Introduction

Are you curious about plastic moulded parts and their applications? Whether you're a manufacturer or a consumer, understanding the versatility and benefits of plastic moulded products is essential. From automotive injection molding to custom-designed components, plastic moulding offers endless possibilities for various industries.

Understanding Plastic Moulded Parts

Plastic moulded parts are products created through the process of plastic molding, which involves shaping molten plastic into a desired form. This method allows for the production of intricate designs and complex shapes, making it a popular choice across different sectors.

Benefits of High-Quality Moulded Parts

High-quality plastic moulded parts offer durability, precision, and cost-effectiveness, making them an ideal solution for manufacturers looking to enhance their product offerings. With the ability to withstand harsh conditions and maintain structural integrity, these components provide long-term value.

Choosing the Right Manufacturer

Selecting a reputable manufacturer for your plastic moulded parts is crucial in ensuring superior quality and reliability. With expertise in mold design, injection molding techniques, and adherence to industry standards, partnering with the right manufacturer can make all the difference in your production process.

Exploring Plastic Moulding Techniques

Plastic moulded parts are created through various techniques, with injection molding being one of the most popular methods. This process involves melting plastic and injecting it into a mold to form the desired shape. It is called plastic moulding because it involves shaping molten plastic into specific forms. Moulded parts are essential components in various industries and are used in a wide range of products.

Injection Molding 101

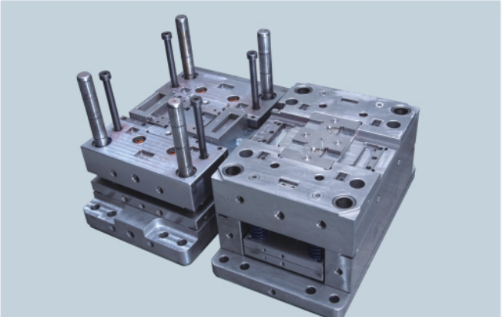

Injection molding is a versatile technique used to manufacture plastic components for different applications. It involves the use of a mold or tool that is filled with molten plastic material, which then solidifies into the desired shape. The process allows for high volume production of complex and precise plastic parts, making it ideal for mass manufacturing needs. Plastic mold components play a crucial role in this process, ensuring the accuracy and quality of the final products.

Injection molding is a versatile technique used to manufacture plastic components for different applications. It involves the use of a mold or tool that is filled with molten plastic material, which then solidifies into the desired shape. The process allows for high volume production of complex and precise plastic parts, making it ideal for mass manufacturing needs. Plastic mold components play a crucial role in this process, ensuring the accuracy and quality of the final products.

Double-Color Moulded Products

Double-color moulded products are created using a specialized injection molding process that combines two different colored resins to produce unique and visually appealing components. This technique offers design flexibility and can be used to create intricate patterns or color combinations in plastic parts, making them stand out in various applications.

Automotive Applications

Automotive injection molding is widely used in the production of interior and exterior components for vehicles, such as dashboards, bumpers, trims, and more. The durability, precision, and cost-effectiveness of plastic moulded parts make them an ideal choice for automotive applications where high performance and reliability are essential.

Automotive injection molding has revolutionized the production of vehicle components, allowing for the creation of complex shapes and designs that were previously impossible with traditional manufacturing methods. This technology has enabled automakers to achieve lightweight yet durable parts that contribute to improved fuel efficiency and overall performance. In addition, plastic moulded parts offer a level of precision that ensures seamless integration and assembly within the vehicle, enhancing both aesthetics and functionality.

Let's dive deeper into Baoyuan's expertise in customizing plastic moulded parts to meet your specific requirements!

The Baoyuan Advantage

Experienced Senior Management

At Baoyuan, our team is led by experienced senior management who have a deep understanding of plastic moulded parts and the industry as a whole. With years of expertise, they provide invaluable guidance and leadership to ensure that our manufacturing processes meet the highest standards.

Proficient in Mold Design and Injection Molding

Our team at Baoyuan is proficient in mold design and injection molding techniques, allowing us to create high-quality plastic moulded products with precision and efficiency. We understand the intricacies of plastic molding 101 and are skilled in producing complex components such as double-color moulded products for various applications including automotive injection molding.

Our expertise in mold design and injection molding extends to our quality assurance processes, ensuring that every plastic moulded product we produce meets the highest standards of durability, functionality, and aesthetic appeal. We employ rigorous testing and inspection protocols to identify any potential defects or imperfections, allowing us to make necessary adjustments before finalizing the production process. This commitment to quality assurance gives our clients the confidence that their plastic moulded products will perform reliably and meet their expectations.

Quality Assurance Expertise

Quality assurance is at the core of what we do at Baoyuan. Our team is dedicated to ensuring that every plastic moulded part meets the highest standards of quality and reliability. Through rigorous testing and inspection processes, we guarantee that our products not only meet industry standards but also exceed customer expectations.

Remember that choosing a manufacturer with expertise in plastic mold components and molding techniques can make all the difference in the quality of your products. At Baoyuan, we pride ourselves on our experienced senior management, proficiency in mold design and injection molding, as well as our unwavering commitment to quality assurance.

Customization Options for Your Needs

When it comes to plastic moulded parts, customization is key in meeting specific requirements. Baoyuan offers tailored moulded parts solutions to ensure that your product needs are met with precision and expertise. Whether you require unique shapes, sizes, or functionalities, our team can deliver the perfect solution for your project.

Tailored Moulded Parts Solutions

At Baoyuan, we understand the importance of providing tailored solutions for plastic moulded products. Our experienced team works closely with clients to develop custom moulded parts that align with their exact specifications. From intricate designs to specific material requirements, we are dedicated to delivering high-quality, personalized solutions for all your plastic moulding needs.

Design Flexibility

With plastic moulding called injection molding, design flexibility is a crucial factor in creating innovative products. Baoyuan offers extensive design flexibility to accommodate various shapes, sizes, and intricate details in the production of plastic moulded parts. Our advanced techniques and expertise allow us to bring your unique design concepts to life with precision and accuracy.

Meeting Specific Manufacturing Requirements

When it comes to manufacturing requirements for plastic moulded parts, Baoyuan excels in meeting specific demands with efficiency and expertise. Whether you need automotive injection molding or specialized components for other industries, our team is equipped to deliver precise manufacturing solutions that adhere to the highest standards of quality and performance.

Remember that at Baoyuan, we prioritize customization options that cater specifically to your needs when it comes to plastic moulded parts production. With our tailored solutions and design flexibility, we ensure that every aspect of your project's manufacturing requirements is met with precision and expertise.

Quality Control and Assurance

When it comes to plastic moulded parts, quality control and assurance are paramount. At Baoyuan, we implement rigorous testing and inspection processes to ensure the highest standards are met. Our team conducts thorough checks at every stage of the manufacturing process, from raw material inspection to final product evaluation.

Testing and Inspection Processes

Our testing and inspection processes are comprehensive, covering aspects such as dimensional accuracy, surface finish, and material properties. We utilize advanced equipment and technology to conduct various tests, including pressure testing, impact testing, and visual inspections. This meticulous approach guarantees that only top-quality plastic moulded products leave our facilities.

In addition to our rigorous testing and inspection processes, we also prioritize environmental sustainability in our production methods. Our commitment to eco-friendly practices ensures that our plastic moulded products not only meet industry standards for quality but also adhere to environmental regulations. By integrating sustainable materials and manufacturing techniques into our processes, we are able to deliver high-quality products that minimize their impact on the environment.

Meeting Industry Standards

At Baoyuan, we are committed to meeting and exceeding industry standards for plastic moulding. Our manufacturing processes adhere to ISO 9001 certification requirements, ensuring that our products meet stringent quality benchmarks. By consistently meeting industry standards, we demonstrate our dedication to delivering reliable and high-performance plastic moulded parts.

Furthermore, our commitment to meeting industry standards extends beyond just the manufacturing process. We also prioritize ongoing training and development for our team, ensuring that they are equipped with the latest knowledge and skills to produce top-quality plastic moulded parts. This dedication to continuous improvement allows us to stay ahead of industry trends and deliver innovative solutions to our customers.

Ensuring Product Reliability

Reliability is a key factor in the production of plastic moulded parts. Our stringent quality control measures are designed to ensure that every component we manufacture is reliable and durable. Whether it's automotive injection molding or custom-designed parts for specific applications, our focus on product reliability sets us apart as a trusted partner for all your plastic moulding needs.

At our plastic moulding facility, we understand the importance of product reliability in meeting the needs of our clients. Our team is dedicated to upholding the highest standards of quality control to ensure that every component we produce meets or exceeds industry expectations. This commitment to reliability has earned us a reputation as a go-to partner for automotive injection molding and custom-designed parts for a wide range of applications.

Conclusion

When it comes to manufacturing, the value of high-quality plastic moulded parts cannot be overstated. These products are essential in various industries, from automotive to consumer goods. With Baoyuan's expertise in plastic moulding techniques and quality control, you can trust that your manufacturing needs will be met with precision and excellence.

The Value of High-Quality Plastic Moulded Parts

Plastic moulded parts are essential components used in a wide range of products, from household items to industrial machinery. These parts are created through a process called plastic moulding, which involves shaping molten plastic into a specific form using a mold. The result is durable, reliable components that are crucial for the functionality and performance of countless products.

High-quality plastic moulded parts not only provide structural support and stability to the products they are used in, but they also contribute to their overall aesthetic appeal. The precision and consistency achieved through plastic moulding ensure that the parts fit seamlessly within the final product, enhancing its visual appeal and functionality. Whether it's a sleek modern design for a consumer product or a robust, industrial-grade component, high-quality plastic moulded parts play a crucial role in elevating the overall quality of the end product.

Choosing Baoyuan for Your Manufacturing Needs

With Baoyuan's extensive experience in plastic moulding and commitment to quality assurance, choosing them for your manufacturing needs is a wise decision. Their proficiency in mold design and injection molding techniques ensures that you will receive top-notch, tailor-made solutions for your specific requirements. By partnering with Baoyuan, you can rest assured that your products will meet the highest standards of excellence.

By partnering with Baoyuan, you can also benefit from their cost-effective solutions that help maximize your return on investment. With their efficient production processes and attention to detail, you can expect timely delivery of high-quality products without compromising on the quality. This means that you can streamline your manufacturing operations and meet your production targets with ease, giving you a competitive edge in the market.

Advantages of Partnering with an Expert Moulded Parts Manufacturer

Partnering with an expert moulded parts manufacturer like Baoyuan offers numerous advantages for your business. From customized solutions to meeting specific manufacturing requirements, Baoyuan's expertise in plastic moulded parts gives you the flexibility and reliability you need to succeed in today's competitive market. By choosing an industry leader like Baoyuan, you can elevate your products with high-quality components that meet or exceed industry standards.

In addition, partnering with Baoyuan allows you to benefit from their extensive knowledge and experience in the industry. Their expertise in plastic moulded parts means that you can tap into their wealth of insights and best practices, giving you a competitive edge in the market. By leveraging their know-how, you can streamline your manufacturing processes and optimize your product design for maximum efficiency and performance.