Introduction

When it comes to creating precision parts and components, injection molding is a game-changer. Baoyuan is a leading expert in Taiwan Injection Moulding, offering top-notch expertise in this field. Let's delve into the world of high-quality injection molded components and explore the exceptional quality that Baoyuan delivers.

Understanding Injection Molded Components

Injection molded components are produced using a process that involves injecting molten material into a mold, which then cools and solidifies into the desired shape. This method allows for the production of intricate and complex parts with high precision and consistency.

Baoyuan’s Expertise in Injection Molding

Baoyuan boasts extensive experience and expertise in injection molding, providing innovative solutions for various industries. With cutting-edge technology and a dedicated team, they excel in delivering top-quality injection molded components to meet diverse needs.

Exploring the Quality of High-Quality Injection Molded Components

The quality of injection molded components is crucial for ensuring optimal performance and durability. Baoyuan's commitment to excellence shines through in their meticulous attention to detail and stringent quality control measures, resulting in superior products that exceed expectations.

The Basics of Injection Molding

The Process of Injection Molding

Injection molding is a manufacturing process for producing parts by injecting material into a mold. The process begins with the material being heated and then injected into a mold cavity, where it cools and hardens to the configuration of the cavity. This process is commonly used for manufacturing a variety of plastic products, including injection molded components.

After the material has been injected into the mold, it undergoes a cooling process to harden and take on the shape of the cavity. The cooling time can vary depending on the thickness of the part and the material being used. Once the part has solidified, it is ejected from the mold, ready for further processing or assembly. This efficient and precise process allows for high-volume production of intricate plastic parts.

Key Components of an Injection Molding Machine

An injection molding machine consists of several key components, including the injection unit, clamping unit, mold, and the hydraulic system. The injection unit melts the polymer resin and injects it into the mold, while the clamping unit holds the two halves of the mold together during this process. The hydraulic system powers these movements and ensures precision in creating injection molded components.

In addition to the injection unit, clamping unit, mold, and hydraulic system, an injection molding machine also includes an ejection system. This system is responsible for pushing the finished part out of the mold once it has solidified. Without this component, the molded part would remain stuck in the mold, causing production delays and inefficiencies. The ejection system plays a crucial role in ensuring a smooth and continuous manufacturing process.

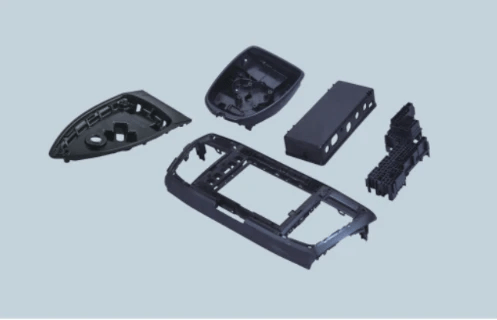

What Parts Can Be Injection Molded?

A wide range of parts can be created through injection molding, from small precision parts to large automotive panels. Common examples include caps, containers, combs, appliance housing, and even musical instruments. With modern advancements in technology and materials, nearly any design can be achieved through Taiwan Injection Moulding processes.

In addition to the wide range of parts that can be created through injection molding, the process also allows for the production of intricate and complex designs. This means that items with intricate patterns, detailed textures, and unique shapes can be easily manufactured using injection molding techniques. The versatility of injection molding makes it an ideal choice for industries such as consumer goods, electronics, medical devices, and more.

The Composition of Injection Mold

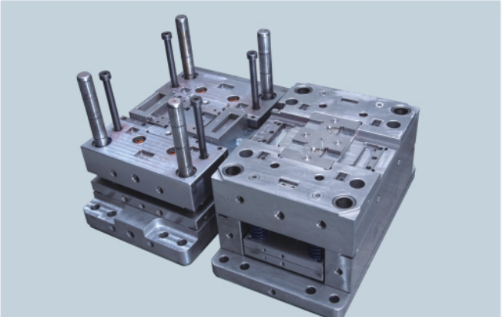

Understanding the Components of an Injection Mold

When it comes to the components of an injection mold, it's important to consider the core and cavity, which form the actual shape of the part being produced. Additionally, there are also cooling channels to regulate temperature and ejector pins to remove the finished product from the mold. The design of these components is crucial in ensuring the quality and efficiency of the molding process. The core and cavity need to be precisely machined to create a seamless final product, while the cooling channels must be strategically placed to maintain consistent temperature throughout the mold. Ejector pins should also be carefully positioned to avoid any damage to the finished part during removal.

Baoyuan’s Specialization in Mold Design

Baoyuan has a strong focus on mold design, ensuring that every aspect of the injection mold is carefully considered and optimized for high-quality production. With years of experience in Taiwan Injection Moulding, Baoyuan has honed their expertise in creating molds that deliver precise and consistent results.

With a keen eye for detail and a commitment to excellence, Baoyuan takes into account every aspect of mold design, from material selection to cooling system layout. This meticulous approach ensures that the injection mold is optimized for high-quality production, minimizing defects and maximizing efficiency. By prioritizing precision and consistency in their mold designs, Baoyuan has established a reputation for delivering superior results in the field of Taiwan Injection Moulding.

Quality Assurance in Injection Mold Composition

At Baoyuan, quality assurance is a top priority when it comes to injection mold composition. Each component is meticulously inspected and tested to ensure that they meet strict quality standards, resulting in reliable and durable molds that consistently produce high-quality injection molded components. This attention to detail not only ensures the satisfaction of our clients but also contributes to the overall efficiency and effectiveness of the manufacturing process. By maintaining such high standards, we can guarantee that our injection molds will consistently meet or exceed industry expectations.

By focusing on understanding the components of an injection mold, Baoyuan ensures that their specialization in mold design and commitment to quality assurance result in exceptional products for their clients.

The Significance of High-Quality Components

Importance of Quality in Injection Molded Components

When it comes to injection molded components, quality is paramount. High-quality components ensure durability, precision, and consistency in performance. With Taiwan Injection Moulding, the importance of quality is emphasized through meticulous attention to detail and adherence to strict standards. In order to ensure high-quality products, Baoyuan utilizes advanced technology and state-of-the-art machinery to produce components with minimal defects and maximum precision. Additionally, Baoyuan employs a team of skilled technicians who undergo rigorous training to maintain high standards of quality control throughout the manufacturing process.

How Baoyuan Ensures High-Quality Products

Baoyuan maintains high-quality products through rigorous quality control measures at every stage of the injection molding process. From material selection to final inspection, each step is carefully monitored to guarantee the production of top-notch injection molded components that meet or exceed customer expectations.

Furthermore, Baoyuan's commitment to high-quality products extends beyond the manufacturing process. The company invests in state-of-the-art technology and equipment to ensure precision and consistency in every component produced. This dedication to innovation and modernization sets Baoyuan apart in the industry, giving customers peace of mind knowing they are receiving top-of-the-line injection molded components.

Advantages of Choosing High-Quality Injection Molded Components

Opting for high-quality injection molded components offers a myriad of benefits such as enhanced product reliability, extended lifespan, and reduced maintenance costs. With Taiwan Injection Moulding's commitment to excellence, customers can trust that they are investing in superior products that deliver exceptional performance and value.

Technical Expertise at Baoyuan

At Baoyuan, our team of senior management and technical personnel bring years of experience and expertise in the field of injection molding. With a deep understanding of Taiwan Injection Moulding, our team ensures that every aspect of the production process is handled with precision and care, resulting in high-quality injection molded components that meet the highest industry standards.

Proficiency in Software for Mold Design and Injection Molding

Our technical team at Baoyuan is proficient in using the latest software for mold design and injection molding. This allows us to create intricate designs and molds with utmost accuracy, ensuring that each component meets the exact specifications required by our clients. With a keen eye for detail and a commitment to excellence, we are able to deliver top-notch results consistently.

Our specialization in single-color and double-color plastic products sets us apart in the industry. With a deep understanding of material properties and color blending techniques, we are able to create visually stunning and durable plastic products that meet the highest standards. Whether it's a simple single-color component or a complex double-color design, our team has the expertise to bring your vision to life with precision and finesse.

Specialization in Single-Color and Double-Color Plastic Products

Baoyuan specializes in producing both single-color and double-color plastic products through injection molding. Our expertise in handling different types of materials and colors enables us to cater to a wide range of client needs, from simple components to more complex parts. We take pride in our ability to deliver exceptional quality across all types of injection molded components.

With Baoyuan's technical expertise, we are able to provide comprehensive solutions for all your injection molding needs. From mold design to production, our team is dedicated to delivering top-notch results that exceed expectations every time. Choose Baoyuan for reliable, high-quality injection molded components that you can trust.

Conclusion

When it comes to injection molded components, Baoyuan stands out as a reliable and high-quality choice. With their expertise in Taiwan Injection Moulding, they ensure the production of top-notch components that meet the highest standards. Choosing Baoyuan means choosing quality and reliability for all your injection molding needs.

Choosing Quality with Baoyuan's Injection Molded Components

Baoyuan's commitment to excellence in injection molded components is evident in their meticulous attention to detail and dedication to producing top-quality products. Their expertise in injection molding ensures that every component meets the highest standards of quality, making them the ideal choice for any project.

Baoyuan's dedication to quality is further demonstrated through their use of advanced technology and state-of-the-art equipment in the injection molding process. This commitment to innovation allows them to consistently deliver components that not only meet but exceed industry standards. By staying ahead of the curve, Baoyuan ensures that their products are always at the forefront of quality and reliability, making them a trusted partner for any project.

Finding Reliability in Injection Molded Components

With Baoyuan, you can trust that their injection molded components are not only of superior quality but also highly reliable. Their adherence to strict quality control measures guarantees that every component is durable, dependable, and perfectly suited for its intended purpose.

The Advantage of Baoyuan's Expertise in Injection Molding

The advantage of partnering with Baoyuan lies in their unmatched expertise in injection molding. Their knowledge and experience allow them to produce components that exceed expectations, setting them apart as a leader in the industry.

Furthermore, Baoyuan's commitment to innovation means that they are constantly exploring new techniques and materials to improve the quality and efficiency of their injection molding processes. This dedication to staying at the forefront of industry advancements ensures that partnering with Baoyuan guarantees access to the latest and most effective manufacturing methods available. By choosing Baoyuan, you are not just getting a product - you are gaining a competitive edge in your market.

Remember that when it comes to injection molded components, choosing Baoyuan means choosing superior quality and reliability every time.