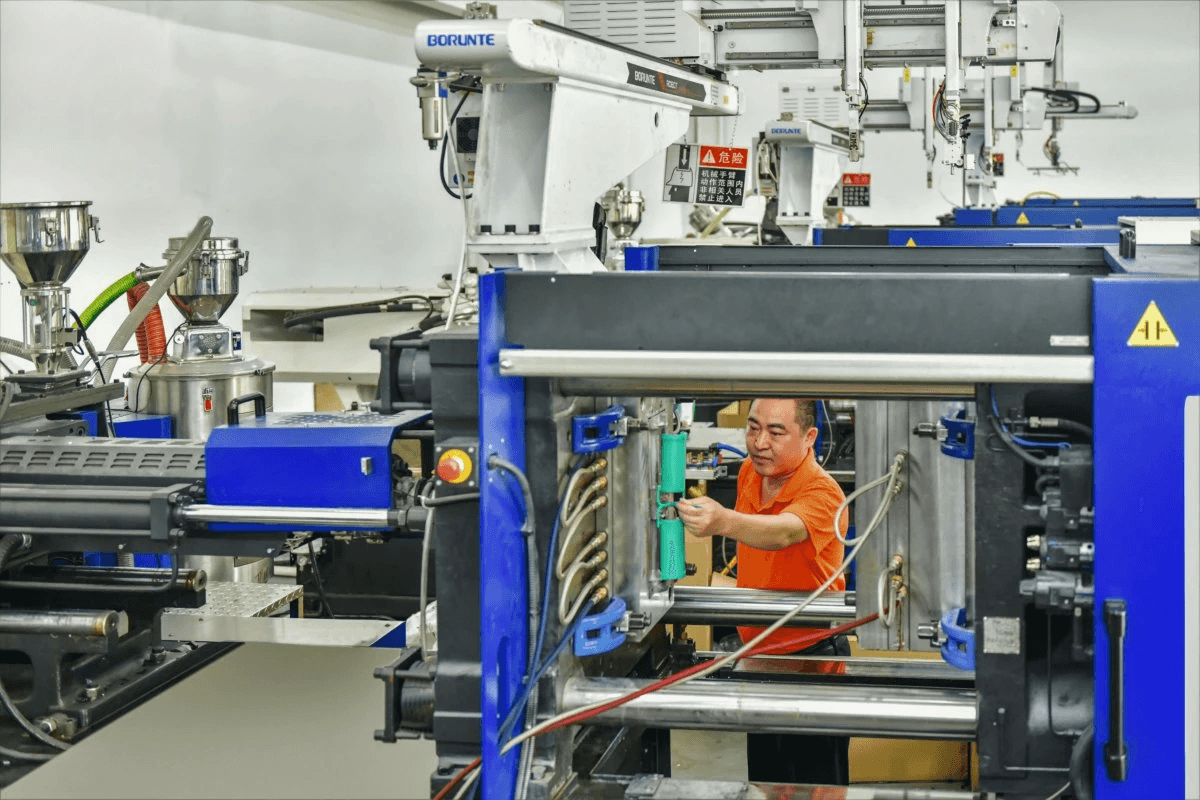

When diving into the world of manufacturing, one of the most pivotal processes is injection moulding. Understanding injection moulding costs can be a game-changer for businesses looking to optimize their production budgets. With various factors influencing expenses, having a grasp of what drives these costs is essential for making informed decisions.

Understanding Injection Moulding Costs

At its core, understanding injection moulding costs involves dissecting several elements that contribute to the overall expenditure. For instance, many ask, What is the average cost of an injection mold? This question often leads to further inquiries such as How much does it cost to make injection mould? and How much does injection molding cost per kg? Each of these questions highlights different aspects of the financial landscape in which manufacturers operate.

Factors Influencing Injection Moulding Expenses

Several factors significantly impact injection moulding expenses, ranging from material selection to production volume. The choice of raw materials can dramatically alter both quality and price; thus, careful consideration is necessary when choosing materials for your project. Additionally, understanding how complexity in design affects costs can help streamline your budget and expectations.

Importance of Accurate Cost Estimates

Accurate cost estimates are crucial when planning any manufacturing project involving injection moulding. Knowing how to calculate injection mold cost effectively allows businesses to avoid unexpected financial pitfalls down the line. Utilizing tools like an injection mould cost calculator or a cost for injection molding calculator can provide clarity and precision in budgeting efforts.

Overview of Injection Moulding Pricing

When diving into the world of injection moulding, understanding pricing is crucial for budgeting your project effectively. The cost for injection molding can vary widely based on several factors, including mold complexity and material choice. In this section, we will break down the average costs associated with injection molds and what you can expect when planning your production.

What is the average cost of an injection mold?

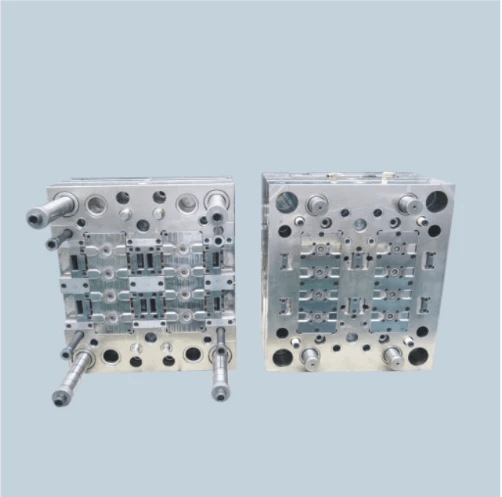

The average cost of an injection mold typically ranges from $1,000 to $100,000 or more, depending on various factors like size and complexity. For simpler designs and smaller molds, you might find costs closer to the lower end of that spectrum. However, intricate molds designed for high precision can push costs significantly higher; hence understanding what is the average cost of an injection mold is essential for accurate budgeting.

How much does it cost to make injection mould?

When considering how much it costs to make an injection mould, it's important to factor in not just the initial price but also ongoing expenses such as maintenance and modifications over time. The upfront investment in a quality mold can be substantial but often pays off with efficient production runs. So when asking how much does it cost to make injection mould?, remember that this figure encompasses both creation and longevity in production.

Analyzing the cost for injection molding per kg

Analyzing how much does injection molding cost per kg reveals another layer of complexity within pricing structures. Generally speaking, production costs can range from $2 to $20 per kilogram based on material type and design intricacies involved in manufacturing each part. Utilizing tools like an Injection mould cost calculator or a Cost for injection molding calculator can help streamline this analysis by providing tailored estimates that reflect specific project requirements.

Key Factors Affecting Costs

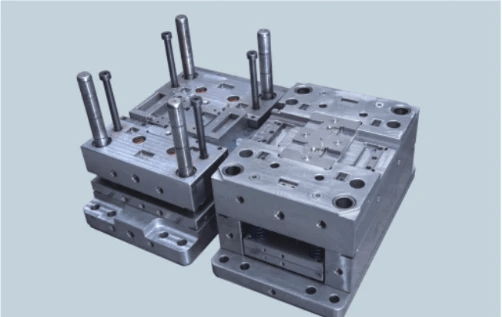

Material Selection and Its Impact

Material selection is one of the most critical aspects affecting the cost for injection molding. The type of plastic used can vary widely in price; for instance, engineering plastics tend to be more expensive than standard thermoplastics. Additionally, certain materials may require specialized processing or tooling that can further raise costs—so when asking yourself, How much does it cost to make injection mould? remember that your choice of material plays a pivotal role.

Different materials also have varying characteristics such as strength, flexibility, and temperature resistance which can affect not just the initial cost but also long-term performance and durability. These factors lead to questions like “How much does injection molding cost per kg?” as heavier or denser materials will naturally increase your overall expenditure. Therefore, using an injection mould cost calculator can help you evaluate how different materials will impact your budget.

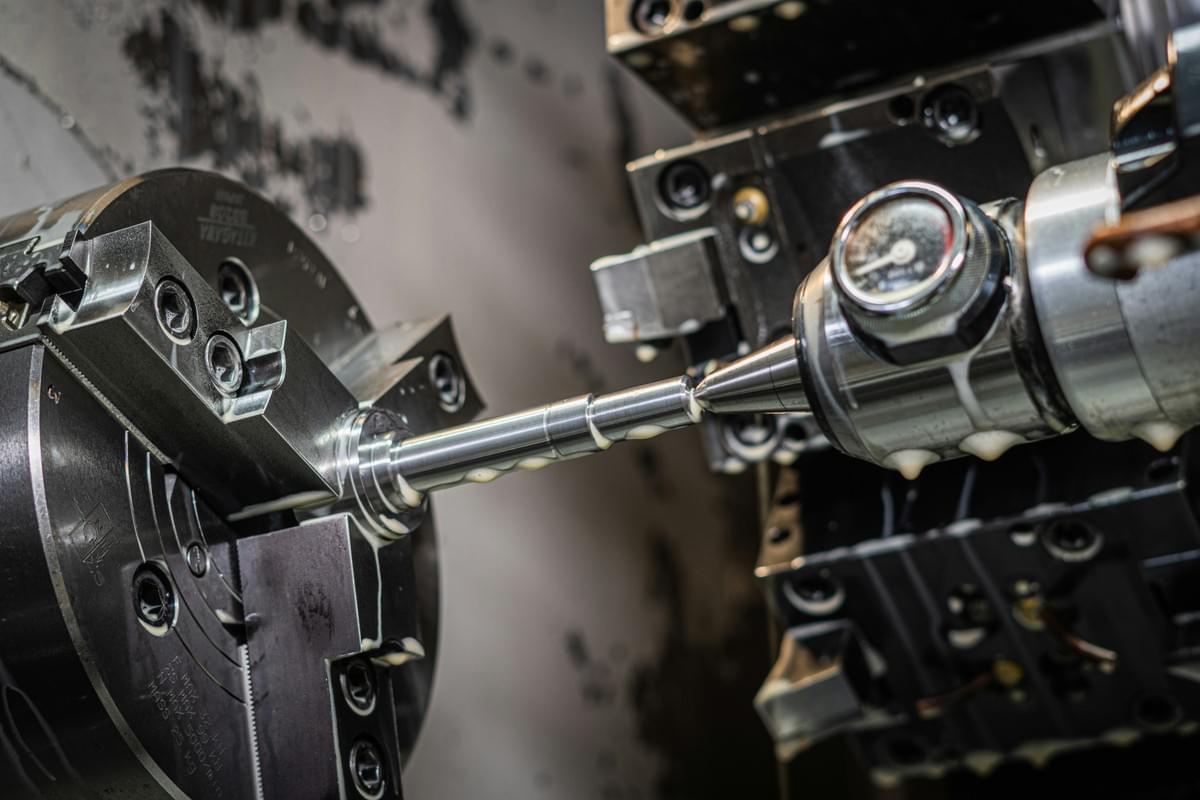

Complexity of the Design and Its Role

The complexity of your design is another crucial factor that directly impacts costs in injection molding projects. Intricate designs often necessitate more advanced molds which are not only pricier but also take longer to produce—leading to higher labor costs overall. So when pondering What is the average cost of an injection mold?, keep in mind that simpler designs typically yield lower costs due to reduced machining time and fewer technical challenges.

Moreover, complex geometries may require additional features such as undercuts or inserts that complicate both mold design and manufacturing processes. This complexity can lead you down a rabbit hole of increased expenses if not properly managed from the outset. To navigate this effectively, consider using a cost for injection molding calculator early in your project planning phase; it allows you to see how changes in design complexity could affect your bottom line.

Production Volume: Small Batch vs. Mass Production

Production volume is yet another critical element influencing the overall costs associated with injection molding projects. Producing small batches often incurs higher per-unit costs because fixed expenses like tooling are spread over fewer items—resulting in less economical pricing compared to mass production runs where these same costs are diluted across thousands of units produced at once. When evaluating “How much does it cost to make an injection mould?”, remember that larger volumes typically lead to lower per-unit prices due to economies of scale.

However, while mass production decreases unit costs significantly, it requires a substantial upfront investment in molds and machinery capable of handling large outputs efficiently—making careful budgeting essential before jumping into high-volume production scenarios! Utilizing an Injection mould cost calculator can help clarify potential savings by allowing you to input various production volumes into your calculations easily.

In summary, understanding these key factors affecting costs will empower you with better insights into managing your budget effectively throughout each stage of the injection molding process.

Using Cost for Injection Molding Calculator

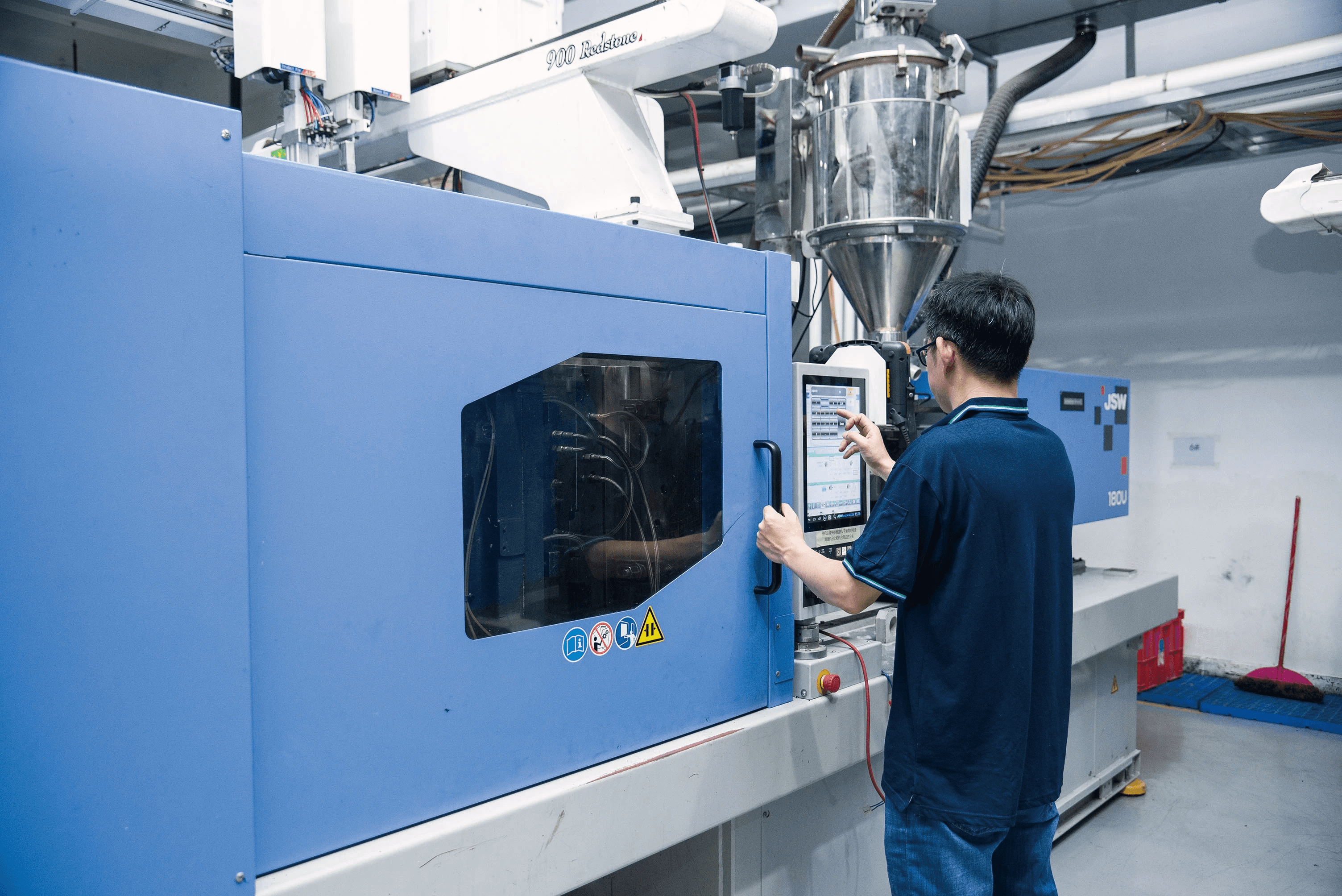

Calculating the cost for injection molding can seem like trying to decipher a secret code, but with the right tools and knowledge, it becomes much simpler. A cost for injection molding calculator is designed to break down various elements that contribute to overall expenses, allowing you to make informed decisions. Understanding how to leverage these calculators can save you time and money in your injection molding projects.

How to calculate injection mold cost?

To calculate injection mold cost effectively, one must consider several key factors including material costs, labor, overhead, and machine time. The question What is the average cost of an injection mold? often pops up; on average, it can range from a few thousand dollars to tens of thousands depending on complexity and size. Additionally, understanding How much does it cost to make injection mould? involves not just the initial mold creation but also ongoing production costs which are influenced by design intricacies and material choices.

Utilizing online tools for accurate estimates

In today's digital age, utilizing online tools such as an injection mould cost calculator can be a game changer for manufacturers and designers alike. These calculators allow users to input specific parameters regarding their project—like material type and part dimensions—to receive tailored estimates on costs. By answering questions like How much does injection molding cost per kg? these online calculators streamline the process of gathering accurate financial projections.

Benefits of a cost for injection molding calculator

The benefits of using a cost for injection molding calculator extend beyond mere convenience; they provide clarity in budgeting and project planning. With precise calculations at your fingertips, you can avoid common pitfalls associated with hidden fees or unexpected expenses that might arise during production. Ultimately, having access to reliable data empowers businesses to make strategic decisions that align with their financial goals while ensuring quality output.

Real-World Examples of Injection Moulding Costs

When it comes to understanding the intricacies of costs for injection molding, real-world examples can provide invaluable insights. By examining case studies and comparing costs across various industries, we can grasp the nuances that influence pricing. This section will highlight Baoyuan's cost assessments, delve into industry comparisons, and draw lessons from successful injection molding projects.

Case study: Baoyuan's cost assessments

Baoyuan, a leading player in the injection molding sector, offers a comprehensive case study showcasing their cost assessments. They meticulously analyzed what is the average cost of an injection mold for different applications, revealing that prices can vary significantly based on complexity and material choice. Their findings indicate that understanding how much does it cost to make injection mould is crucial for businesses looking to optimize their budgets.

In their evaluations, Baoyuan utilized an injection mould cost calculator to streamline their estimates. This tool allowed them to factor in variables like production volume and design intricacies effectively. By sharing these insights, they not only demystified how much does injection molding cost per kg but also provided a framework for other companies aiming to navigate similar challenges.

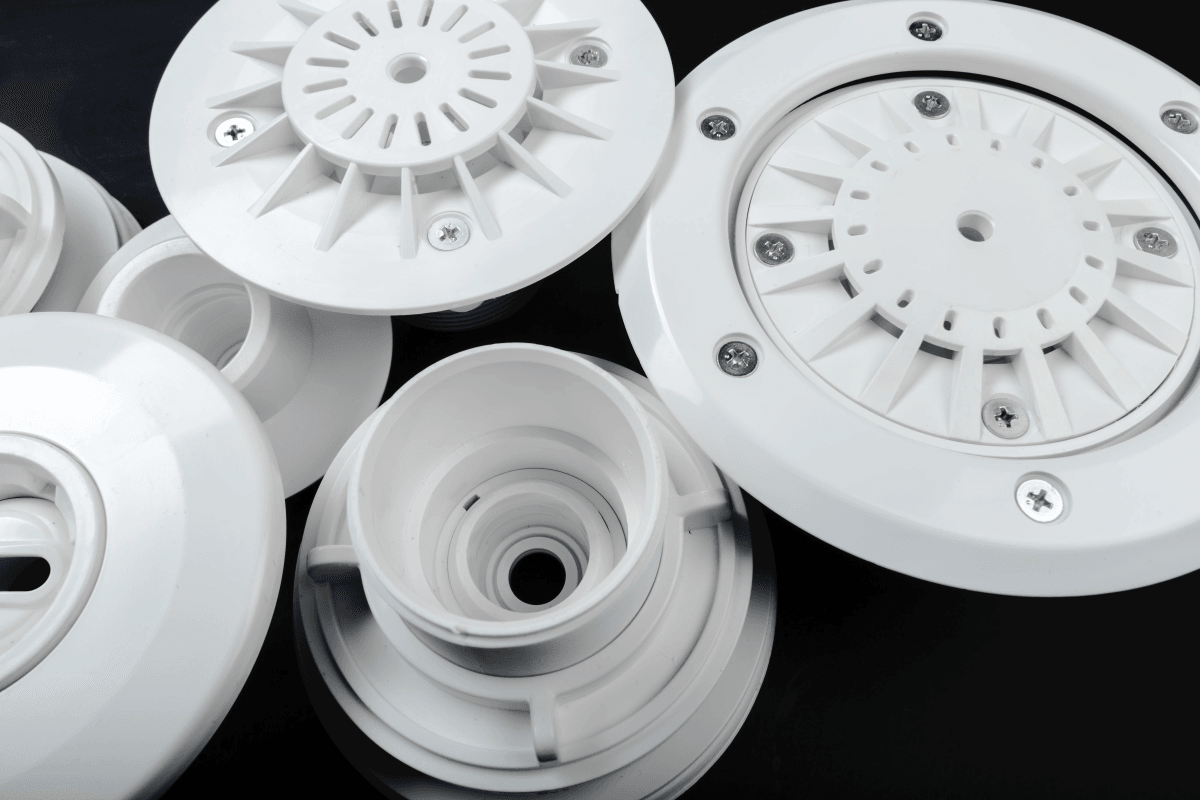

Comparing costs across different industries

The landscape of injection molding costs varies dramatically across different sectors—from automotive to consumer goods—each with its unique financial implications. For instance, in the automotive industry, high-volume production often leads to reduced per-unit costs due to economies of scale; however, initial mold creation expenses can be steep. Conversely, smaller industries may struggle with higher per-unit costs but benefit from lower upfront investments in molds.

By analyzing these trends and asking how to calculate injection mold cost accurately within each context, businesses can tailor their strategies accordingly. The differences highlight the importance of using a cost for injection molding calculator specifically designed for each industry’s needs. Understanding these variations empowers companies to make informed decisions that align with their financial goals.

Lessons learned from successful injection moulding projects

Successful projects often reveal critical lessons about managing costs effectively in the realm of injection molding. One key takeaway is that early engagement with suppliers can lead to better estimates regarding how much does it cost to make an injection mould or even how much does injection molding cost per kg overall. Establishing clear communication channels fosters collaboration and helps identify potential hidden costs before they become problematic.

Additionally, leveraging tools like an injection mould cost calculator allows teams to simulate various scenarios and assess financial implications quickly—an invaluable resource during project planning stages. Ultimately, understanding common pitfalls and best practices derived from past experiences enhances future project outcomes while ensuring accurate budgeting remains a priority throughout the process.

Common Misconceptions About Moulding Costs

Injection moulding is often misunderstood, particularly when it comes to costs. Many assume that the process is inherently cheap, leading to unrealistic expectations about pricing. In reality, understanding the true cost for injection molding requires a deeper dive into various influencing factors beyond just the initial price tag.

Myths about the affordability of injection moulding

One common myth is that injection moulding is always an affordable manufacturing solution. While it can be cost-effective for large production runs, the initial investment in molds can be significant; typically, what is the average cost of an injection mold? This upfront expense can deter small businesses or startups from utilizing this method without fully grasping its long-term benefits.

Another misconception revolves around how much does it cost to make injection mould? Many people think that once you have your mold, production will be inexpensive. However, factors like material choice and design intricacy can dramatically affect overall expenses. Understanding these nuances helps dispel myths surrounding affordability in this manufacturing process.

Understanding hidden costs in the process

Hidden costs are another factor that complicates perceptions of injection molding expenses. For instance, while calculating how much does injection molding cost per kg might give you a ballpark figure, additional elements like maintenance fees for machinery and labor costs are often overlooked. These hidden expenses can add up quickly and significantly impact your budget if not accounted for from the start.

Furthermore, using an injection mould cost calculator may provide an estimate but does not always encompass all variables involved in production. Factors such as setup time and post-production processes—like finishing or quality checks—can contribute to unexpected costs that catch many off guard later on. By understanding these hidden costs upfront, businesses can better prepare their budgets and avoid financial pitfalls.

Dispelling the notion of cheap injection moulding

The idea that cheap injection moulding exists is a dangerous misconception that could lead companies astray. While it's possible to find lower-cost options overseas or with less experienced manufacturers, this often sacrifices quality and reliability—a gamble few should take when considering long-term production needs. Instead of searching for cheap, focus on value; investing appropriately in quality molds ensures durability and efficiency over time.

Moreover, many people wonder how to calculate injection mold cost accurately without falling prey to misleading quotes from suppliers eager to win business at any price point. Utilizing tools like a cost for injection molding calculator can help clarify expenses by providing detailed breakdowns based on specific project requirements rather than vague estimates alone. This approach leads to more informed decision-making regarding budget allocation and project planning.

Conclusion

In the world of manufacturing, understanding the intricacies of injection molding costs is paramount for success. From the average cost of an injection mold to how much it costs to make injection moulds, every detail matters when budgeting your project. Furthermore, knowing how much does injection molding cost per kg can significantly influence your decision-making process and overall financial planning.

Recap of Key Cost Factors in Moulding

Several key factors play a crucial role in determining the overall cost for injection molding. Material selection is vital; different materials come with varying price tags that can impact your budget significantly. Additionally, the complexity of your design and whether you're opting for small batch or mass production will further dictate how to calculate injection mold cost effectively.

The Importance of Getting Accurate Quotes

Obtaining accurate quotes is essential for avoiding unexpected expenses down the road. Utilizing an injection mould cost calculator can provide you with a clearer picture based on your specific requirements and help ensure that you aren't left with hidden costs lurking in the shadows. Remember, accurate estimates allow you to plan better and allocate resources wisely, making it easier to stick to your budget.

Next Steps for Budgeting Your Injection Project

Now that you've grasped the importance of understanding costs associated with injection molding, it's time to take actionable steps towards budgeting your project effectively. Start by gathering multiple quotes from suppliers and using a cost for injection molding calculator to compare options thoroughly. Finally, consider consulting industry experts or case studies like Baoyuan's assessments to learn from real-world experiences before diving into production.