Introduction

Are you wondering how to get plastic parts made? Understanding plastic manufacturing processes is crucial in selecting the ideal manufacturing partner for your metal & plastic machined parts. This will ensure cost-effective custom plastic parts manufacturing through injection molding services.

Understanding Plastic Manufacturing Processes

To get plastic parts made, it's essential to understand the various manufacturing processes for plastics. Injection molding, for example, is a widely used method for manufacturing plastic parts due to its versatility and efficiency. It's crucial to grasp these processes to make informed decisions about your custom plastic parts manufacturing.

Choosing the Right Manufacturing Partner

Selecting the ideal plastic manufacturing process involves finding the right manufacturer. Researching and evaluating potential partners is key in ensuring high-quality metal & plastic machined parts. Look for a company with expertise in injection molding services and a track record of delivering top-notch custom plastic parts.

Tips for Cost-Effective Plastic Part Production

When it comes to manufacturing plastic parts, cost-effectiveness is paramount. Optimizing designs for injection molding and streamlining the production process are essential tips for reducing production costs while maintaining quality standards.

Overview of Plastic Manufacturing Processes

When it comes to manufacturing plastic parts, there are several processes to consider. Injection molding is a popular method that involves injecting molten material into a mold to create the desired shape. Metal & plastic machined parts, on the other hand, are produced using CNC machining and other techniques. Selecting the ideal plastic manufacturing process depends on factors such as the complexity of the part, production volume, and material requirements.

Injection Molding Basics

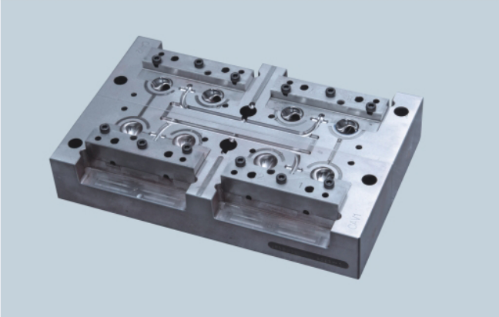

Injection molding is a versatile and efficient process for manufacturing plastic parts. It allows for high-volume production with minimal waste and can accommodate a wide range of materials and part geometries. The process involves injecting molten plastic into a mold cavity, where it cools and solidifies into the desired shape. Injection molding services offer cost-effective solutions for producing custom plastic parts with consistent quality.

Metal & Plastic Machined Parts

Metal & plastic machined parts are produced using CNC machining, turning, milling, and other precision techniques. These methods allow for tight tolerances and complex geometries to be achieved in both metal and plastic components. Manufacturers specializing in metal & plastic machined parts can provide custom solutions for various industries such as automotive, aerospace, medical devices, and consumer electronics.

Selecting the Ideal Plastic Manufacturing Process

When it comes to selecting the ideal plastic manufacturing process, it's essential to consider factors such as part complexity, material properties, production volume, lead times, and cost-effectiveness. Custom plastic parts manufacturing companies like Baoyuan offer expertise in injection molding services as well as metal & plastic machined parts production. Their comprehensive capabilities enable them to assist clients in choosing the most suitable manufacturing process for their specific needs.

Finding the Right Manufacturer

Researching Plastic Manufacturing Companies

When looking for a manufacturer for metal & plastic machined parts, it's crucial to conduct thorough research on potential companies. Check their experience in manufacturing plastic parts, their reputation in the industry, and their track record of delivering high-quality products. Look for customer reviews and testimonials to gauge their reliability and expertise in injection molding services.

What to Look for in a Manufacturing Partner

In selecting the ideal plastic manufacturing process, consider a partner that offers custom plastic parts manufacturing tailored to your specific needs. Look for a manufacturer that utilizes advanced technology and innovative techniques to ensure precision and efficiency in production. Additionally, prioritize a partner that emphasizes quality assurance to guarantee the durability and functionality of your plastic parts.

Baoyuan: A Leader in Custom Plastic Parts Manufacturing

Baoyuan is a trusted leader in custom plastic parts manufacturing, specializing in injection molding services and producing top-notch metal & plastic machined parts. With extensive experience and cutting-edge facilities, Baoyuan offers a wide range of manufacturing processes for plastics, ensuring that clients receive cost-effective solutions without compromising on quality.

Designing Your Plastic Parts for Cost Efficiency

When it comes to manufacturing plastic parts, designing for cost efficiency is crucial. Optimizing designs for injection molding can significantly reduce production costs by minimizing material usage and cycle times. Baoyuan's expertise in mold design and injection molding ensures that your plastic parts are designed with cost efficiency in mind, resulting in high-quality products at competitive prices. By working with a knowledgeable manufacturer like Baoyuan, you can benefit from their injection molding services to achieve cost-effective custom plastic parts manufacturing.

Optimizing Designs for Injection Molding

Optimizing designs for injection molding involves carefully considering factors such as part geometry, wall thickness, and draft angles to ensure smooth and efficient production processes. By designing parts that are conducive to the injection molding process, you can minimize material waste and reduce overall production costs. Baoyuan's team of experts can provide valuable insights into optimizing designs for injection molding, helping you create cost-effective plastic parts without compromising on quality.

Baoyuan's Expertise in Mold Design and Injection Molding

Baoyuan specializes in metal & plastic machined parts and has extensive experience in mold design and injection molding. Their team of engineers is well-versed in creating molds that maximize production efficiency while maintaining the highest standards of quality. With their expertise, they can help you streamline the manufacturing process and achieve cost-effective plastic part production without sacrificing durability or performance.

Tips for Reducing Production Costs

In addition to optimizing designs for injection molding, there are various tips and strategies that can further reduce production costs when manufacturing plastic parts. These may include selecting the right materials, minimizing secondary operations, or leveraging economies of scale through bulk ordering. Baoyuan's experience in custom plastic parts manufacturing allows them to offer valuable advice on reducing production costs while delivering top-notch products.

Quality Assurance in Plastic Part Production

When it comes to manufacturing plastic parts, ensuring high-quality products is crucial. Quality assurance processes such as thorough inspections and testing are essential to guarantee the durability and functionality of plastic parts. Baoyuan's proficiency in quality assurance for plastic products is evident in their meticulous attention to detail and strict adherence to industry standards, providing customers with top-notch plastic parts that meet their exact specifications.

Ensuring High-Quality Plastic Parts

To ensure high-quality plastic parts, manufacturers must implement rigorous quality control measures throughout the production process. This includes using high-grade materials, precise molding techniques, and comprehensive testing procedures to identify any defects or inconsistencies. By prioritizing quality at every stage of manufacturing, companies can deliver reliable and durable plastic parts that meet the highest standards of performance and safety.

Baoyuan's Proficiency in Quality Assurance for Plastic Products

Baoyuan is a leader in custom plastic parts manufacturing, known for its expertise in quality assurance for plastic products. With state-of-the-art facilities and advanced testing equipment, Baoyuan conducts thorough inspections to verify the integrity of each plastic part before it reaches the customer. Their commitment to excellence ensures that every product meets stringent quality criteria, earning them a reputation for reliability and customer satisfaction.

Common Pitfalls to Avoid in Plastic Manufacturing

In the process of manufacturing plastic parts, there are common pitfalls that can compromise the quality of the final product if not addressed properly. These include issues such as inadequate material selection, poor mold design, and insufficient quality control measures. By partnering with an experienced manufacturer like Baoyuan who understands these potential pitfalls and has established protocols to mitigate them, businesses can avoid costly mistakes and deliver exceptional plastic parts that exceed expectations.

Tips for Cost-Effective Plastic Part Production

When it comes to manufacturing plastic parts, maximizing efficiency in production is key. By optimizing the production process, you can reduce costs and improve turnaround times. Baoyuan has extensive experience in providing efficient injection molding services, ensuring that your plastic parts are produced in a cost-effective manner.

Maximizing Efficiency in Production

To maximize efficiency in production, it's important to streamline the manufacturing processes for plastics. By carefully selecting the ideal plastic manufacturing process for your specific needs, such as metal & plastic machined parts or custom plastic parts manufacturing, you can minimize waste and reduce production time. Baoyuan's expertise in injection molding services allows for efficient and cost-effective production of high-quality plastic parts.

By leveraging Baoyuan's expertise in injection molding services, you can benefit from their advanced technology and state-of-the-art equipment to optimize the production process. This allows for greater precision and consistency in the manufacturing of plastic parts, resulting in higher quality products with minimal defects. The streamlined production also leads to reduced lead times, enabling you to meet tight deadlines and fulfill customer orders promptly.

Baoyuan's Experience in Cost-Effective Plastic Part Manufacturing

Baoyuan is a leader in custom plastic parts manufacturing, with a focus on delivering cost-effective solutions to their clients. Their team of experts understands the intricacies of manufacturing plastic parts and can provide valuable insights into optimizing designs for injection molding. With their experience and knowledge, Baoyuan ensures that every project is executed with efficiency and cost-effectiveness in mind.

Baoyuan's team is dedicated to streamlining the production process, ensuring that each step is optimized for efficiency and cost-effectiveness. By carefully analyzing the design and material selection, Baoyuan can identify opportunities for improvement and cost savings. This proactive approach allows them to deliver high-quality plastic parts at competitive prices, giving their clients a significant advantage in their respective industries.

Streamlining the Production Process

Streamlining the production process involves careful planning and execution at every stage of manufacturing plastic parts. From design optimization to quality assurance, each step should be meticulously managed to minimize costs without compromising on quality. Baoyuan's commitment to excellence extends to streamlining the production process, ensuring that your custom plastic parts are produced efficiently and cost-effectively.

Streamlining the production process also involves implementing the latest technology and automation to increase efficiency and reduce human error. By incorporating advanced machinery and robotics, Baoyuan can ensure that your custom plastic parts are produced with precision and consistency, leading to a higher quality end product. This investment in technology not only improves the overall production process but also allows for quicker turnaround times, meeting your deadlines with ease.

Conclusion

In conclusion, getting plastic parts made requires a deep understanding of the manufacturing processes for plastics and selecting the ideal plastic manufacturing process. It also involves finding the right partner for custom plastic parts manufacturing and ensuring cost-effective production through injection molding services. Baoyuan is committed to excellence in metal & plastic machined parts, offering quality assurance and expertise in achieving cost-effective custom plastic parts.

Ensuring Quality in Plastic Parts Production

Quality assurance is paramount in manufacturing plastic parts, as it ensures that the final products meet the highest standards. By partnering with a reputable manufacturer like Baoyuan, you can be confident that your metal & plastic machined parts will be of superior quality, meeting all your specifications and requirements. With state-of-the-art technology and a team of experienced professionals, Baoyuan is dedicated to delivering precision-engineered plastic parts that exceed industry standards. Our commitment to excellence is evident in every step of the production process, from design and prototyping to final inspection and testing.

Baoyuan's Commitment to Excellence

Baoyuan is dedicated to excellence in custom plastic parts manufacturing, offering top-notch injection molding services and expertise in metal & plastic machined parts. With a strong focus on quality assurance and cost-effective production, Baoyuan stands out as a reliable partner for all your plastic part production needs.

Baoyuan's commitment to excellence extends beyond just the manufacturing process. We also prioritize sustainability and environmental responsibility in our operations, ensuring that our custom plastic parts are produced with minimal impact on the planet. By choosing Baoyuan as your manufacturing partner, you can be confident that your products are not only of the highest quality but also align with eco-friendly practices.

Achieving Cost-Effective Custom Plastic Parts

With Baoyuan's expertise in optimizing designs for injection molding and streamlining the production process, you can achieve cost-effective custom plastic parts without compromising on quality. By maximizing efficiency in production and leveraging Baoyuan's experience, you can ensure that your manufacturing process is both efficient and economical.