Introduction

Injection molding is a popular manufacturing process that has captured the attention of many industries, but one question often looms large: how expensive is injection molding? Understanding the costs associated with this method is crucial for businesses looking to optimize their production processes and budget effectively. In this guide, we will explore the key factors influencing pricing, address common misconceptions about costs, and provide insights into making informed decisions regarding injection molding.

Understanding Injection Molding Costs

When considering how much it costs to set up injection molding, it's essential to look beyond just the initial investment. The total cost encompasses various elements including material selection, mold design, and production volume—each contributing to the overall expense. Additionally, understanding what goes into these costs can help businesses better prepare for their financial commitments.

Key Factors Influencing Pricing

Are injection molds expensive? The answer depends on several factors such as complexity of design, material types, and production scale. For instance, intricate designs may require more advanced tooling which can drive up costs significantly. Moreover, fluctuations in raw material prices can also impact overall expenses—making it vital for manufacturers to stay informed about market trends.

Common Misconceptions About Costs

Many people wonder if injection molding is a cheap process compared to alternatives like machining. However, this perception often overlooks important aspects like economies of scale that come into play during mass production runs. A common misconception is that high upfront costs mean long-term losses; in reality, efficient injection molding can lead to significant savings over time when properly managed.

The Basics of Injection Molding

Injection molding is a fascinating process that has revolutionized manufacturing across various industries. Understanding how this technique works is crucial for anyone considering its implementation, especially when pondering questions like how expensive is injection molding? and are injection molds expensive? Let's dive into the basics.

Definition and Process Overview

At its core, injection molding is a manufacturing process where molten material, typically plastic, is injected into a mold to create specific shapes and designs. This method involves heating the raw material until it becomes pliable and then forcing it into a precisely engineered mold cavity under high pressure. Once cooled, the material solidifies, resulting in a finished product that can be easily ejected from the mold.

The efficiency of this process makes it popular for mass production, allowing manufacturers to produce thousands of identical parts quickly. However, many potential users often wonder how much it costs to set up injection molding and whether it's worth the investment in the long run. By understanding the intricacies of this procedure, businesses can better evaluate their options and make informed decisions.

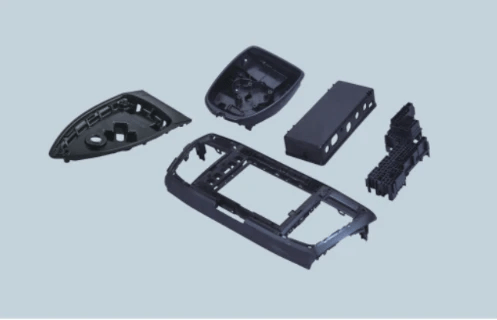

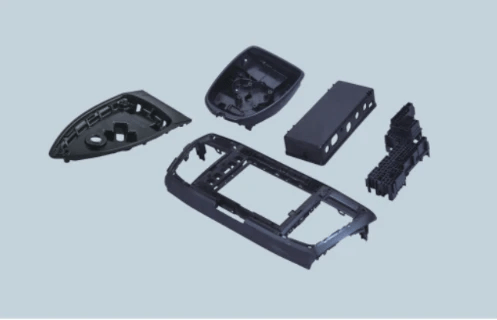

Common Applications in Various Industries

Injection molding finds applications in numerous industries due to its versatility and efficiency. From automotive components like dashboard panels to consumer goods such as toys and household items, almost every sector utilizes this technology for producing high-quality products at scale. Moreover, medical devices are increasingly made using injection molding techniques due to stringent quality requirements.

The ability to create complex geometries while maintaining tight tolerances makes injection molding an attractive option for manufacturers looking to innovate without breaking the bank. When evaluating if is injection molding a cheap process? one must consider not only initial costs but also long-term benefits across various applications. The widespread use of this method highlights its importance in modern manufacturing practices.

Comparison to Other Manufacturing Processes

When comparing injection molding with other manufacturing processes such as machining or 3D printing, several factors come into play regarding cost-effectiveness and suitability for different projects. Machining typically involves removing material from a solid block to achieve desired shapes; thus, it's often more labor-intensive and time-consuming than injection molding processes. Consequently, people frequently ask: is injection molding cheaper than machining?

In terms of setup costs—how much does it cost to set up injection molding?—initial investments are generally higher due to mold creation; however, once established for mass production runs, per-unit costs tend to decrease significantly compared with machining methods over time. Additionally, tools like an injection molding cost estimator can provide valuable insights into potential expenses associated with either approach based on project specifications.

Are Injection Molds Expensive?

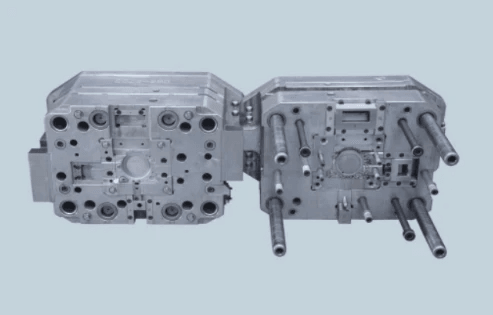

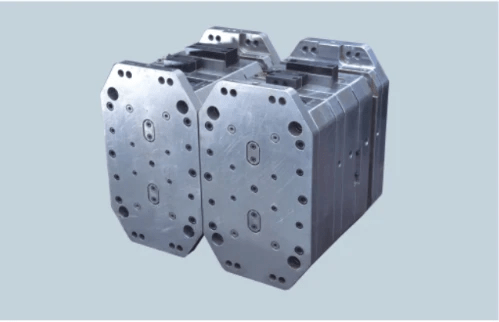

Analyzing Material and Design Costs

The materials used in injection molding can vary widely in cost, with options ranging from inexpensive plastics to high-performance materials that command a premium price. The design of the mold itself also plays a crucial role; intricate designs or those requiring high precision will naturally increase expenses. Consequently, if you're pondering how expensive is injection molding, remember that both material selection and design complexity significantly impact overall costs.

For instance, while basic thermoplastics may be relatively affordable, specialty polymers designed for specific applications can elevate your budget substantially. Additionally, custom molds tailored for unique designs typically incur higher upfront costs but can lead to greater efficiencies during mass production. A well-planned design can mitigate some expenses associated with material waste and production time.

The Role of Complexity in Pricing

Complexity is another key factor when considering whether injection molds are expensive; more complex parts require more sophisticated molds which drive up costs considerably. This complexity isn't just about aesthetics—functional aspects like wall thickness variations or undercuts can complicate mold fabrication and therefore increase pricing. So if you're asking yourself how much does it cost to set up injection molding for complex designs versus simpler ones, expect a marked difference in investment.

Moreover, intricate designs might necessitate additional engineering hours or even multiple iterations before arriving at an optimal solution—each step adding to your overall expenditure. It’s essential to balance complexity with functionality to avoid unnecessary costs while still achieving desired performance outcomes in your products. Ultimately, understanding this relationship between complexity and pricing will help you make informed decisions about your projects.

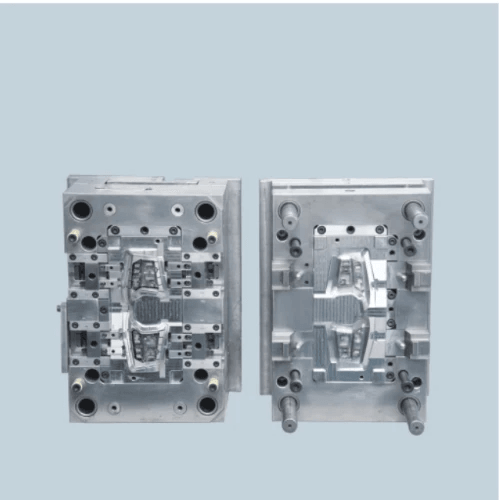

Real-World Examples from Baoyuan

To illustrate these concepts further, let’s take a look at real-world examples from Baoyuan's portfolio of projects that highlight how expensive is injection molding based on specific cases. One project involved producing automotive components where high precision was crucial; this required advanced tooling techniques leading to higher initial investments but ultimately resulted in significant savings due to reduced scrap rates during production runs.

Conversely, Baoyuan also undertook a project involving consumer goods where simpler designs were employed—this meant lower mold complexity and reduced material requirements resulting in lower overall setup costs. By providing tailored solutions based on client needs while keeping an eye on cost-effectiveness strategies such as bulk purchasing of materials or optimizing mold designs for easier manufacturing processes has allowed Baoyuan to demonstrate that while injection molds may seem costly upfront, they often yield substantial long-term benefits.

In conclusion, when evaluating whether are injection molds expensive? it's essential to consider both the initial investment related to material choices and design intricacies along with potential long-term savings through efficient production methods tailored by companies like Baoyuan.

How Much Does It Cost to Set Up Injection Molding?

Setting up an injection molding operation can be a significant financial commitment, but understanding the costs involved can help businesses make informed decisions. So, how expensive is injection molding? The answer lies in breaking down the various components of initial investments, machinery expenses, and ongoing operational costs.

Initial Investment Breakdown

When considering how much it costs to set up injection molding, the initial investment is often the most daunting aspect. This includes expenses such as mold design and fabrication, which can vary widely based on complexity and material choices. Additionally, businesses must account for facility modifications and utilities that support heavy machinery—a factor that can add to the upfront cost.

Many potential users wonder: Are injection molds expensive? In short, yes—especially when you factor in the design intricacies required for high-quality production. However, these costs should be viewed as an investment into future production efficiency and product quality rather than just a one-time expense.

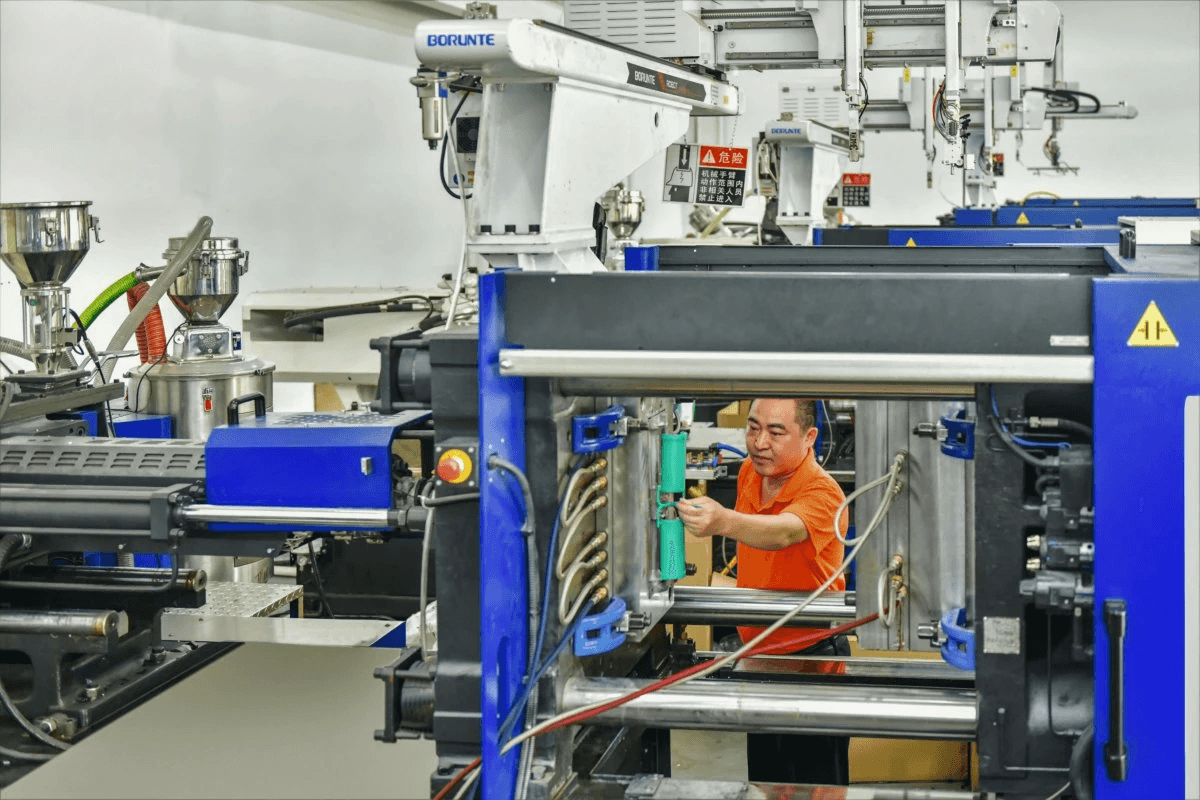

Machinery and Equipment Expenses

The heart of any injection molding setup lies in its machinery; thus, understanding how much an injection molding machine costs is crucial for prospective buyers. Depending on size and capabilities, prices for these machines can range from tens of thousands to several hundred thousand dollars. To complicate matters further, additional equipment such as chillers or dryers may also be necessary to ensure optimal processing conditions.

Investing in state-of-the-art technology might seem excessive at first glance; however, it often pays off by enhancing productivity and reducing waste over time. This leads us back to our earlier question: Is injection molding a cheap process? While the initial outlay may suggest otherwise, mass production capabilities ultimately offer substantial cost savings.

Ongoing Operational Costs

Once your setup is established with machinery in place, ongoing operational costs will come into play—these are essential for maintaining profitability in your injection molding venture. These expenses include raw materials (which fluctuate based on market conditions), labor costs (for skilled workers who operate complex machines), and maintenance fees (to keep everything running smoothly).

Moreover, companies should utilize tools like an injection molding cost estimator to predict future expenses accurately. This foresight allows businesses to budget effectively while also determining whether they should explore alternatives like machining—after all, many ask themselves if injection molding is cheaper than machining when weighing their options.

In conclusion, while setting up an injection molding operation involves significant expenditures initially—ranging from machine costs to operational upkeep—the long-term benefits often justify these investments through increased efficiency and reduced per-unit pricing over time.

Is Injection Molding a Cheap Process?

When considering manufacturing options, one question often arises: is injection molding a cheap process? While it may not be the most budget-friendly option upfront, its cost-effectiveness in mass production can make it an appealing choice for many businesses. Let's dive into the nuances of injection molding costs and explore how it stacks up against other manufacturing methods.

Cost-Effectiveness in Mass Production

Injection molding shines when it comes to mass production, offering significant cost savings per unit as production scales up. The initial investment for setting up injection molding can be steep—how much does it cost to set up injection molding? However, once the molds are created and machinery is operational, the price per part drops dramatically with larger quantities. This efficiency makes injection molding a go-to solution for companies looking to produce high volumes of identical parts without breaking the bank.

Long-Term Savings vs. Initial Costs

Many potential users wonder, Are injection molds expensive? The answer depends on how you view costs over time. While the initial setup costs—including mold design and machinery—can be significant, these expenses are often offset by long-term savings in labor and material waste during production runs. In fact, when comparing total lifecycle costs, businesses frequently find that investing in injection molding pays off handsomely down the line.

Factors that Can Make It More Affordable

Several factors can contribute to making injection molding more affordable than one might initially think. For instance, utilizing an injection molding cost estimator can provide insights into optimizing designs or materials that reduce overall expenses without sacrificing quality. Additionally, factors such as choosing simpler designs or leveraging economies of scale can significantly lower costs and lead to a more favorable comparison against machining processes—so is injection molding cheaper than machining? In many cases, yes!

Is Injection Molding Cheaper Than Machining?

When weighing the costs of manufacturing processes, many ask, Is injection molding cheaper than machining? The answer isn't straightforward, as it heavily depends on the specific project requirements and production volume. While both methods have their merits, understanding the cost structures can clarify which option might be more economical for your needs.

Comparing Cost Structures

To determine how expensive injection molding is compared to machining, we must first analyze their cost structures. Injection molding typically involves higher initial setup costs due to mold fabrication and machinery investment; however, these costs can be offset by lower per-unit prices in mass production. In contrast, machining often incurs lower upfront costs but may result in higher expenses per part when scaling up production volumes.

Injection molds can be expensive initially—often running into thousands of dollars—but they allow for rapid production once set up. On the other hand, machining processes tend to require more labor and time per unit produced, especially for complex designs that need multiple setups or adjustments. Ultimately, if you're looking at high-volume runs, injection molding may prove to be a more cost-effective choice over time.

When to Choose Injection Molding Over Machining

Deciding whether to use injection molding or machining comes down to several key factors: volume, complexity of design, and material requirements. If you're producing large quantities of a simple part with consistent dimensions, injection molding is generally the way to go—its efficiency shines in mass production scenarios where setup costs are amortized over thousands of units. Conversely, if your project requires low volumes or intricate designs that demand flexibility in material selection or precision adjustments during the process, machining may offer better value.

Another consideration is turnaround time; while setting up an injection mold might take longer initially (how much does it cost to set up injection molding?), once it's operational, parts can be produced rapidly and consistently. This makes it ideal for projects with tight deadlines where speed is essential. Therefore, understanding your specific needs will help you choose between these two manufacturing giants effectively.

Case Studies Highlighting Cost Differences

To illustrate how much an injection molding machine costs versus traditional machining operations—and why one might be favored over the other—let’s look at a couple of case studies from various industries. In one instance involving consumer electronics components produced by Baoyuan Manufacturing Solutions (a leader in this field), switching from machined aluminum parts to injection-molded plastic resulted in a 40% reduction in overall production costs when scaled for high volume runs.

In another case study focused on automotive parts manufacturing using CNC machining methods versus custom-designed molds for plastic components showed that while initial mold creation was costly (Are injection molds expensive?), the long-term savings were significant due to reduced labor and faster cycle times associated with injecting molded parts compared to those machined from solid materials.

These examples highlight that while upfront investments may vary significantly between processes (Is injection molding a cheap process?), careful consideration of long-term operational efficiencies often reveals that choosing the right method can lead to substantial financial benefits over time.

Using an Injection Molding Cost Estimator

When it comes to understanding how expensive injection molding can be, using a cost estimator can be invaluable. An injection molding cost estimator allows you to input various parameters, such as material type, part complexity, and production volume, to get a more accurate picture of the overall costs involved. This tool not only helps clarify whether are injection molds expensive but also assists in making informed decisions before diving into production.

How to Accurately Estimate Costs

To accurately estimate costs associated with injection molding, start by gathering all necessary information about your project. This includes details such as the dimensions of the part, the type of material you'll use, and any specific design features that could affect pricing. Understanding how much does it cost to set up injection molding involves considering both initial mold creation expenses and ongoing production costs; thus, being thorough in your data collection is crucial for reliable estimates.

One common pitfall is overlooking hidden costs like maintenance or potential revisions needed for the mold design after initial trials. It’s essential to factor in these variables when determining if injection molding is a cheap process in the long run or if it might lead to unforeseen expenses down the line. The better your initial estimates are, the more likely you’ll stay within budget throughout your project.

Tools and Resources Available

There are several tools and resources available online that cater specifically to estimating injection molding costs effectively. Many manufacturers provide free calculators on their websites where you can input key parameters and receive instant feedback on estimated pricing—helping you answer questions like how much does an injection molding machine cost? without breaking a sweat! Additionally, specialized software packages designed for product development often include cost estimation modules tailored for injection molding projects.

Industry forums and communities can also be treasure troves of information where experienced professionals share insights about their own projects' costs. Engaging with these platforms may help clarify whether other companies found that is injection molding cheaper than machining for their specific applications—providing real-world context that generic calculators can't always offer.

Tips for Getting the Best Price

To ensure you're getting the best price possible when estimating your project’s costs, consider these tips: first and foremost, don’t hesitate to reach out directly to manufacturers or suppliers for quotes tailored specifically to your needs; personalized quotes often reveal nuances that standard estimators might miss. Additionally, exploring bulk order discounts can significantly reduce per-unit costs—especially if you're planning mass production runs.

Another effective strategy is comparing multiple estimators or services before settling on one; this will give you a broader perspective on what constitutes reasonable pricing in today’s market landscape—ultimately helping you determine if are injection molds expensive relative to other manufacturing methods like machining. Remember: being proactive about research not only saves money but also enhances your understanding of how expensive is injection molding overall.

Conclusion

In summary, understanding the costs associated with injection molding is essential for anyone considering this manufacturing process. Questions like How expensive is injection molding? and Are injection molds expensive? often arise, but the answers depend on various factors including materials, design complexity, and production volume. By breaking down these costs and analyzing real-world examples, it becomes clear that while initial investments can be significant, the long-term benefits often outweigh them.

Recap on Injection Molding Costs

When exploring how much it costs to set up injection molding, one must consider not just the price of equipment but also material expenses and operational overheads. Initial setup costs can be daunting—especially when comparing Is injection molding a cheap process? to other manufacturing methods. However, once you dive into mass production, the cost-effectiveness of injection molding shines through as a viable option for many industries.

Insights from Baoyuan on Cost Management

Baoyuan offers valuable insights into managing these costs effectively. They emphasize that understanding how much an injection molding machine costs is crucial for budgeting purposes. Moreover, using an injection molding cost estimator can help businesses forecast their expenses more accurately and make informed decisions about whether to pursue this method over alternatives like machining.

Final Thoughts on Making Informed Decisions

Ultimately, deciding whether is injection molding cheaper than machining? requires careful consideration of both immediate and long-term financial impacts. Each project will have its unique requirements that influence overall pricing structures; thus being well-informed is key to achieving cost efficiency. As you weigh your options in manufacturing processes, remember that knowledge is power—so arm yourself with insights to make strategic decisions.